Patents

Literature

69results about How to "Constant size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

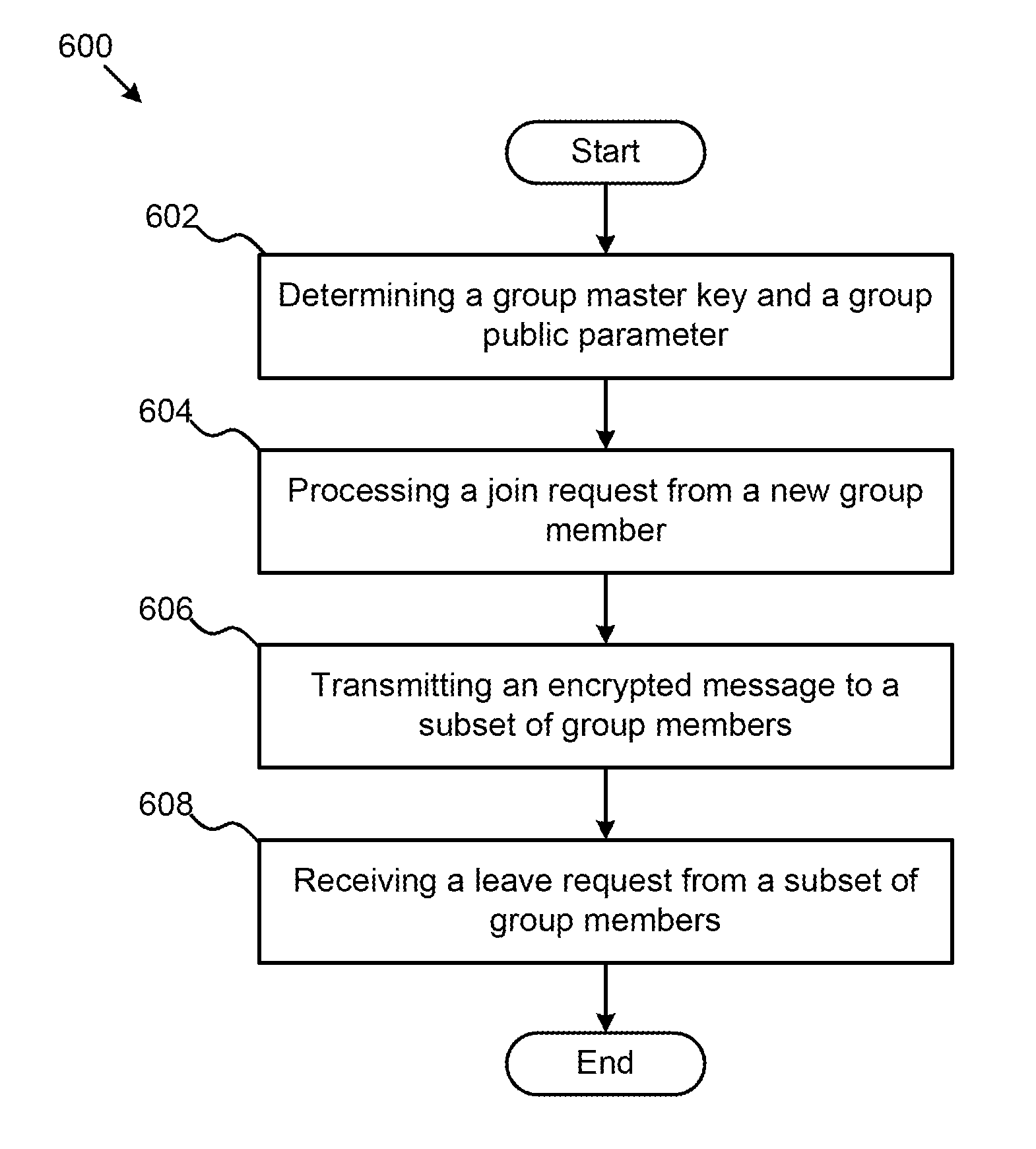

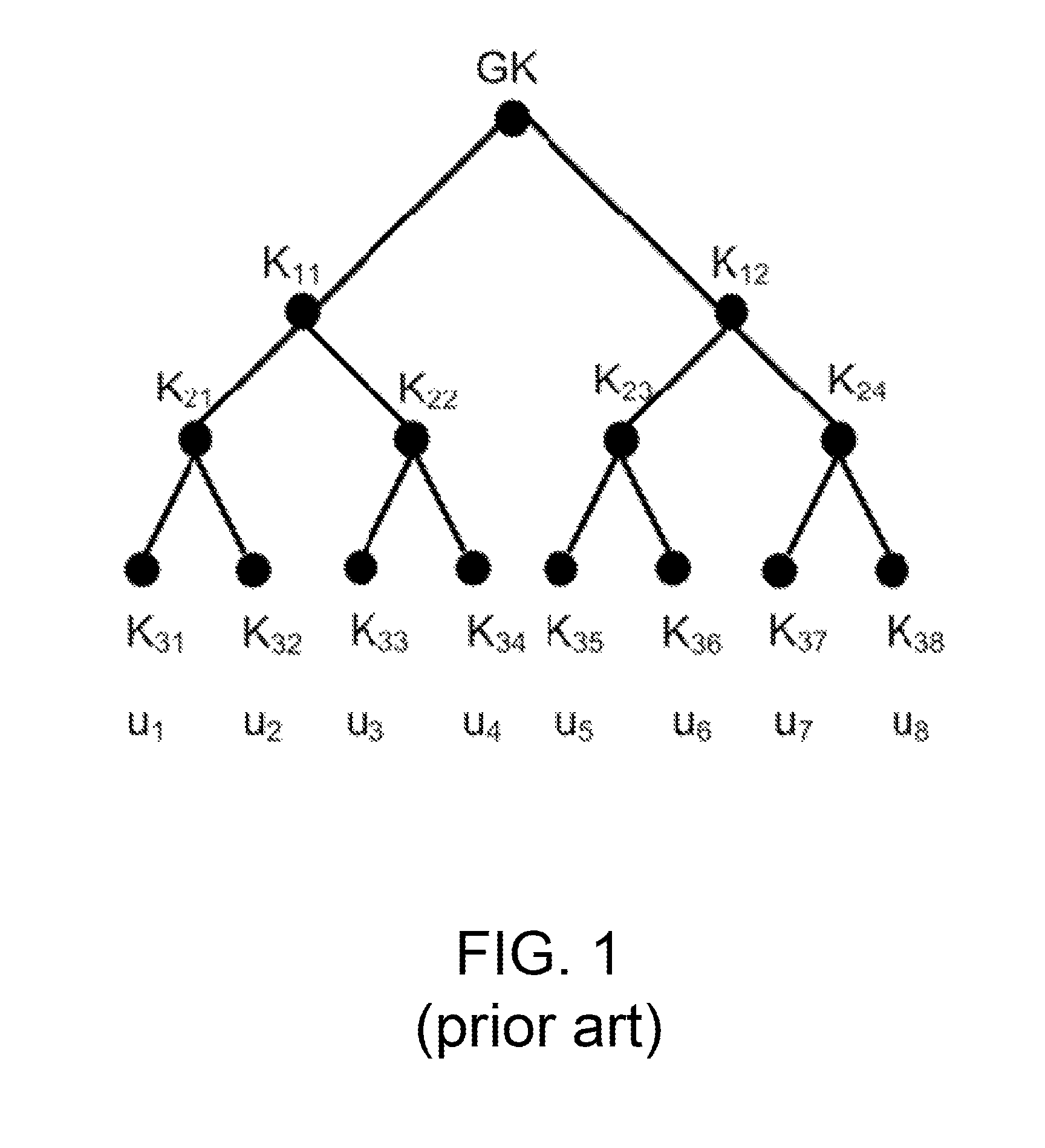

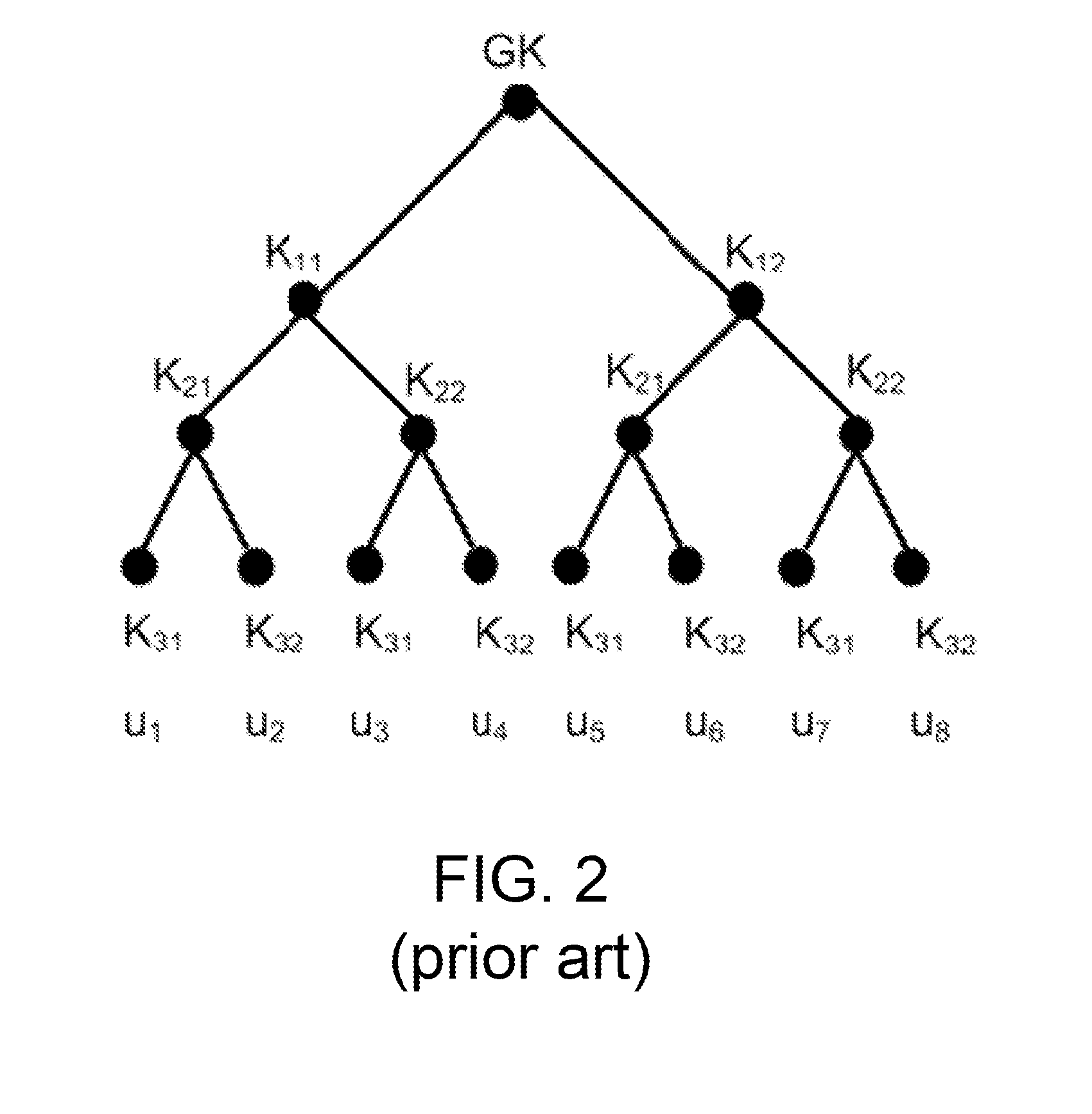

Methods, Systems, and Apparatuses for Optimal Group Key Management for Secure Multicast Communication

InactiveUS20120257756A1Constant message sizeImmune to collusion attackKey distribution for secure communicationGroup controllerSecure multicast

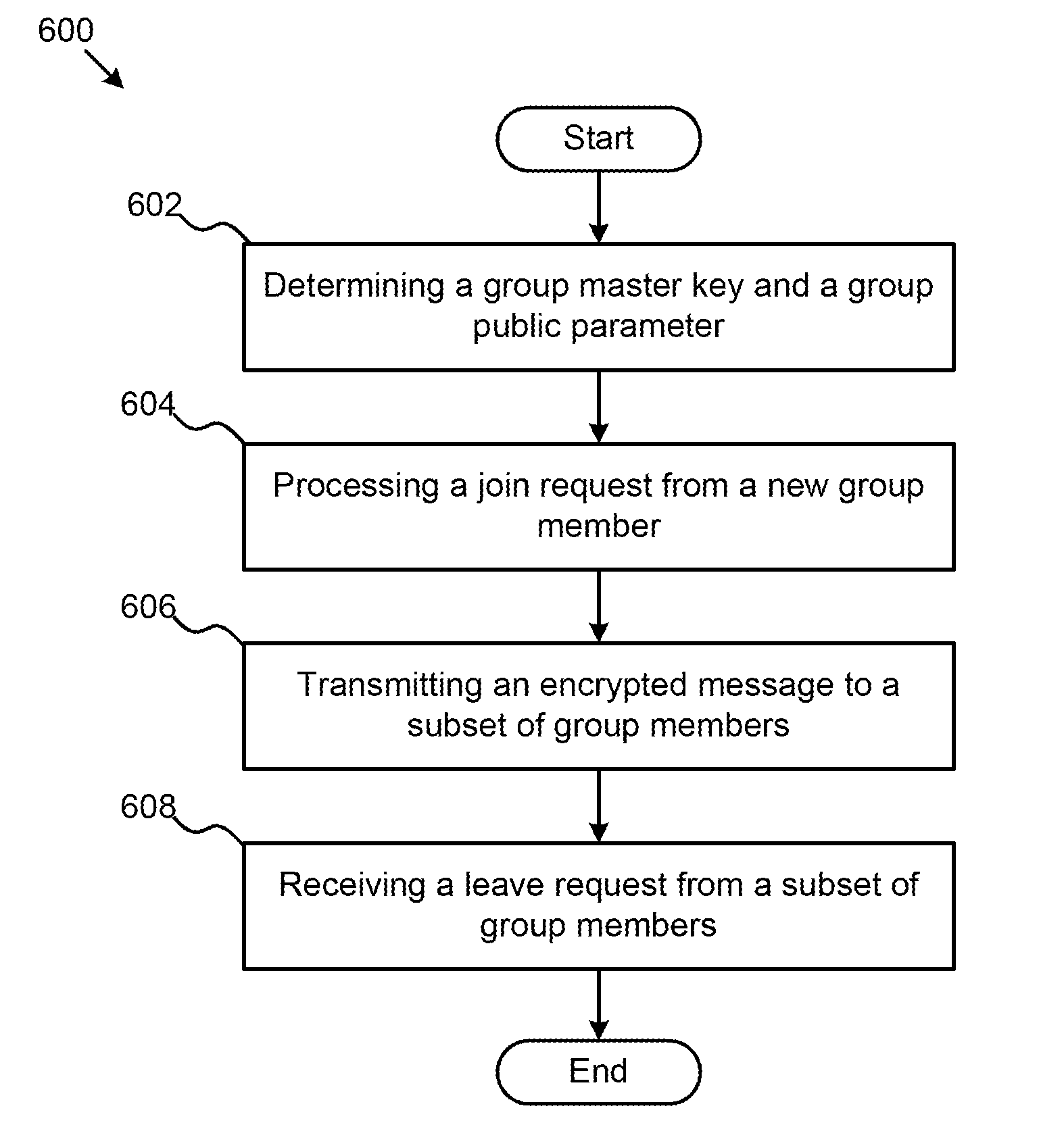

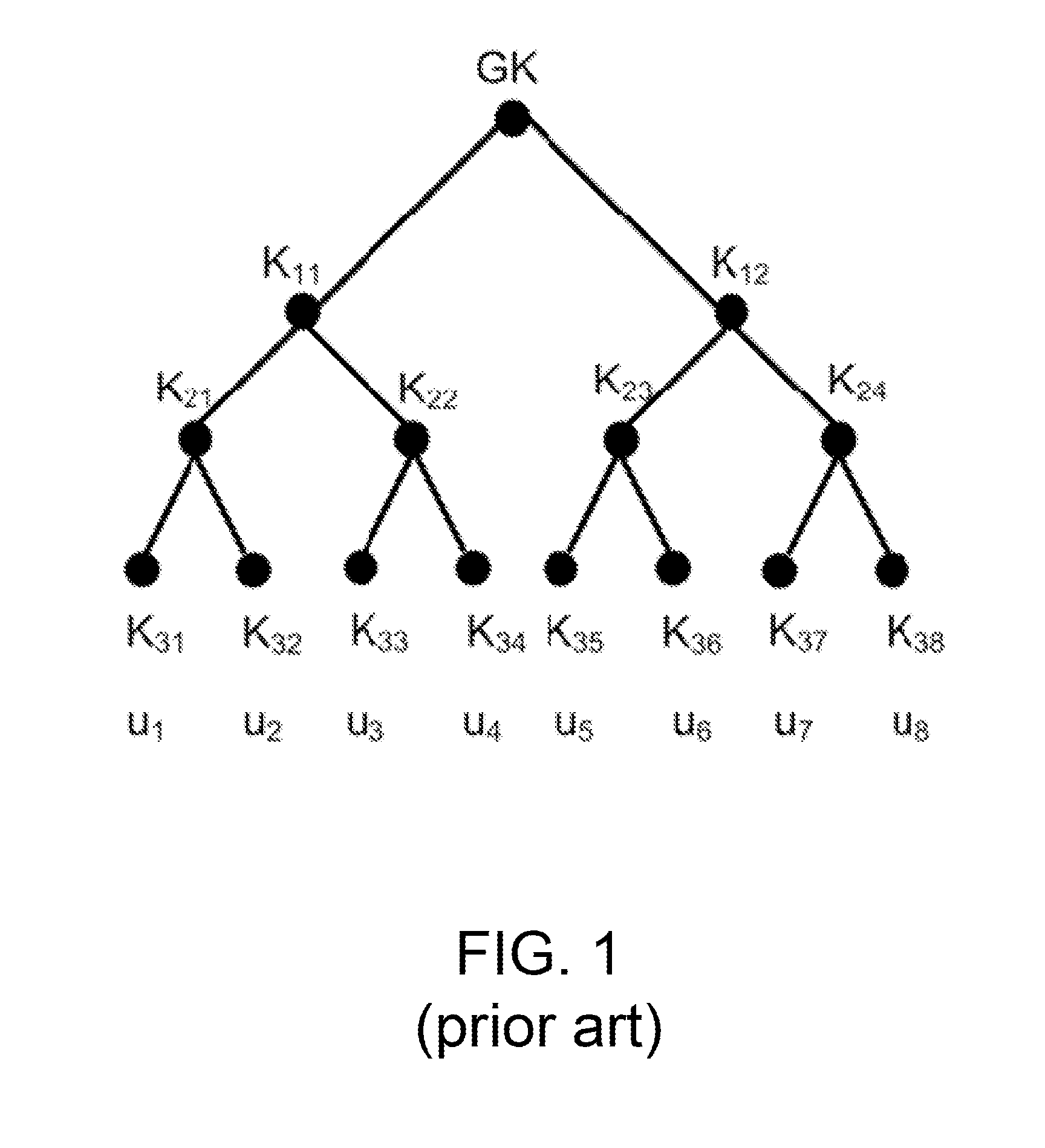

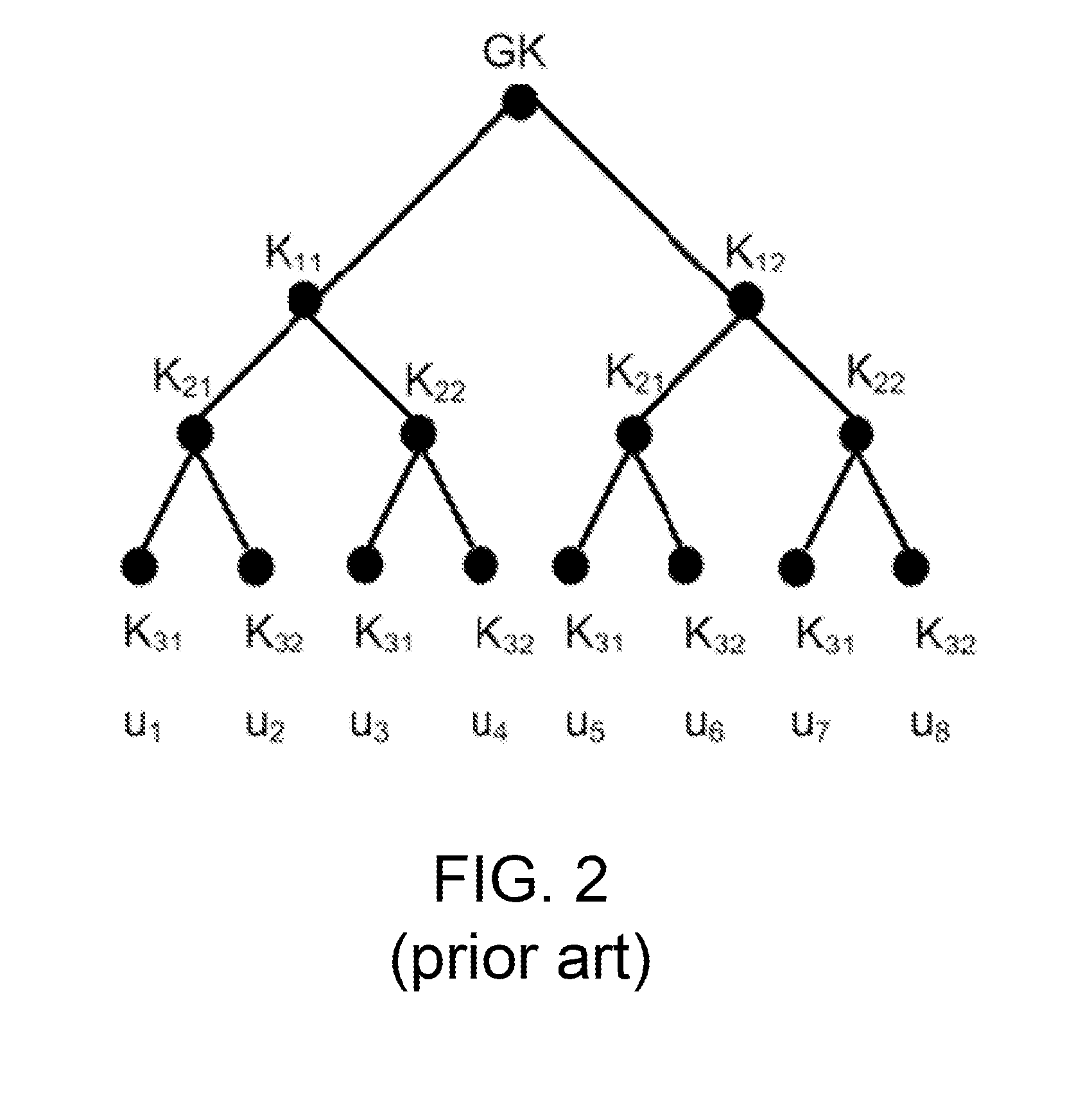

Apparatuses, systems, and methods for optimal group key (OGK) management that may achieve non-colluding and / or the storage-communication optimality are disclosed. In some embodiments, a group controller (GC) is responsible for key generation and distribution and the group data are encrypted by a group key. When joining the group, in some embodiments, each group member (GM) is assigned a unique n-bit ID and a set of secrets, in which each bit is one-to-one mapped to a unique secret. Whenever GMs are revoked from the group, in some embodiments, the GC will multicast an encrypted key-update message. Only the remaining GMs may be able to recover the message and update GK as well as their private keys. The disclosed OGK scheme can achieve storage-communication optimality with constant message size and immune to collusion attack and also may outperform existing group key management schemes in terms of communication and storage efficiency.

