Apparatus for separating transporting air in fibrous material transportation

A technology for fiber materials and conveying airflow, applied in fiber processing, fiber feeding, fiber opening and cleaning machines, etc., can solve problems such as irregularities and fluctuations, and achieve the effect of reducing energy costs and preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

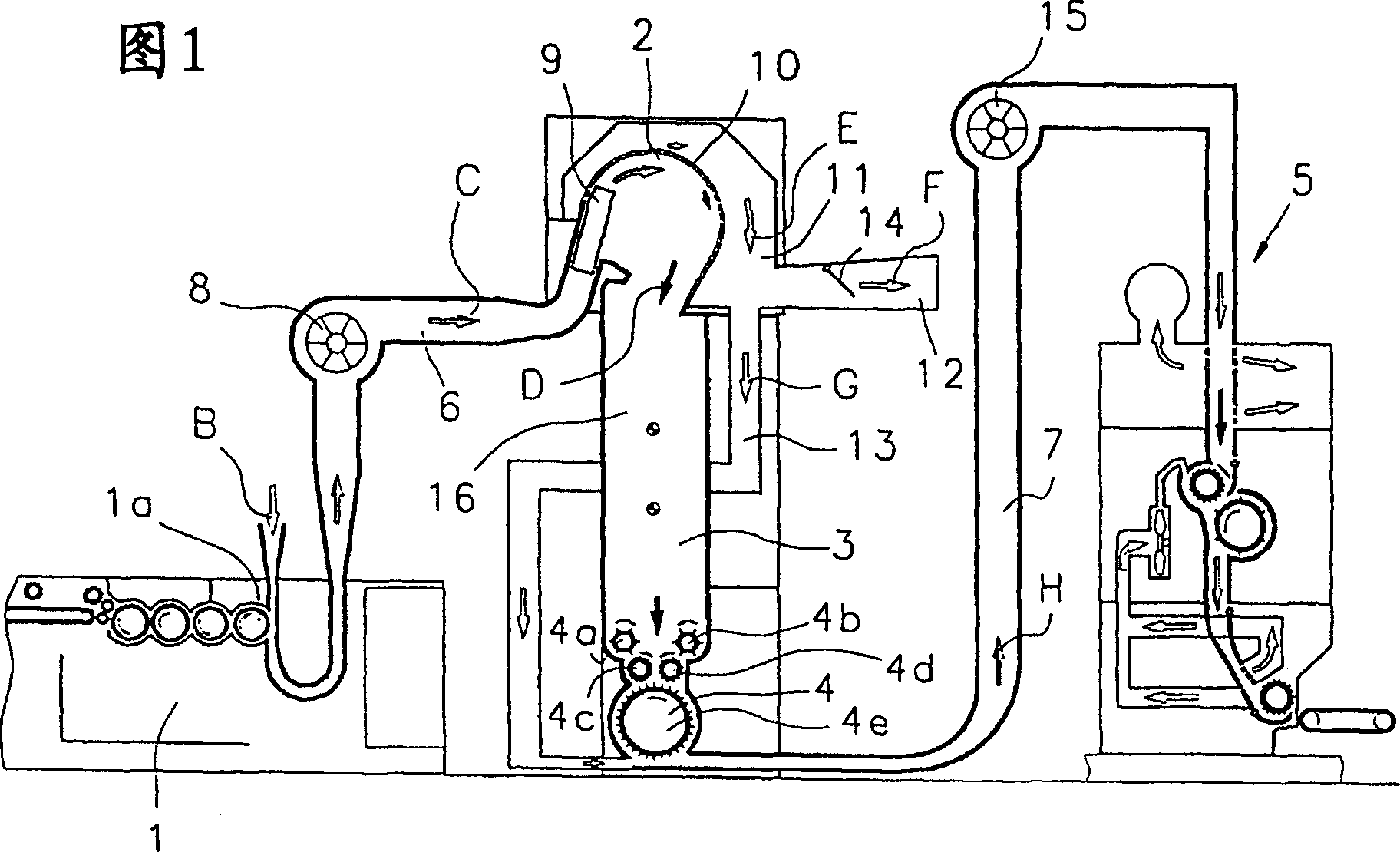

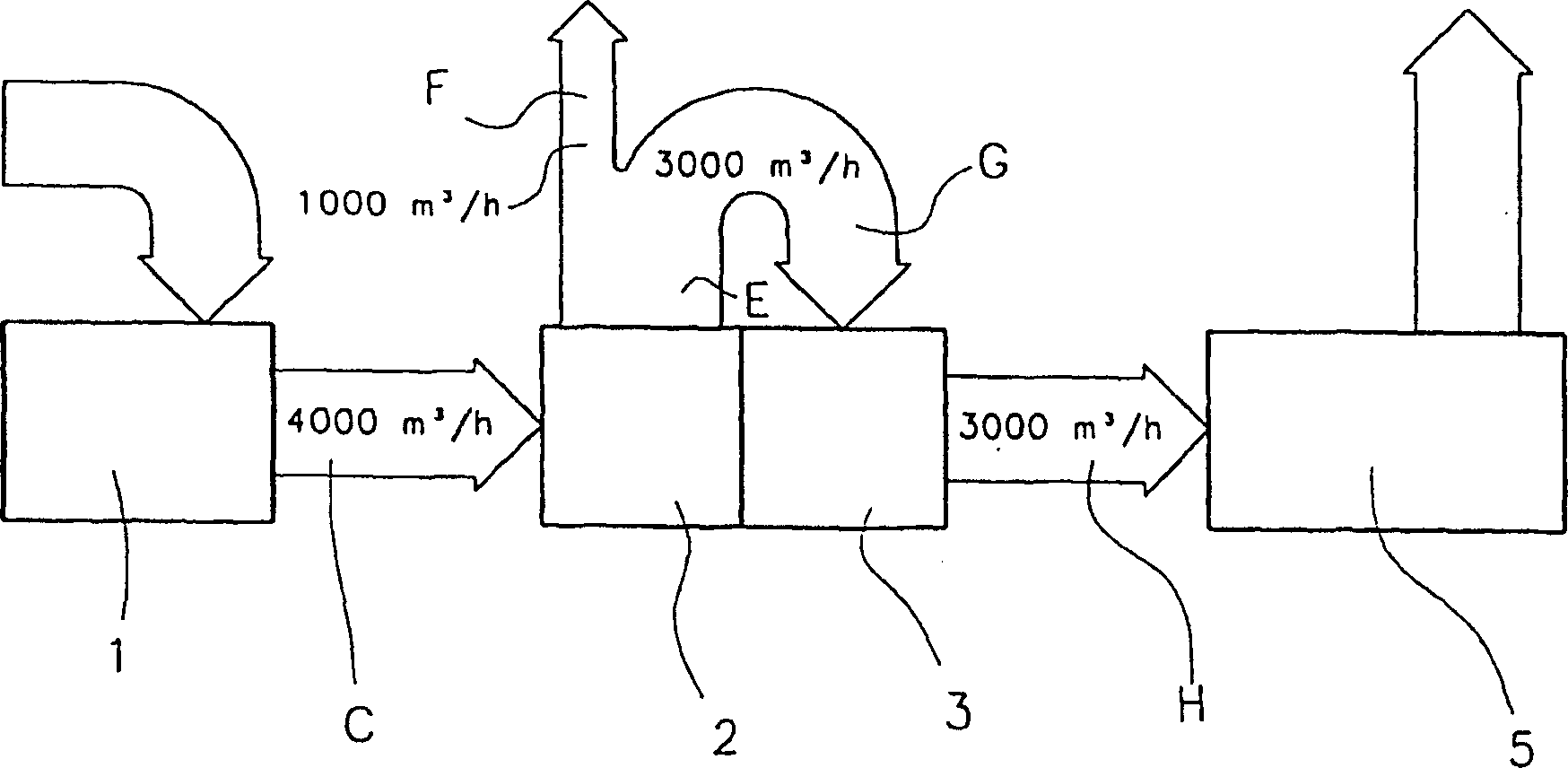

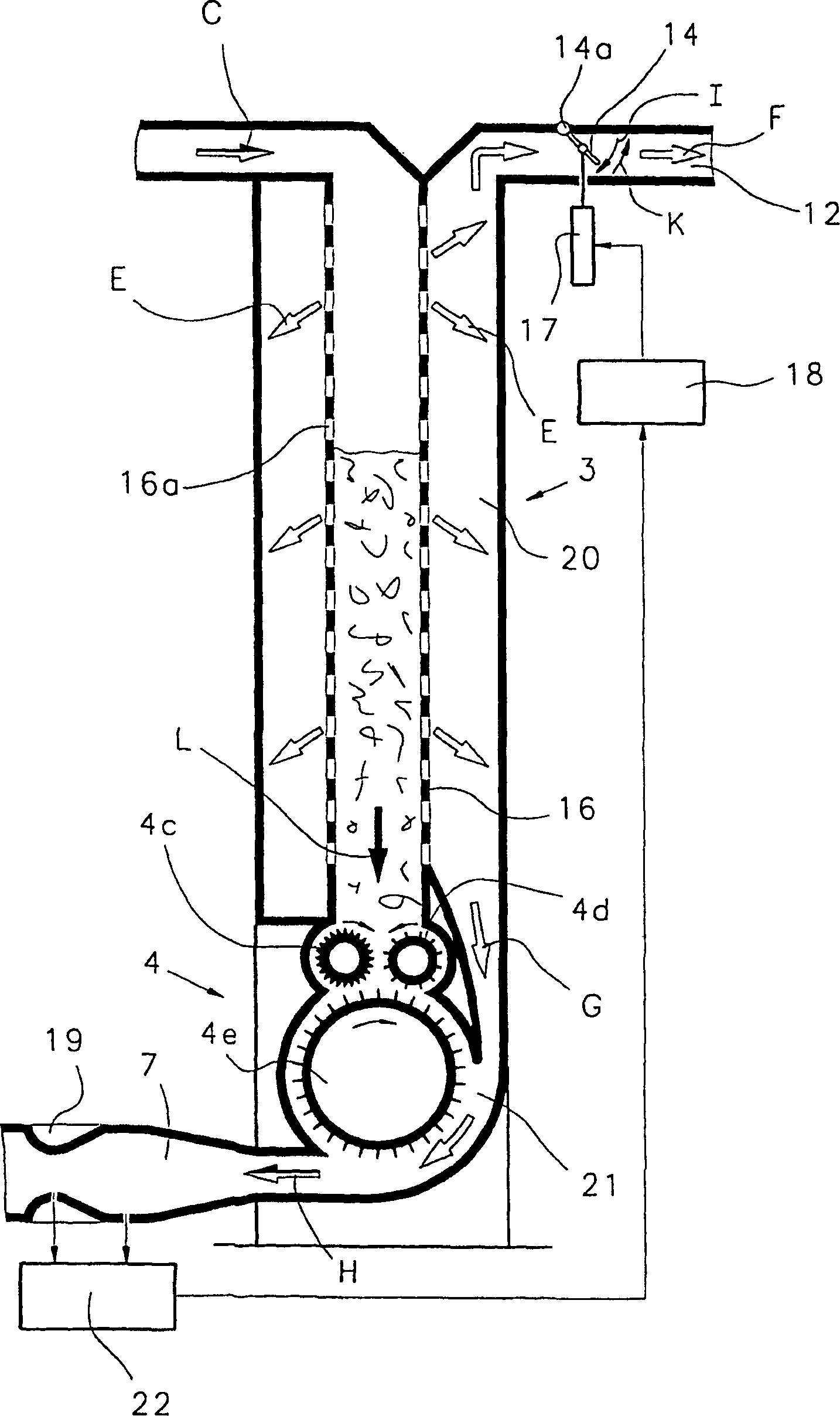

[0011] According to Fig. 1 - opener 1, such as TXL4 Trützschler opener, a fibrous material separator (Fasermaterialabschneider) 2, such as MAS Trützschler material separator, a fibrous material with opening device 4, such as dosing opening roller A store 3 , for example a MSC Trützschler material store, and a fiber batt feeder 5 , for example a Trützschler SCANFEED, are connected sequentially to one another. Instead of the opening roller, it is also possible to use a yarn clearer, for example a Trützschler CVT4 yarn clearer. Use A to indicate the working direction.

[0012] Between the opening roller 1 and the material separator 2 there is a duct 6 for the pneumatic feeding of the fiber batts, and between the dosing opening roller 4 and the fiber batt feeder 5 there is a duct 7 . The fibrous material is removed from the last roll 1 a of the four-roll opening machine 1 by means of an air flow B which is sucked in by a fibrous material conveying fan 8 arranged in the duct 6 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com