Casting system capable of eliminating detects of ZG35 valve casting and design method thereof

A casting defect, ZG35 technology, applied in casting molding equipment, casting mold, casting mold composition, etc., can solve the problems of metal material waste, complex structure, casting cracks, etc., to eliminate local cracks, improve mechanical properties, and eliminate shrinkage cavities. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

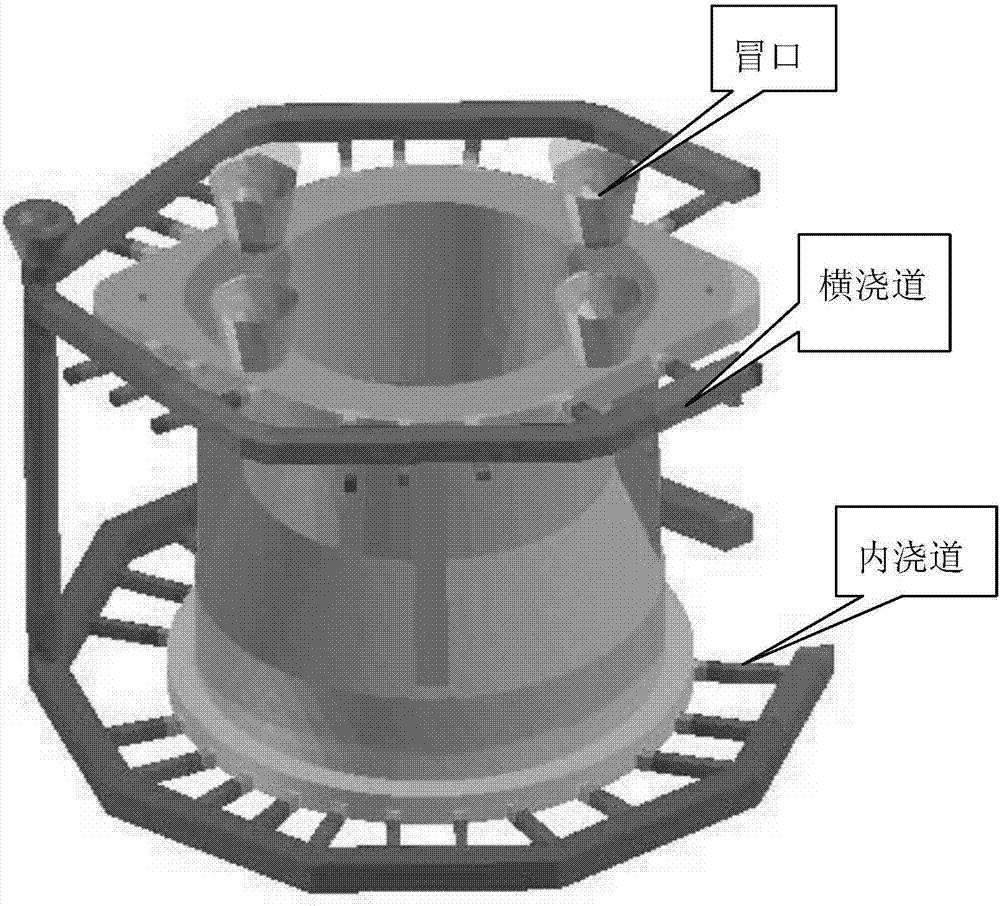

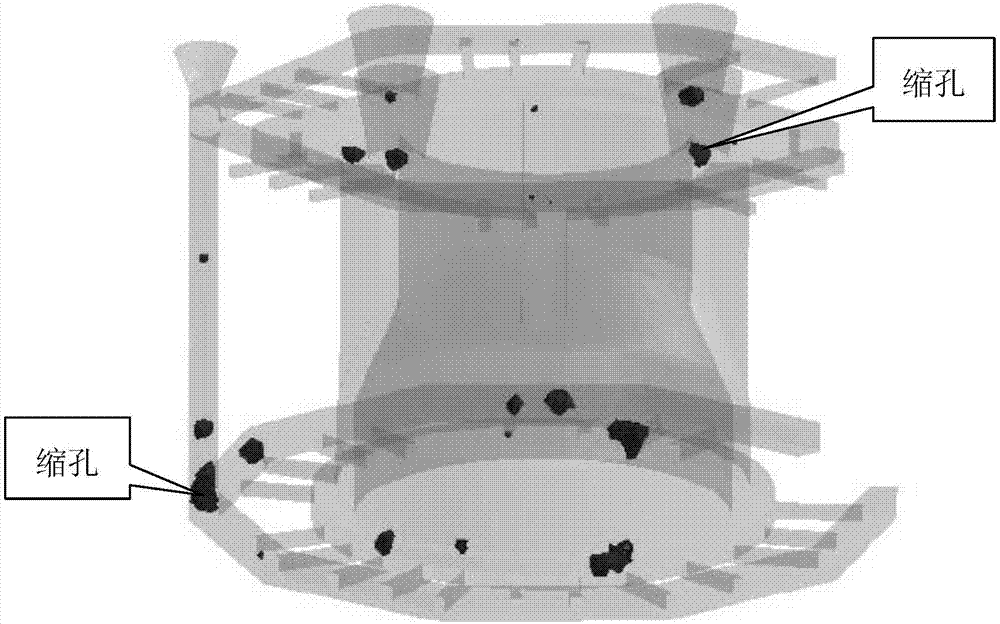

[0041] Figure 1-3 It is an existing technology. The gating system in the prior art mostly adopts a multi-runner ladder type. A large arc-shaped runner and 