Inflatable nano microvesicle high-ash coal slime flotation equipment and flotation method thereof

An air-inflated, high-ash coal technology, applied in flotation, solid separation, etc., can solve the problems of unable to normally introduce air, difficult flotation standard clean coal, foam impact damage, etc., to improve the separation speed and selectivity, Improve fusion efficiency and increase production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

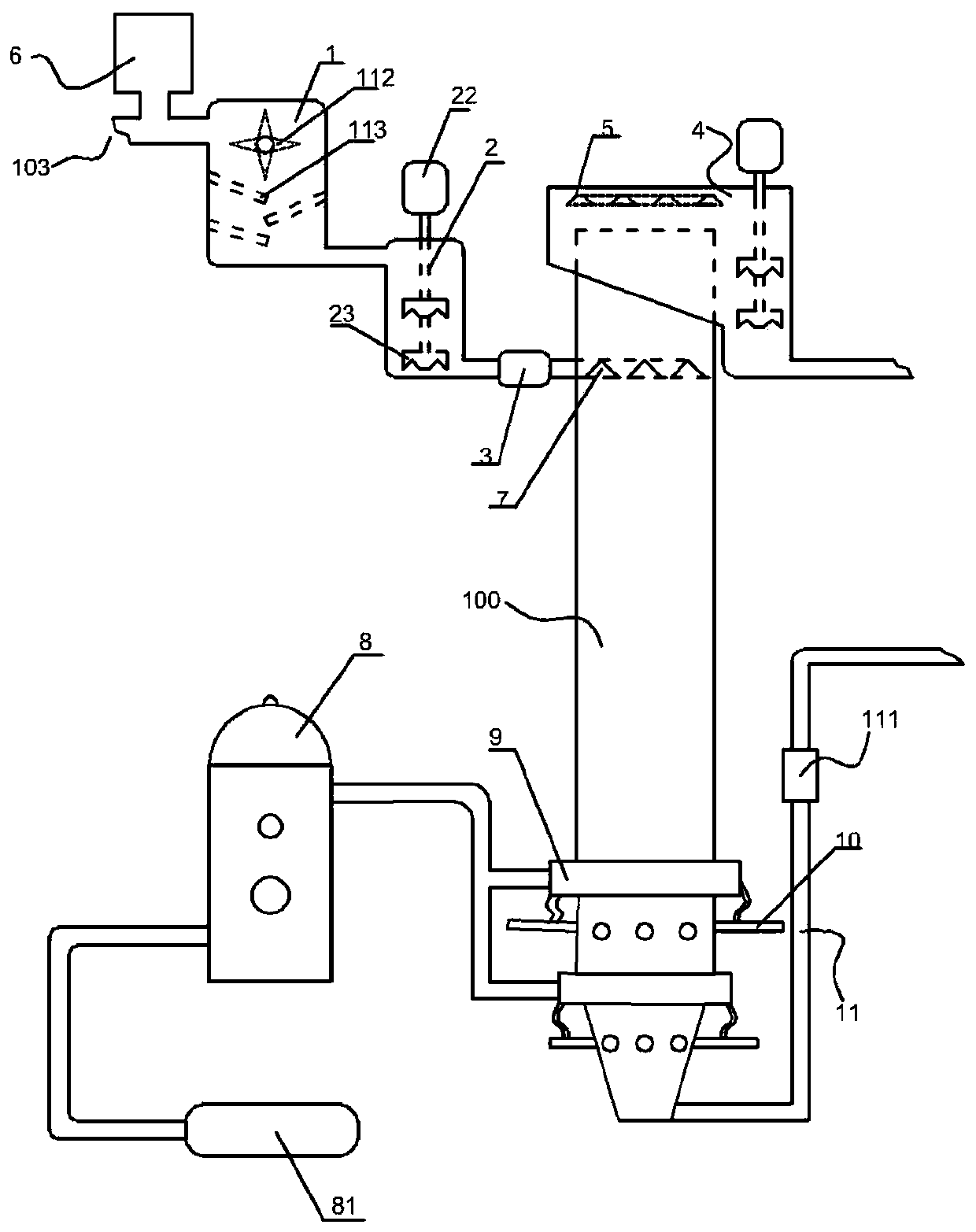

[0055] Example 1 reference figure 1 .

[0056] An inflatable nano-microbubble ultra-high ash tailings flotation equipment, including a main flotation column 100, the main flotation column 100 includes a pulp multi-point distributor 7 arranged at the upper middle position inside it, and a multi-point distributor 7 arranged at the top of it The foam trapping device 4, the atomizing spray device 5 arranged on the foam trapping device 4, the high-speed disperser device 2 arranged in the foam trapping device 4, and several bubble generators 10 are arranged around its lower outer wall position , surrounding the delivery air pipe 9 that is arranged on the outside thereof and communicated with the bubble generator 10 through a pipeline, the gas storage tank 8 and the air compressor 81 that are arranged on the outside of it and are connected with the delivery air pipe 9 in turn through a pipeline, are arranged on the outside of it and connected with the air delivery pipe 9 The tailing...