Owner:ARIZONA STATE UNIVERSITY

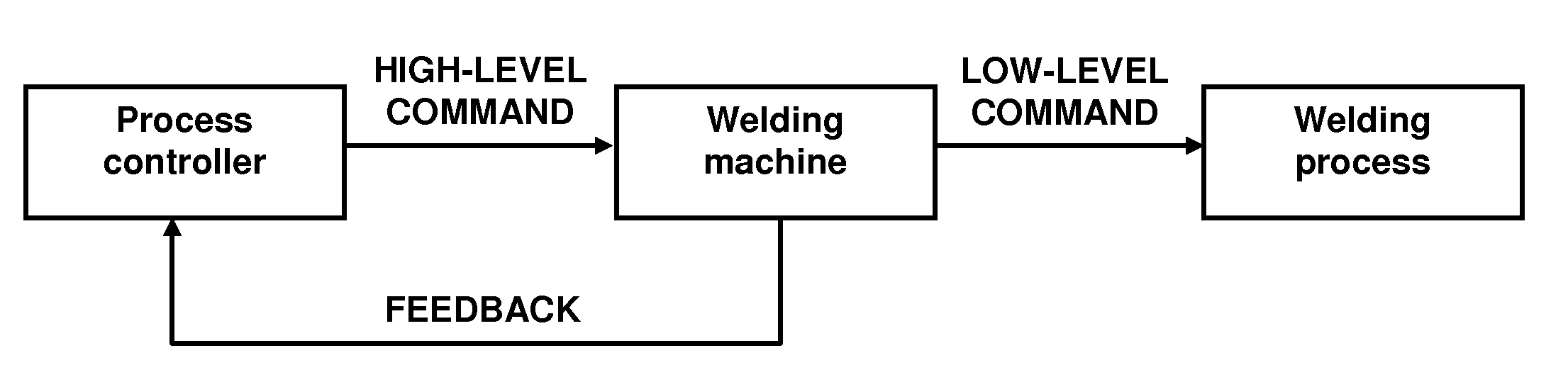

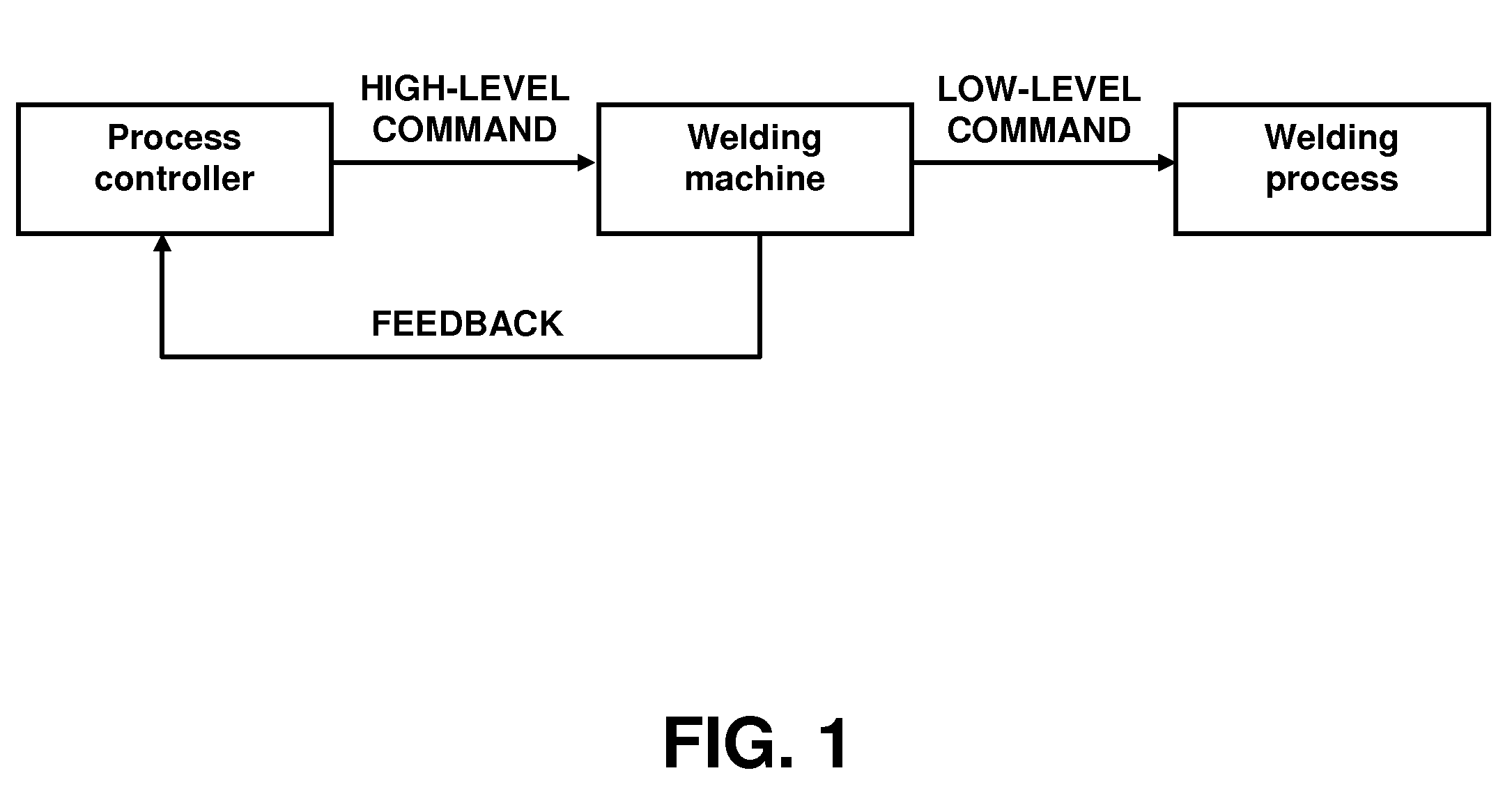

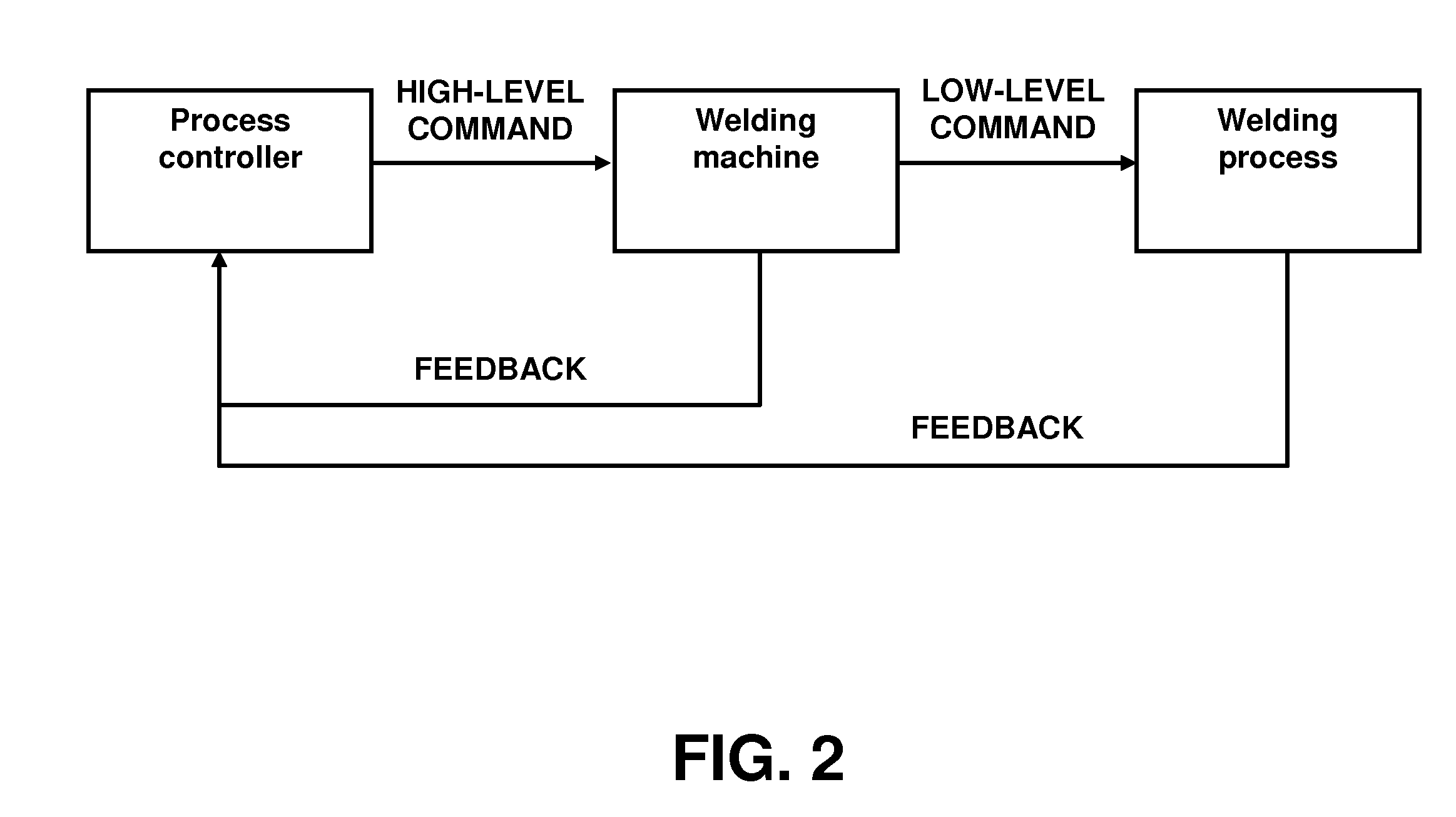

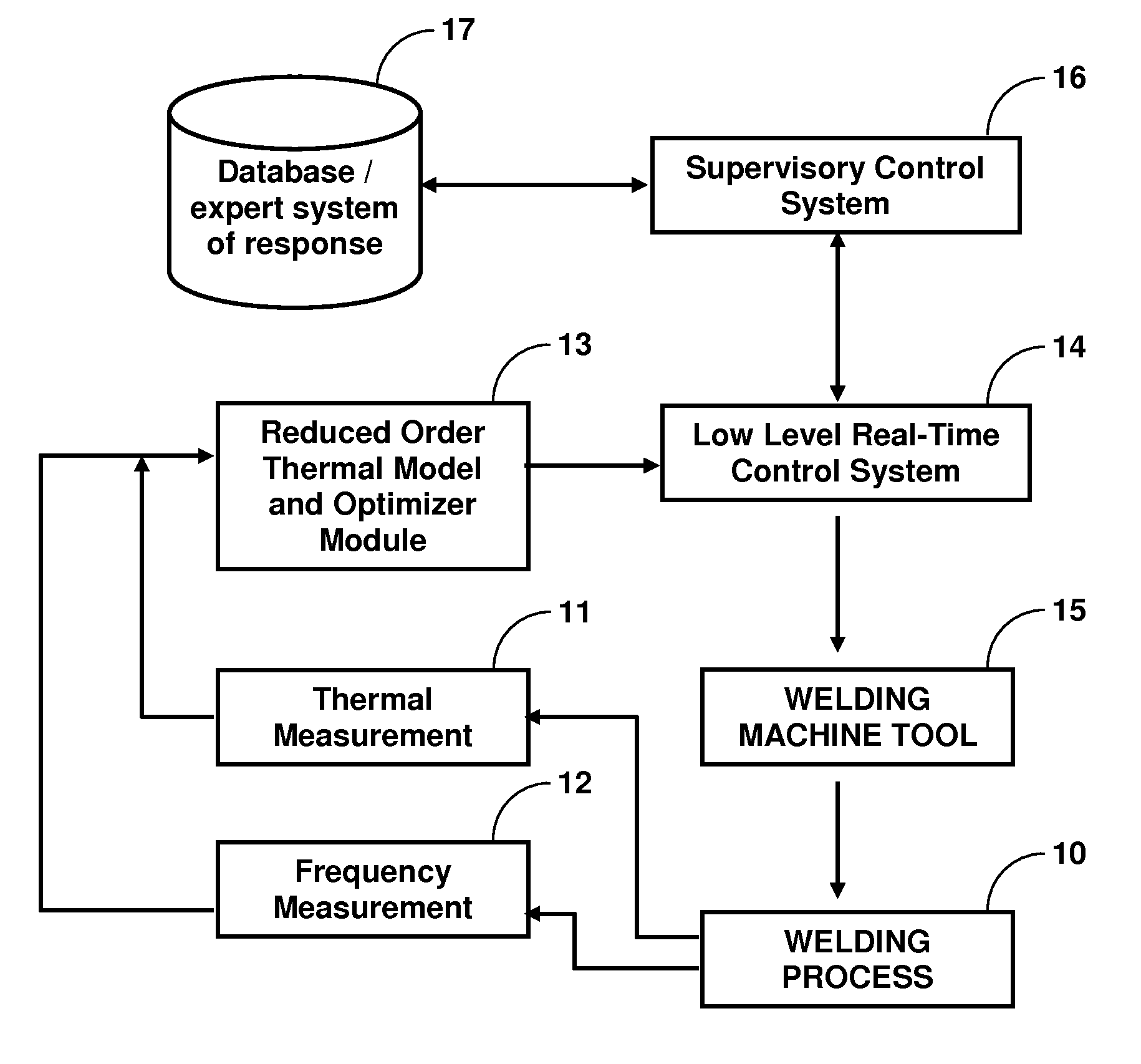

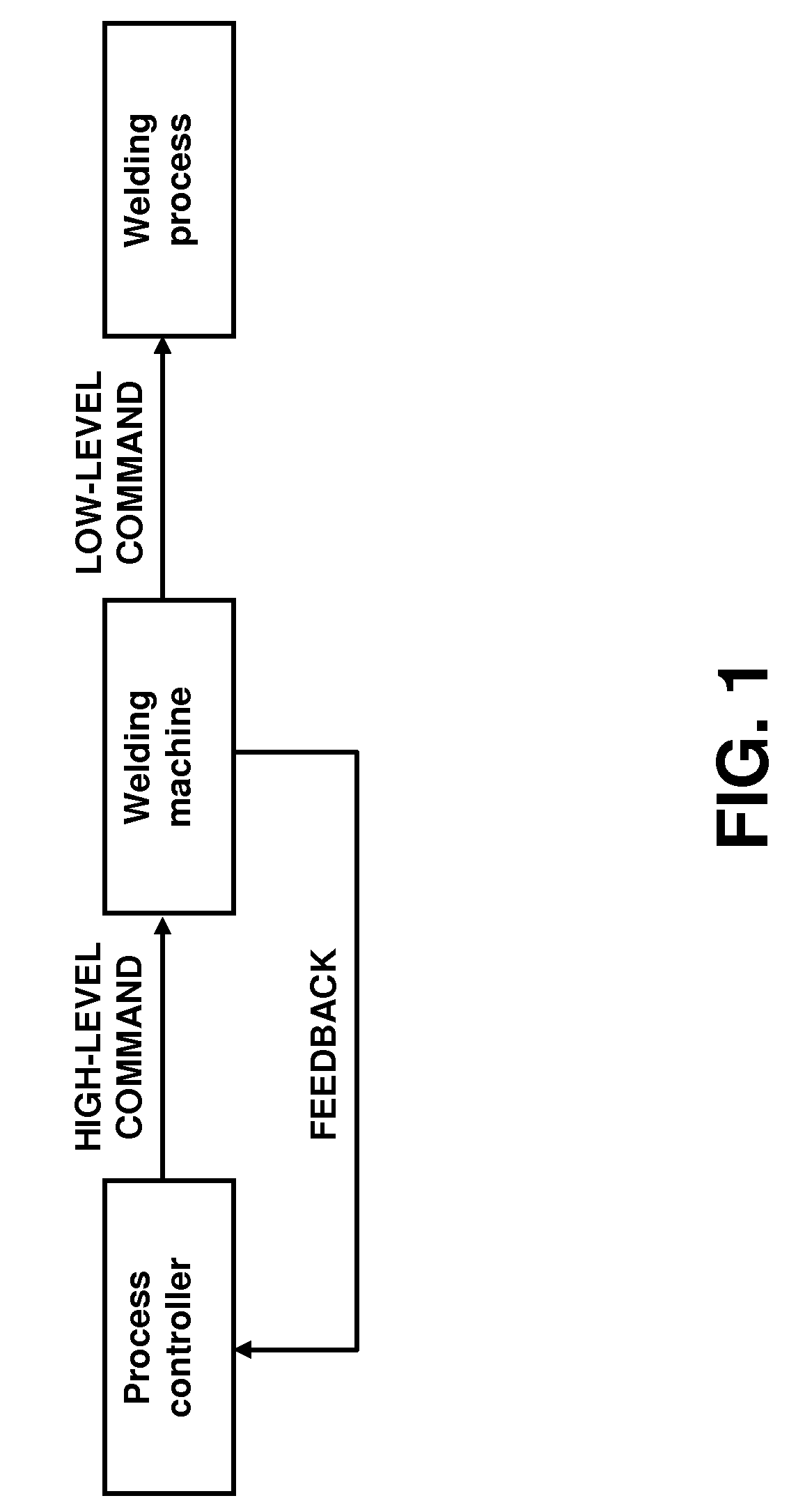

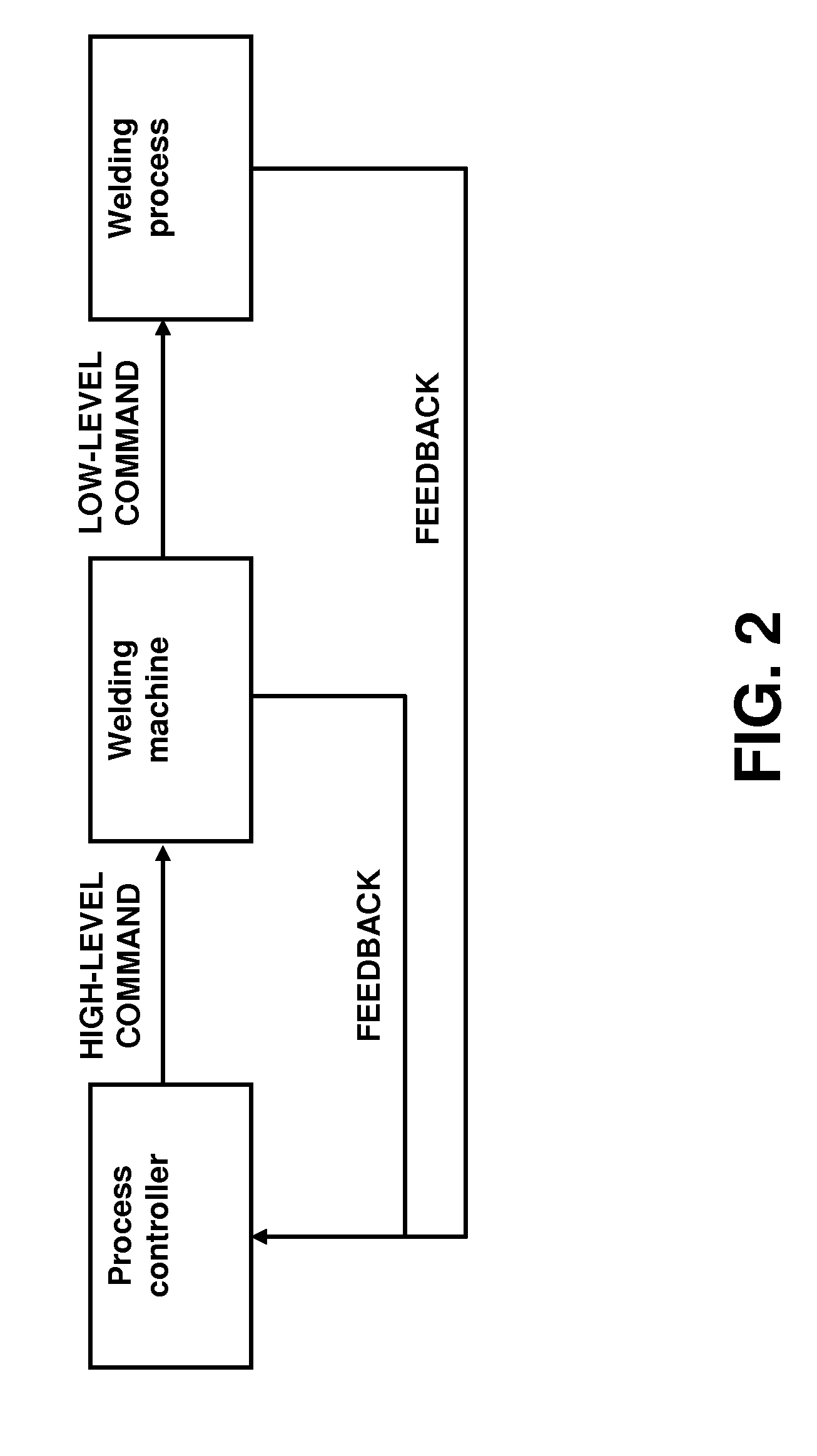

Controlled weld pool volume control of welding processes

ActiveUS20100288734A1Easy to controlAccurate volumeTemperatue controlElectron beam welding apparatusReal-time dataEngineering

A new method of process control for fusion welding maintains a controlled weld pool size or volume, for example in some applications a substantially constant weld pool size or volume. The invention comprises a method of linking machine and process variables to the weld pool size or volume in real time, thereby enabling constant weld pool volume control. The invention further comprises a method of using thermal inverse models to rapidly process real-time data and enable models-based control of welding processes so as to implement constant weld pool volume control.

Owner:SIGMA LAB OF ARIZONA

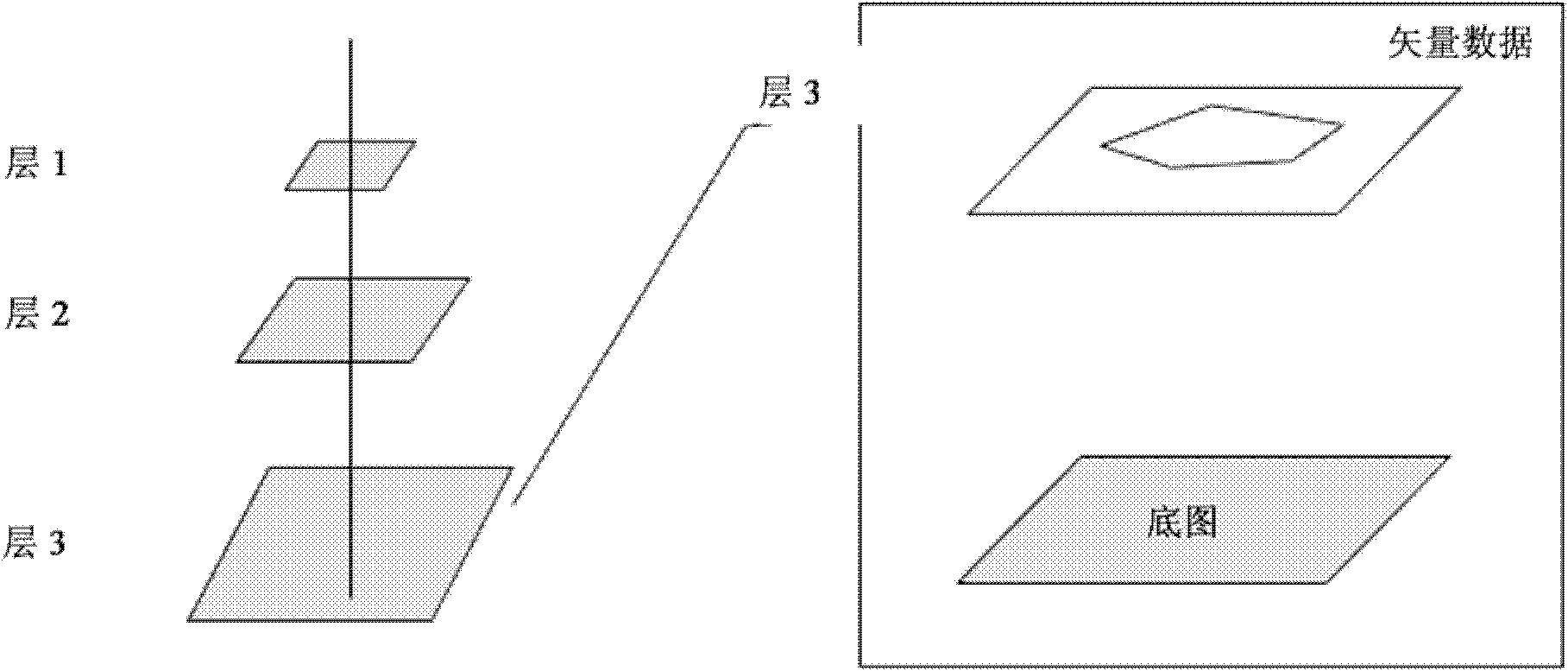

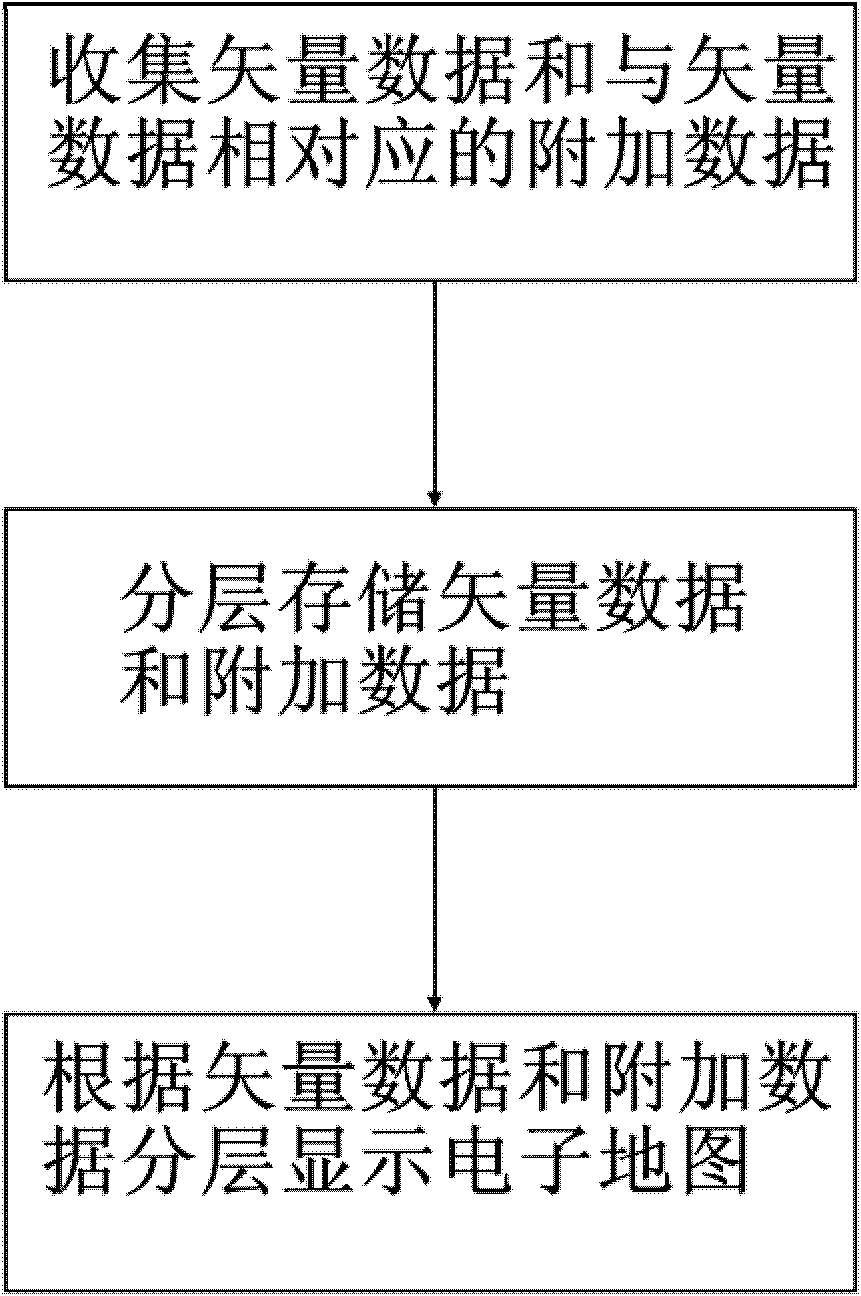

Method for generating electronic map

InactiveCN103187002AShortcut displayClear logicMaps/plans/chartsGeographical information databasesElectronic mapCollections data

The invention provides a method for generating an electronic map. The method includes a data collecting procedure, a data storage procedure and an electronic map displaying procedure, wherein the data collecting procedure includes a step of collecting vector data and additional data corresponding to the vector data; the data storage procedure includes the steps of storing the collected vector data and the collected additional data in a server database, enabling the vector data corresponding to different types of main body elements to be stored in a plurality of layers, and enabling the vector data of each type of main body elements to be stored in one layer; the electronic map displaying procedure includes the steps that an electronic map displaying end obtains the vector data and the additional data from a server, draws vector diagrams corresponding to each layer of vector data layer by layer according to the vector data in each layer, and adds the additional data related to main body element identification data (ID) in the layer of vector data, and consequently the electronic map is generated in a displaying device.

Owner:北京点道互联科技有限公司

Methods, systems, and apparatuses for optimal group key management for secure multicast communication

InactiveUS8837738B2Storage-communication optimalityConstant sizeKey distribution for secure communicationGroup controllerSecure multicast

Apparatuses, systems, and methods for optimal group key (OGK) management that may achieve non-colluding and / or the storage-communication optimality are disclosed. In some embodiments, a group controller (GC) is responsible for key generation and distribution and the group data are encrypted by a group key. When joining the group, in some embodiments, each group member (GM) is assigned a unique n-bit ID and a set of secrets, in which each bit is one-to-one mapped to a unique secret. Whenever GMs are revoked from the group, in some embodiments, the GC will multicast an encrypted key-update message. Only the remaining GMs may be able to recover the message and update GK as well as their private keys. The disclosed OGK scheme can achieve storage-communication optimality with constant message size and immune to collusion attack and also may outperform existing group key management schemes in terms of communication and storage efficiency.

