3D printing device integrating material supplying, fluxing and crystal leveling assistance

A 3D printing and feeding technology, applied in the field of 3D printing, can solve the problems of no processing process of printing equipment, inability to form the compactness of the workpiece, etc., to achieve the effect of cost reduction, avoid material sputtering, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

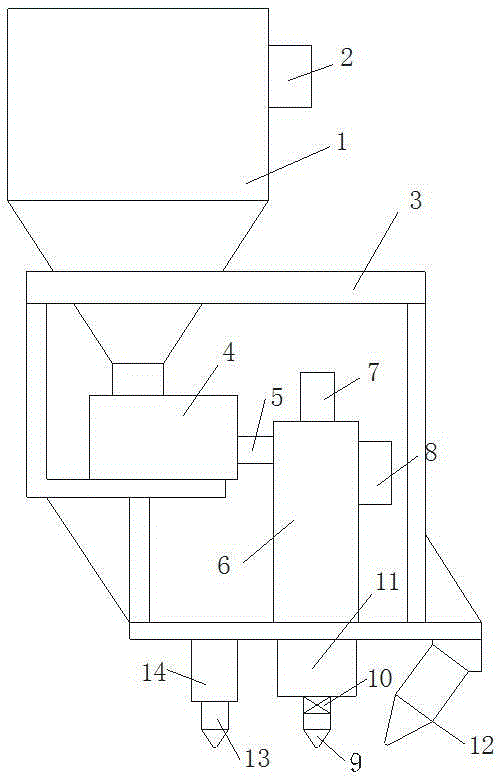

[0021] Such as figure 1 As shown, the integrated device for 3D printing feeding, melting and crystal leveling of the present invention includes a silo 1, a screw feeder 4, a screw extruder 6, a heating device 11, a nozzle 9, an auxiliary heating head 12 and Auxiliary crystallization leveling vibration head 13 , feed bin 1 , screw feeder 4 , screw extruder 6 , auxiliary heating head 12 and auxiliary crystallization flattening vibration head 13 can be installed on support 3 . The outlet of the silo 1 is connected to the feed port of the screw feeder 4, and the silo 1 is provided with a blanking vibrator 2, through the vibration of the blanking vibrator 2, the material continuously enters the screw feeder 4 to prevent the occurrence of feeding Material interruption or intermittent feeding phenomenon. Blanking vibrator 2 can adopt ultrasonic vibration device. The screw feeder 4 is used as the first forced feeding mechanism, and the screw extruder 6 is used as the second forced f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com