Marine anticorrosive coating

A marine anti-corrosion and coating technology, applied in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of reducing the service life and safe use of submarine steel pipes, cannot prevent the immersion of small molecular corrosive media, and needs to be improved. Achieve excellent anti-rust performance, high strength and improved compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A kind of marine anticorrosion paint 30g of the present invention, marine anticorrosion paint is made up of following components by mass percentage:

[0033]

[0034] Wherein the film-forming substance is composed of 20% (6g) of water-based novolac epoxy resin and 14% (4.2g) of water-based polyurethane by mass percentage; the pigment and filler include graphene; and the solvent is deionized water.

[0035] The pigments and fillers are composed of the following components by mass percentage:

[0036]

[0037] The auxiliary agent is composed of dispersant 0.8% (0.24g), defoamer 0.7% (0.21g), coupling agent 1.2% (0.36g), cosolvent 3% (0.9g), thickener 0.3% by mass percent % (0.09g) and curing agent 0.4% (0.12g).

[0038] The dispersant is a combination of one or more of sodium tripolyphosphate, sodium tetrapolyphosphate, sodium hexametaphosphate, ammonium polymethacrylate; the defoamer is a GPE type defoamer, polyether modified At least one of the permanent silicon...

Embodiment 2

[0057] A kind of marine anticorrosion coating 50g of the present invention, marine anticorrosion coating is made up of following components by mass percentage:

[0058]

[0059]

[0060] Wherein the film-forming substance is composed of 18% (9g) of water-based novolac epoxy resin and 15% (7.5g) of water-based polyurethane according to the mass percentage; the solvent is deionized water.

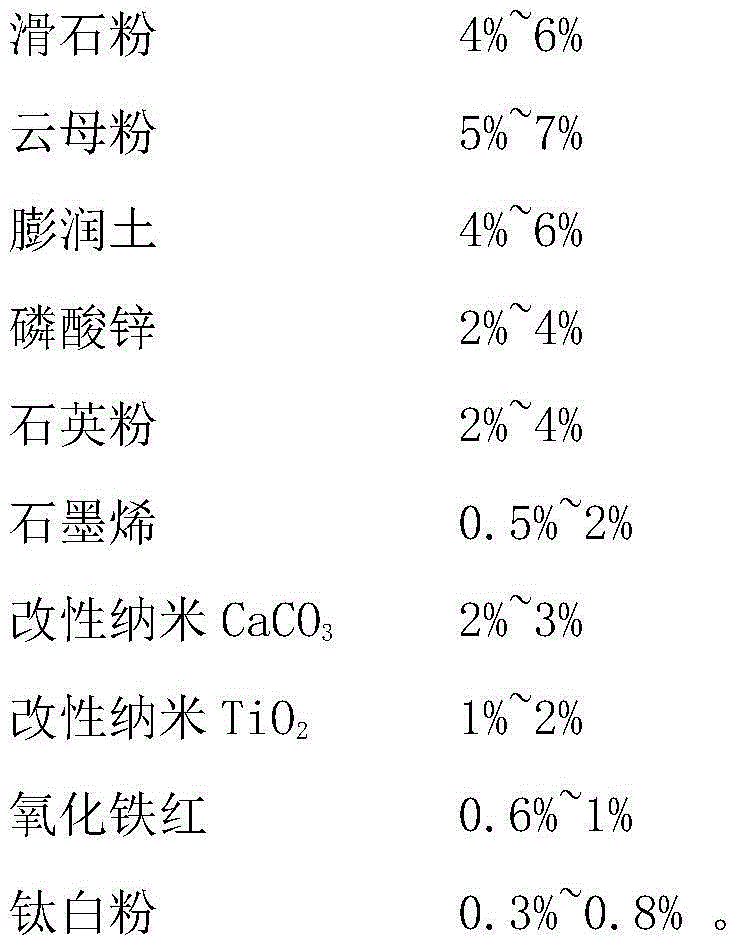

[0061] The pigments and fillers are composed of the following components by mass percentage:

[0062]

[0063] The auxiliary agent is composed of dispersant 0.8% (0.4g), defoamer 0.7% (0.35g), coupling agent 3% (1.5g), cosolvent 3% (1.5g), thickener 0.4% by mass percent % (0.2g) and curing agent 0.5% (0.25g).

[0064] The method for preparing above-mentioned marine anticorrosion paint, this comprises the following steps:

[0065] (1) Put the dispersant, 1 / 2 of the defoamer, talcum powder, iron oxide red, titanium dioxide, mica powder, bentonite, zinc phosphate and quartz powder int...

Embodiment 3

[0076] A kind of marine anticorrosion paint 100g of the present invention, marine anticorrosion paint is made up of following components by mass percentage:

[0077]

[0078] Wherein the film-forming substance is composed of 17% (17g) of water-based novolak epoxy resin and 14% (14g) of water-based polyurethane according to the mass percentage; the solvent is deionized water.

[0079] The pigments and fillers are composed of the following components by mass percentage:

[0080]

[0081] Described auxiliary agent is by mass percent by dispersant 1.2% (1.2g), defoamer 1% (1g), coupling agent 5% (5g), cosolvent 4% (4g), thickener 0.5% (0.5 g) and curing agent 0.6% (0.6g).

[0082] The method for preparing above-mentioned marine anticorrosion coating, comprises the following steps:

[0083] (1) Put the dispersant, 1 / 2 of the defoamer, talcum powder, iron oxide red, titanium dioxide, mica powder, bentonite, zinc phosphate and quartz powder into the sand mill according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com