Owner:ARIZONA STATE UNIVERSITY

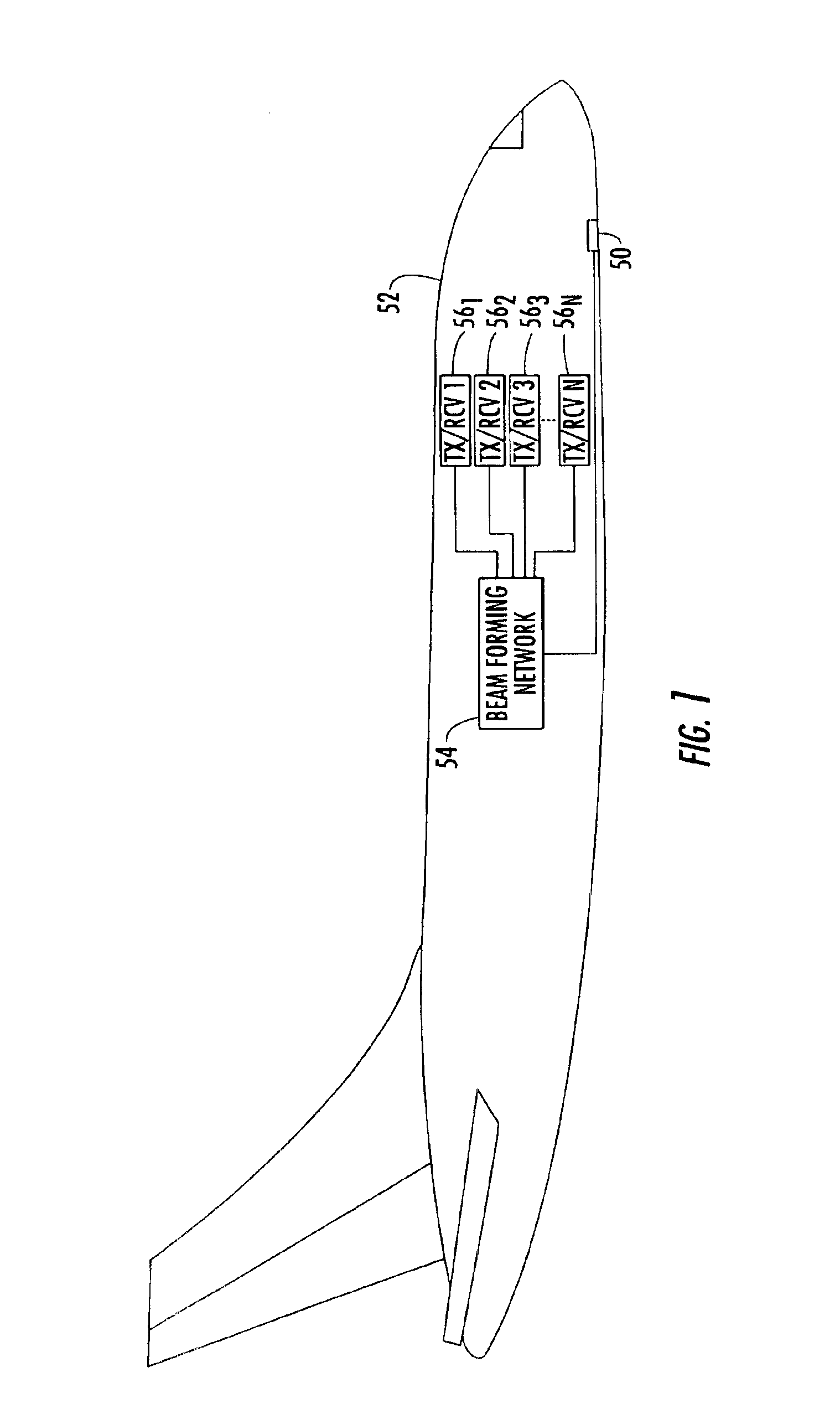

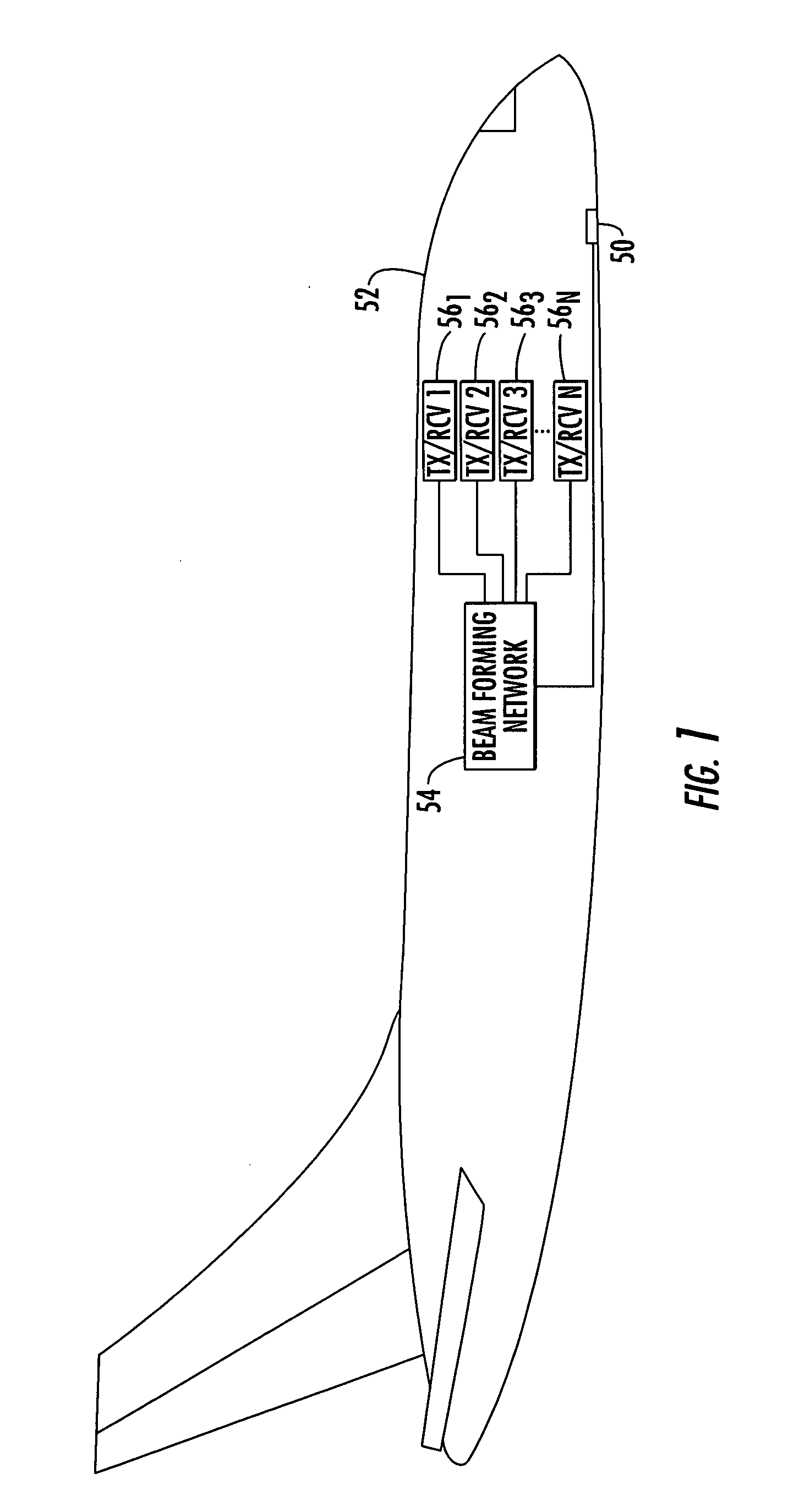

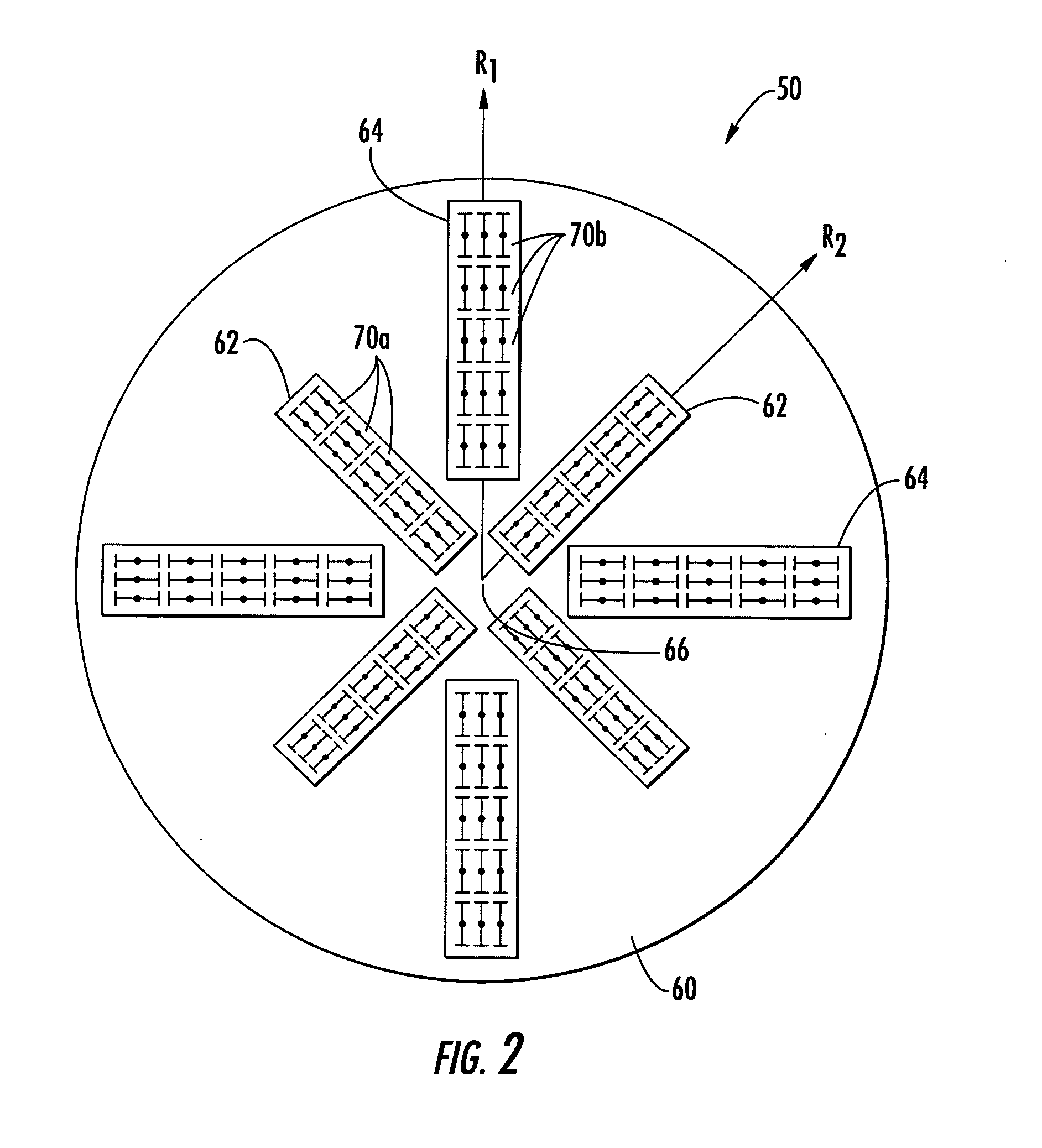

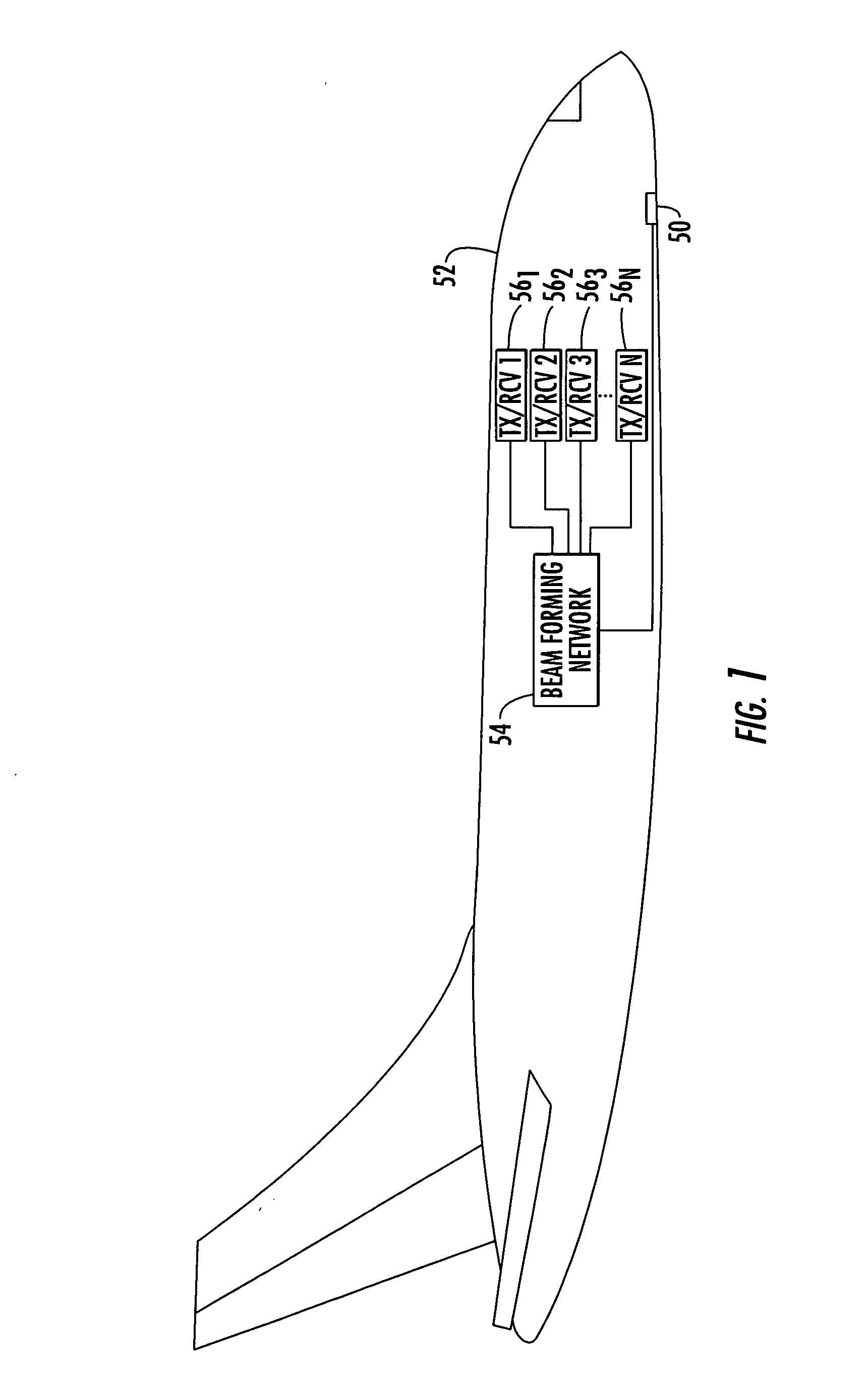

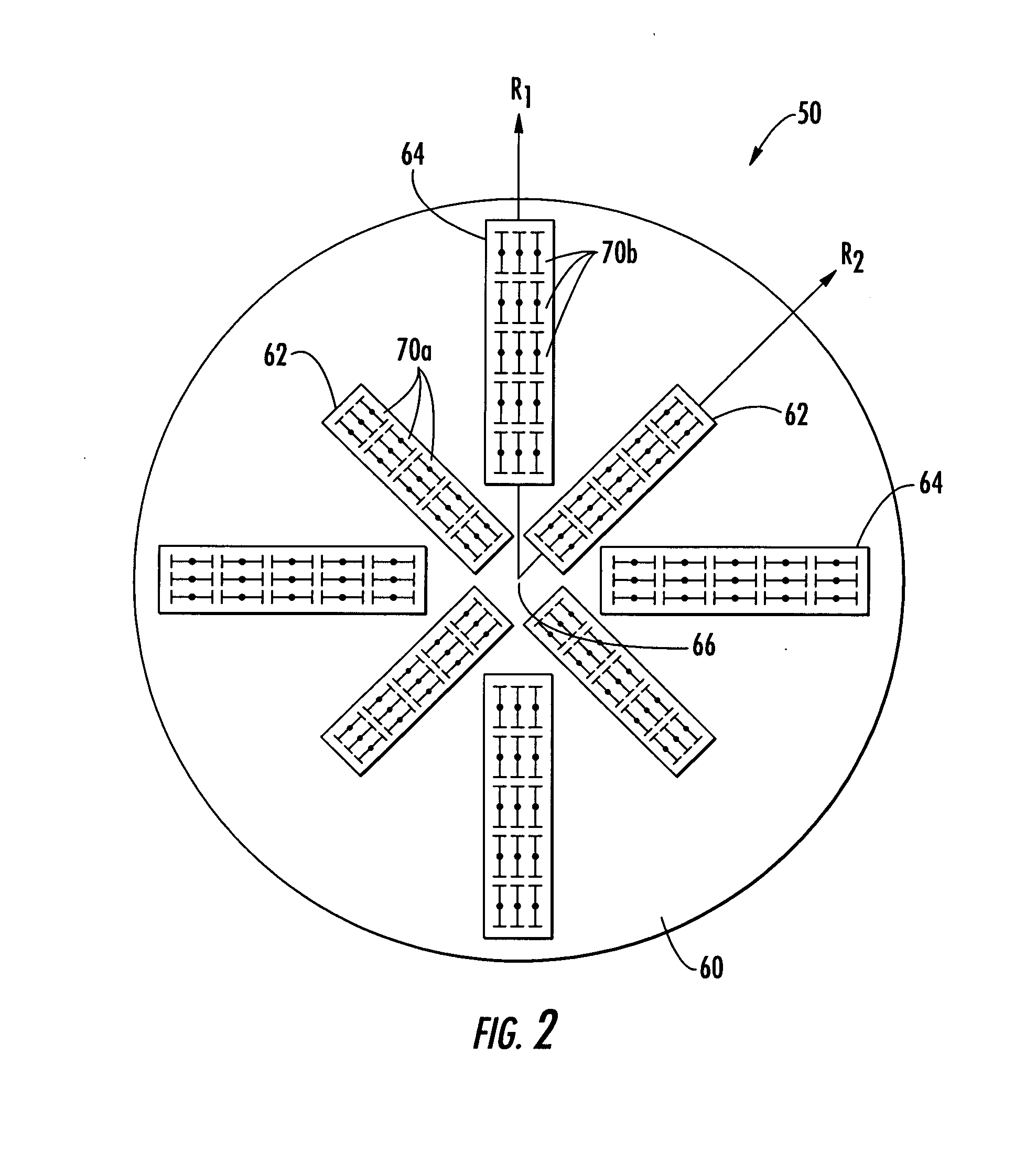

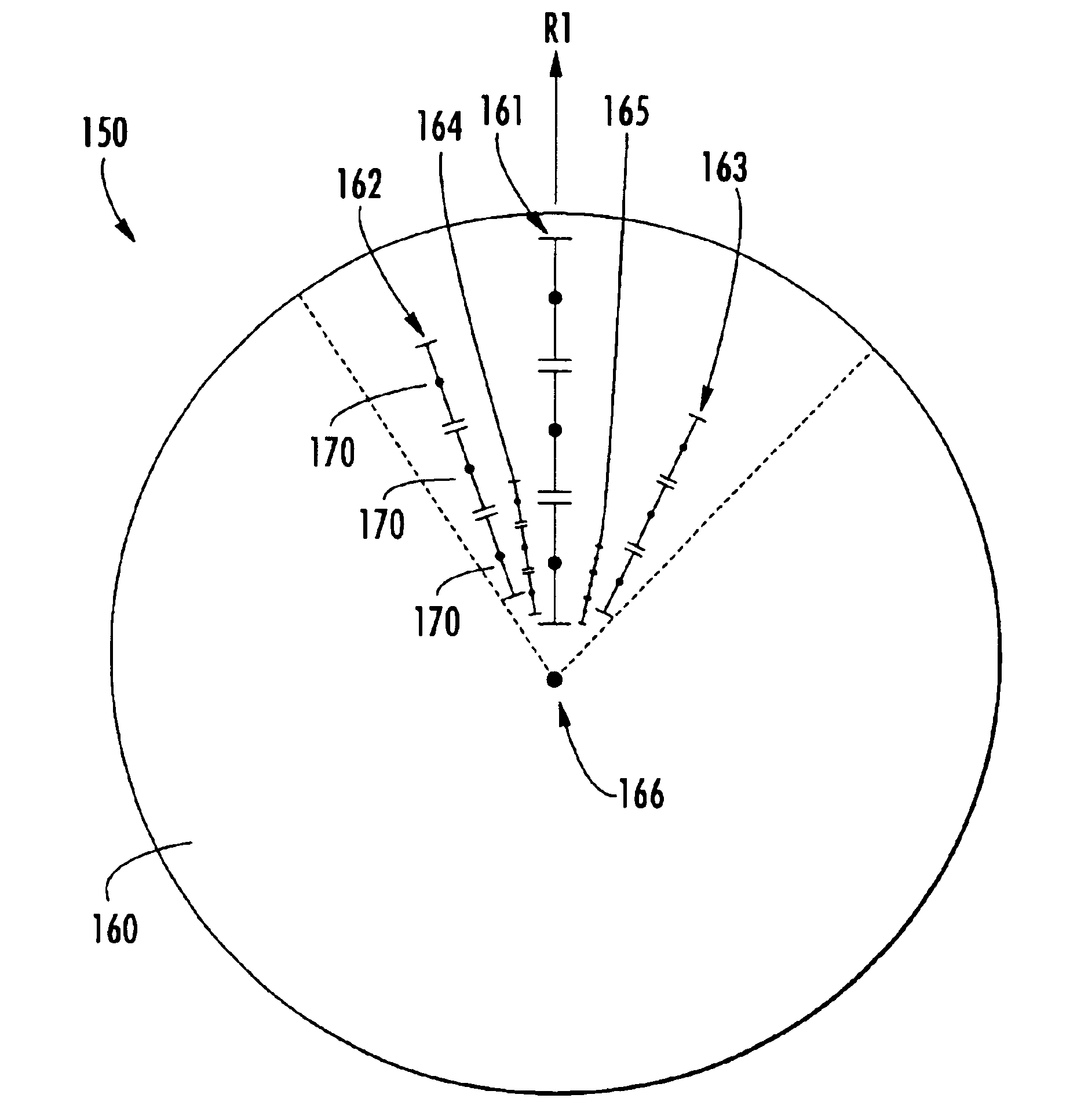

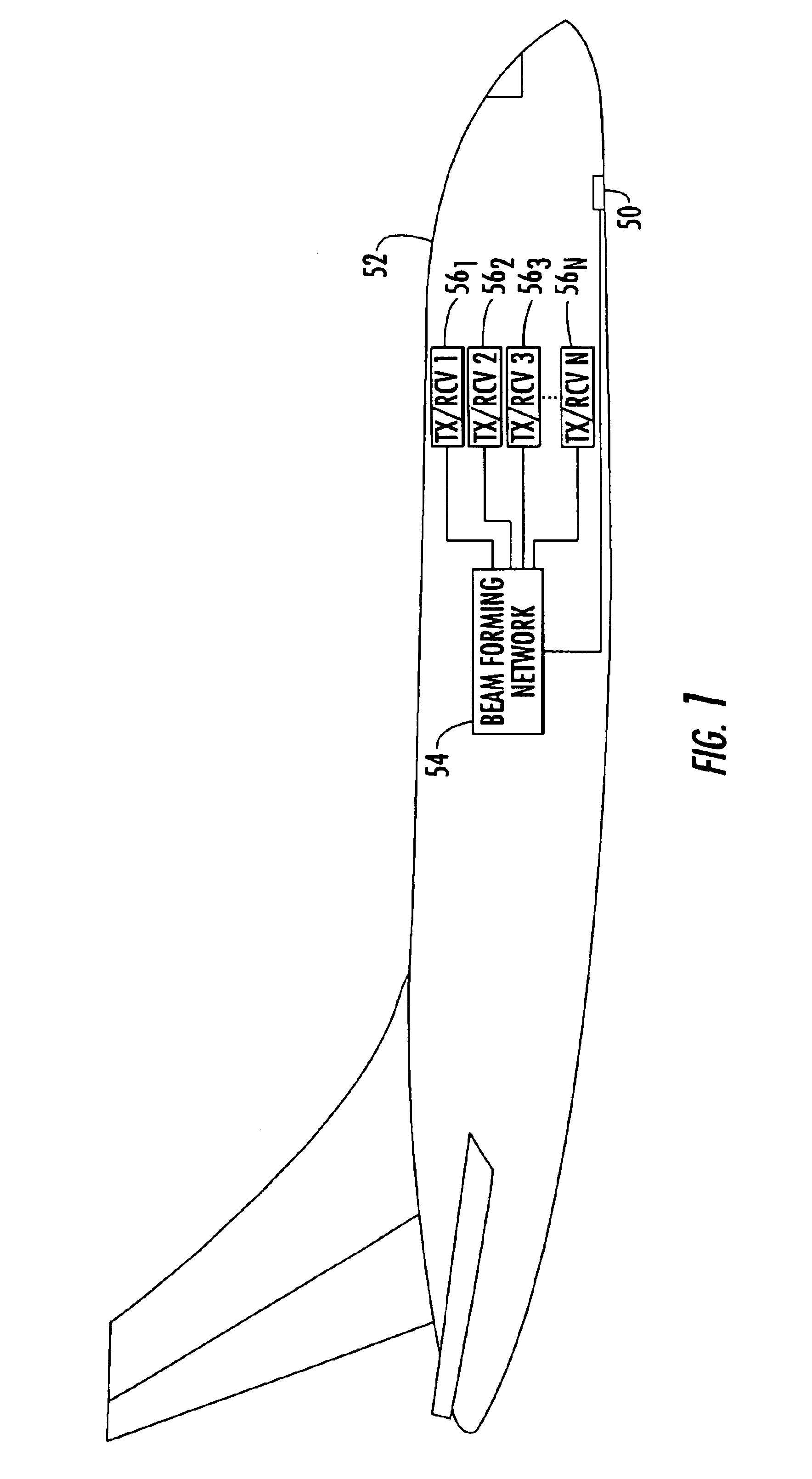

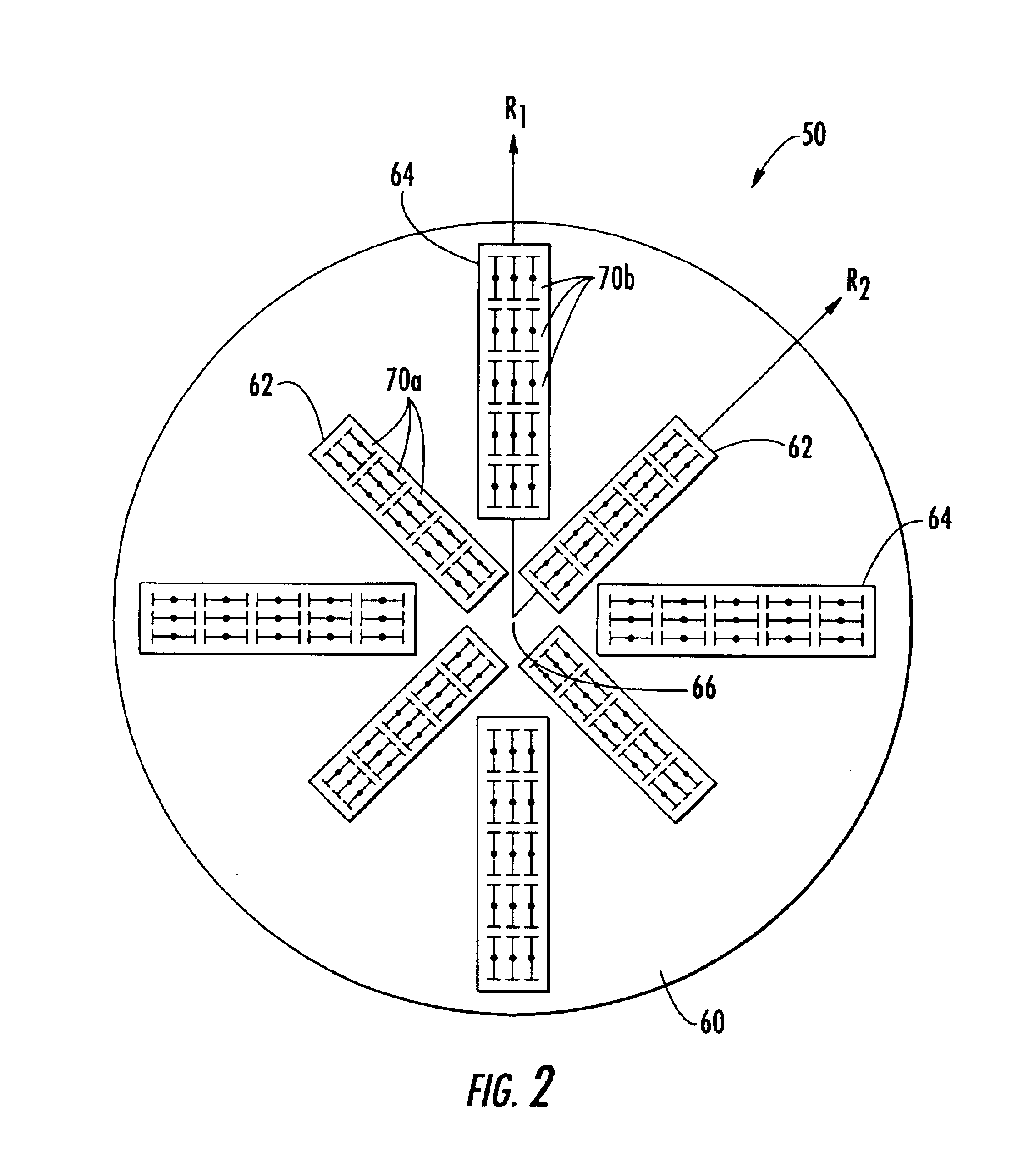

Multiband radially distributed phased array antenna with a sloping ground plane and associated methods

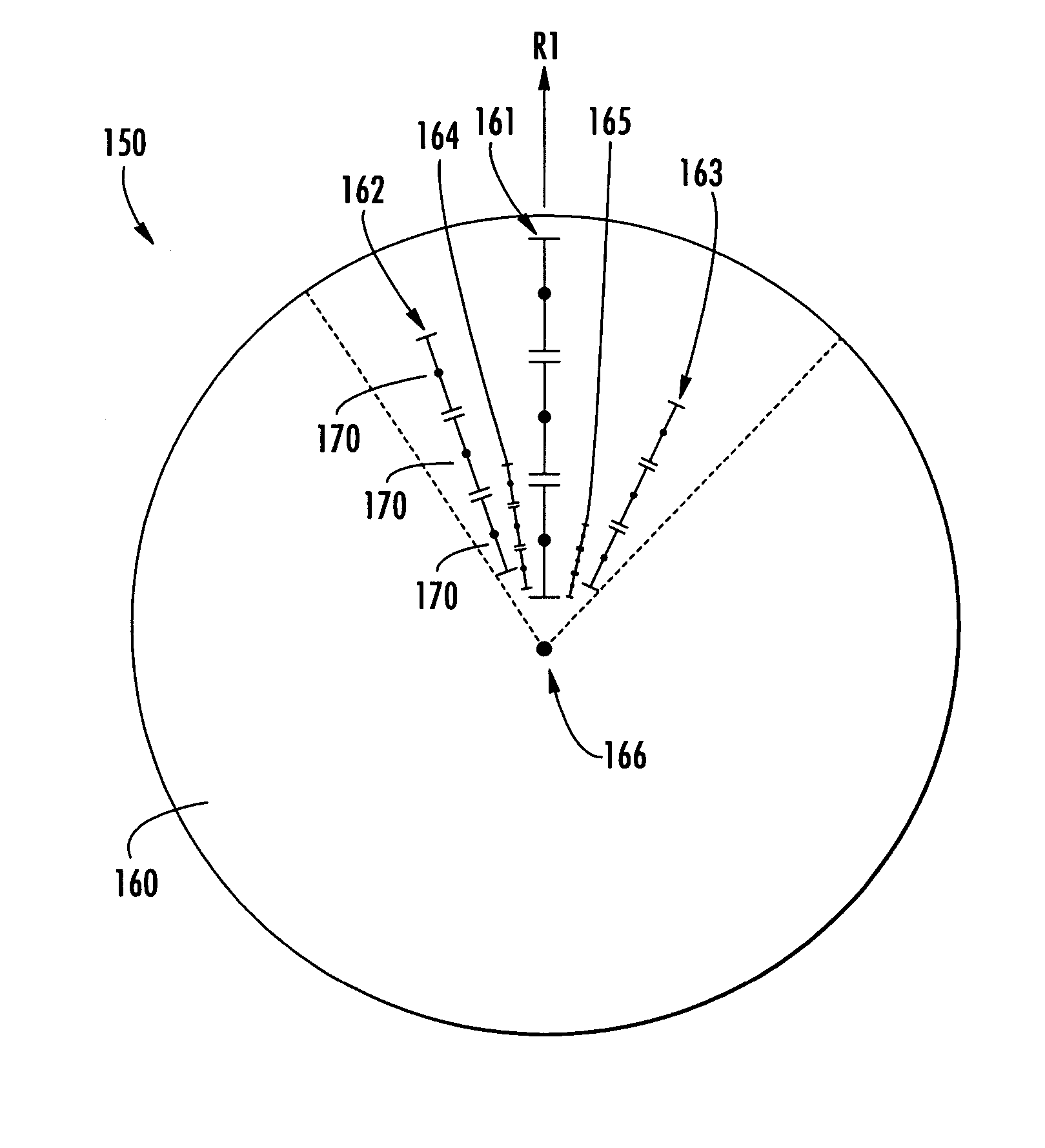

InactiveUS6903703B2Improve efficiencyConstant beamwidth and pattern controlSimultaneous aerial operationsRadiating elements structural formsGround planeDipole antenna

A multiband phased array antenna includes a substrate, and dipole element arrays extending outwardly from an imaginary center point on the substrate. Each dipole element array includes dipole antenna elements arranged in an end-to-end relation and having a dipole size different than a dipole size of dipole antenna elements of at least one other dipole element array. A ground plane is adjacent the dipole element arrays and has a different spacing therefrom in an outward direction from the imaginary center point. The different spacing between the ground plane and the dipole element arrays increases from the imaginary center point towards an edge of the substrate.

Owner:NORTH SOUTH HLDG

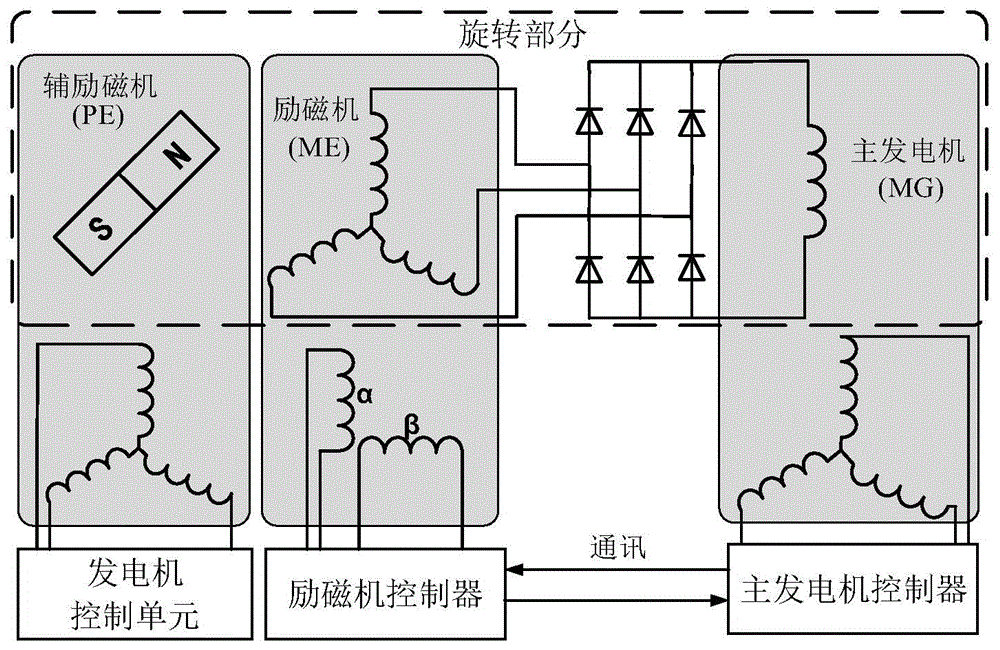

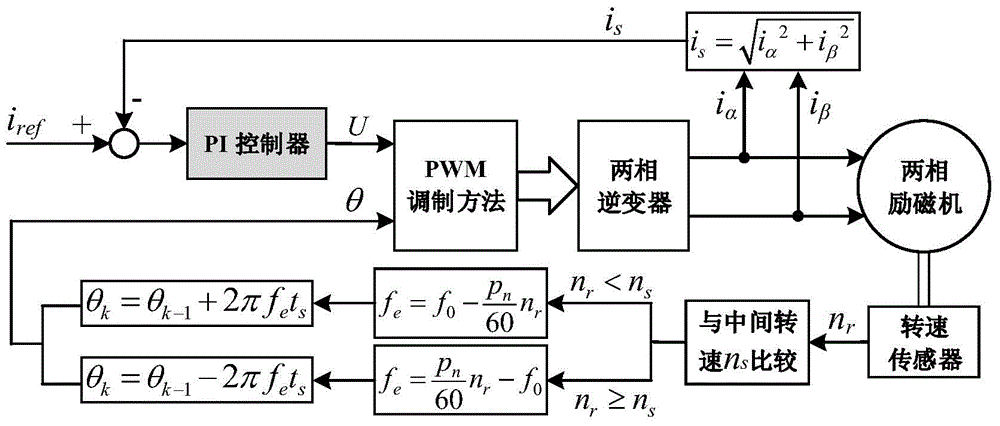

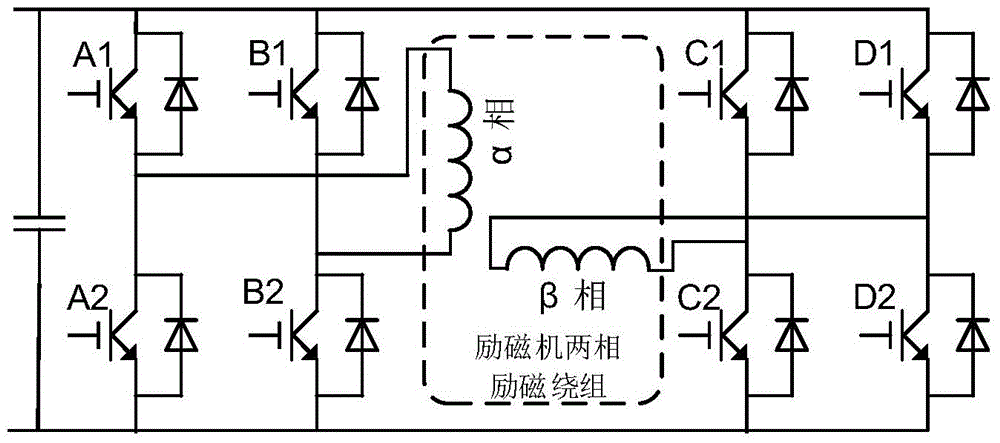

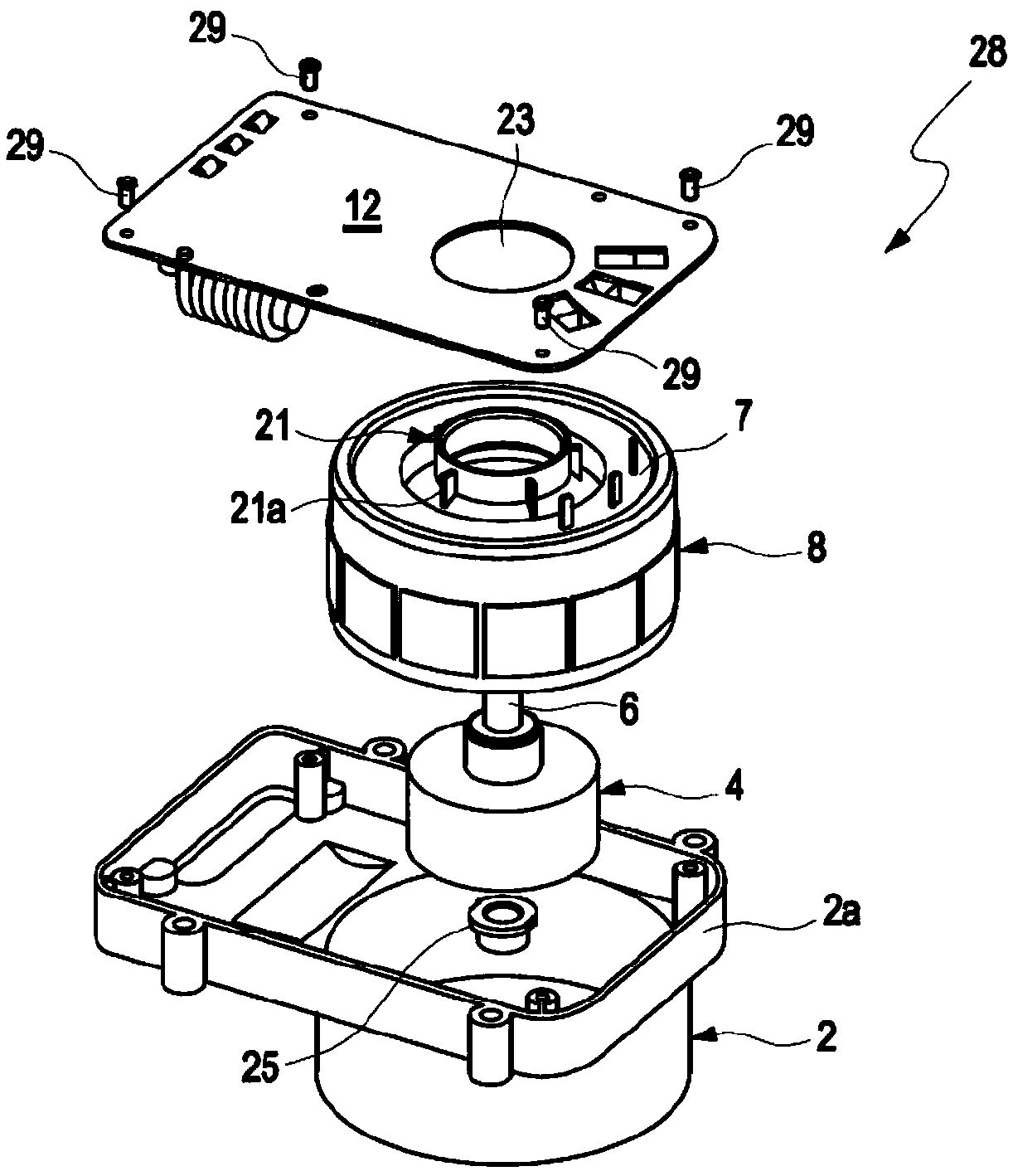

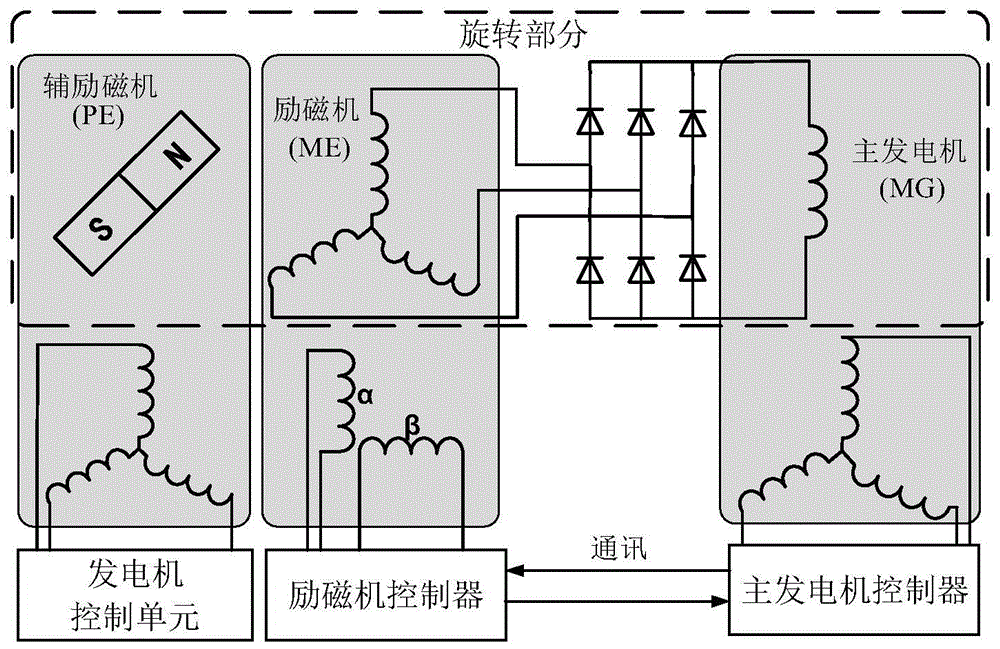

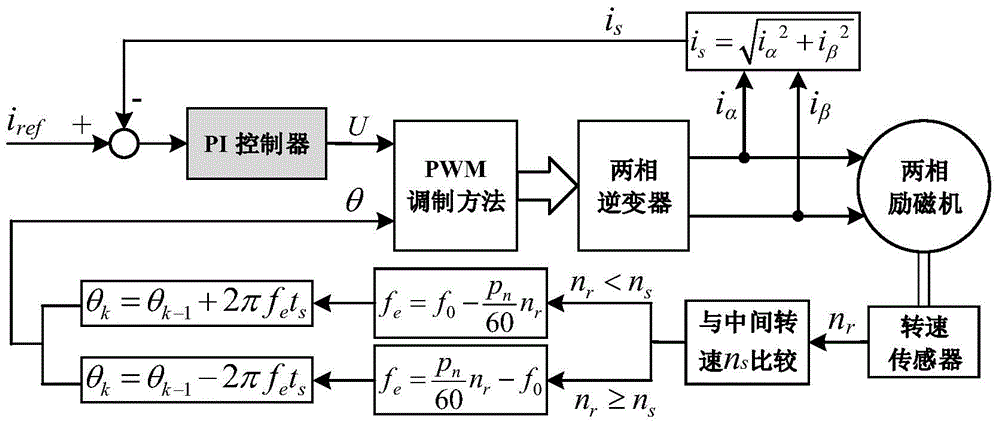

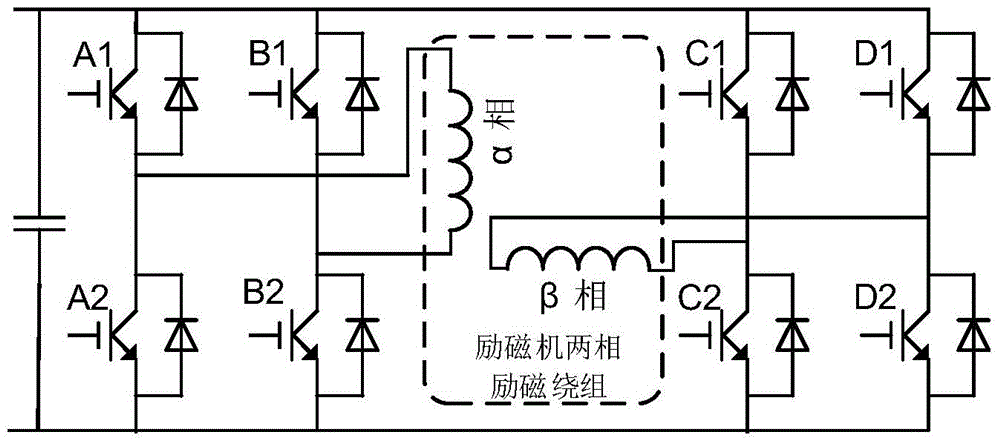

Excitation control method for starting stage of aviation tertiary starting power generation system

ActiveCN104935214AConstant sizeConstant relative speedAC motor controlElectric generator controlMotor speedAviation

The invention relates to an exciter whole-process two-phase alternating-current excitation control method for the starting stage of an aviation tertiary brushless starting power generation system based on a two-phase exciter. In the motor starting process, an exciter adopts two-phase alternating-current excitation in the whole process. The amplitude of a modulation voltage vector is determined through exciter excitation current closed-loop control, and the phase angle of the modulation voltage vector is determined through motor speed reference. When the method of the invention is applied to the starting stage of a tertiary brushless synchronous starting power generation system, the size of the excitation magnetic field of the exciter can be kept constant, and the speed of a rotor armature winding relative to the excitation magnetic field can be kept constant. Finally, the excitation current of a main generator can be kept constant in the whole motor starting process, and the complexity of main generator variable-frequency starting control is reduced.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

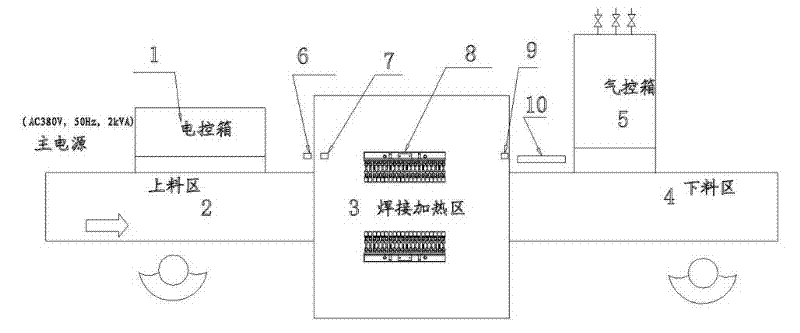

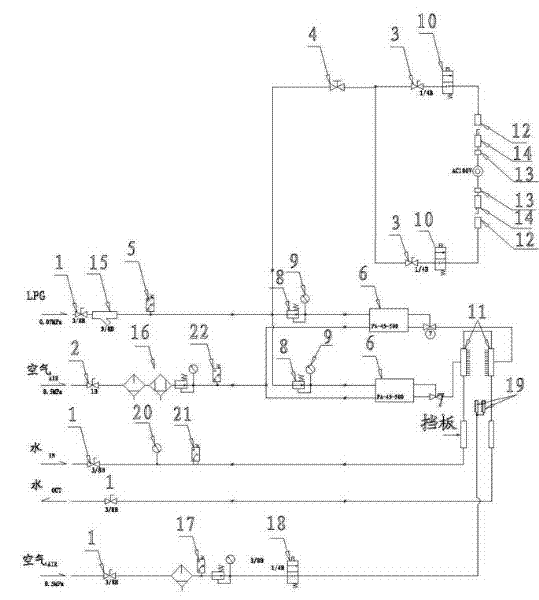

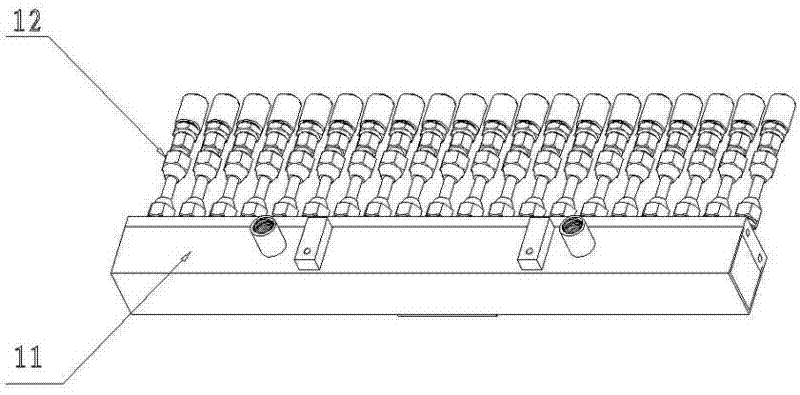

Digital display precision flow controllable and adjustable multi-column aluminum heat exchanger flame brazing equipment

The invention discloses torch soldering equipment which is used for linearly moving on a rail and is used for soldering the U-shaped tube of an all aluminum heat exchanger. The equipment is composed of an electric control unit, a material feeding area, a welding and heating area, a blanking area and a pneumatic control unit. Under the condition that liquefied petroleum gas (LPG), air, cooling water, a power supply and the like are switched on as required, the existing product specification (technological parameters, such as chosen transmission link speed, flame size and the like) is chosen, and then, ignition is carried out to start a conveyor, and a conveying chain is operated under a constant speed. Workpieces (parts and welding rings which are assembled as required) which need to be welded are continuously put in the material feeding area to a conveying link plate; products are conveyed to two sides of a welding area by the conveying link plate automatically at a constant speed to be heated and welded by symmetrical fire row flames; then the products are conveyed to the blanking area; and the products are continuously unloaded from a conveying link in the blanking area and simultaneously a welding effect is monitored.

