Organosilicon modified silica sol/polyacrylate composite emulsion and its preparation method

A technology of polyacrylate and composite emulsion, applied in the direction of coating, etc., can solve the problems of serious whitening and foaming of the coating film, poor water resistance and solvent resistance of the coating film, and achieve enhanced water resistance, good water resistance and repeatability good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

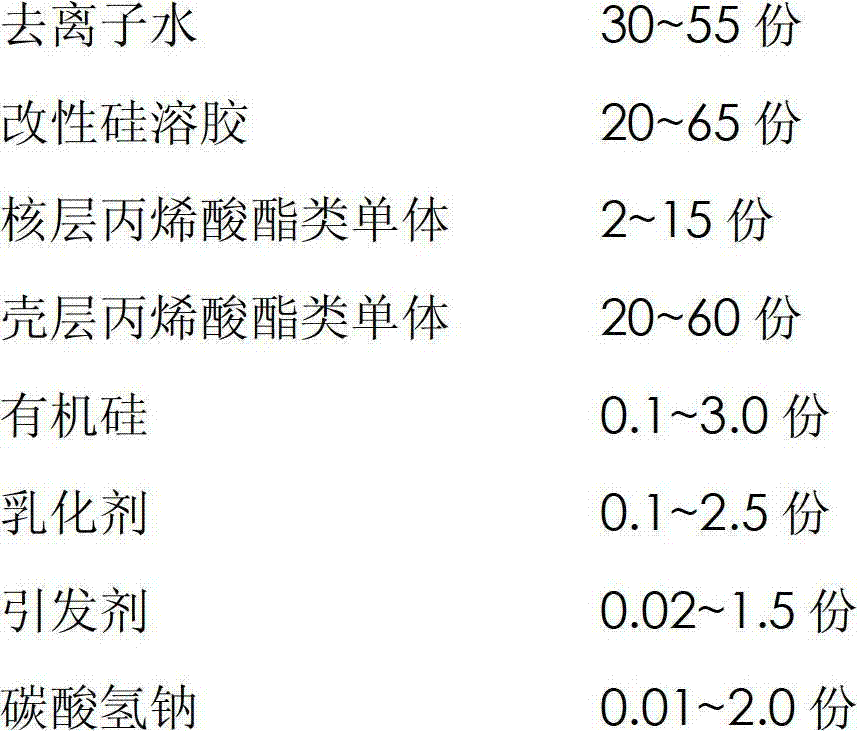

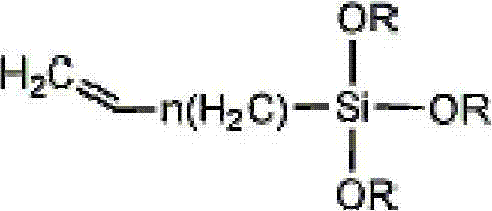

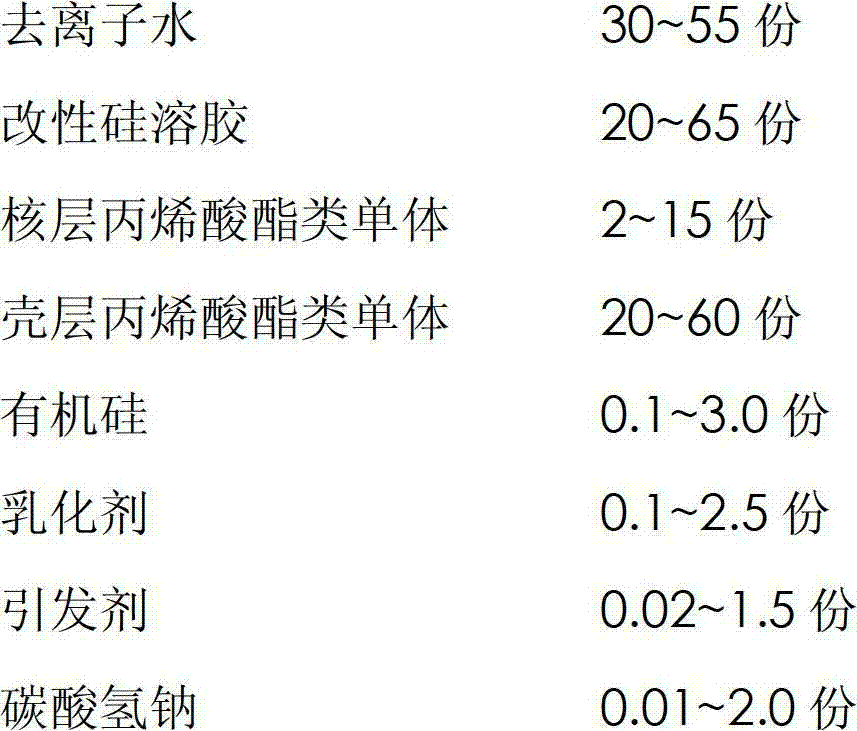

Method used

Image

Examples

Embodiment 1

[0043] Add 10 g of isopropanol and 0.84 g of Y-(methacryloyloxy)propyltrimethoxysilane to 35 g of silica sol, stir and react at 60° C. for 8 h to obtain modified silica sol.

[0044] Add 2g of deionized water, 0.08g of PEO-10 and T-80 (mass ratio: 2:1) into the jar, after dissolving evenly, add 3.8g of core layer mixed monomer methyl acrylate dropwise within 5min , butyl acrylate (mass ratio 3:1) and methacrylic acid, after the dropwise addition, stir with a magnetic stirrer at a speed of 1000 rpm for 25 minutes, and then stir at a speed of 500 rpm for 8 minutes to obtain a pre-emulsified nuclear monomer.

[0045] Add 12g of deionized water, 0.3g of PEO-10 and T-80 (mass ratio: 2:1) into the jar, dissolve evenly, add 20g of acrylate monomer methyl acrylate to the shell at a constant speed within 20min ester, butyl acrylate (mass ratio 3:1), methacrylic acid, hydroxyethyl acrylate and N-methylolacrylamide, after the dropwise addition, stir with a magnetic stirrer at a speed...

Embodiment 2

[0049] Add 15g of ethylene glycol and 1.20g of γ-glycidyloxypropyltrimethoxysilane to 40g of silica sol, stir and react at 25°C for 12h to obtain modified silica sol.