15 inner runners are arranged at the upper and lower flanges of the valve casting, and the intention is to use the inner runner. The mouth feeds the thick flanges at the top and bottom of the casting, and achieves the purpose of sequential filling from bottom to top, but the casting system has serious cracks due to the network gating system.

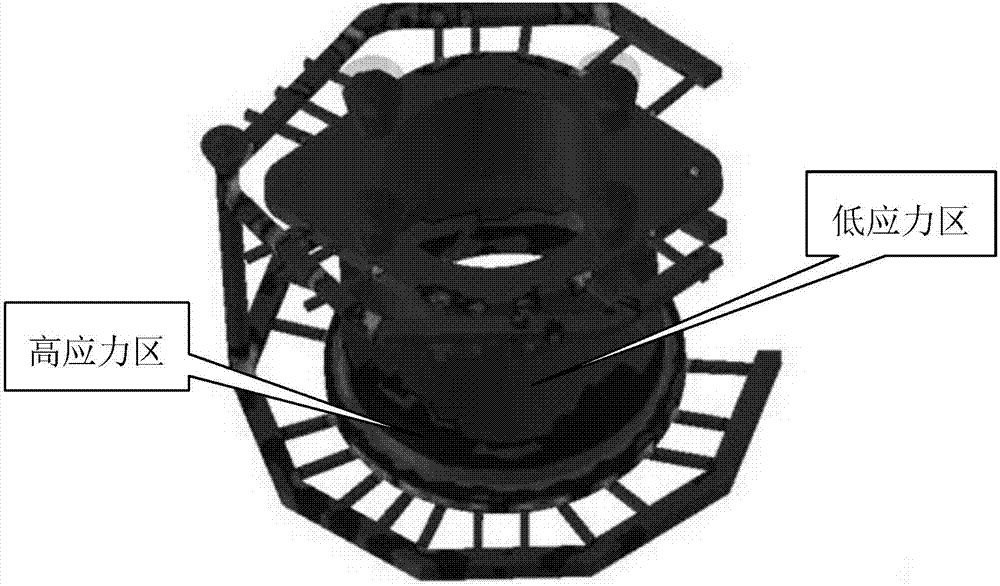

[0042] Depend on figure 1 It can be seen that at this moment, the casting body is still not solidified, but the gating system has been solidified, which makes the casting body be hindered by the gating system and cause stress when it solidifies a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com