Owner:ZHEJIANG XINRUI WELDING MATERIAL

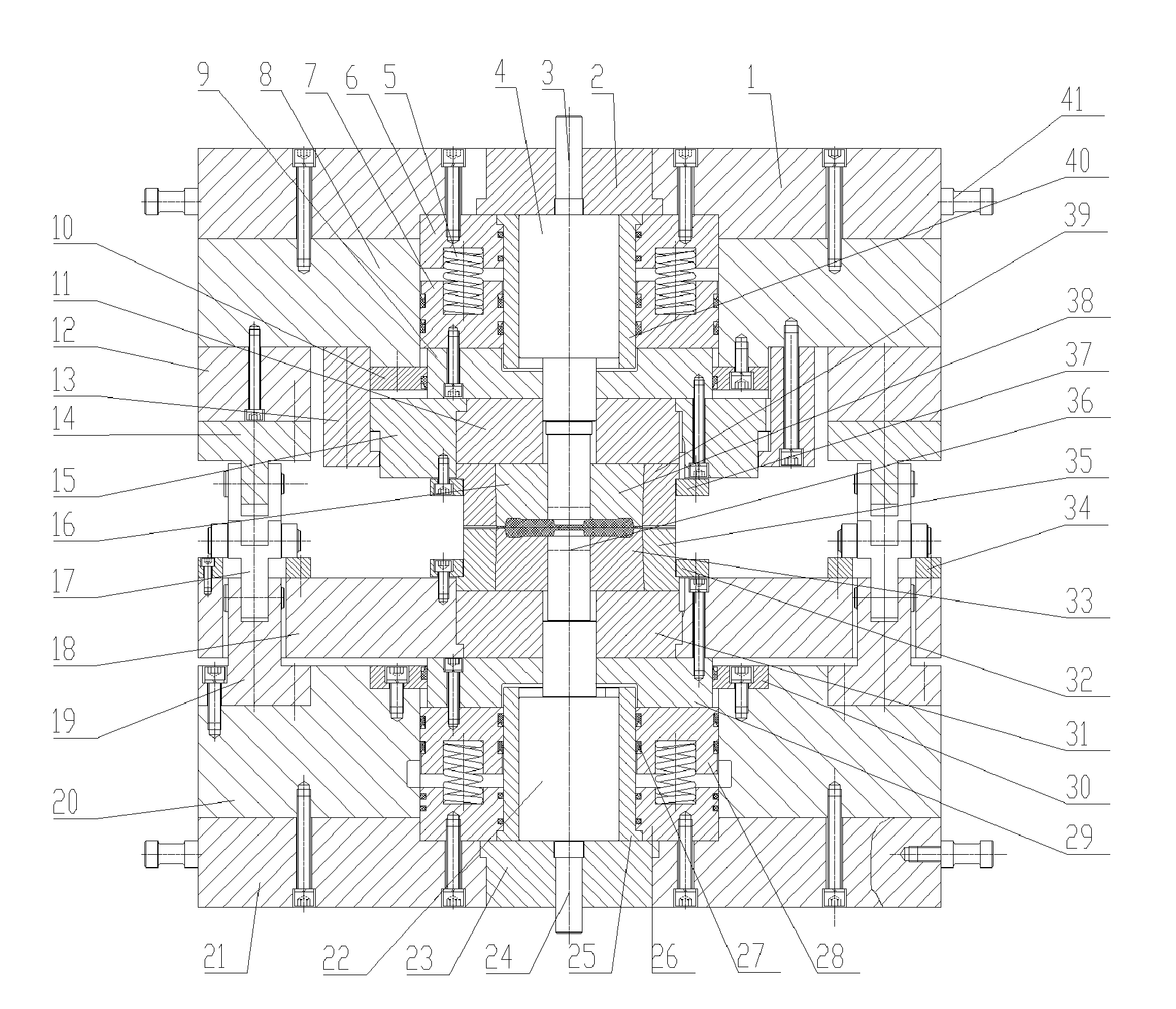

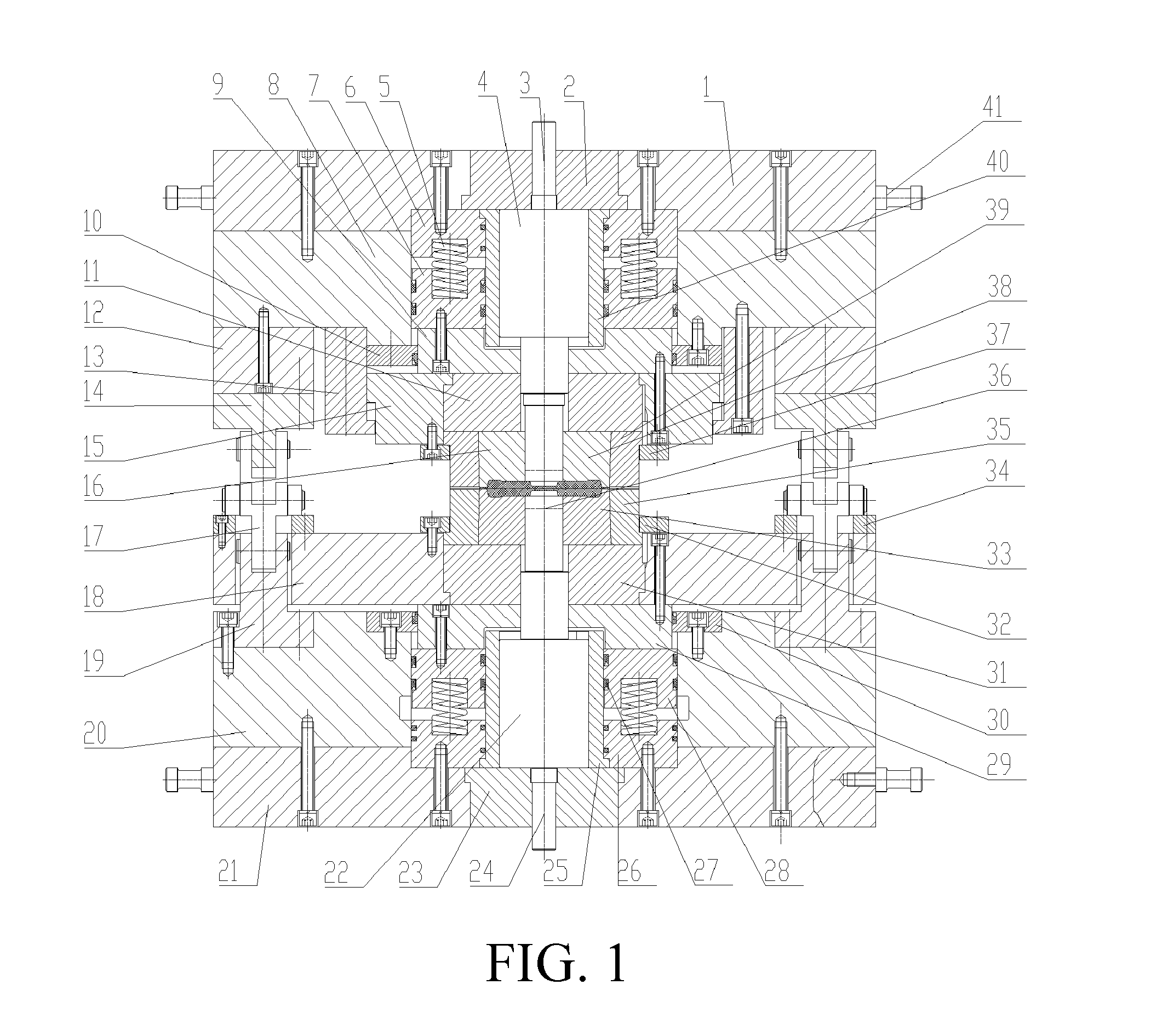

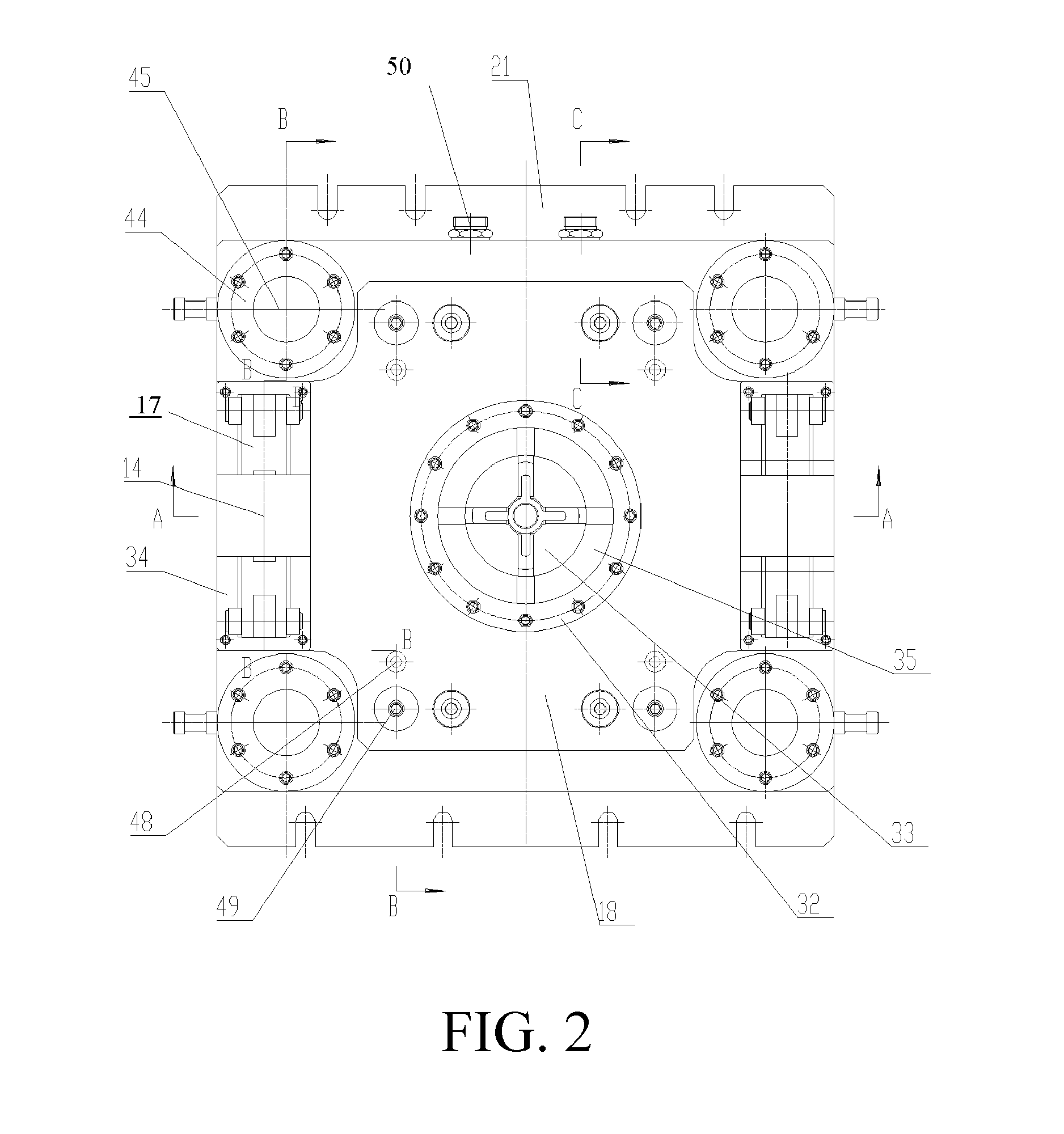

Double Closed Hydraulic Mould Stand

ActiveUS20110030443A1Easily processed and and maintainedForce is great and stableForging/hammering/pressing machinesForging press drivesProduction rateNitrogen gas

A double closed hydraulic mould stand is provided, which includes an up bottom plate (1), a down bottom plate (21), an up mould plate (8), a down mould plate (20), four guide sleeves (42), four guide columns (45), and a four mechanical linkage velocity ratio mechanism. The four guide sleeves (42) and the four guide columns (45) are distributed symmetrically and slidingly fit each other. An up piston cylinder, a down piston cylinder, an up bed piece (11), a down bed piece (31), an up concave mould seat (15), a down concave mould seat, an up concave mould (16), and a down concave mould (33) are fixed at the up bottom plate and the down bottom plate. An up pin-lift (3), a down pin-lift (24), an up punch pin seat (4), a down punch pin seat (22), an up punch pin (38), and a down punch pin (36) form an up piston and a down piston respectively. The up piston cylinder and the down piston cylinder have a split combined structure, which is convenient for manufacturing, installation, and maintenance. The up piston cylinder is repositioned by using a cylindrical spring. The down piston cylinder is repositioned by using a cylindrical spring and a nitrogen gas spring. The reposition is strong and fast, which facilitates vacuum oil absorption, power consumption saving, and productivity improvement. The present invention can be installed on a single-acting hydraulic press or a single-acting mechanical press for use, and has a wide application range.

Owner:JIANGSU PACIFIC PRECISION FORGING +1

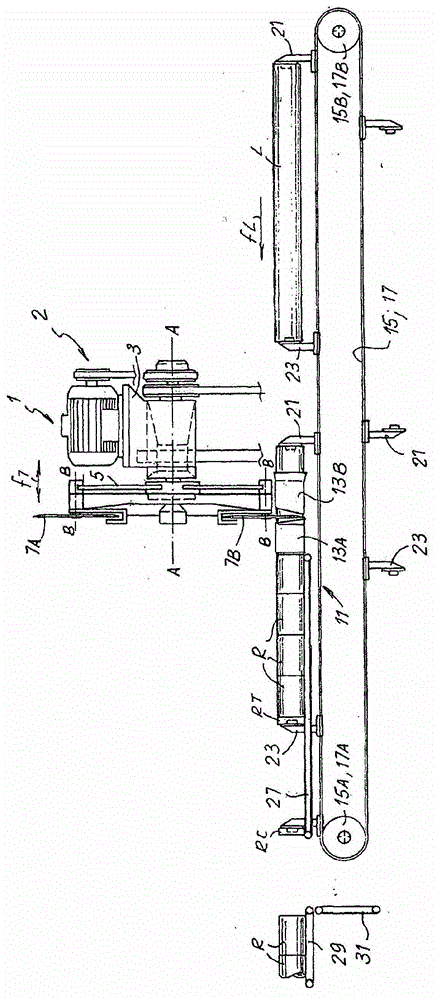

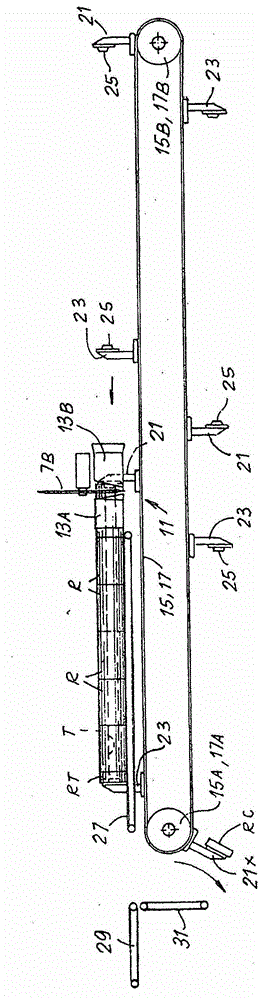

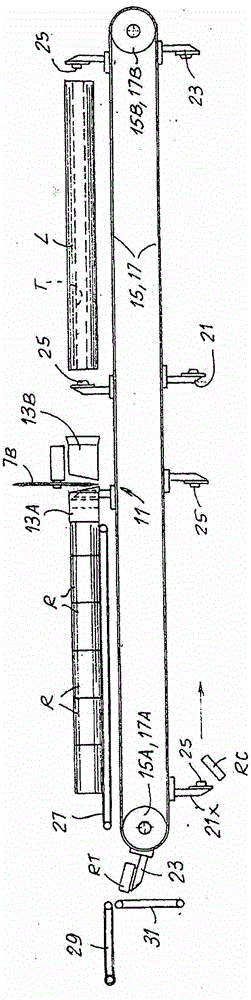

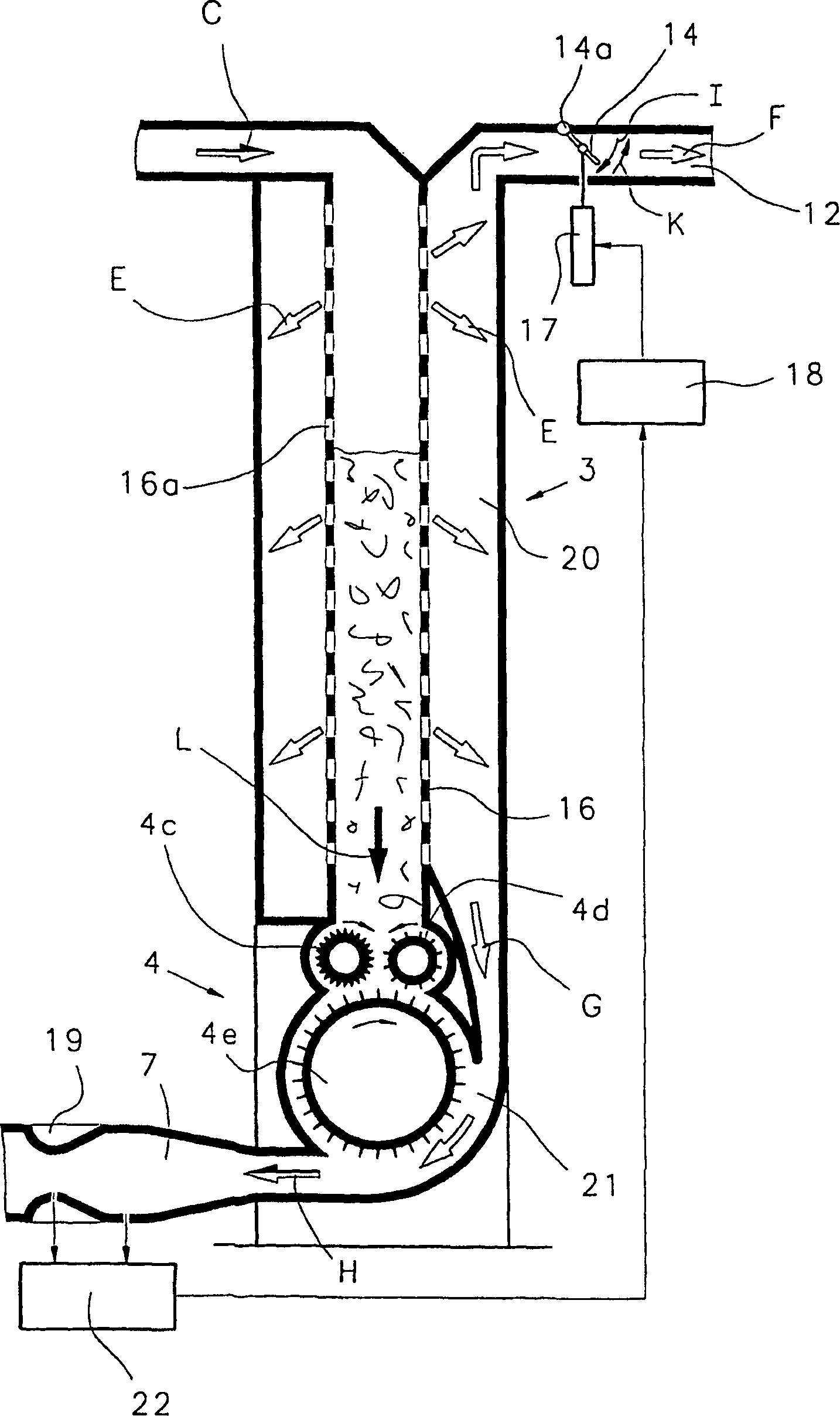

Machine for cutting web rolls

InactiveCN102753317AConstant sizeEliminate needMetal working apparatusEngineeringMechanical engineering

The cutting machine comprises: at least one log feed channel; a cutting station along said feed channel, with at least one cutting blade for dividing each log into individual rolls plus front and rear trims; a log feed device along said feed channel, comprising at least one rear member for pushing the logs to be cut, movable along the feed channel to push each log through said cutting station. The feed device also comprises at least one front member for engaging with the log to be cut, arranged and controlled so as to engage frontally with each log, or series of rolls obtained after the log has been cut, for at least a part of its travel along said feed channel.

Owner:FABIO PERINI SPA

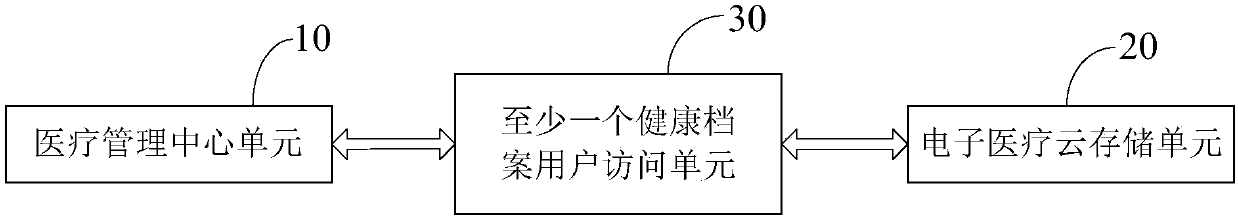

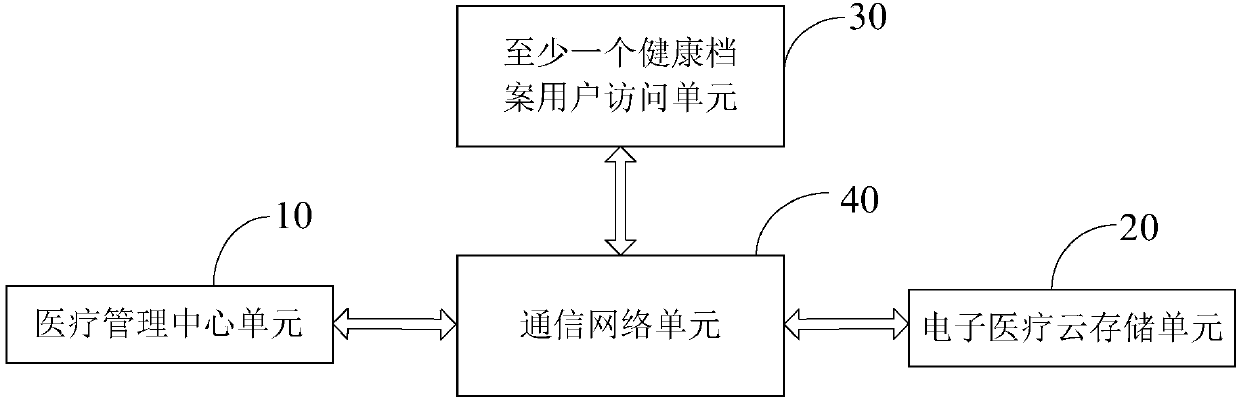

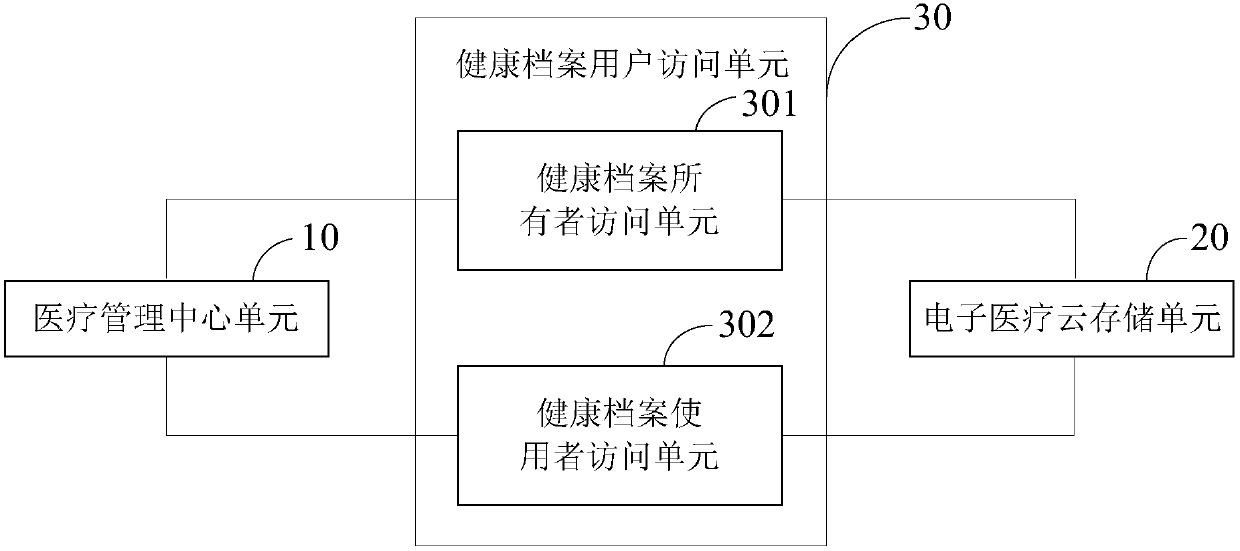

Health record access control system and method in electronic medical cloud

ActiveCN107682353AProtection confidentialityImplement fine-grained access controlData processing applicationsPublic key for secure communicationControl systemConfidentiality

The invention provides a health record access control system and method in electronic medical cloud. The system comprises a medical management center unit used for generating a system public key and asystem private key, and generating a corresponding user attribute private key according to the system public key, the system private key and a user attribute set; an electronic medical cloud storageunit used for receiving and storing health record ciphertexts with privacy protection; and at least one health record user access unit used for encrypting health records according to the system publickey to obtain the health record ciphertexts with privacy protection; and / or generating the user attribute set and decrypting the health record ciphertexts with privacy protection according to the system public key and the user attribute private key. By adoption of the health record access control system and method in electronic medical cloud provided by the invention, the confidentiality of the health records is not only guaranteed, and the security and the computational efficiency of the health record access are also improved.

Owner:XIAN UNIV OF POSTS & TELECOMM

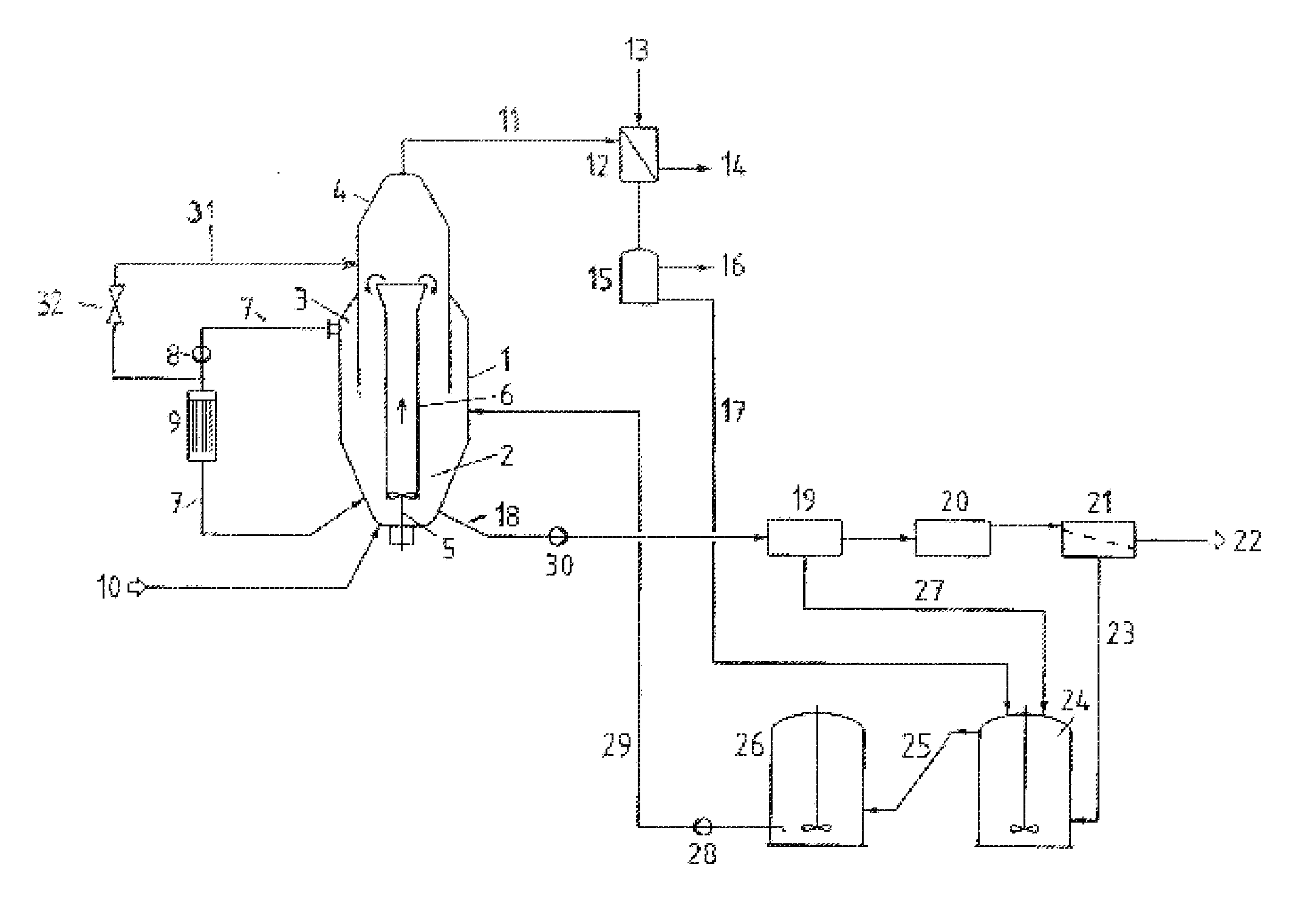

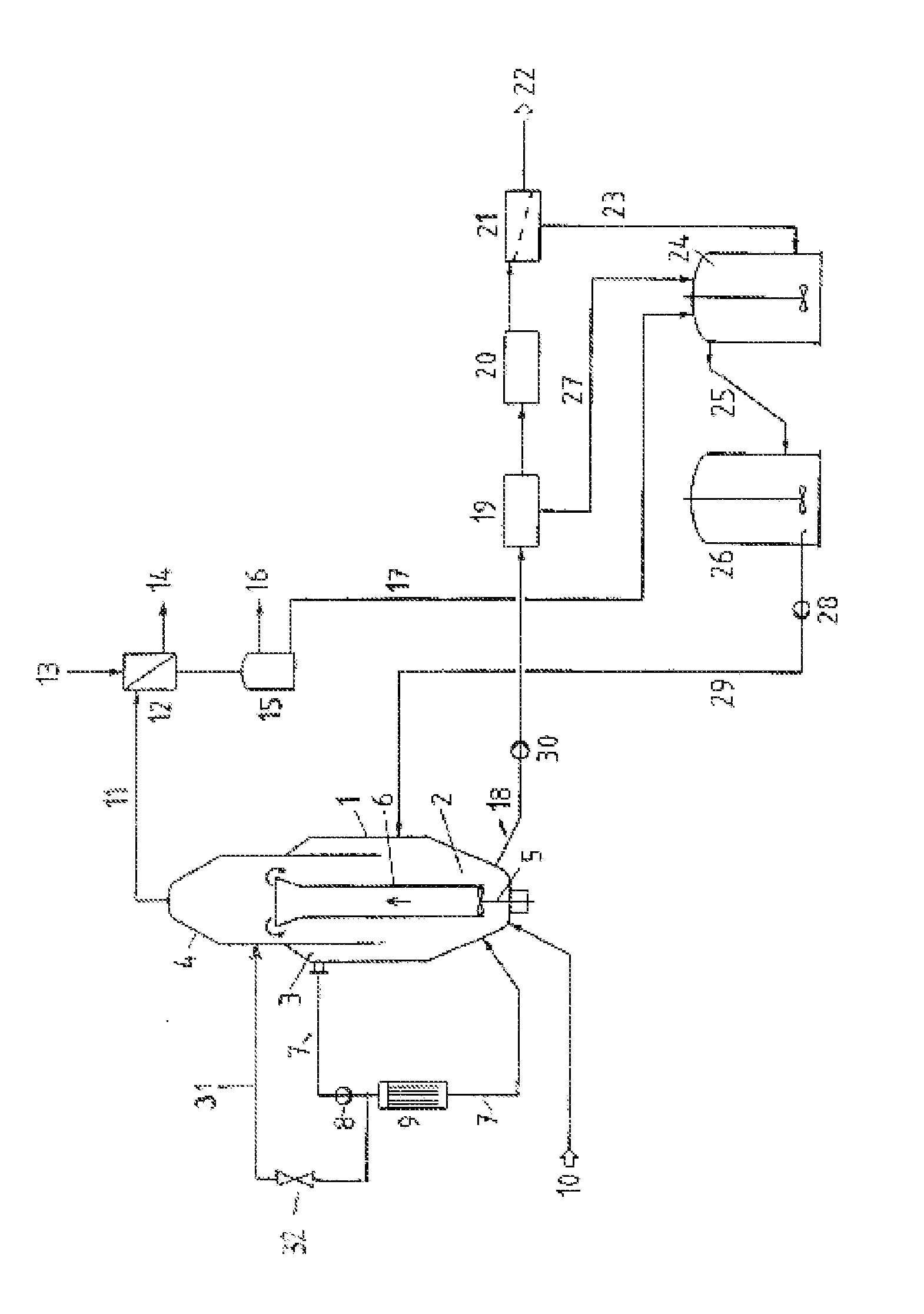

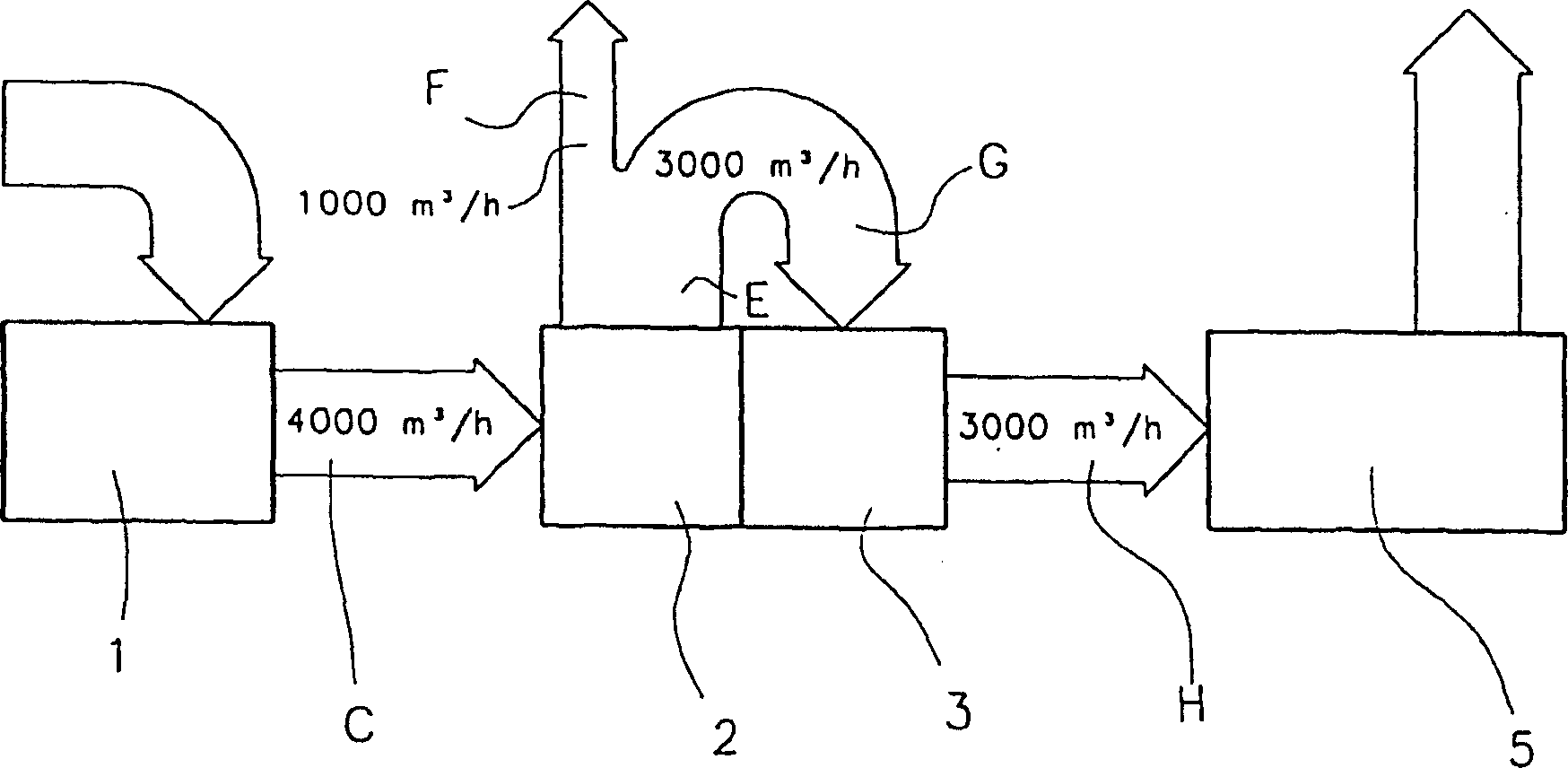

Method for producing a coarse-grained ammonium sulfate product via crystallization and installation for operating the method

ActiveUS20130230446A1Reduce yieldSmallest possible outlayNitrogen compoundsCrystallization by component evaporationSulphate IonDissolution

Method for the production of a coarse-grained ammonium sulphate product by crystallization and installation for carrying out the method. A method for the continuous production of a coarse-grained ammonium sulphate product from an ammonium sulphate solution in a crystallizer operates in accordance with the DTB principle and has an internal suspension circuit and a clarifying zone, from which a clarified partial flow of solution is constantly drawn off into an external circuit, is heated in a heat exchanger so as to dissolve the solids contained therein and is then guided back as a clear solution into the lower region of the crystallizer. In order to ensure production of a product crystallizate with a grain coarseness which is practically constant over time, a fine crystal suspension flow may be drawn off from the clarifying zone as a further partial flow and guided back into the internal circuit of the crystallization stage without any previous dissolution of the solid proportion contained therein.