[0050] Add 6g of deionized water, 0.45g of DNS-86 and OP-10 (mass ratio: 3:1) into the jar, after dissolving evenly, add 12g of core layer mixed monomer methyl methacrylate dropwise within 10min ester, butyl acrylate (mass ratio 2:1) and acrylic acid, after the dropwise addition, stir with a magnetic stirrer at a speed of 2000rpm for 20min, and then stir at a speed of 800rpm for 10min to obtain a pre-emulsified nuclear monomer.

[0051] Add 16g of deionized water, 1.1g of DNS-86 and OP-10 (mass ratio: 3:1) into the jar, after dissolving evenly, add 55g of acrylate monomer methyl Methyl acrylate, butyl acrylate (mass ratio is 2:1), butyl methacrylate, N-methylolacrylamide and hydroxyethyl methacrylate, after the dropwise addition, use a magnetic stirrer at a speed of 1500rpm Stir for 20 minutes, then stir for 7...

Embodiment 3

[0055] Add 30 g of ethanol and 3.20 g of vinyltriethoxysilane to 75 g of silica sol, and stir and react at 70° C. for 18 hours to obtain modified silica sol.

[0056] Add 3g of deionized water, 0.1g of PEO-10 and T-80 (mass ratio 3:1) into the jar, after dissolving evenly, add 5g of the core layer mixed monomer methyl methacrylate dropwise within 10min ester, butyl acrylate (mass ratio 2:1) and methacrylic acid, after the dropwise addition, stir with a magnetic stirrer at a speed of 1500rpm for 15min, and then stir at a speed of 500rpm for 5min to obtain a pre-emulsified nuclear monomer .

[0057] Add 8g of deionized water, 0.5g of PEO-10 and T-80 (mass ratio: 3:1) into the jar, after dissolving evenly, add 25g of acrylate monomer methyl Methyl acrylate, butyl acrylate (mass ratio is 2:1), methacrylic acid, butyl methacrylate and N-methylolacrylamide, after the dropwise addition, stir with a magnetic stirrer at a speed of 1500rpm for 20min, Then stir at a speed of 500rpm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com