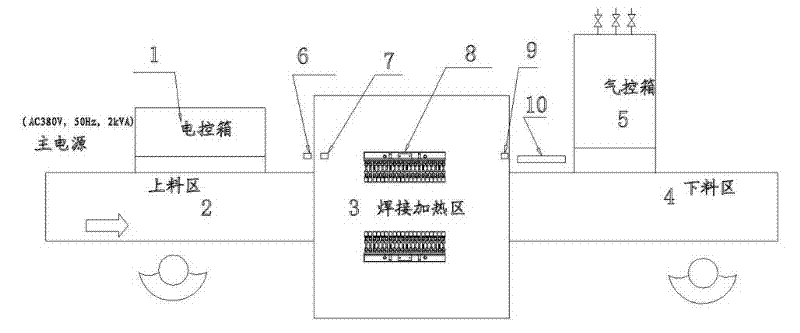

Digital display precision flow controllable and adjustable multi-column aluminum heat exchanger flame brazing equipment

A flame brazing and exchanger technology, applied in welding equipment, metal processing equipment, electric heating devices, etc., can solve problems such as unsuitable for brazing of all-aluminum heat exchangers, high leakage rate, loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

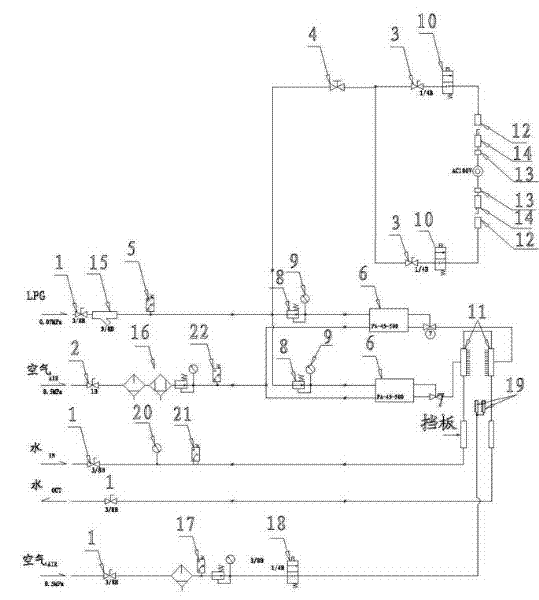

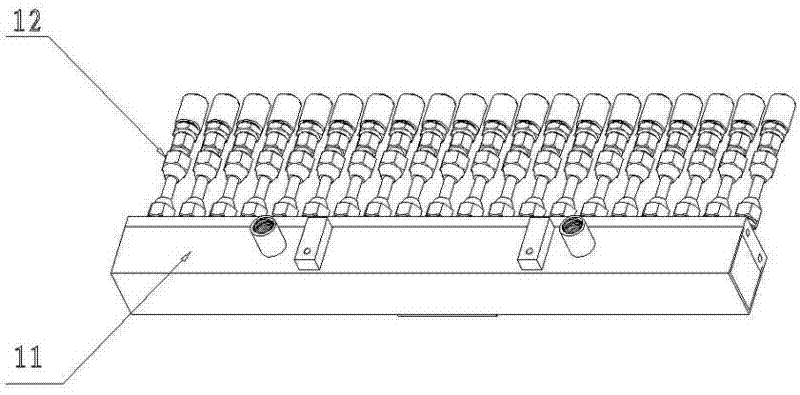

[0013] 1. For a good flame generation suitable for flame brazing of aluminum heat exchangers, the most important thing is to have a sophisticated and agile air flow control system to control the real-time control of the gas flow of liquefied petroleum gas and air generated by the flame to ensure that the gas The flow is constant. Liquefied petroleum gas (LPG) and compressed air pipelines are installed with dry filters (15 in Figure 1) to make the gas relatively clean, and then decompressed through the precision pressure reducing valve (16, 8 in Figure 1) to make the liquefied petroleum gas Gas (LPG) pressure and air pressure for combustion are relatively stable, which lays the foundation for the mass flow meter (Figure 16, on-off solenoid valve, mass flow meter) to control the air flow in a good, precise and agile manner. The flow rate of liquefied petroleum gas and air is set on the touch screen, and the PLC program continuously and precisely detects the gas flow at the outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com