Owner:GEA MESSO

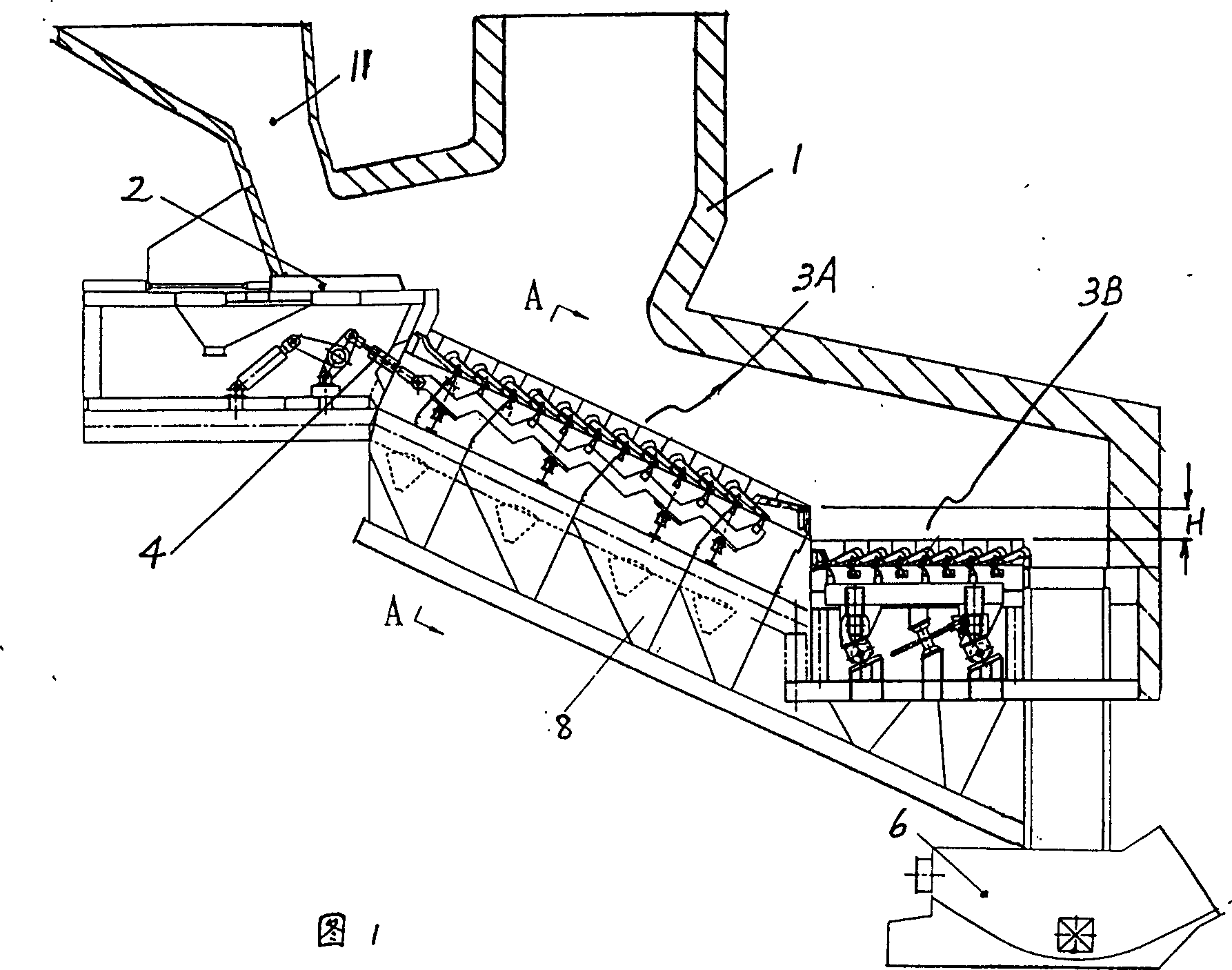

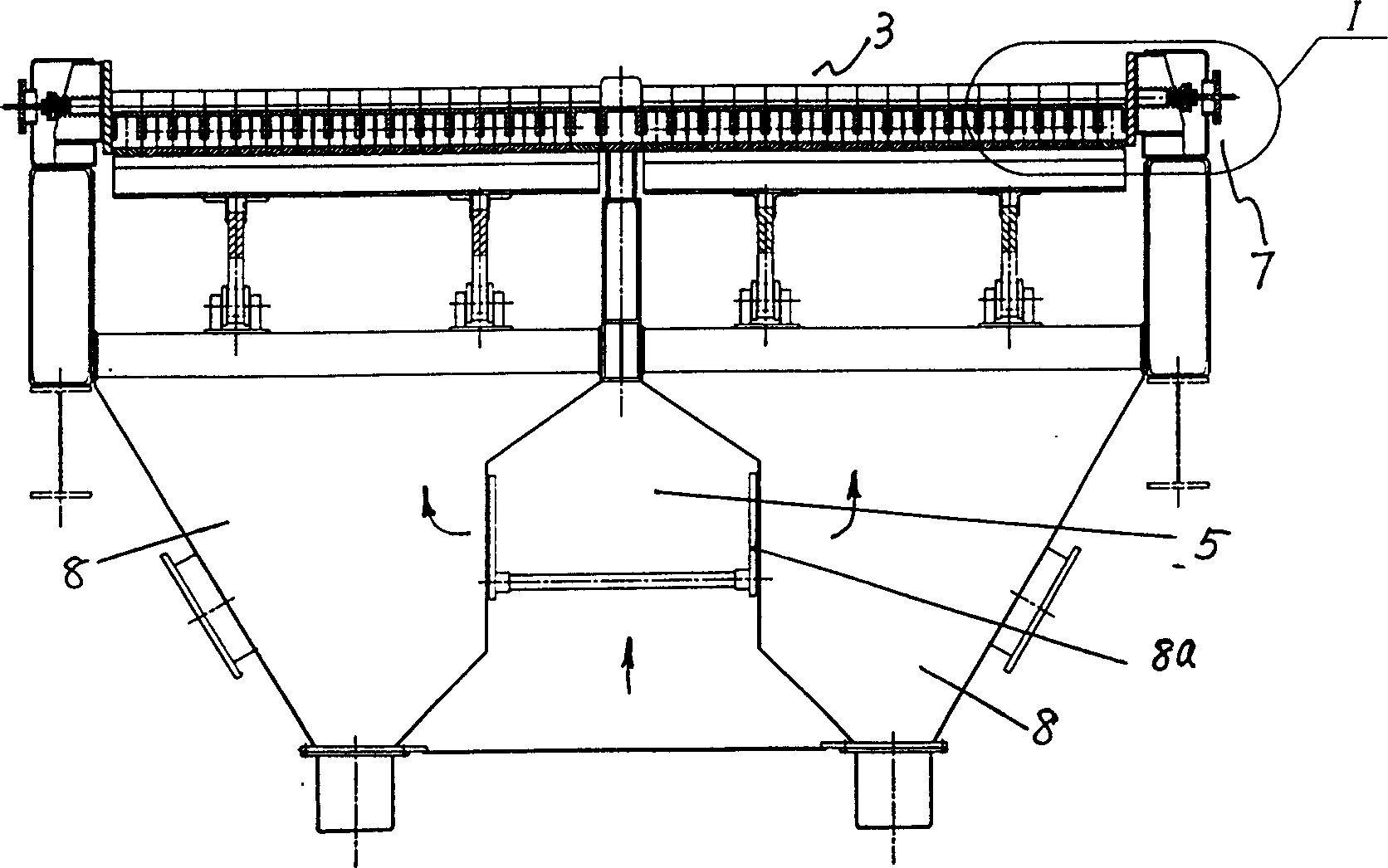

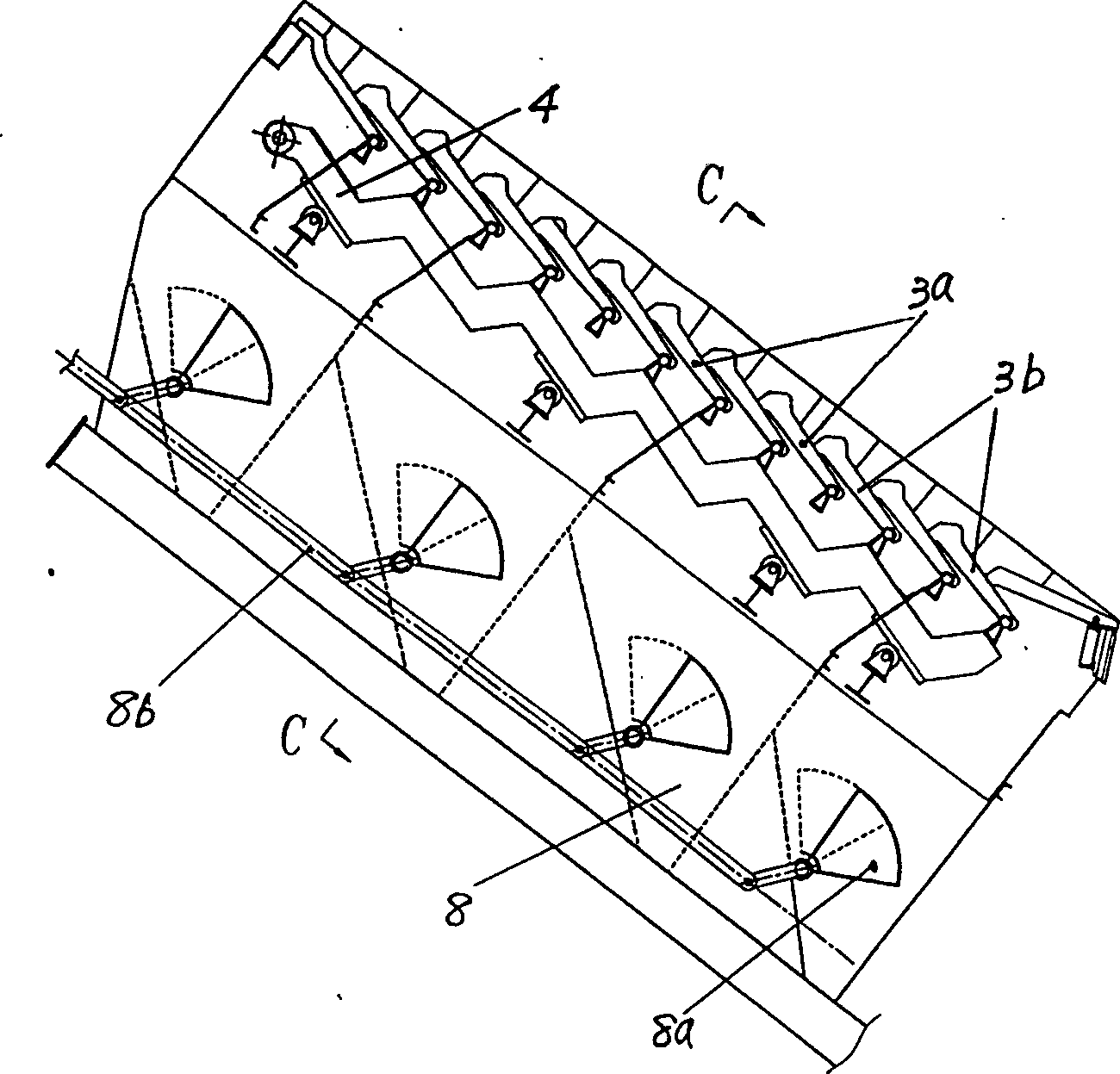

Domestic refuse incinerator

InactiveCN1162646CImprove mashing effectChange the ventilation sectionTravelling grateIncinerator apparatusAir volumeLitter

The domestic refuse incinerator is characterized by that two-stage reciprocating grate, it is suitable for incinerating low-calority high water content and non-sorted domestic refuse, it comprises furnace body with bunker, feeding machine, fire grate, air chamber positioned under the grate and ash-discharge hole, in which said fire grate comprises fixed grate segments fixed on the furnace body and movable grate segments connected on the reciprocating bar. Said fire grate can be divided into two portions of front-stage grate and rear-stage grate, between them there is a position head with a certain height, said fire grate can make refuse automatically be turned, stirred and crushed, and its air intake can be regulated conveniently, and the refuse can be fully incinerated.

Owner:屠柏锐 +2

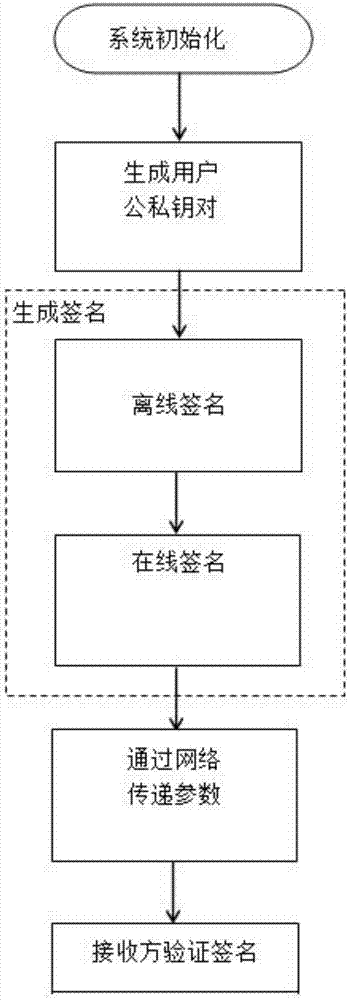

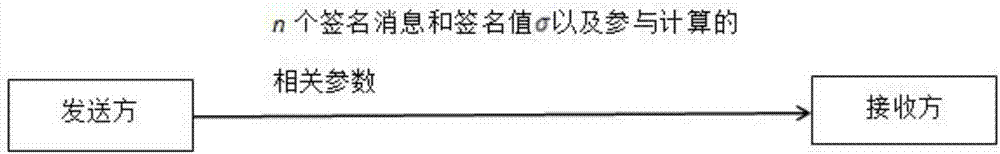

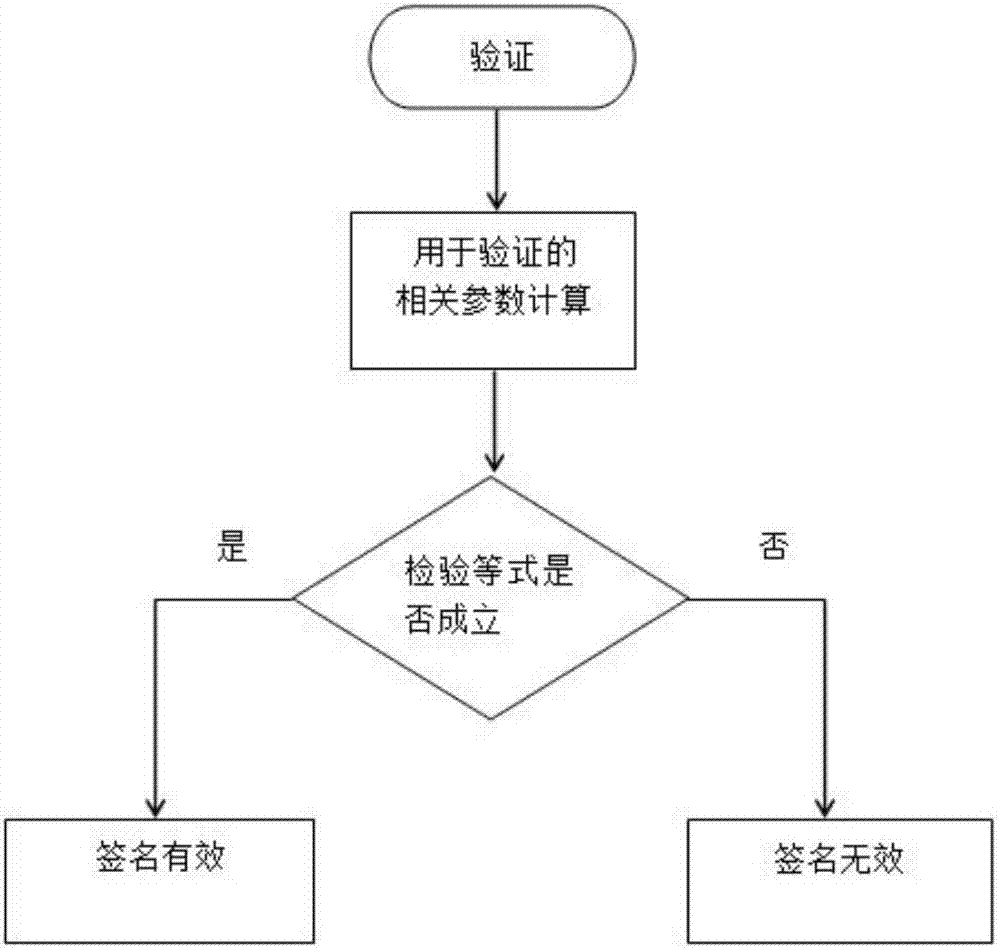

Online and offline aggregated signature method based on identity and constant signature length

ActiveCN107171788AReduce bandwidth requirementsSolving limited computing powerKey distribution for secure communicationUser identity/authority verificationOnline and offlineInformation security

The invention belongs to the technical field of information security, and discloses an online and offline aggregated signature method based on identity and constant signature length. The method is divided into an online stage and an offline stage, pre-computation of a signature is performed in the offline stage, and the signature is generated according to a message and a user identity ID based on a computation result of the offline stage and verified at a receiving side in the online stage; when a user further signs the message, pre-computation of the signature of the offline stage does not need to be performed again, and computation directly starts from the online stage to generate the signature. The signature is performed in the online and offline stages, just once computation is needed in the offline stage, when the user further signs the signature, generation of the signature only needs to start from the online stage; when the user signs the plurality of messages, the length of the finally generated signature is not increased along with the number of the messages, the short and constant length is always kept, and thus signature speed and transmission efficiency are improved; the method is simple and strong in practicability, and has a popularization function.

Owner:西安千喜网络科技有限公司

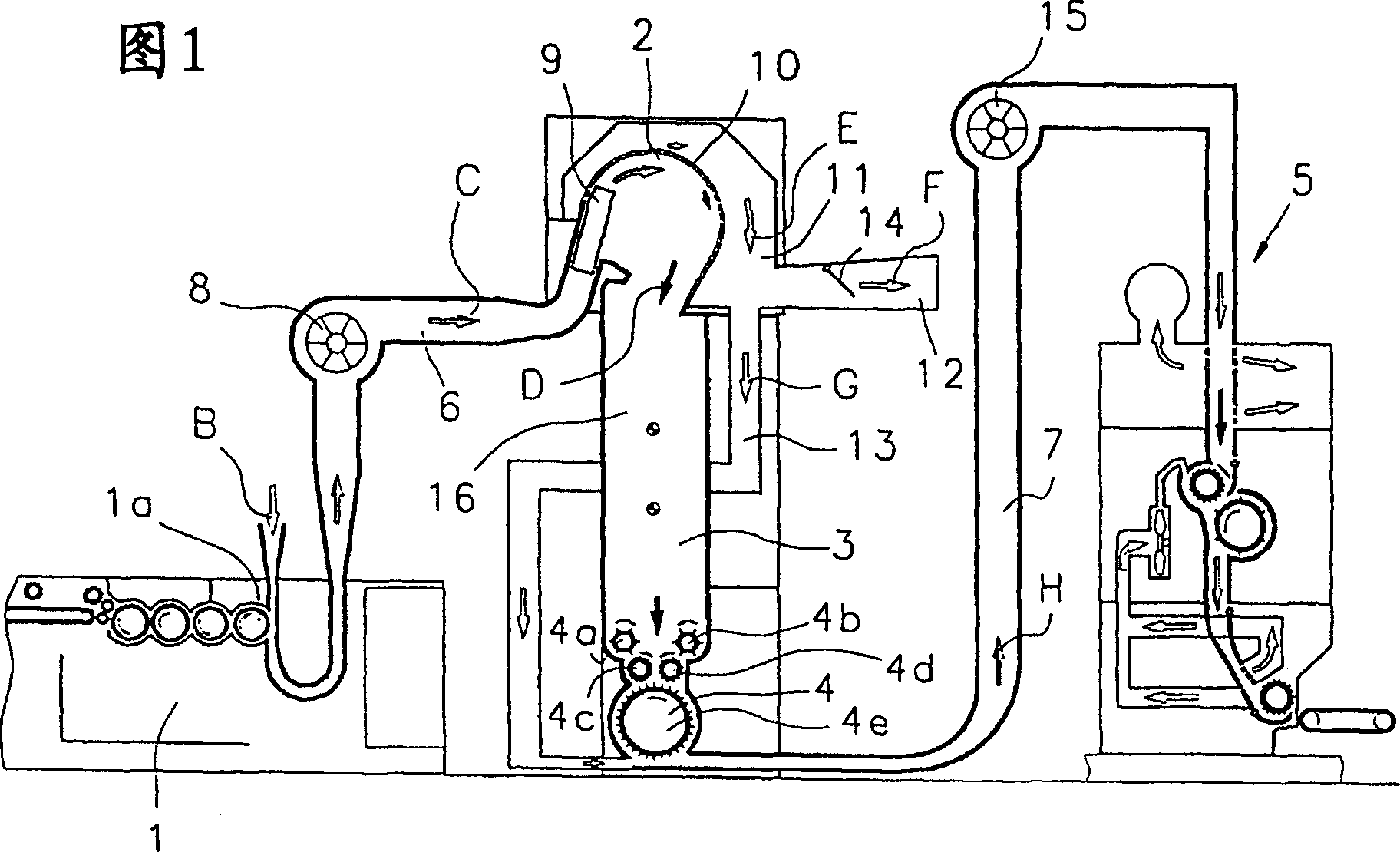

Apparatus for separating transporting air in fibrous material transportation

InactiveCN1448556AConstant sizeLow costFibre cleaning/opening by air draught arrangementsFibre cleaning/opening machinesFiberEngineering

An arrangement used for filtering out conveying air when supplying fiber material, e.g. cotton and the like to a processing machine is provided. The arrangement has an essentially vertical filling chute for the fiber material, the chute having a device with pneumatic fiber feed at the upper intake opening, and a floccule-forming device at the lower exit opening including a system of draw-in rolls and a fast-rotating opening roll. The chute includes at least one air-permeable surface for separating the fiber material from the conveying air. An evacuating device evacuates the filtered out conveying air. An exhaust air device is coupled to the evacuating device and has an air stream regulator which is connected to a control and regulating device. The conveying air stream is guided along the opening roll, and a partial air stream of the filtered out conveying air is guided into the exhaust air device.

Owner:TRUETZSCHLER GMBH & CO KG

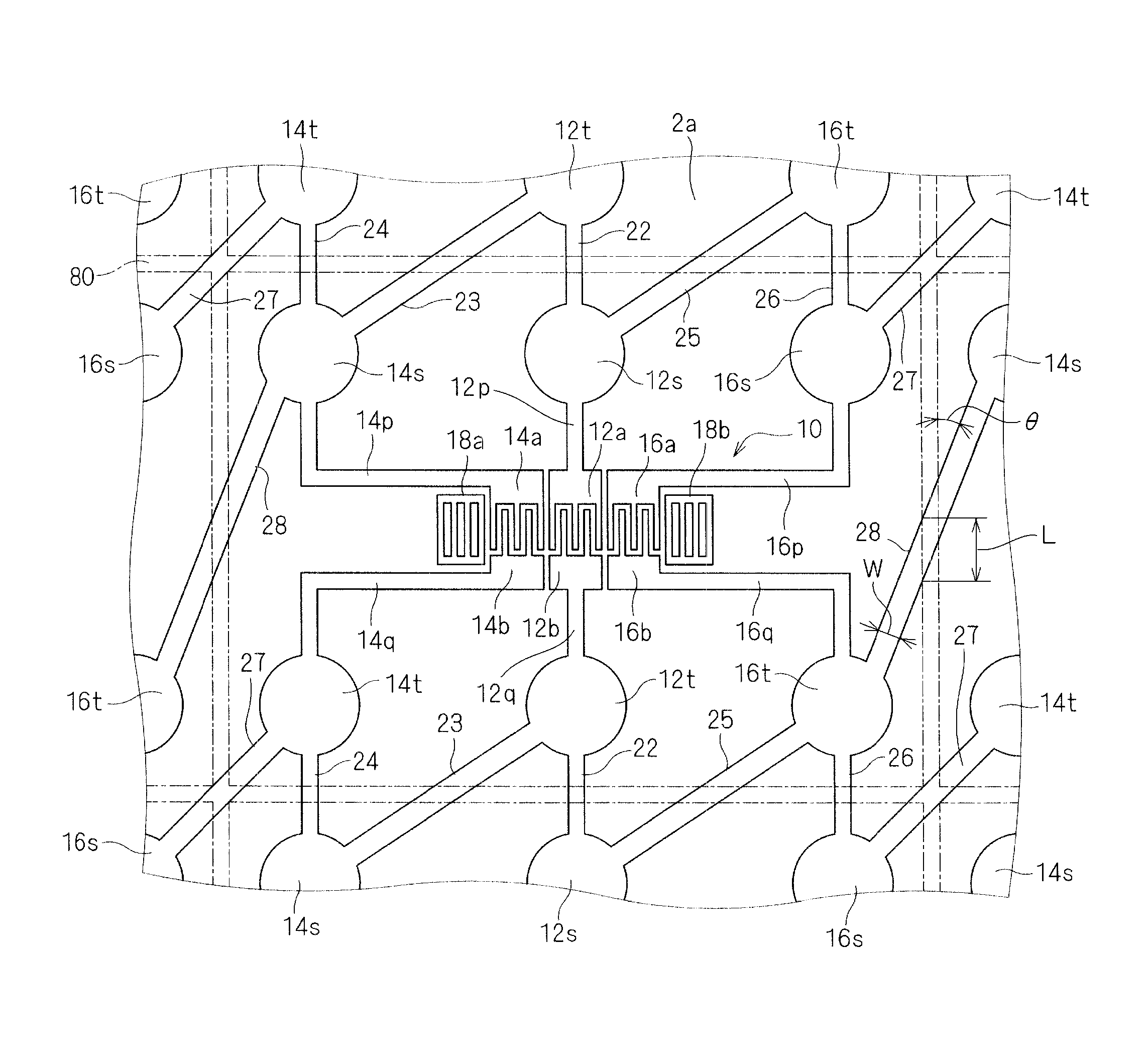

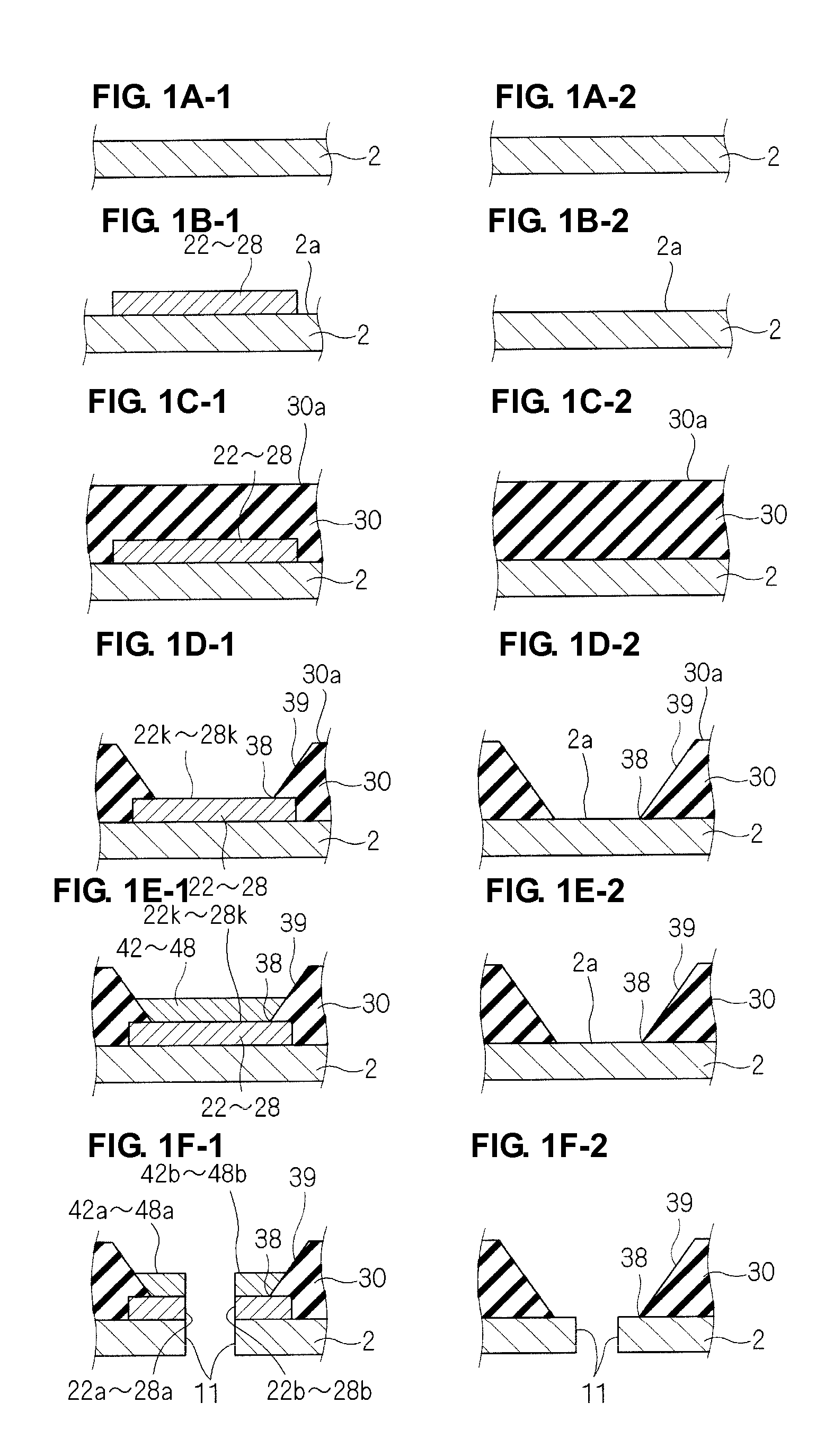

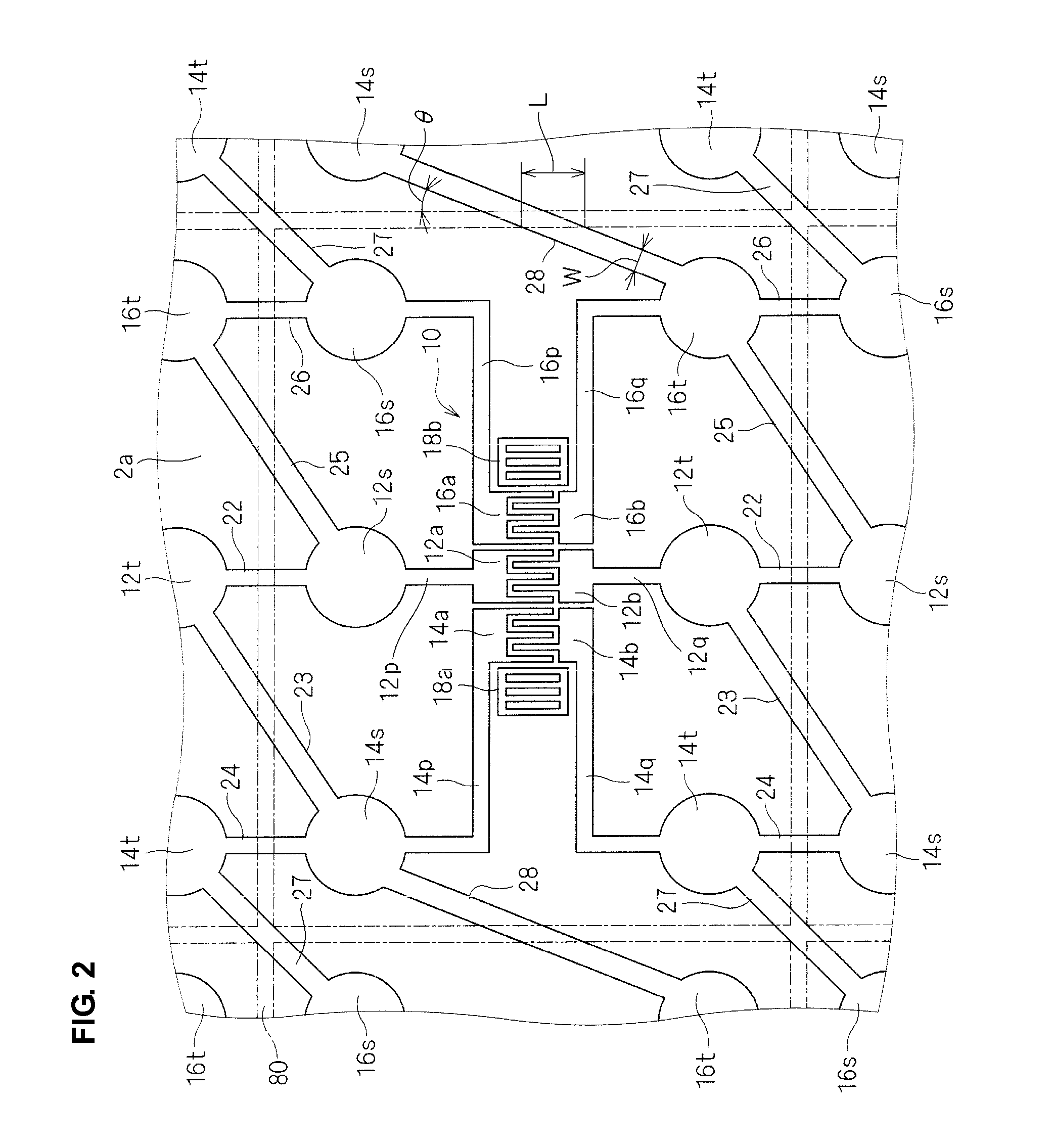

Electronic component and method for manufacturing electronic component

ActiveUS20110176264A1Constant sizeIncrease lifeImpedence networksSolid-state devicesEngineeringElectronic component

An electronic component and method for manufacturing thereof allow efficient separation of a mother substrate into electronic components defining individual devices. The method includes forming a conductive layer including electrodes and pads for a plurality of devices, an insulating layer that partially covers the conductive layer and that includes pad openings surrounding the pads and exposing at least central portions of the pads, and power supply lines that connect the pads of neighboring ones of the devices in the mother substrate. Power is applied to the power supply lines, and electrolytic plating is performed. Thus, plating layers are formed in the pad openings. Subsequently, external terminals are formed on the plating layers. By cutting the mother substrate, the mother substrate is separated into individual components defining electronic devices. Divided surfaces of the plurality of power supply lines are formed on each of the components so as to be separated from one another.

