Material blend crusher

A pulverizing device and material mixing technology, applied in grain processing and other directions, can solve the problems of uneven mixing, high operating cost, long mixing time, etc., and achieve the effect of shortening working time, reducing production cost and improving productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

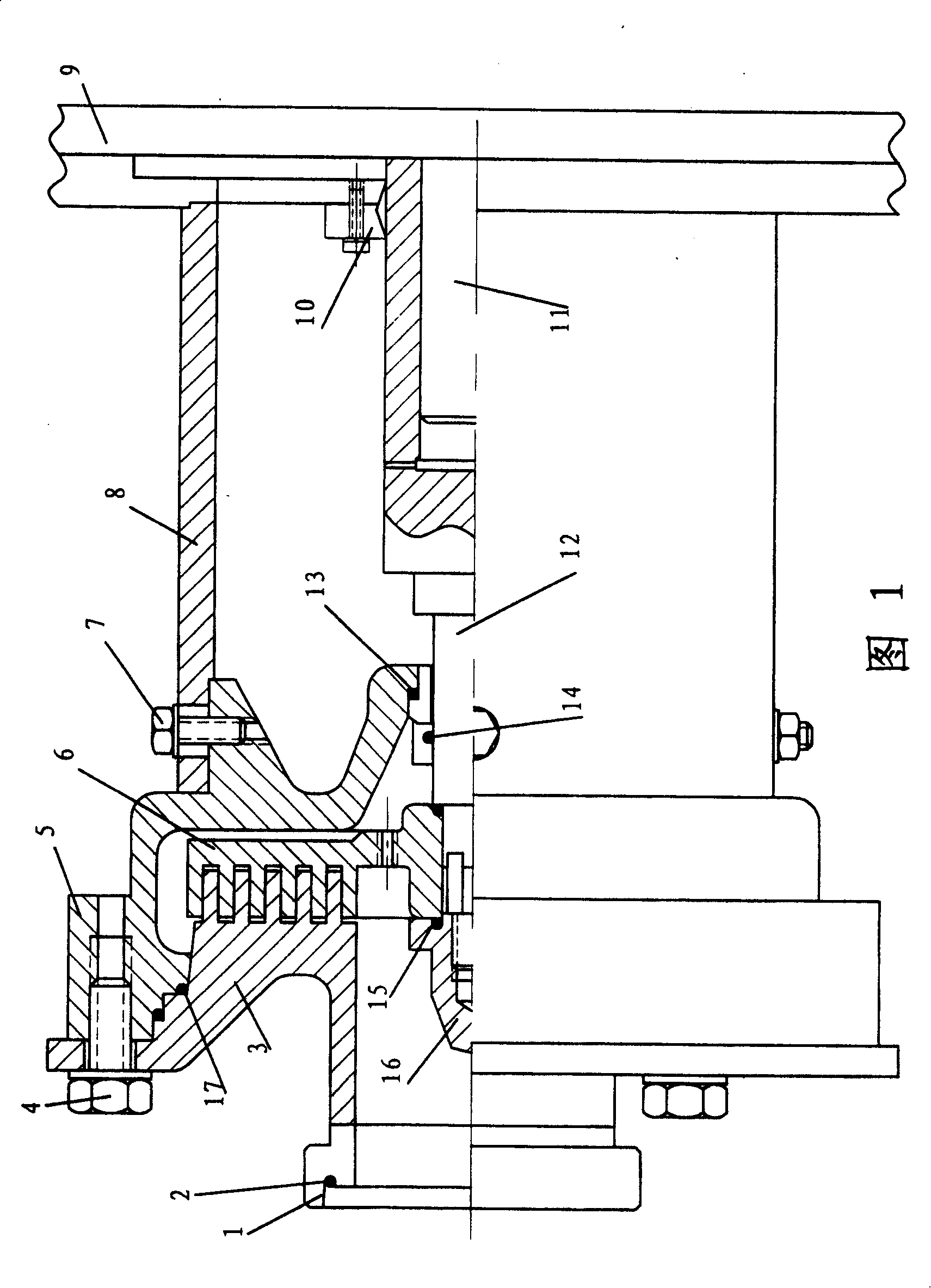

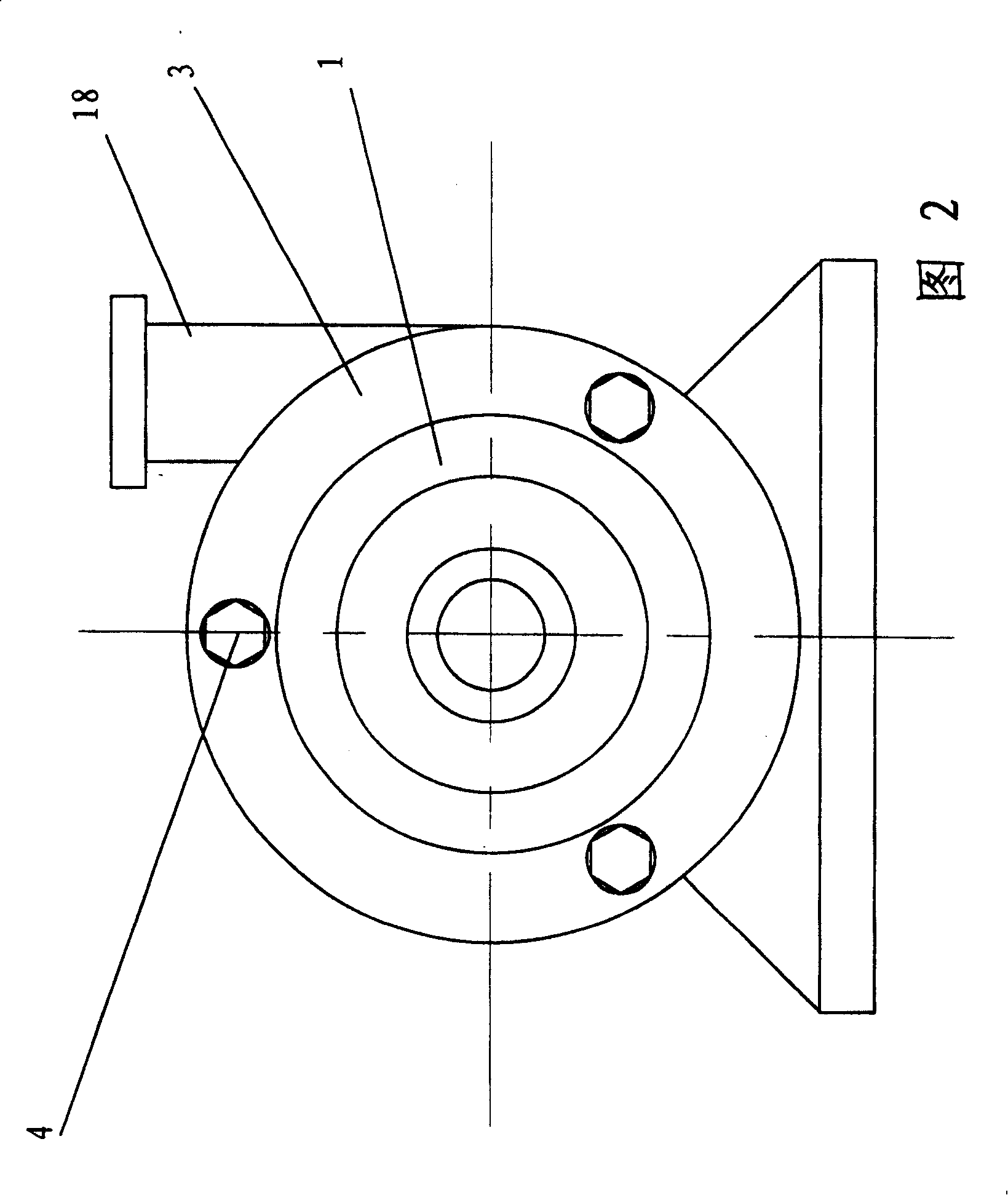

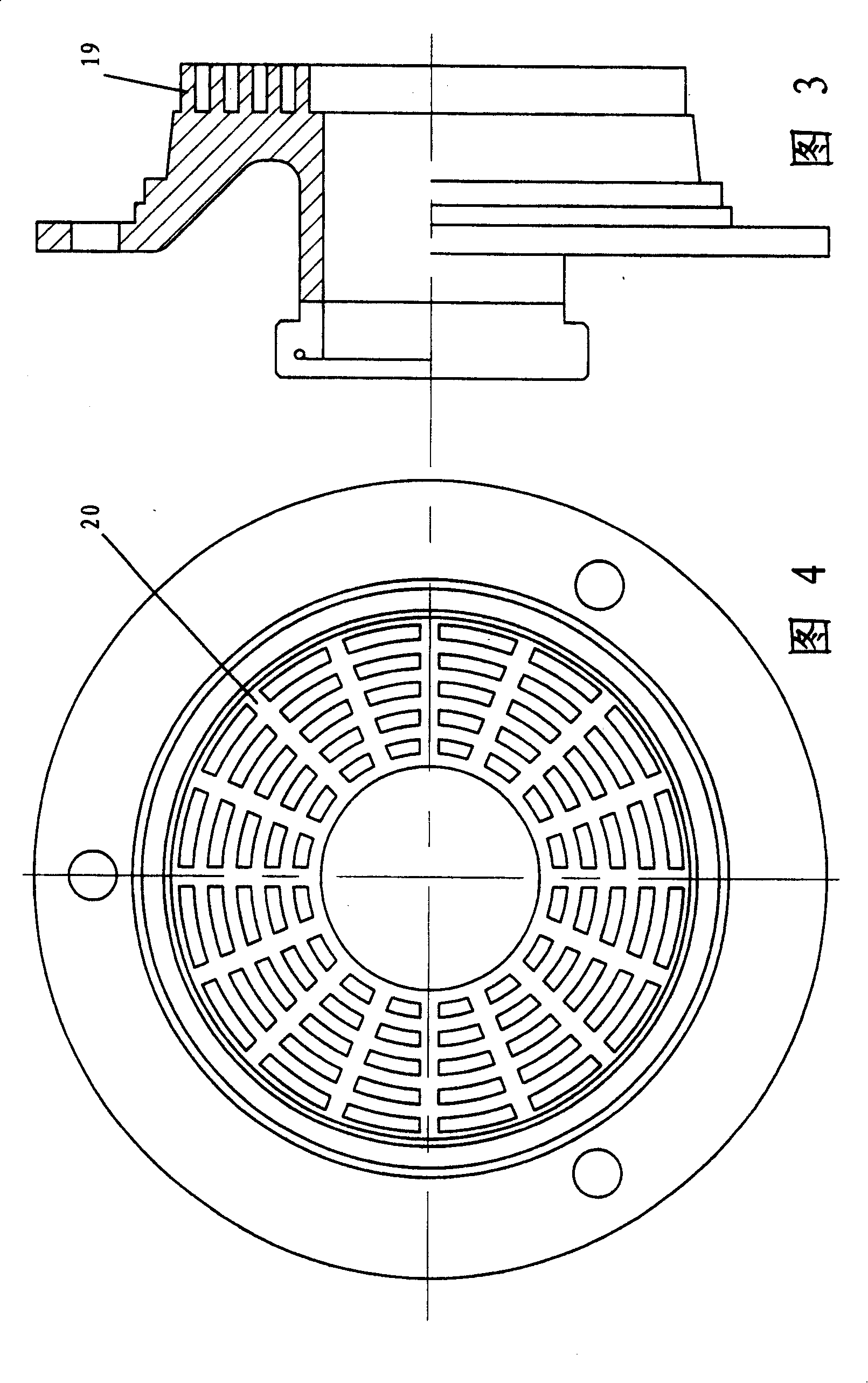

[0029] 1 and 2, the material mixing and pulverizing device according to the present invention includes a cavity 5, a stator 3 fixedly connected with the cavity and having a central feeding port, and a stator 3 fitted with the stator and fixedly mounted on the rotating shaft sleeve 12. Rotor 6. One end of the cavity 5 is connected to the motor flange 9 through the connecting cylinder 8, and its inner hole is mounted on the rotating sleeve 12, which is connected to the motor shaft 11 through a coupling 10 (commercially available).

[0030] The cavity 5 is the main part of the mixing and pulverizing device, and its shape is like a snail shell, with a discharge port on one side of the cavity, the outer surface of the end connected with the connecting cylinder 8 is tightly fitted with the connecting cylinder, and has threaded holes. 3-6. The connecting cylinder 8 has an axially long through hole matched with the threaded hole of the cavity 5 for adjusting the axial gap between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com