Embodiment 2

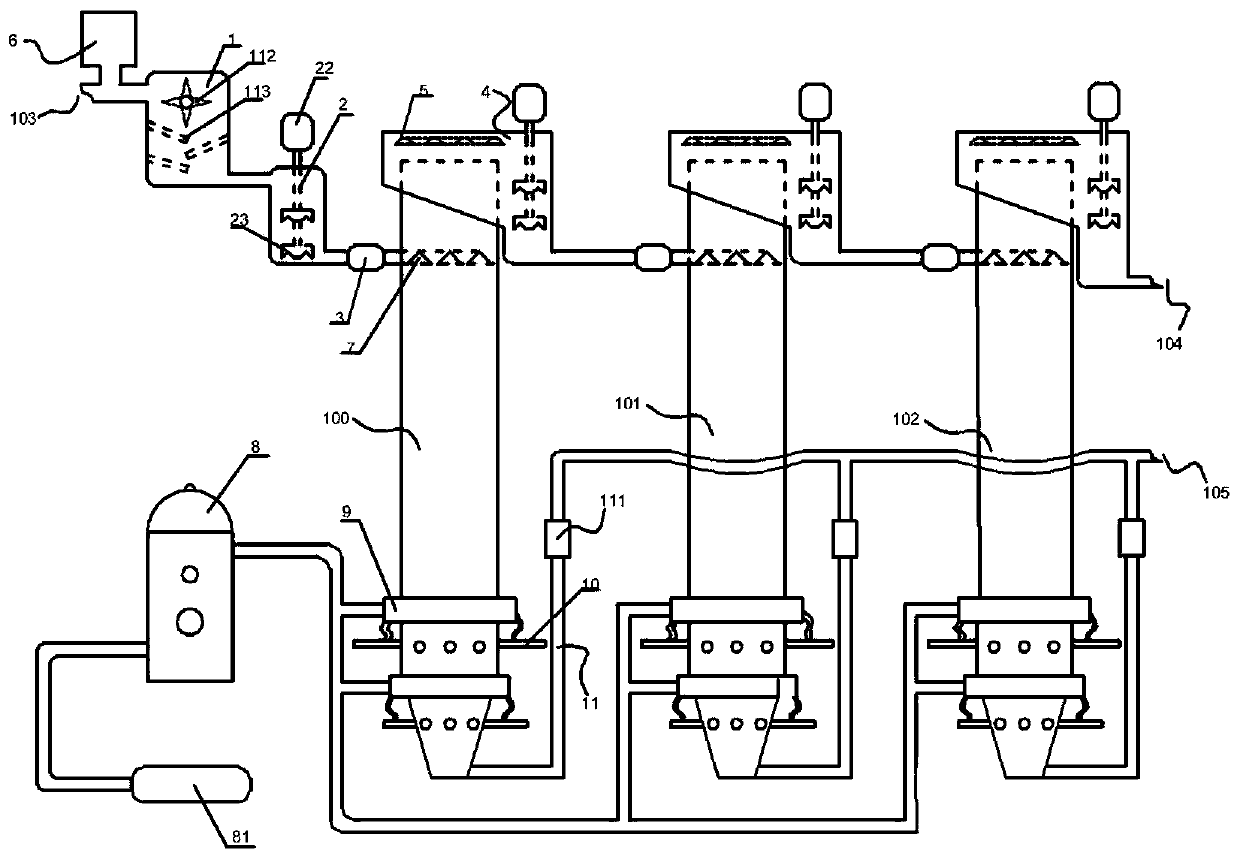

[0076] Example 2 reference figure 2 .

[0077] The main flotation column 100 is sequentially connected with two secondary flotation columns 101, 102;

[0078] Both the main flotation column 100 and the secondary flotation columns 101, 102 include a slurry multi-point distributor 7 arranged in the middle and upper position inside it, a foam trapping device 4 arranged on the top thereof, and a foam trapping device 4 arranged on the top. The atomizing spray device 5 on the top, the high-speed disperser device 2 arranged in the foam trapping device 4, several bubble generators 10 are arranged around the outer wall of the lower part, and are arranged around the outside of it and pass through the pipeline and the bubble generator 10 The communicating conveying air pipe 9 and the tailings overflow discharge pipe 11 arranged outside and communicating with the bottom thereof.

[0079] The delivery air pipe 9 is sequentially connected with the air storage tank 8 and the air compresso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com