Owner:MURATA MFG CO LTD

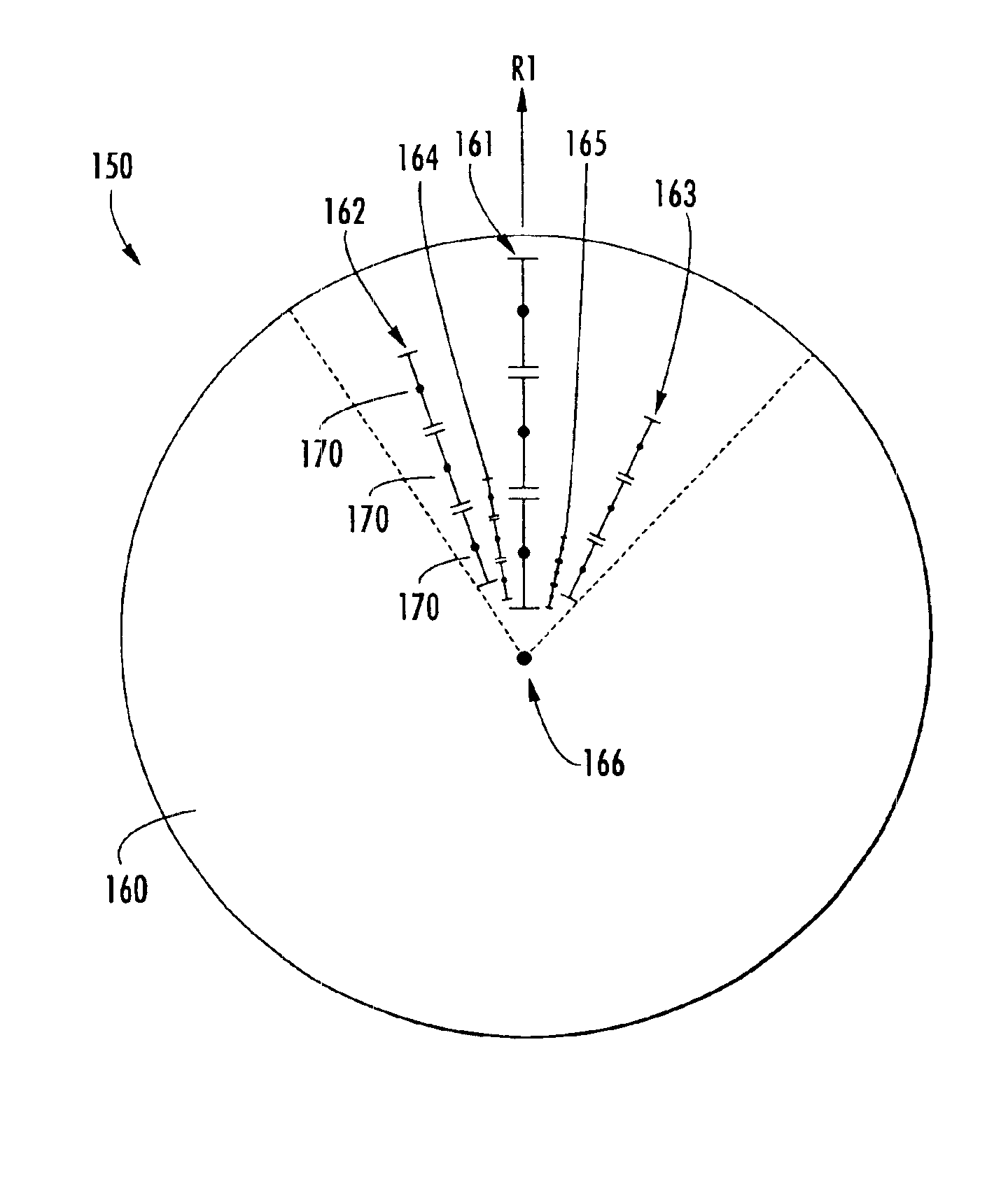

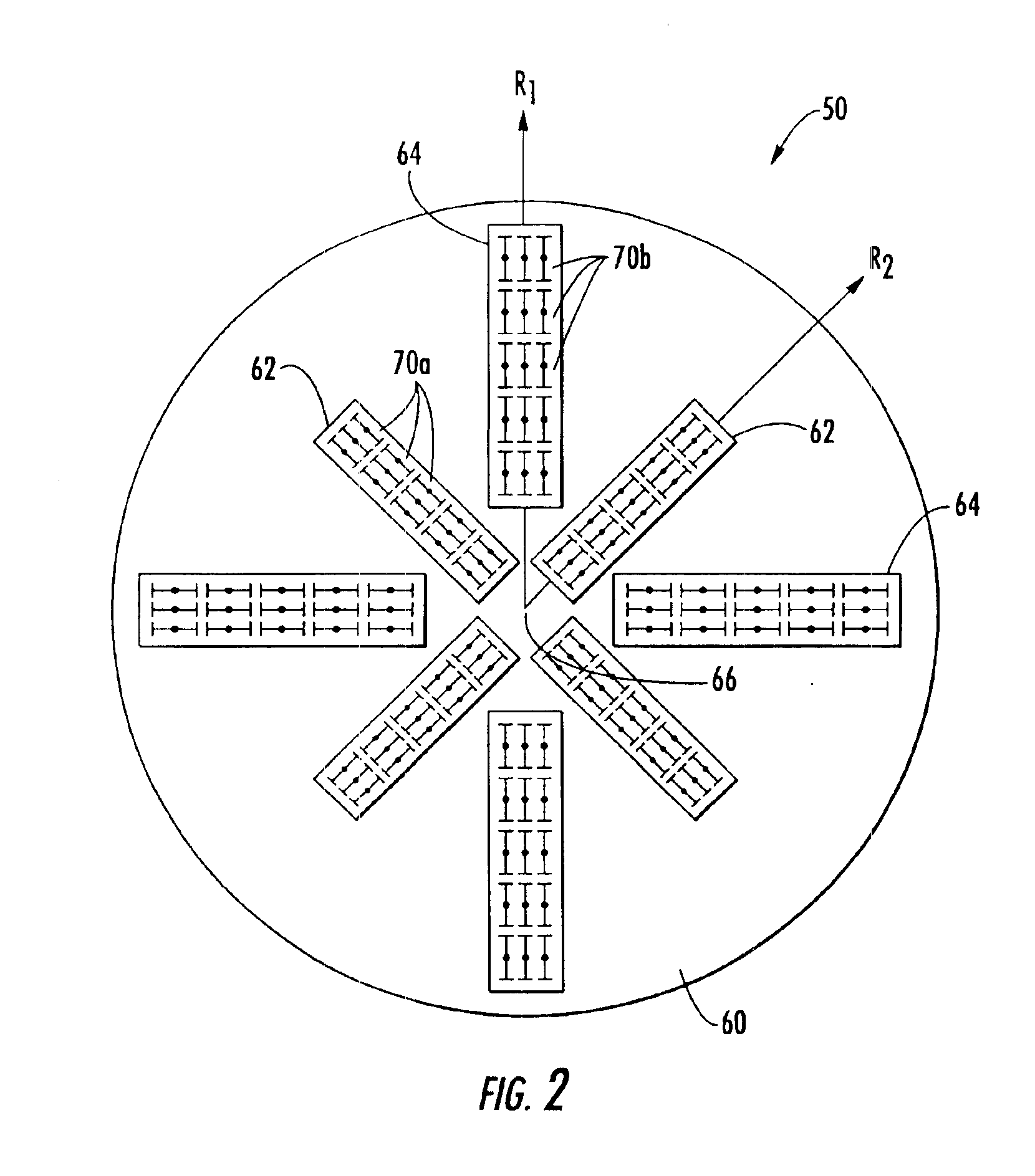

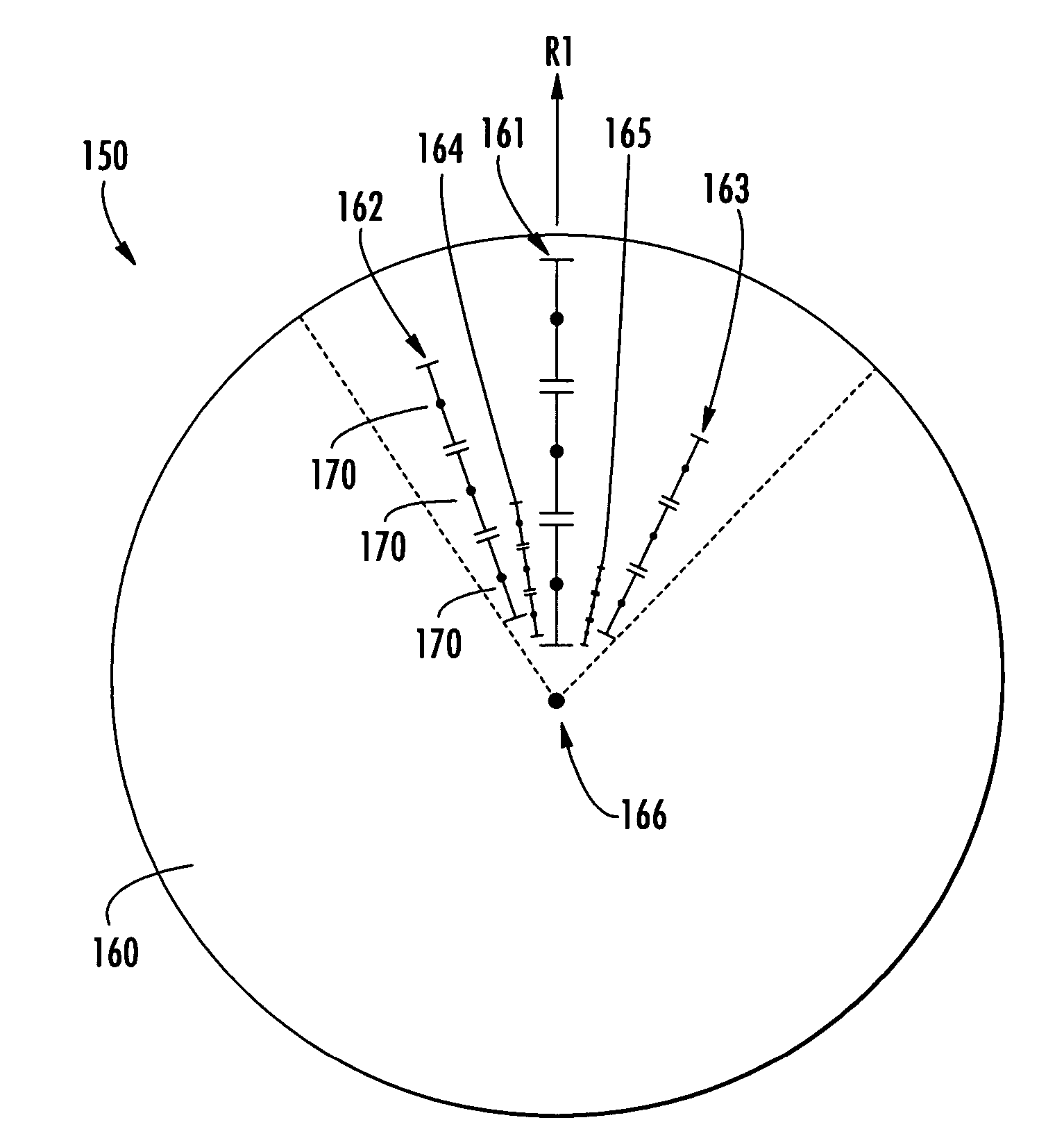

Multiband radially distributed graded phased array antenna and associated methods

ActiveUS20050099356A1Improve efficiencyConstant beamwidth and pattern controlSimultaneous aerial operationsRadiating elements structural formsGround planeDipole antenna

A phased array antenna includes a substrate, and dipole element arrays extending outwardly from an imaginary center point on the substrate. Each dipole element array includes dipole antenna elements arranged in an end-to-end relation and has different dipole sizes for dipole antenna elements in a direction extending outwardly from the imaginary center point. The different spacing between the ground plane and the dipole element arrays increases from the imaginary center point towards an edge of the substrate.

Owner:HARRIS CORP

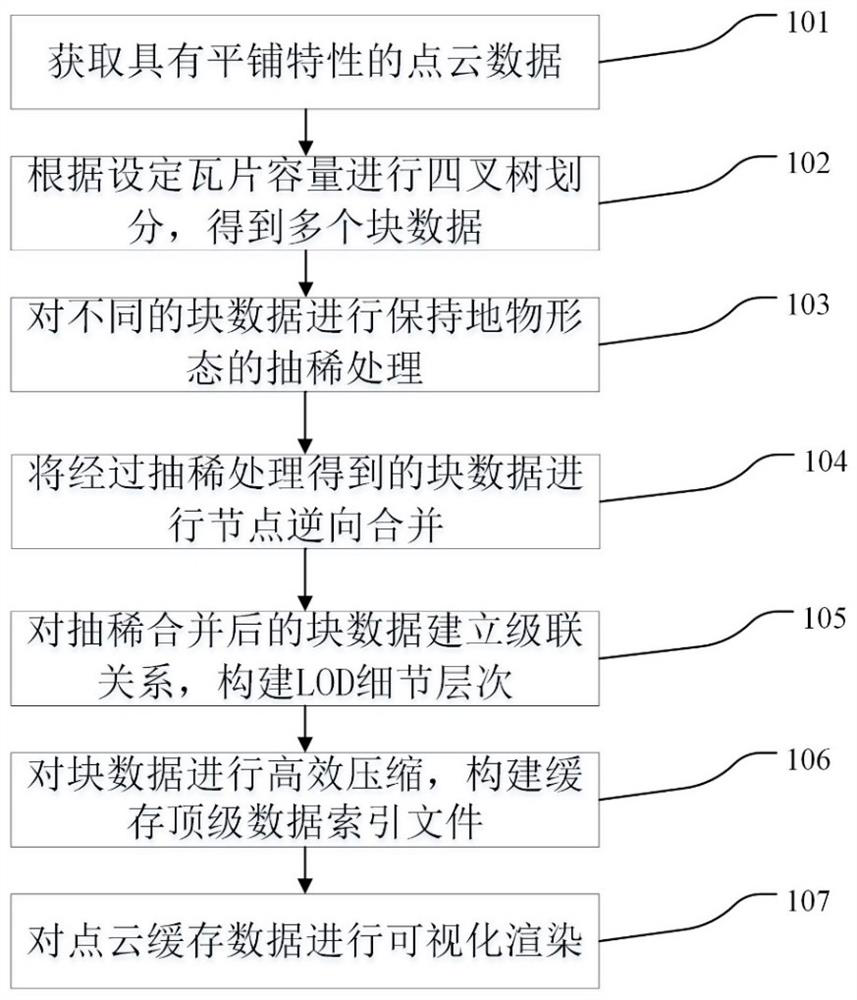

Massive point cloud data processing and visualization method and system

PendingCN113781631AImprove display efficiencyImprove the display effectStill image data browsing/visualisationSpecial data processing applicationsComputational sciencePoint cloud

The invention relates to the technical field of point cloud data processing, in particular to a massive point cloud data processing and visualization method and system. The method are characterized by comprising the following steps: S1, carrying out data acquisition: acquiring a point cloud data file with a tiling characteristic; S2, carrying out data partitioning: performing quadtree partitioning on the point cloud data according to set tile capacity to obtain a plurality of pieces of block data; S3, carrying out data thinning: carrying out thinning processing of keeping a surface feature form on the divided different blocks of data; S4, carrying out node combination: carrying out node reverse combination on the block data obtained through thinning processing; S5, establishing a cascade relationship for the thinned and merged block data, and constructing an LOD detail level model; S6, constructing an index file: efficiently compressing the block data, and constructing a cache top-level data index file; and S7, carrying out visual rendering. The problems of low loading speed, long time consumption, insufficient memory and the like of the massive point cloud data are solved, and the display efficiency and the display effect are improved.

Owner:深圳市中地软件工程有限公司

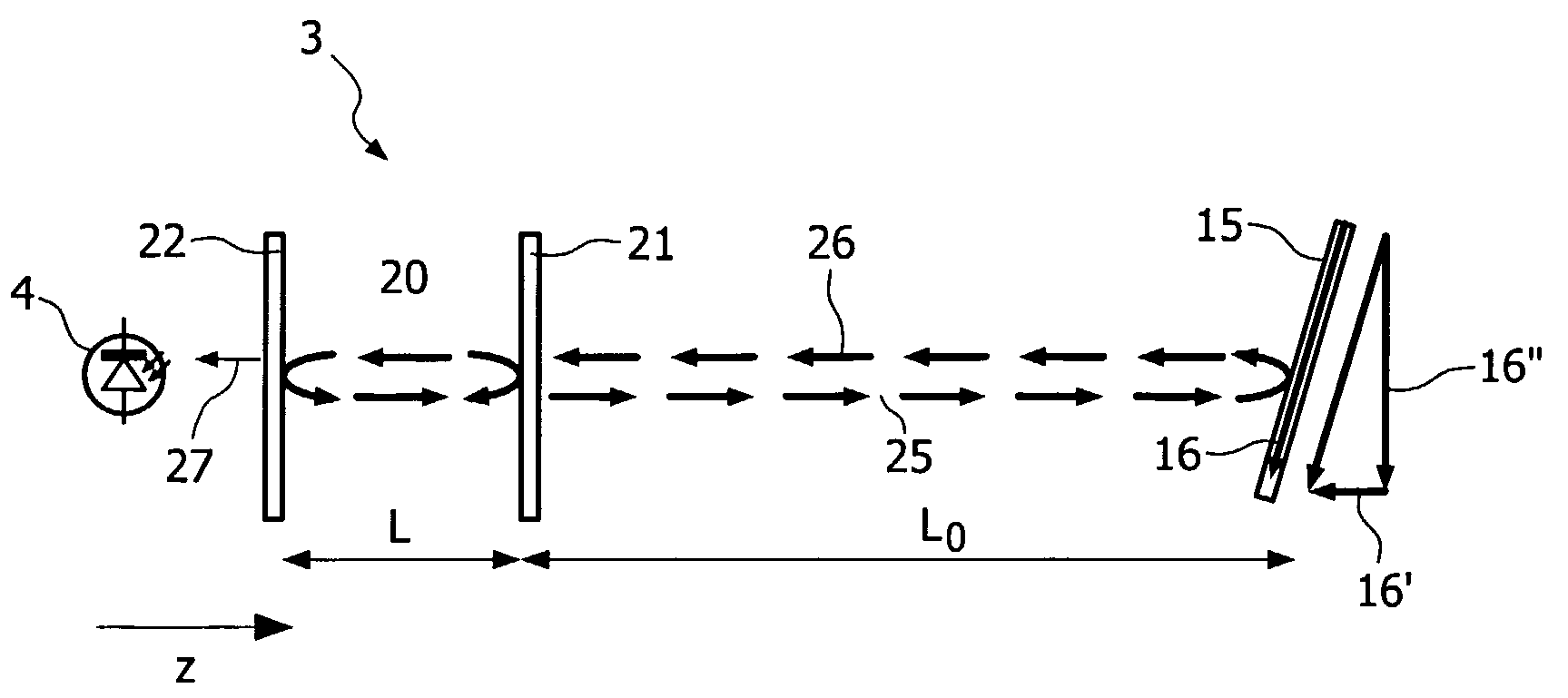

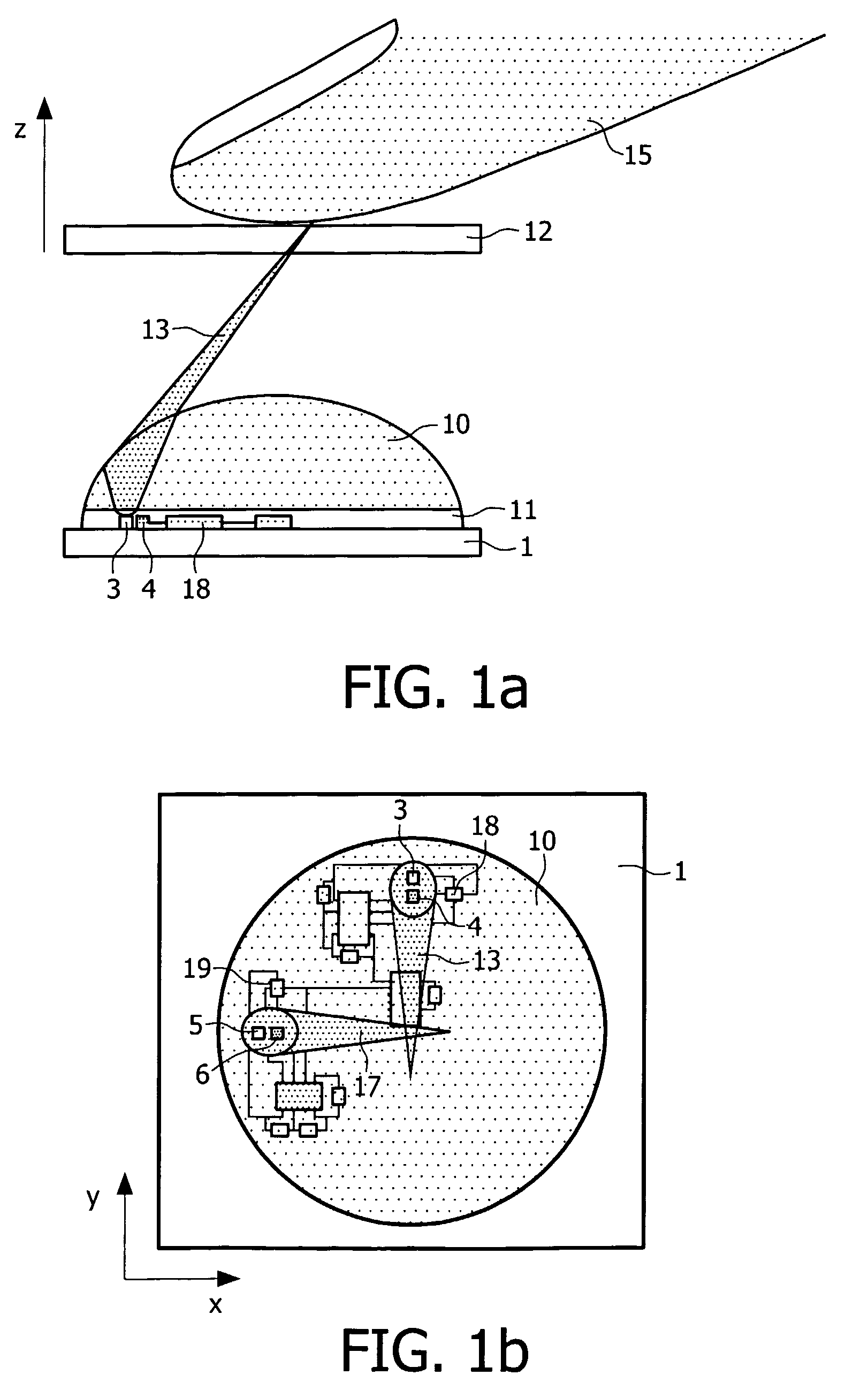

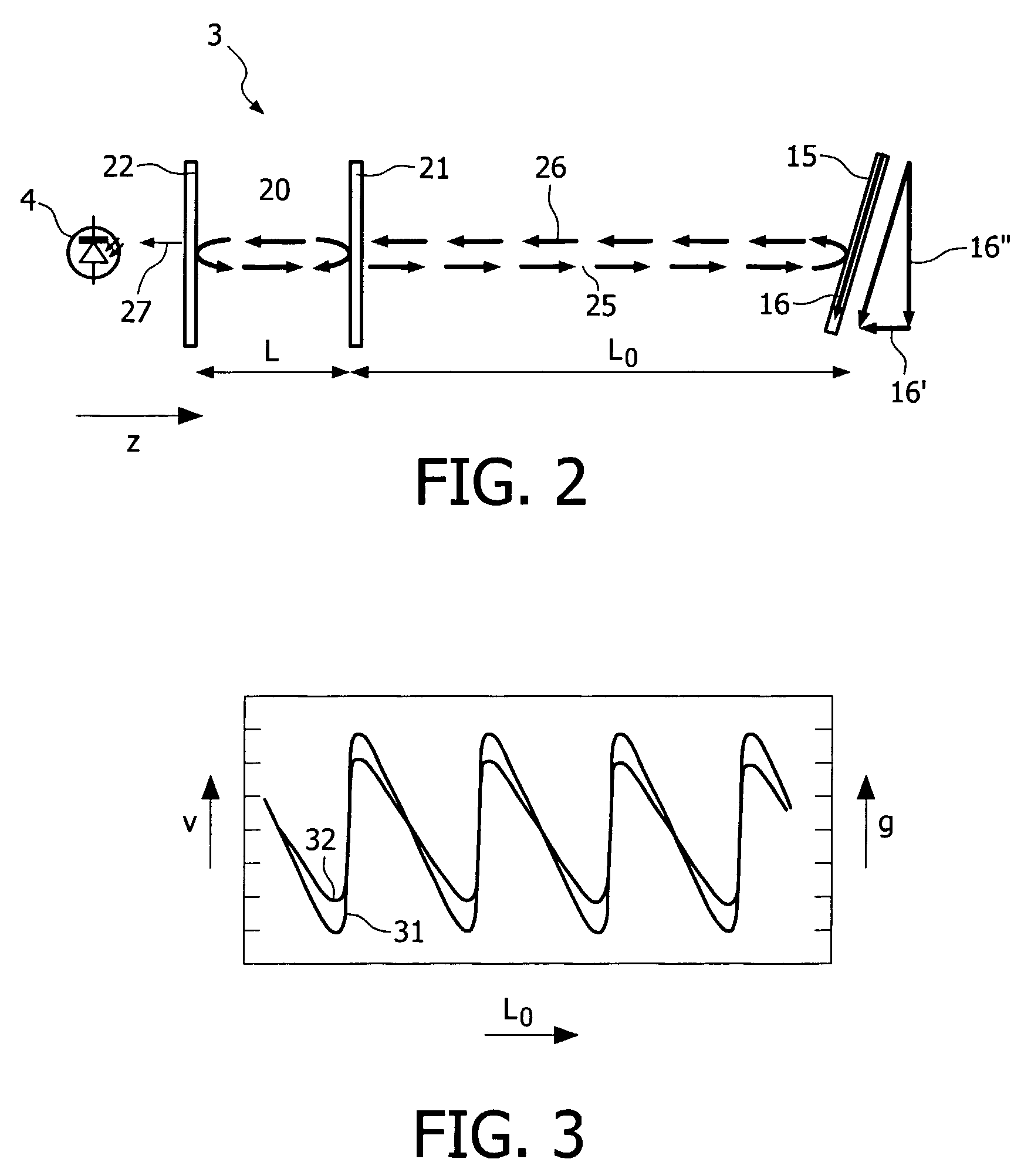

Laser measurement apparatus using self-mixing effect

ActiveUS7439484B2Sufficient performanceLittle effectInput/output for user-computer interactionPhotometry using reference valueMeasurement deviceLight beam

In an optical input device based on movement of an object (15) and the device relative to each other and which comprising at least one optical sensor unit including a laser (3) having a laser cavity for generating a measuring beam (13), converging means (50) for converging the measuring beam in an action plane and for converging measuring beam radiation reflected by the object in the laser cavity to generate a self-mixing effect in the laser and measuring means for measuring the result of the self-mixing effect, which effect is determined by said movement, the converging means (50) is adapted to provide a self-mixing effect that is smaller than a possible maximum but larger than a detection threshold for an extended range of distances (ΔZ) between the object and the device. This allows obtaining the required self-mixing effect in an extended range of distances between the object and the device.

Owner:TRUMPF PHOTONIC COMPONENTS GMBH

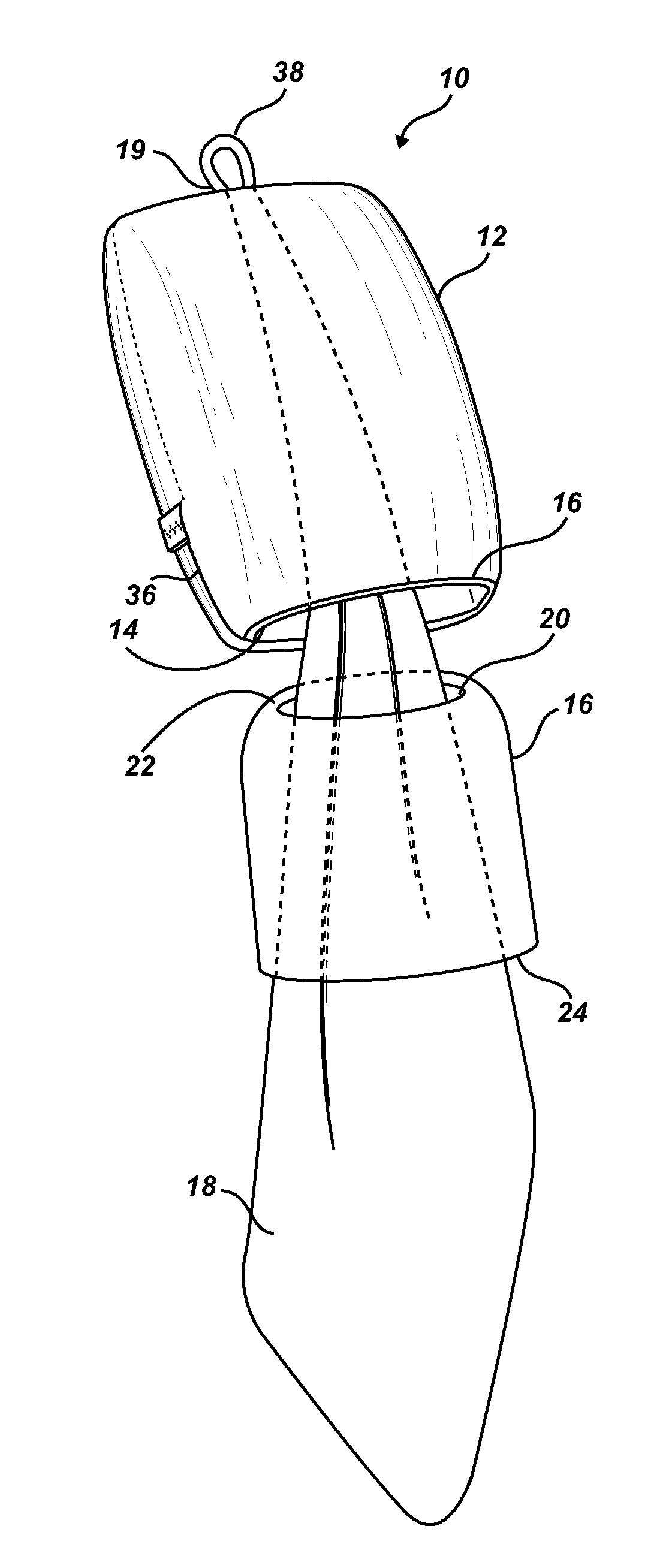

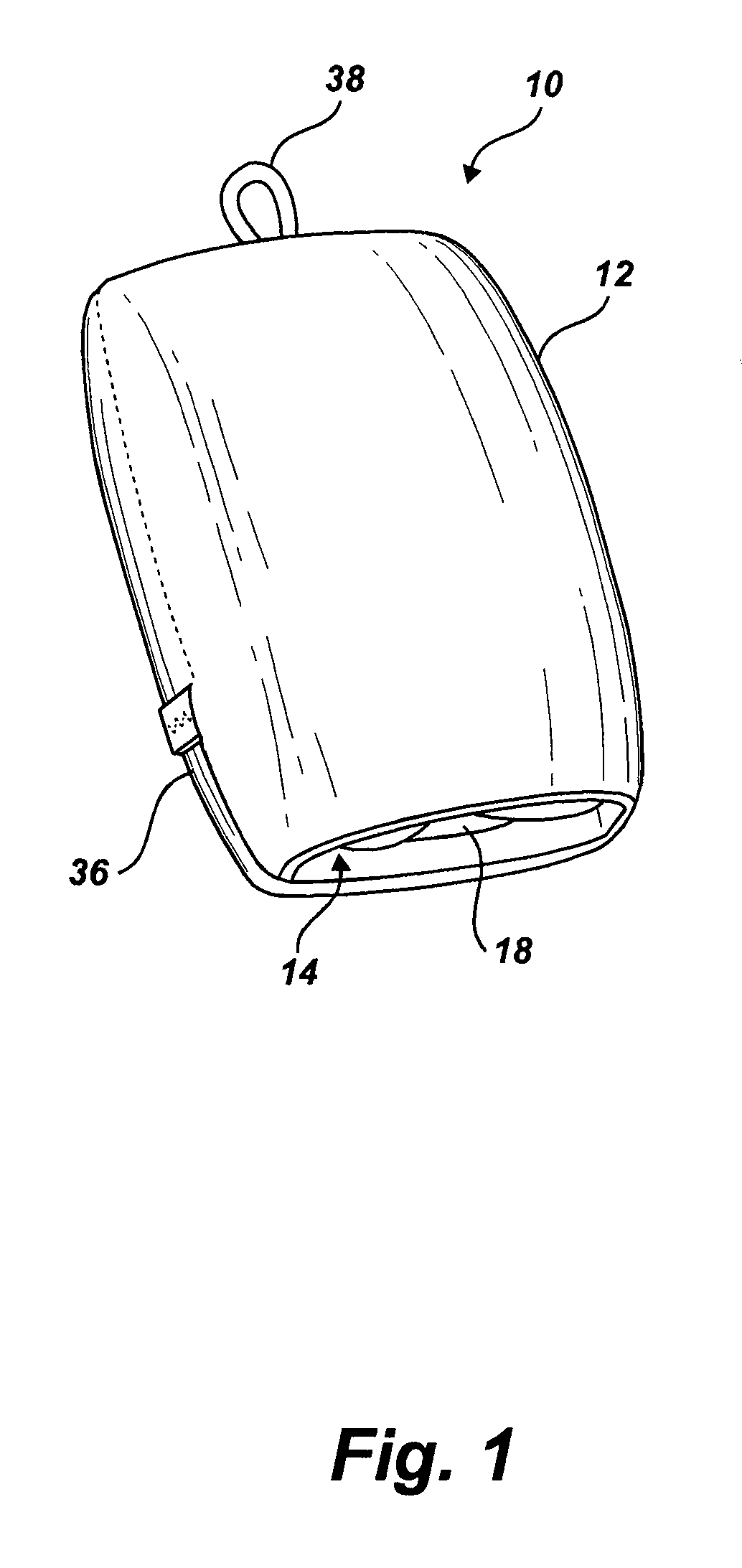

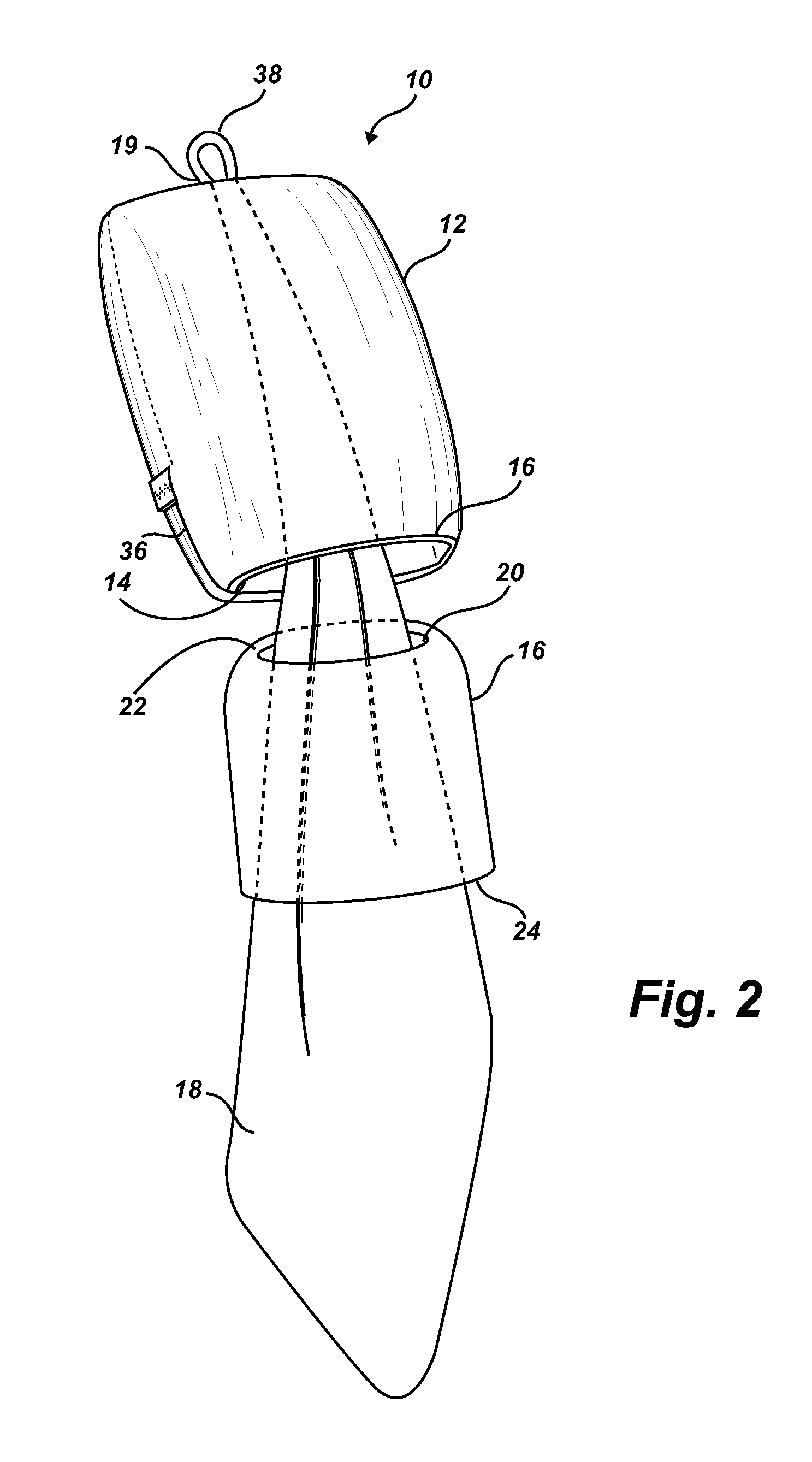

Cloth accessory with removable insert

InactiveUS8060969B2Constant shapeConstant sizeSpectales/gogglesBoard cleaning devicesEngineeringMechanical engineering

A cloth accessory includes a cover member of a soft and flexible material, which forms an enclosure having an opening therein. An insert is configured to fit within the cover member and hold the opening of the cover member in an open position with a substantially constant size and shape. A cloth is coupled to the cover member and has a first and second configuration. The cloth is retracted substantially into the cover member for storage in the first configuration. In the second configuration the cloth is extended through the insert and the opening of the cover member, and substantially out of the cover member for use while remaining coupled to the cover member. An associated method for cleaning or treating a device includes providing a cloth accessory, orienting the cloth into the second configuration and contacting a device with the cloth to clean or treat the device.

