Machine for cutting web rolls

A technology for cutting equipment and coils, applied in metal processing and other directions, can solve problems such as machine volume increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

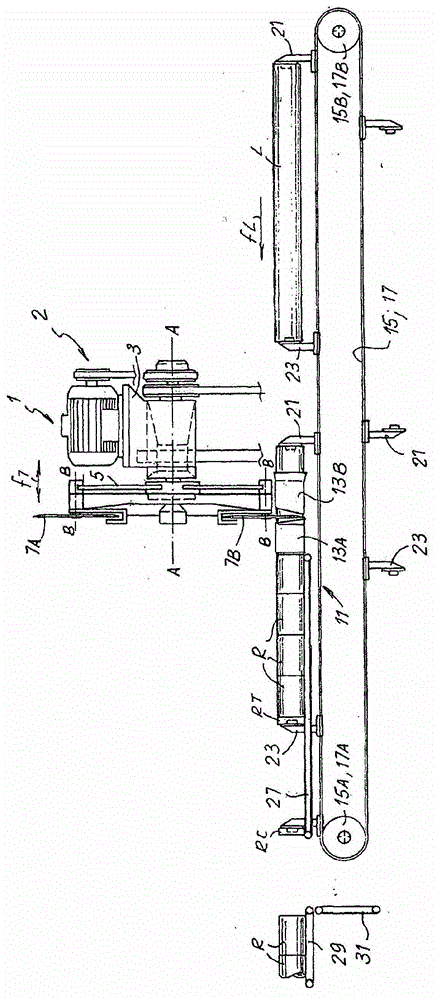

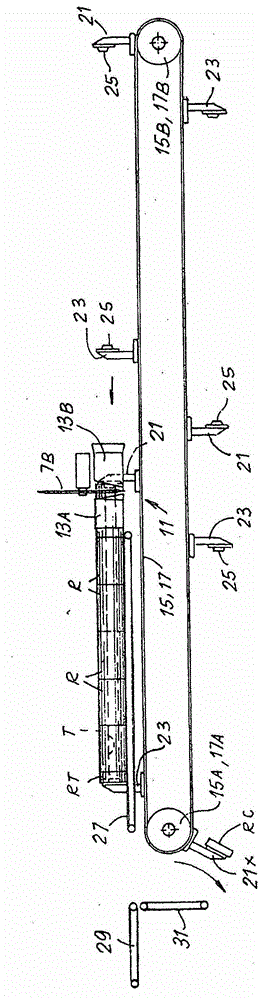

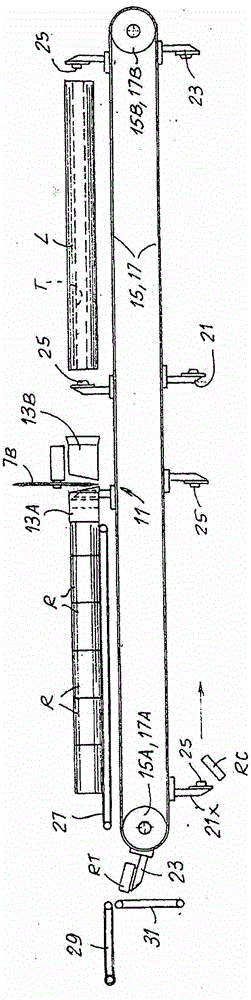

[0030] figure 1 The essential parts of the cutting device are shown schematically. The device has a cutting head 1 with a structure 3 on which a rotating plate 5 is mounted, where A-A designates the axis of rotation of this rotating plate. The rotating plate may support one or more disc-shaped cutting blades. In this example there are two cutting blades 7A and 7B, the line B-B representing the axis of rotation of the cutting blades. The disc-shaped blades 7A, 7B work alternately, in the sense that when the rotating plate 5 rotates about the axis A-A, the disc-shaped blades 7A, 7B sequentially, in the manner described hereinafter, extract from the logs fed through the apparatus. Cut the rolls one by one. It is important to understand that the device can also have a different number of disc-shaped cutting blades, for example only one blade, or three blades, or even more blades on the same rotating plate 5 . In some embodiments, the blades may be paired and coaxial, for examp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com