Owner:ALPINE INNOVATIONS

Multiband radially distributed phased array antenna with a sloping ground plane and associated methods

InactiveUS20050099354A1Improve efficiencyConstant beamwidthSimultaneous aerial operationsRadiating elements structural formsGround planeDipole antenna

A multiband phased array antenna includes a substrate, and dipole element arrays extending outwardly from an imaginary center point on the substrate. Each dipole element array includes dipole antenna elements arranged in an end-to-end relation and having a dipole size different than a dipole size of dipole antenna elements of at least one other dipole element array. A ground plane is adjacent the dipole element arrays and has a different spacing therefrom in an outward direction from the imaginary center point. The different spacing between the ground plane and the dipole element arrays increases from the imaginary center point towards an edge of the substrate.

Owner:NORTH SOUTH HLDG

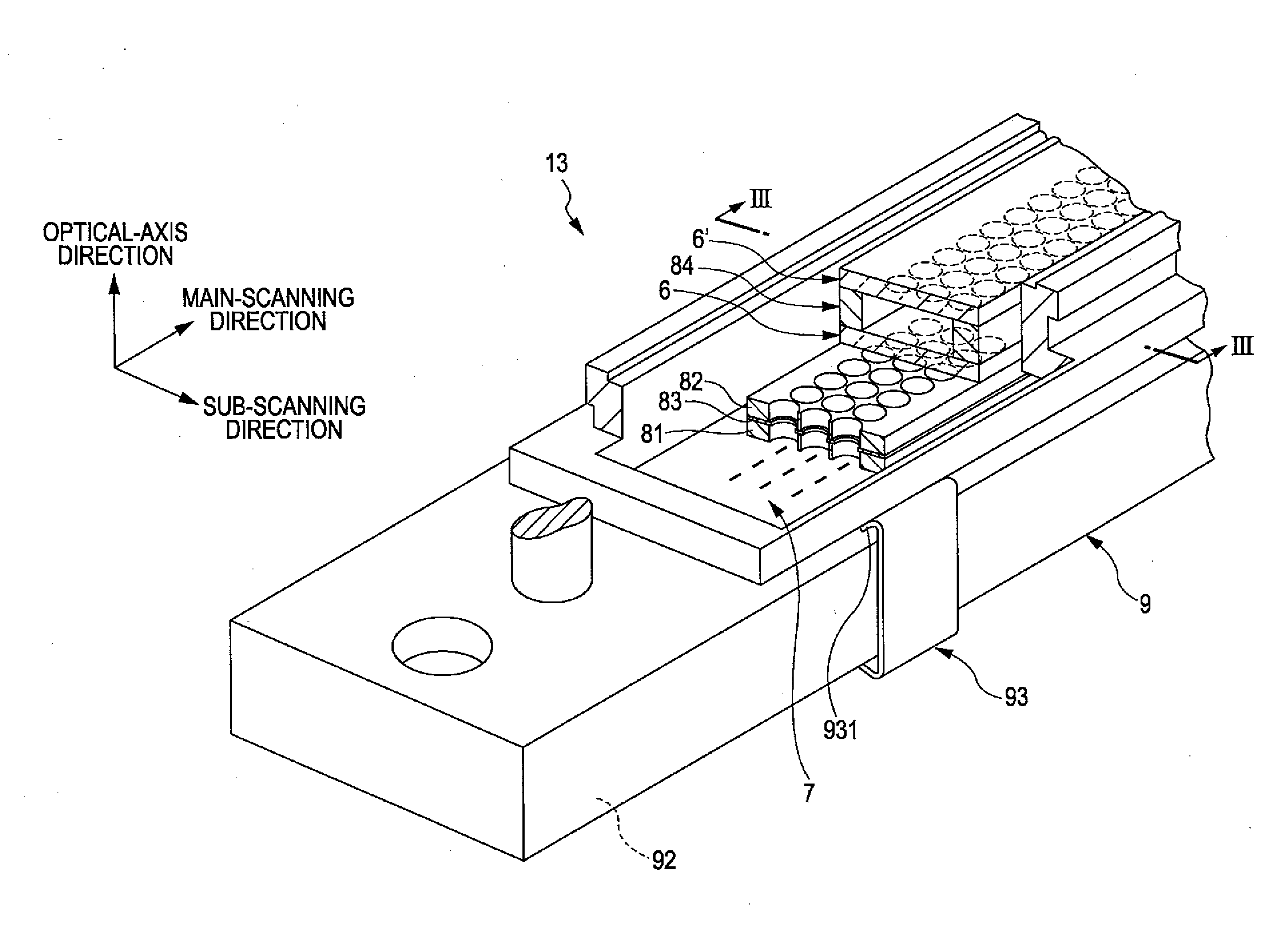

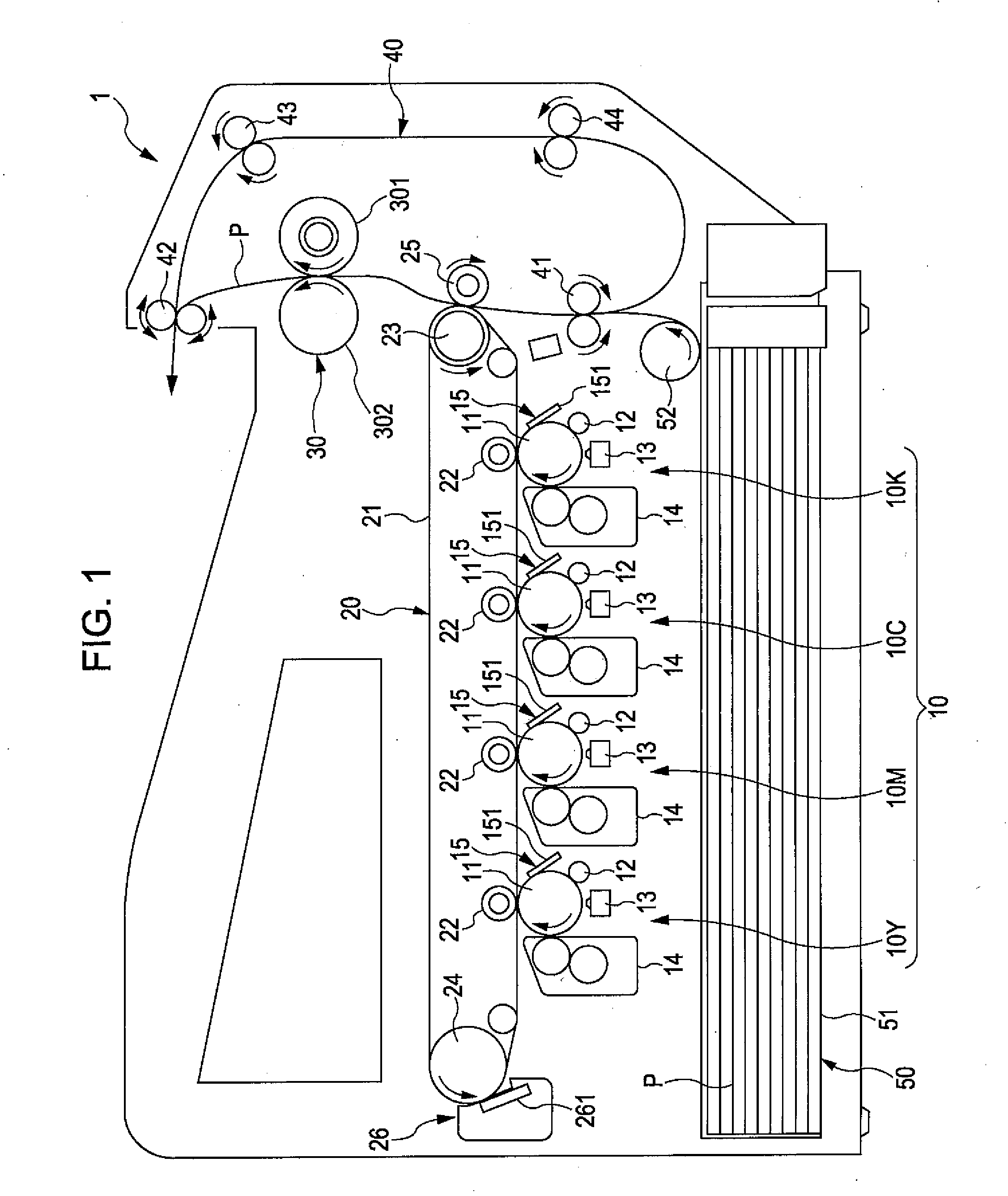

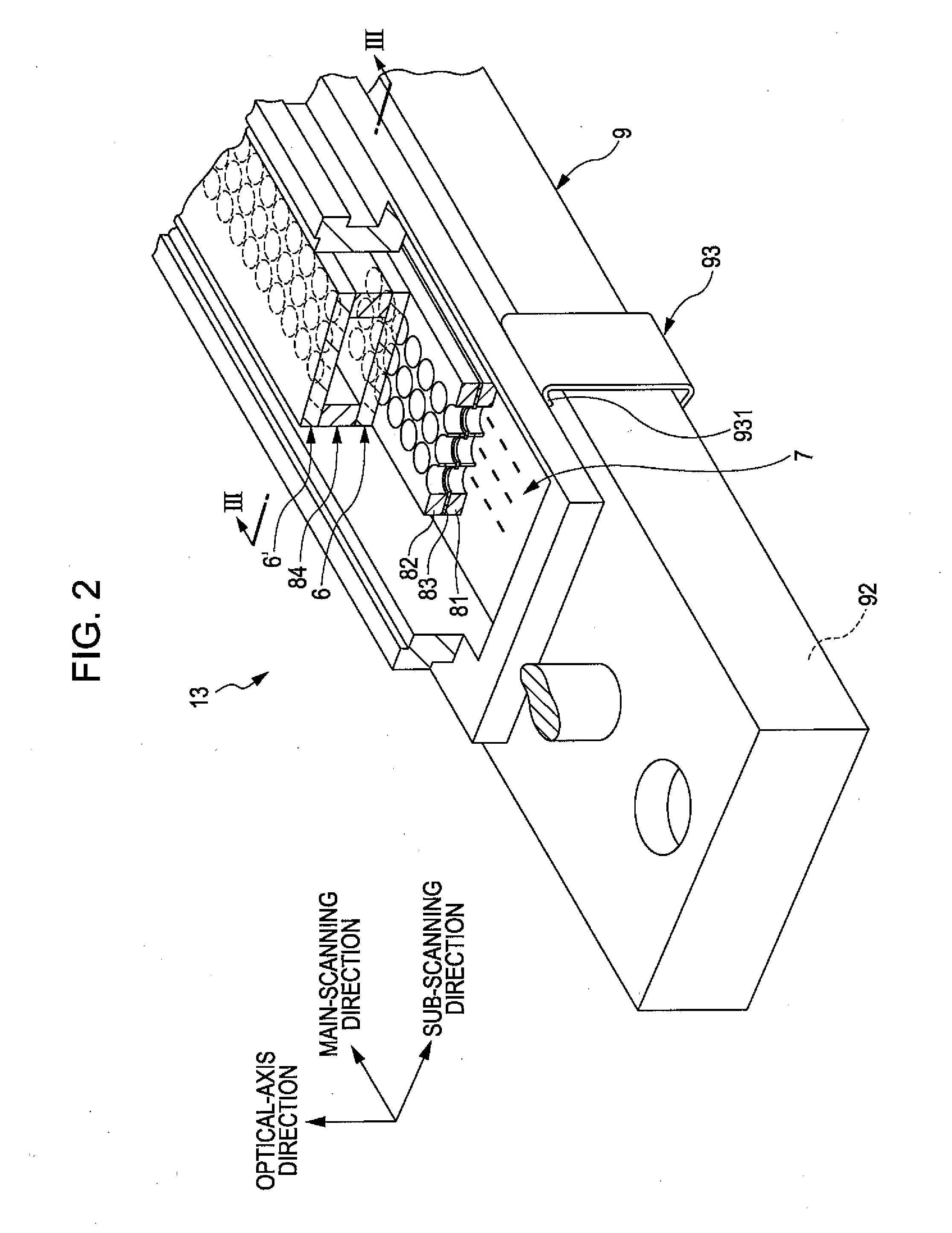

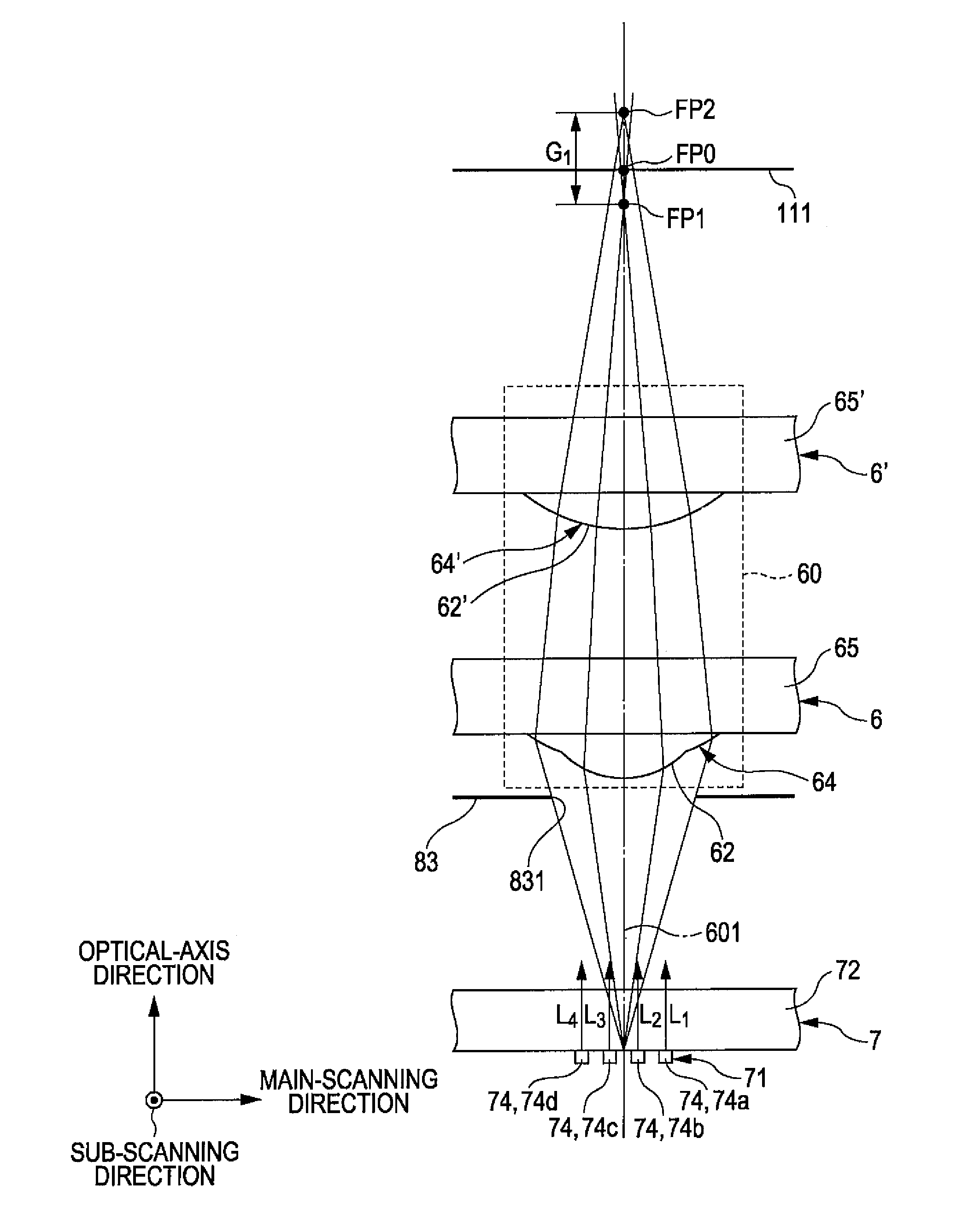

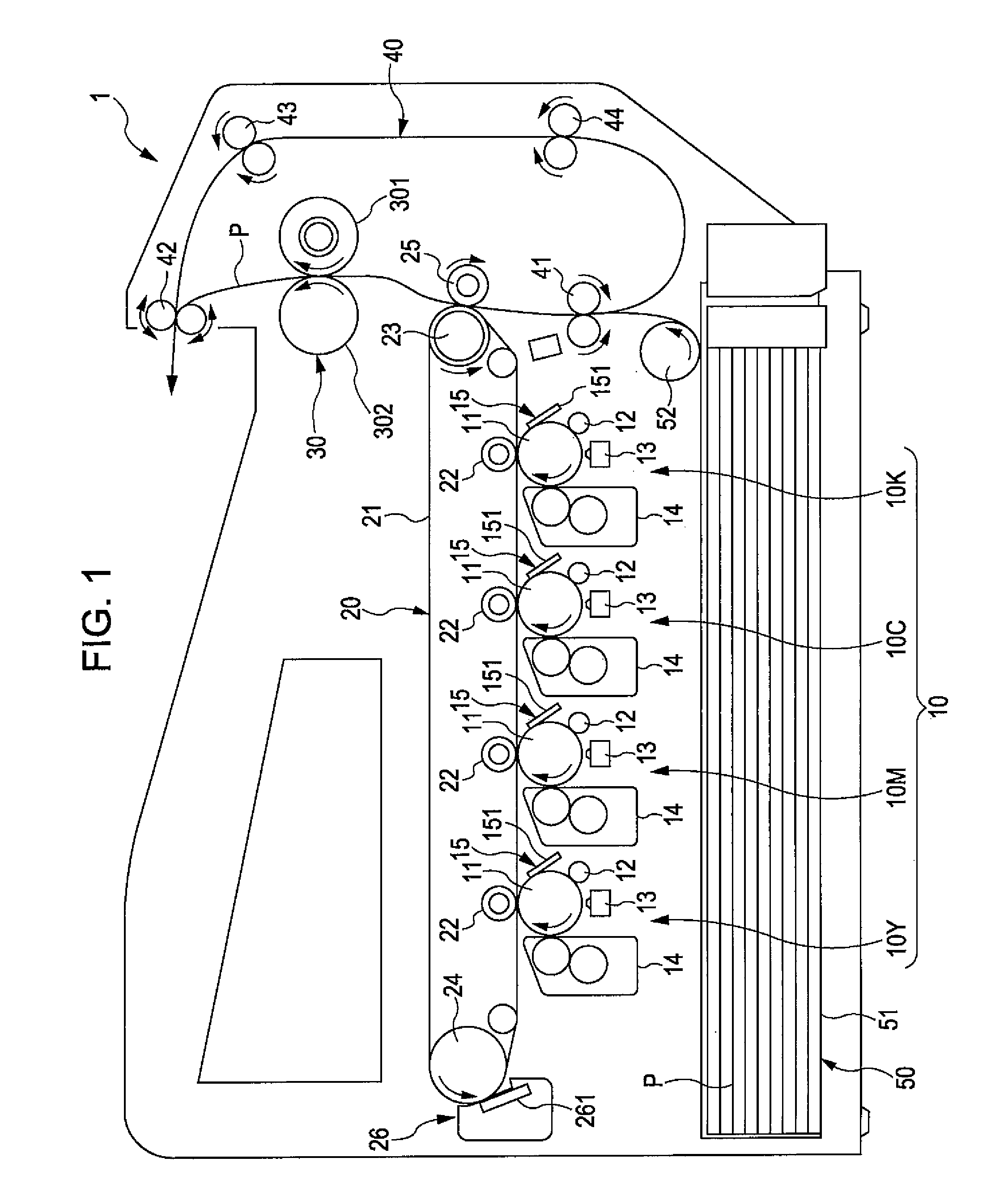

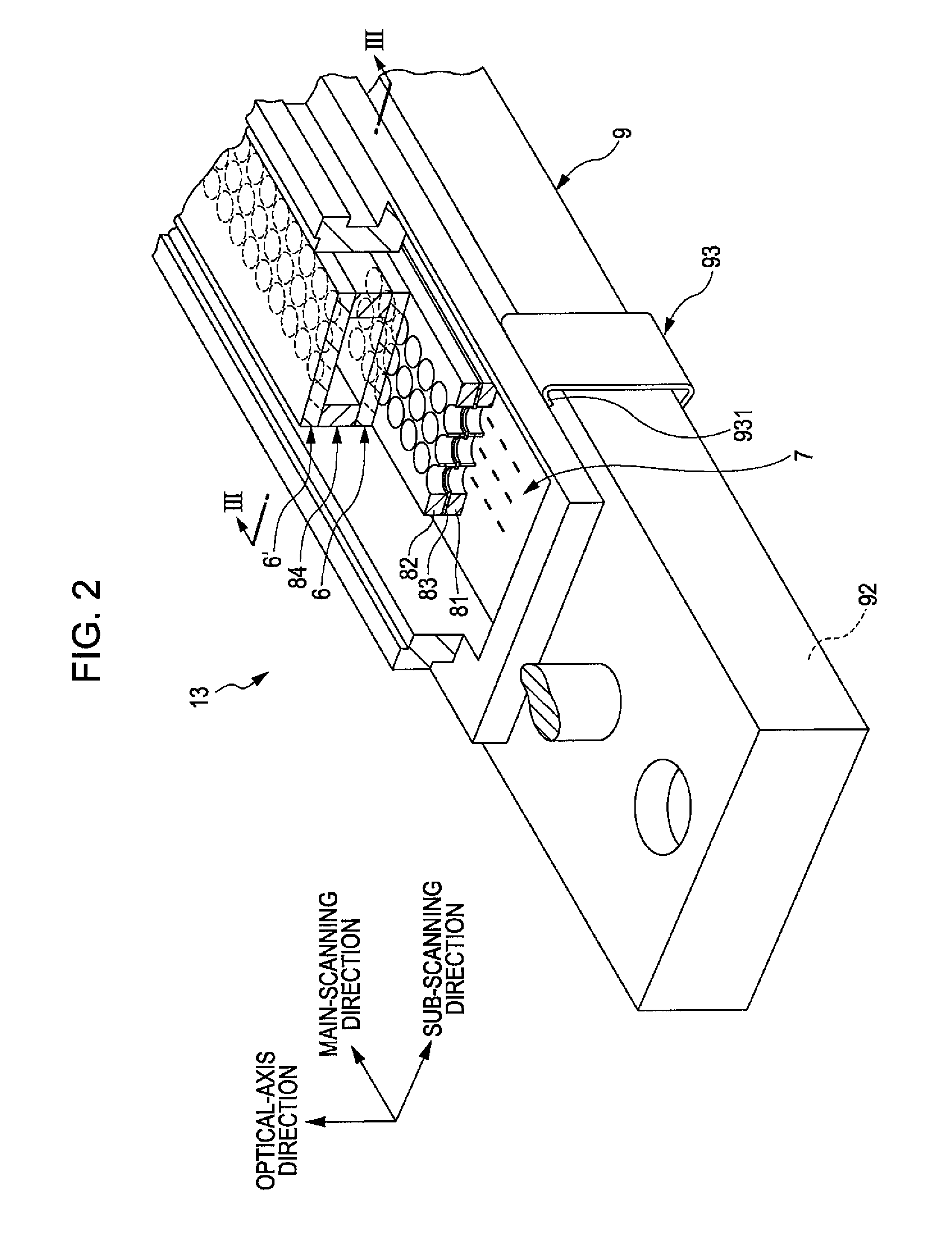

Line Head and Image Forming Apparatus

InactiveUS20100183338A1Prevent variation of spot sizeReliably exhibitElectrographic process apparatusPrintingLatent imageImage formation

An image forming apparatus includes a latent image carrier on which a latent image is formed; and a line head. The line head includes light-emitting elements arranged in a first direction; an aperture diaphragm; and an optical system that images light emitted from the light-emitting elements on a latent image carrier. The aperture diaphragm and the optical system are arranged in a second direction that is orthogonal to or substantially orthogonal to the first direction; and among the lenses included in the optical system, a lens located at the position closest to the aperture diaphragm is a multifocal lens.

Owner:SEIKO EPSON CORP

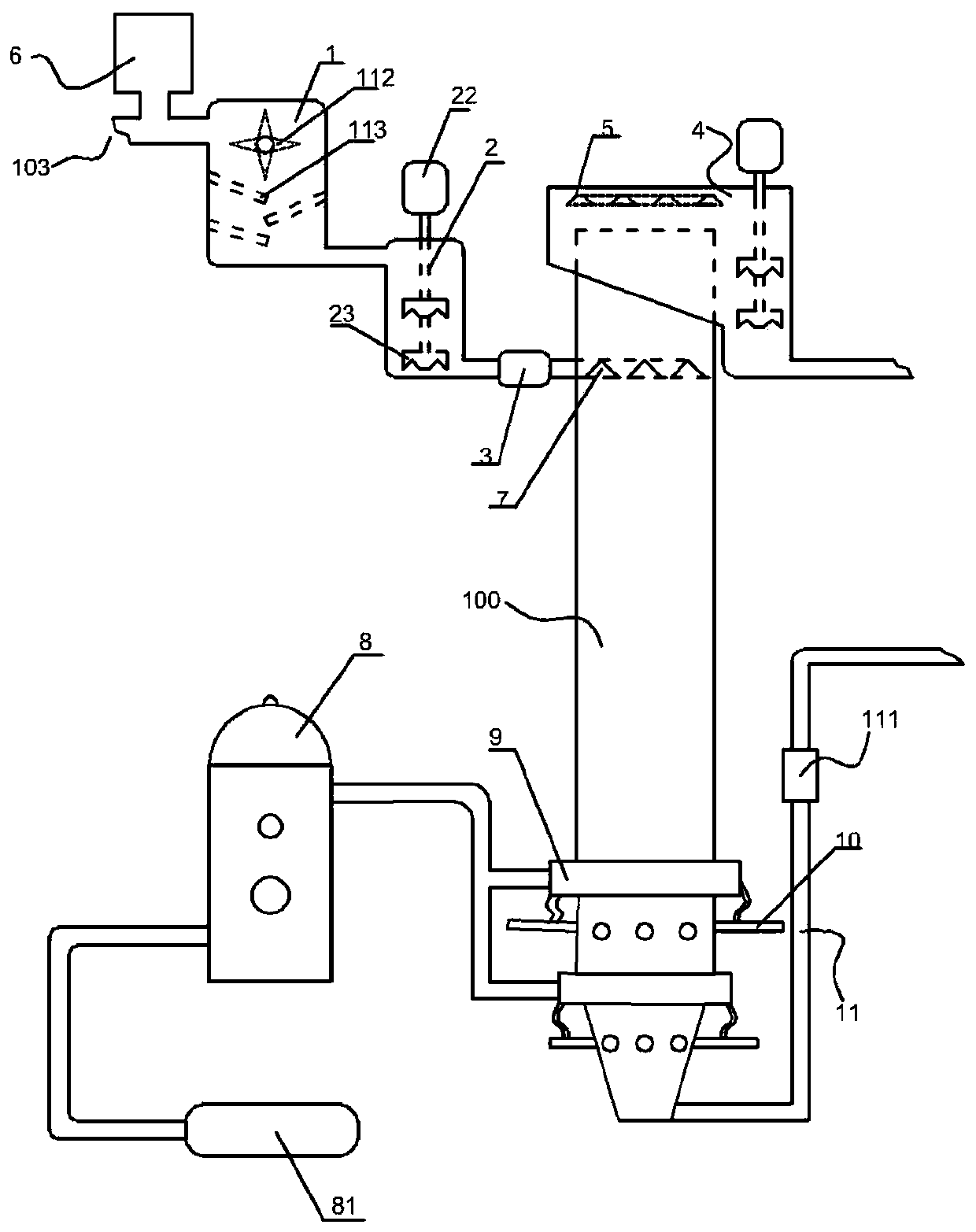

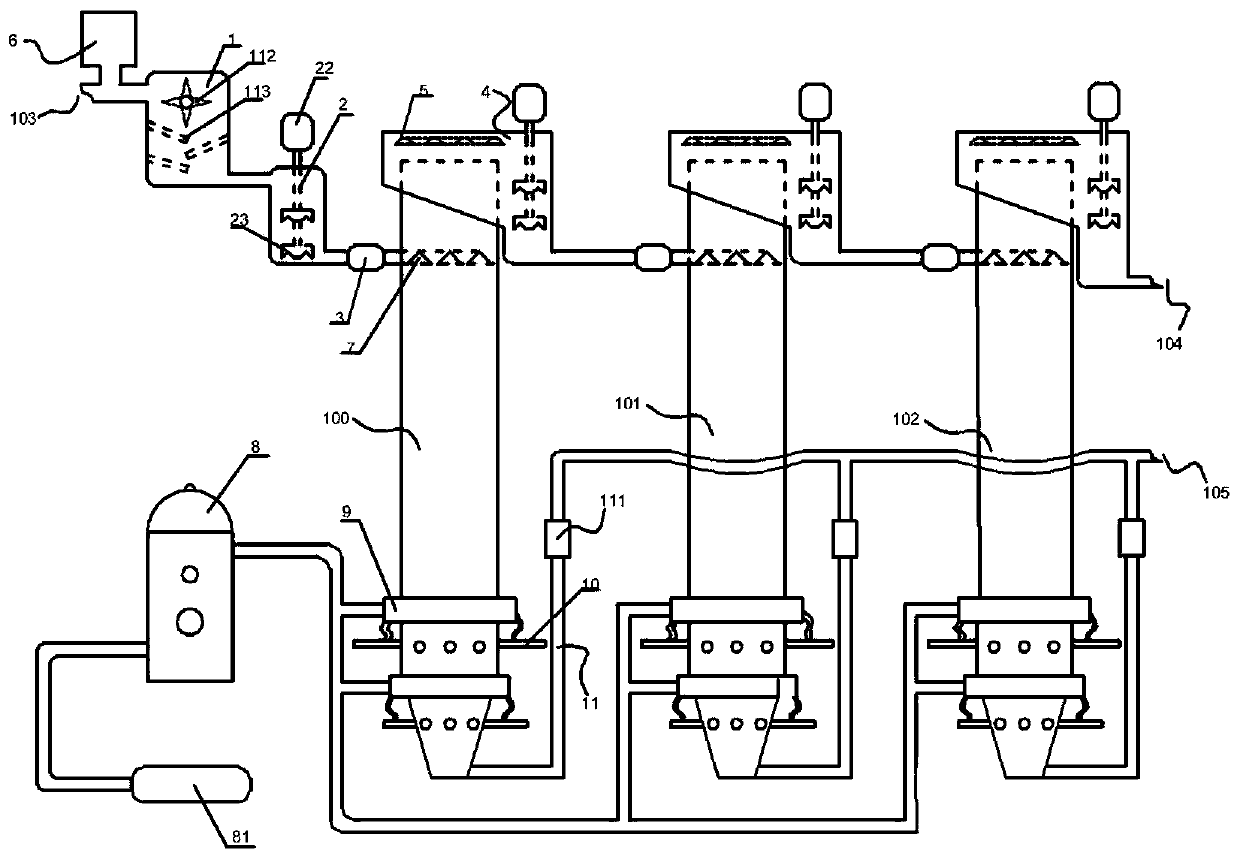

Inflatable nano microvesicle high-ash coal slime flotation equipment and flotation method thereof

The invention provides inflatable nano microvesicle high-ash coal slime flotation equipment. The inflatable nano microvesicle high-ash coal slime flotation equipment comprises a main flotation columnand two secondary flotation columns, the main flotation column comprises an agent box, an ore pulp preprocessor, a high-speed disperser and a delivery pump which are mounted outside the main flotationcolumn, and an ore pulp multi-spot distributor mounted on the main flotation column, a foam collecting device, an atomizing spraying device, a bubble generator surrounding the outer wall of the lowerportion of the main flotation column, a conveying air pipe, an air storage tank and an air compressor are further included. The main flotation column and the secondary flotation columns are adopted for sequentially selecting concentrate, middlings and tailings are removed, and clean coal products with the ash content of 11% or below are finally obtained.

Owner:西安煤科动力科技有限公司

Line head and image forming apparatus

InactiveUS8194112B2High quality imagingPrevent variation of spot sizeElectrographic process apparatusPrintingLatent imageImage formation

An image forming apparatus includes a latent image carrier on which a latent image is formed; and a line head. The line head includes light-emitting elements arranged in a first direction; an aperture diaphragm; and an optical system that images light emitted from the light-emitting elements on a latent image carrier. The aperture diaphragm and the optical system are arranged in a second direction that is orthogonal to or substantially orthogonal to the first direction; and among the lenses included in the optical system, a lens located at the position closest to the aperture diaphragm is a multifocal lens.

Owner:SEIKO EPSON CORP

Multiband radially distributed graded phased array antenna and associated methods

ActiveUS6954179B2Improve efficiencyConstant beamwidth and pattern controlSimultaneous aerial operationsRadiating elements structural formsGround planeDipole antenna

A phased array antenna includes a substrate, and dipole element arrays extending outwardly from an imaginary center point on the substrate. Each dipole element array includes dipole antenna elements arranged in an end-to-end relation and has different dipole sizes for dipole antenna elements in a direction extending outwardly from the imaginary center point. The different spacing between the ground plane and the dipole element arrays increases from the imaginary center point towards an edge of the substrate.

Owner:HARRIS CORP

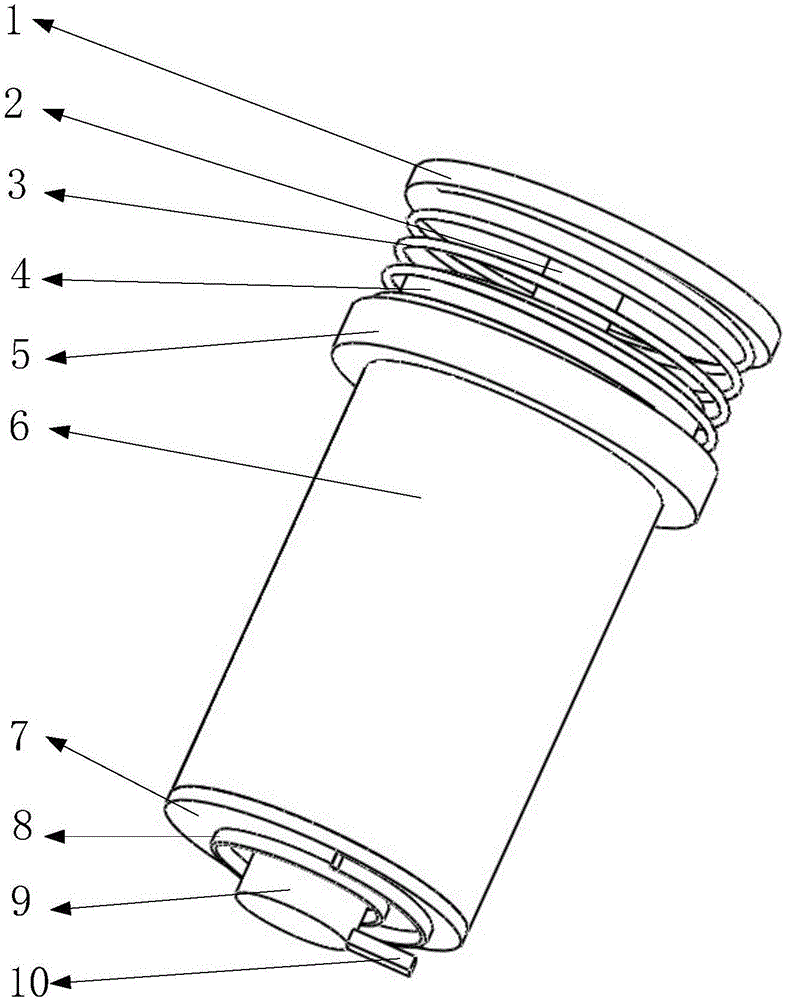

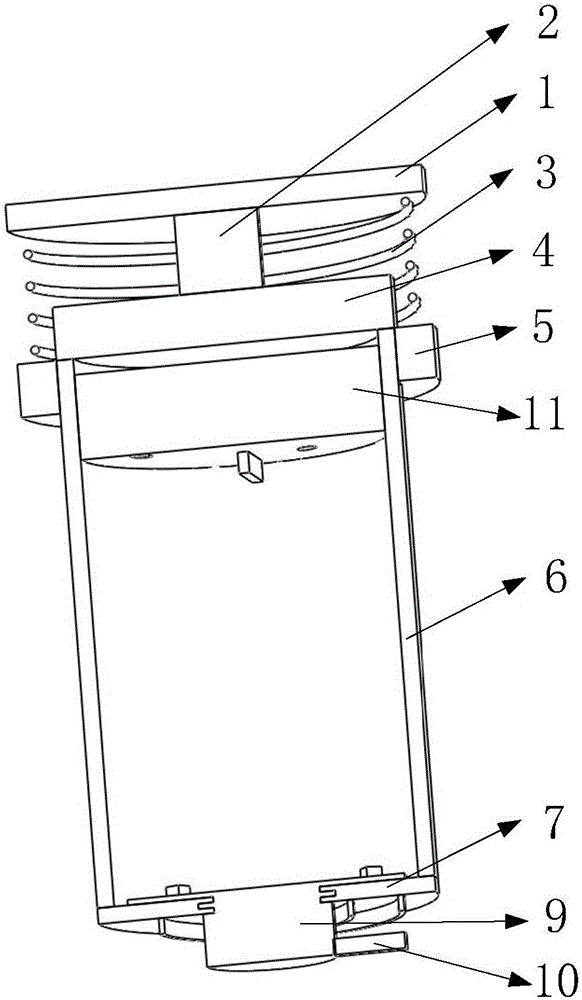

Rotary gravity type clocked trigger

ActiveCN106773608ASmooth rotationBreak critical stabilityTime interval measurement without driving mechanismEngineeringTimer

The invention belongs to the technical field of mechanical timing, and particularly relates to a rotary gravity type clocked trigger. The rotary gravity type clocked trigger comprises a shaking spring, a top cover, a shaking ring, a shell body, a bottom plate, a volute spiral spring, a triggering column and a gravity plug, wherein a fluid oil exists in the shell body, a hydraulic hole is formed in the gravity plug, and the hydraulic oil flows through the hydraulic hole of the gravity plug when the gravity plug moves from the upper part to the lower part; when the gravity plug is close to the bottom plate, a drive stirring block and a driven stirring block are contacted and collide to promote the triggering column to start rotating so as to trigger an outside mechanism. When a timer is shaken, the shaking ring is driven by the external force to swing up and down in a reciprocating manner, then the gravity plug starts to move downwards, and the timing is started. As the hydraulic oil has the effects of lubricating and isolating air from the gravity plug, the gravity plug and the shell body do not have the changes of oxidation or precision, then the timer has the effect of long service life; as no electric power takes part, the range of application is also quite extensive. The rotary gravity type clocked trigger has a better use effect.

Owner:济南市嬴磊信息科技有限公司

Methods for control of a fusion welding process by maintaining a controlled weld pool volume

ActiveUS8354608B2Easy to controlAccurate volumeTemperatue controlElectron beam welding apparatusReal-time dataEngineering

A new method of process control for fusion welding maintains a controlled weld pool size or volume, for example in some applications a substantially constant weld pool size or volume. The invention comprises a method of linking machine and process variables to the weld pool size or volume in real time, thereby enabling constant weld pool volume control. The invention further comprises a method of using thermal inverse models to rapidly process real-time data and enable models-based control of welding processes so as to implement constant weld pool volume control.

Owner:SIGMA LAB OF ARIZONA

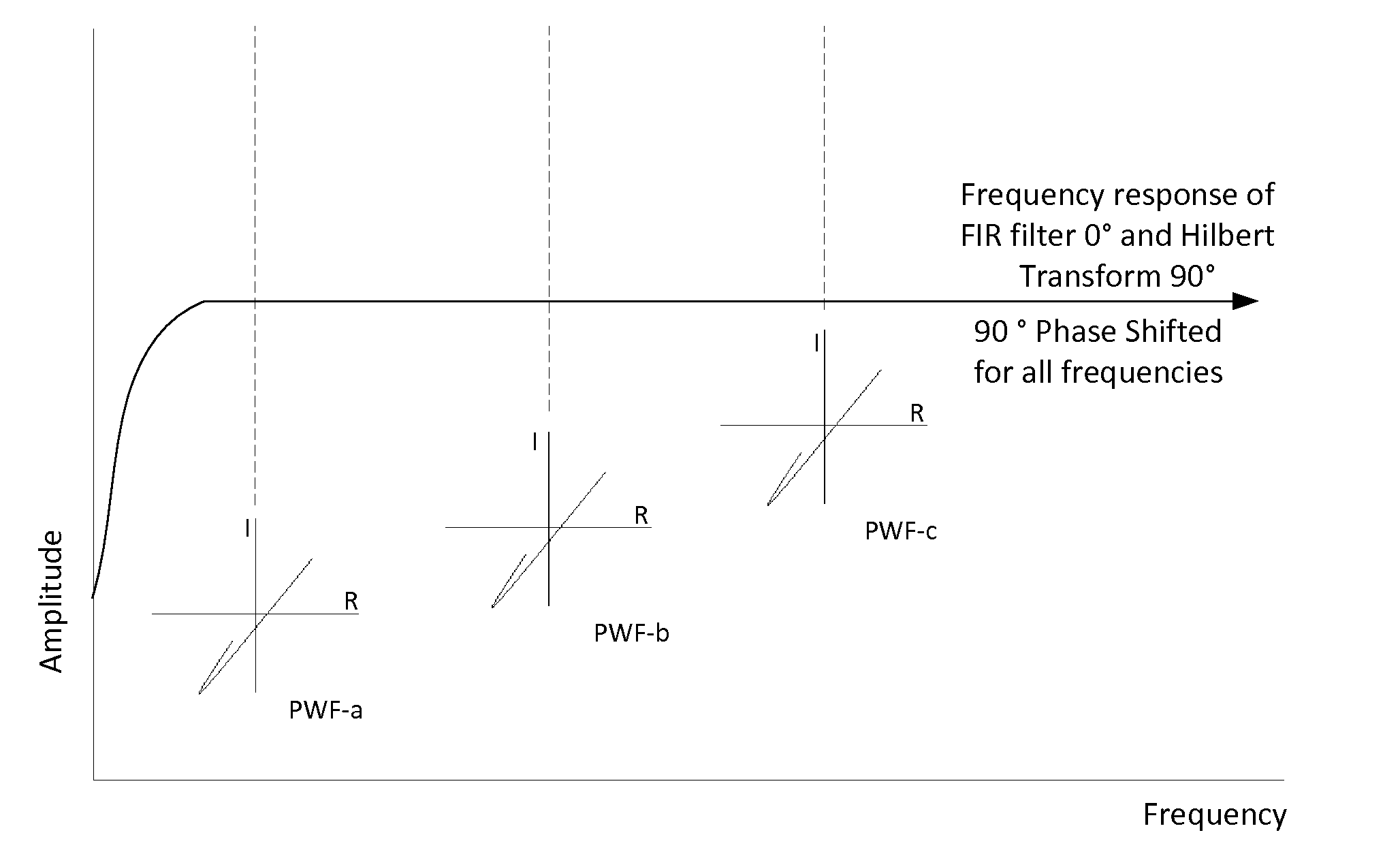

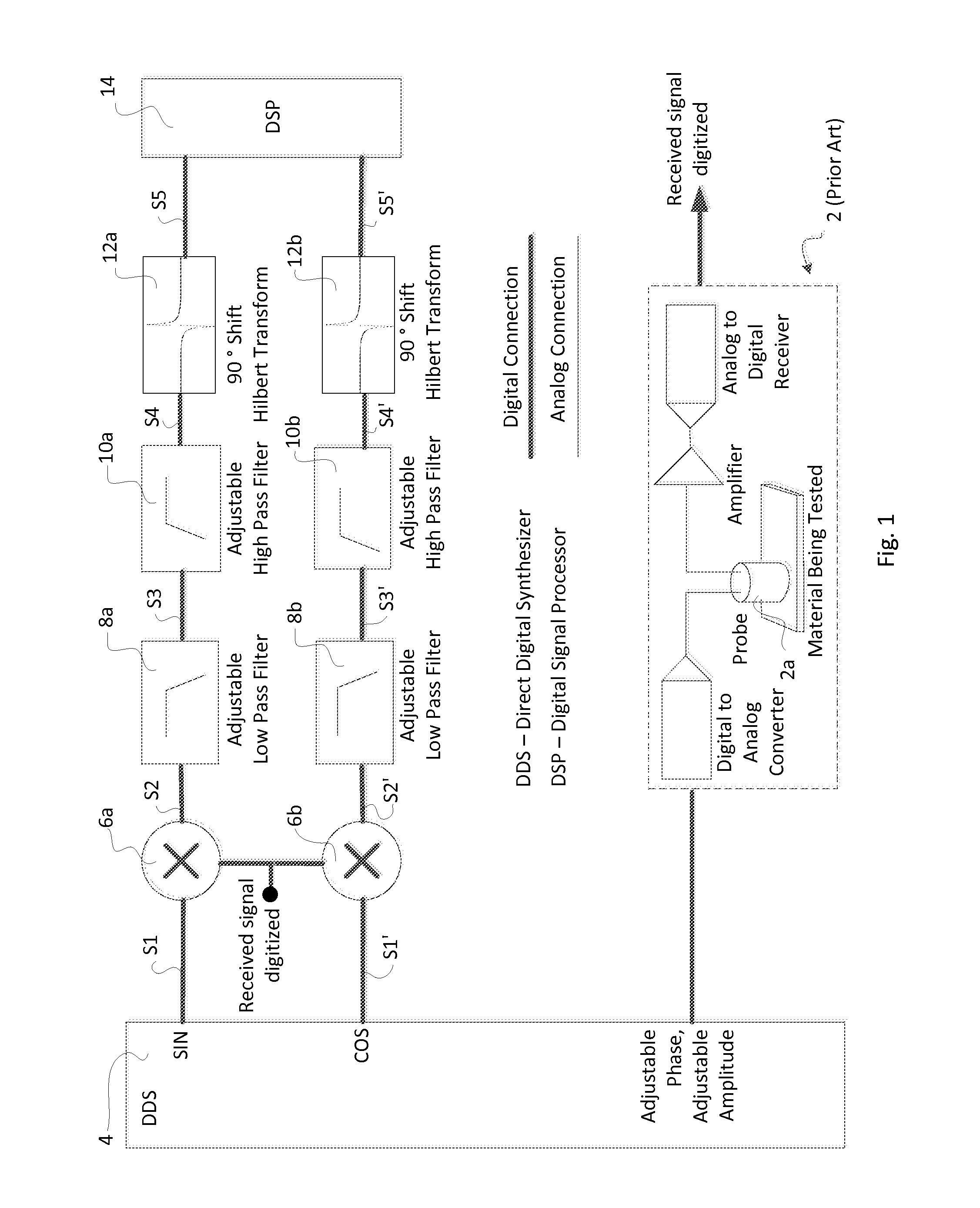

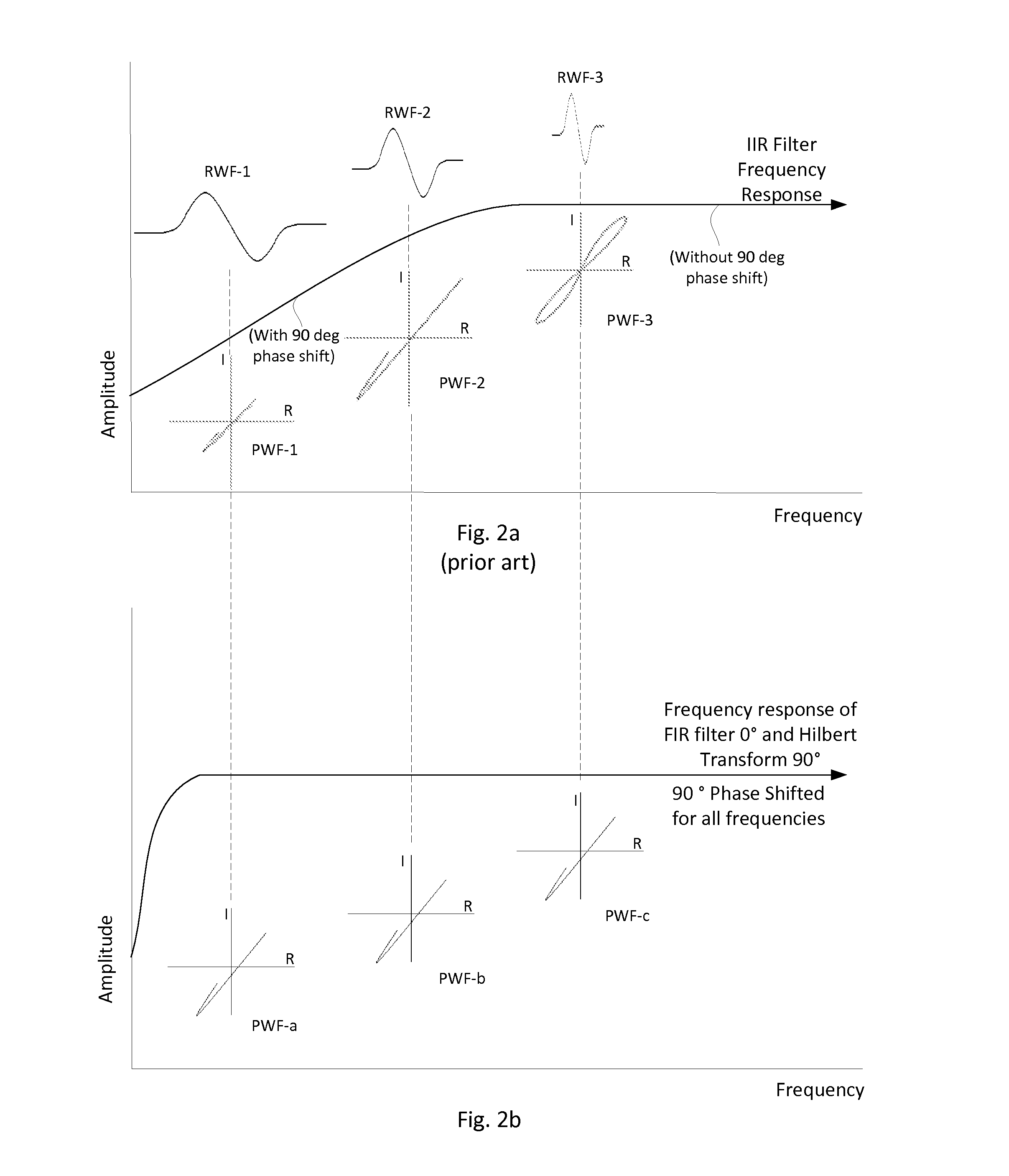

Circuit and method of providing a stable display for eddy current instruments

ActiveUS20160146759A1Reasonable variation rangeConstant signal sizeMaterial magnetic variablesFinite impulse responseSignal on

A rotary bolt hole eddy current inspection scanner using a differential eddy current probe, the circuitry of the scanner is embodied with a filtering circuit with three filters: FIR (Finite Impulse Response), a low pass filter, and a phase control filter (by means of a Hilbert transform). The result from a scan of a bolt hole is an output signal on an impedance plane exhibiting a “backwards 6” shape of stable size when the scanner changes its rotating rate significantly.

Owner:OLYMPUS AMERICA

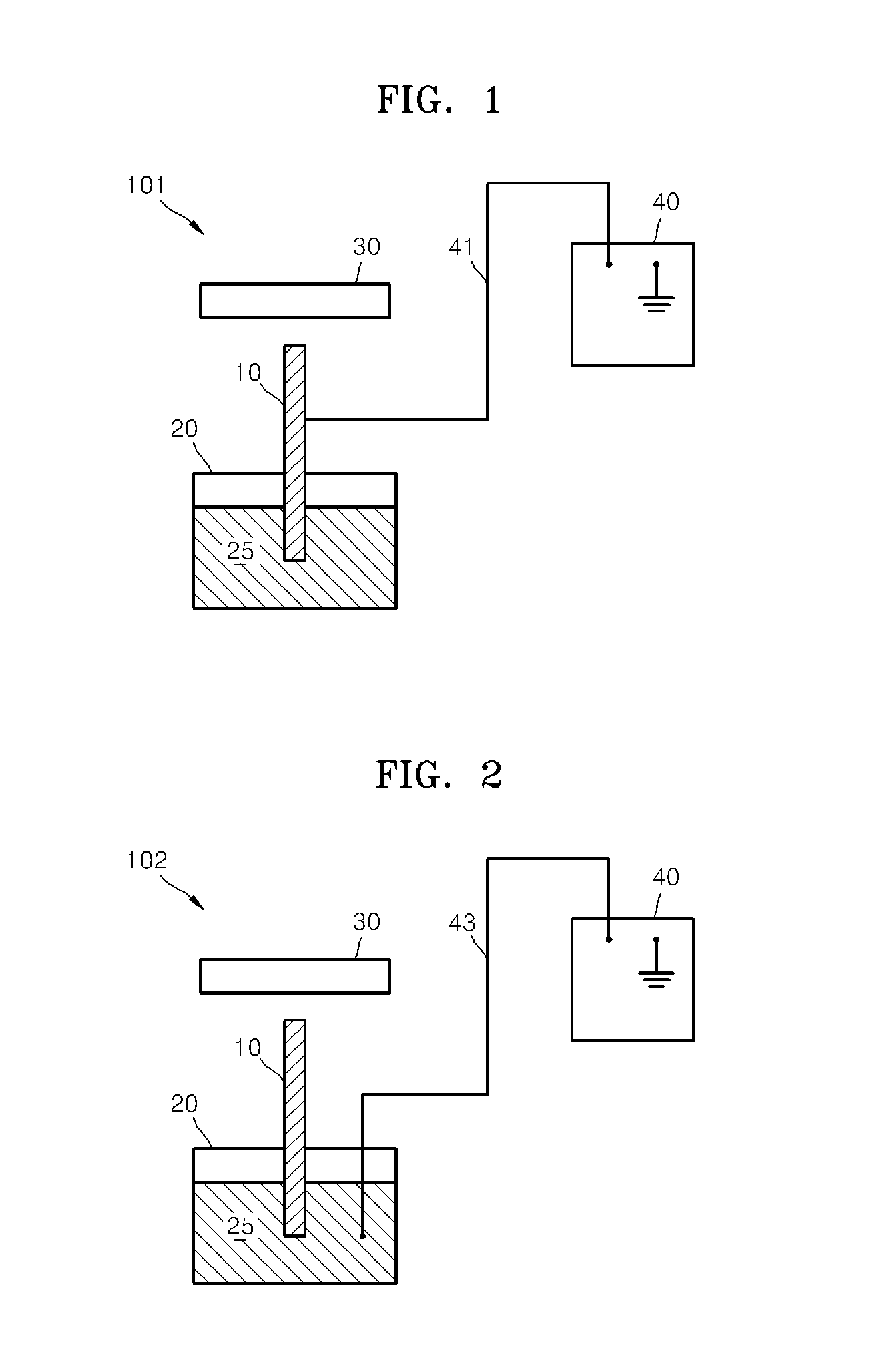

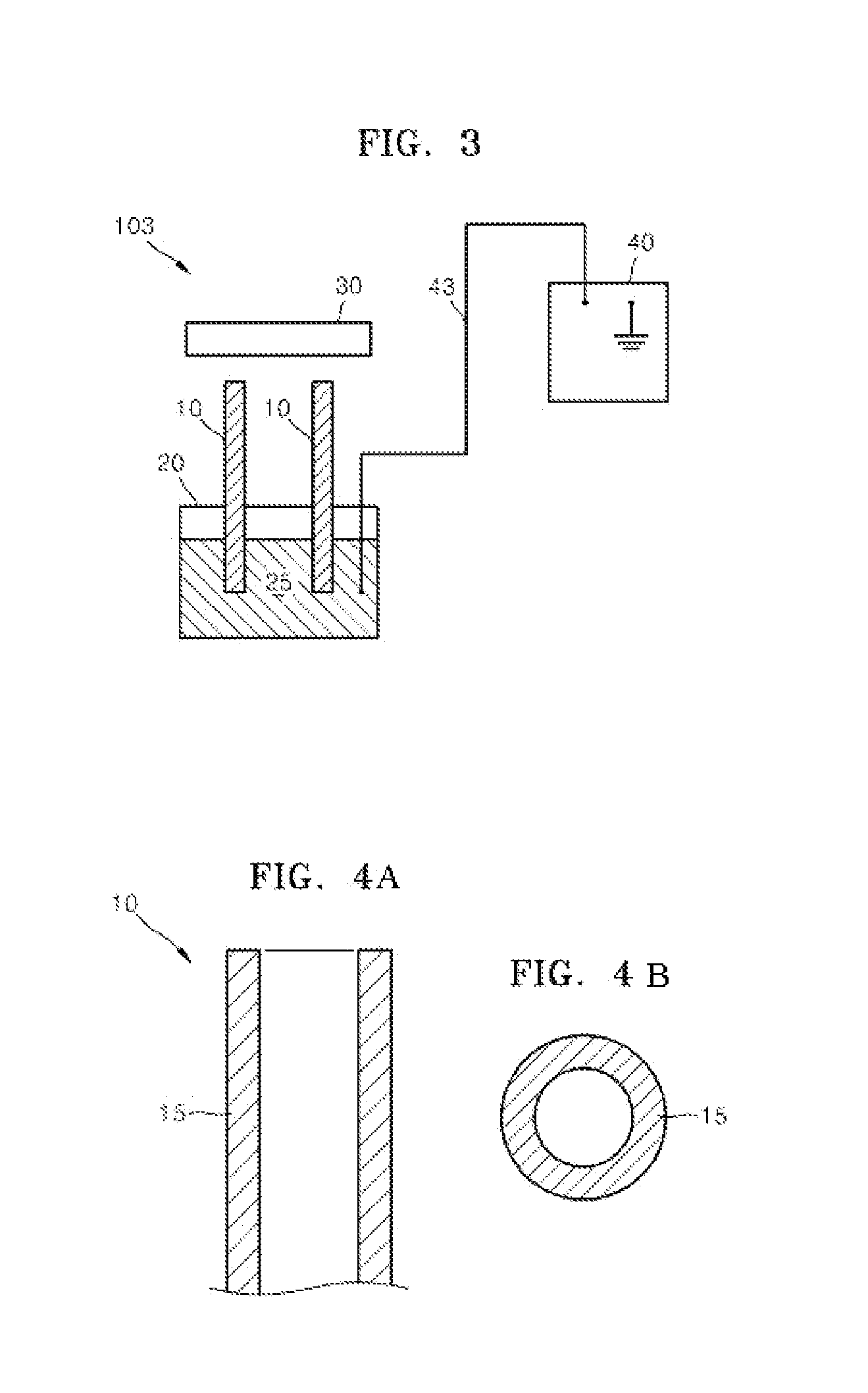

Method of printing droplet using capillary electric charge concentration

A method of printing droplets using capillary electric charge concentration includes: providing a capillary nozzle comprising a back-end part and a front-end part disposed substantially opposite the back-end part; spacing a target member apart from the front-end part of the capillary nozzle at a predetermined distance; immersing the back-end part in a solution; and supplying a voltage to the solution. The back-end part transmits the solution to the front-end part.

Owner:SAMSUNG ELECTRONICS CO LTD

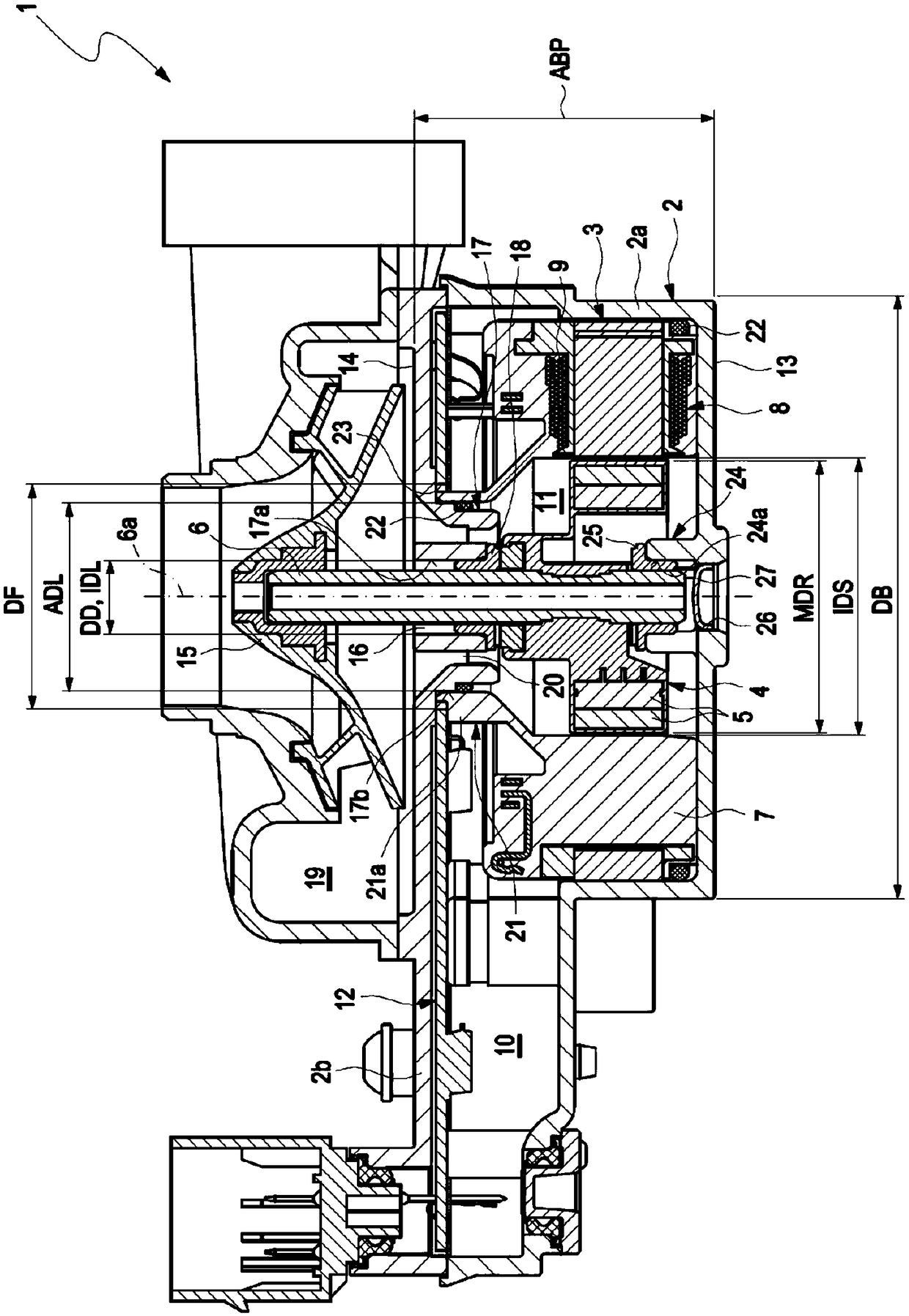

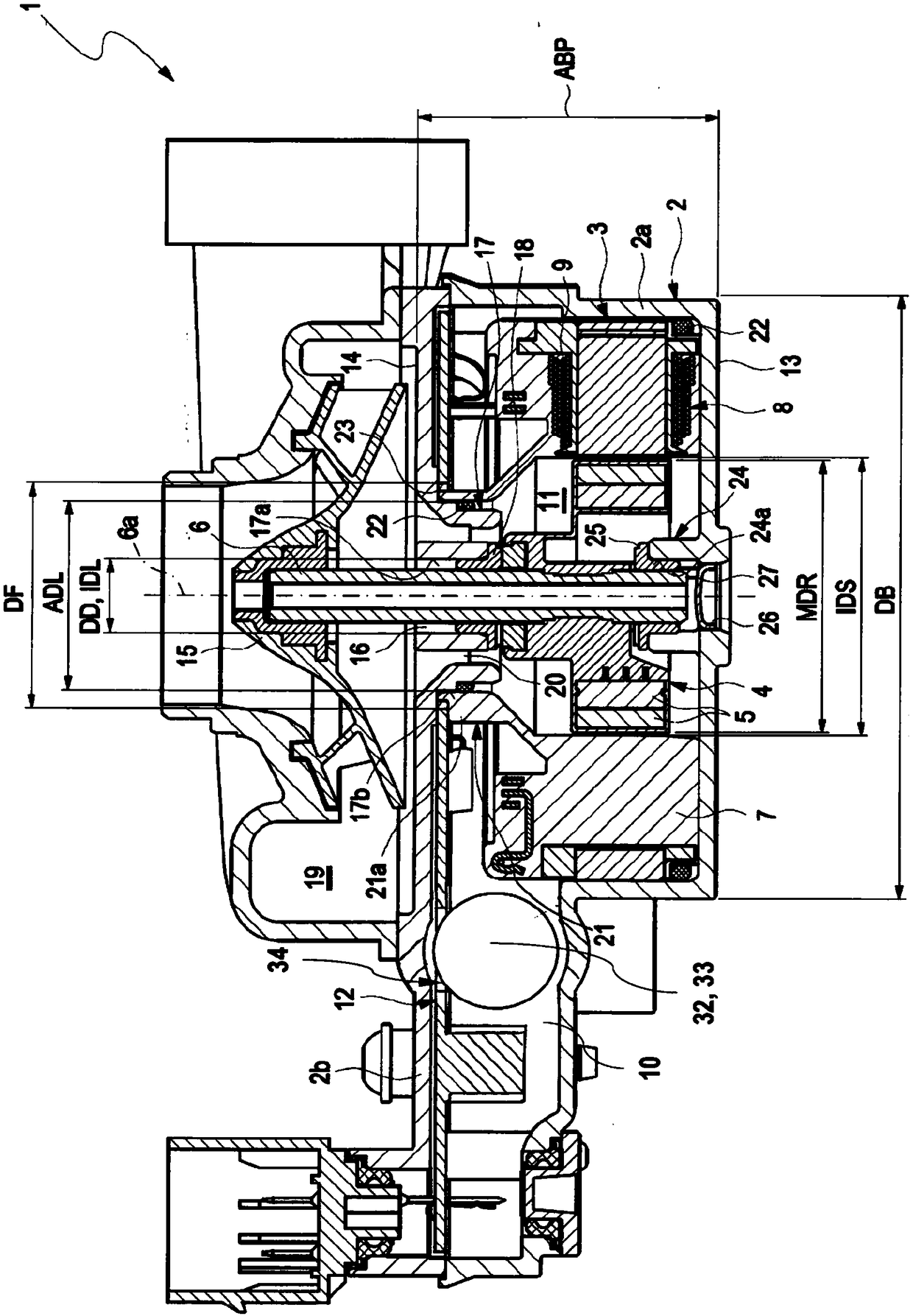

Fluid pump and method for assembling fluid pump

ActiveCN109424555AReduce manufacturing costReduce production capacityPump componentsPump installationsImpellerElectricity

The invention relates to an electric fluid pump which may include a pump housing and an electric motor arranged therein. A rotor of the electric motor may have a rotor shaft and may be mounted in a rotatable manner in a stator body, which may have a stator embedded at least regionally therein. The pump housing may be subdivided into a dry region and a wet region containing the rotor. The rotor shaft may be mounted on a bottom side in the pump housing and may project out of an aperture on a pump-impeller side facing away from the bottom side. In addition, the rotor shaft may be connected in terms of drive to a pump impeller. According to the invention, the pump housing may have an internal first bearing collar arranged around the aperture, wherein the dry region may be located radially around the first bearing collar, and wherein an outside diameter of the first bearing collar may be less than a maximum diameter of the rotor. The invention also relates to a method for assembling the fluid pump.

Owner:MAHLE INT GMBH

Excitation Control Method of Aeronautical Three-Stage Start-up Generator System in Start-up Stage

ActiveCN104935214BConstant sizeConstant relative speedAC motor controlElectric generator controlMotor speedAviation

The invention relates to an exciter whole-process two-phase alternating-current excitation control method for the starting stage of an aviation tertiary brushless starting power generation system based on a two-phase exciter. In the motor starting process, an exciter adopts two-phase alternating-current excitation in the whole process. The amplitude of a modulation voltage vector is determined through exciter excitation current closed-loop control, and the phase angle of the modulation voltage vector is determined through motor speed reference. When the method of the invention is applied to the starting stage of a tertiary brushless synchronous starting power generation system, the size of the excitation magnetic field of the exciter can be kept constant, and the speed of a rotor armature winding relative to the excitation magnetic field can be kept constant. Finally, the excitation current of a main generator can be kept constant in the whole motor starting process, and the complexity of main generator variable-frequency starting control is reduced.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com