Patents

Literature

30results about How to "Adjustable content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

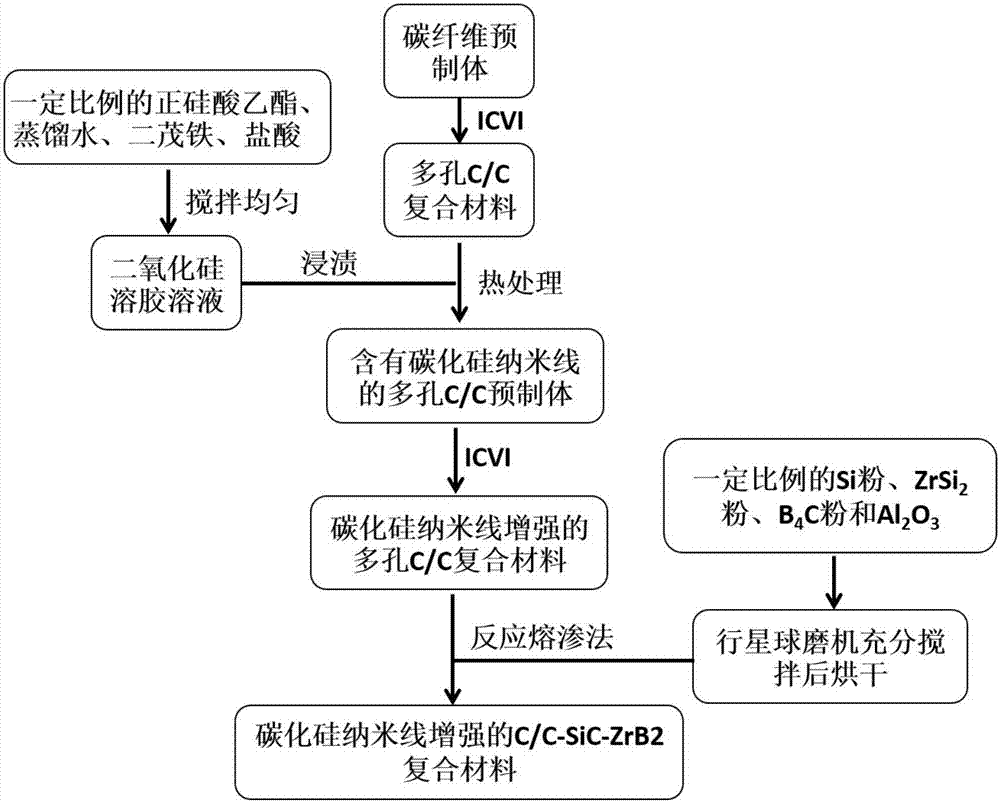

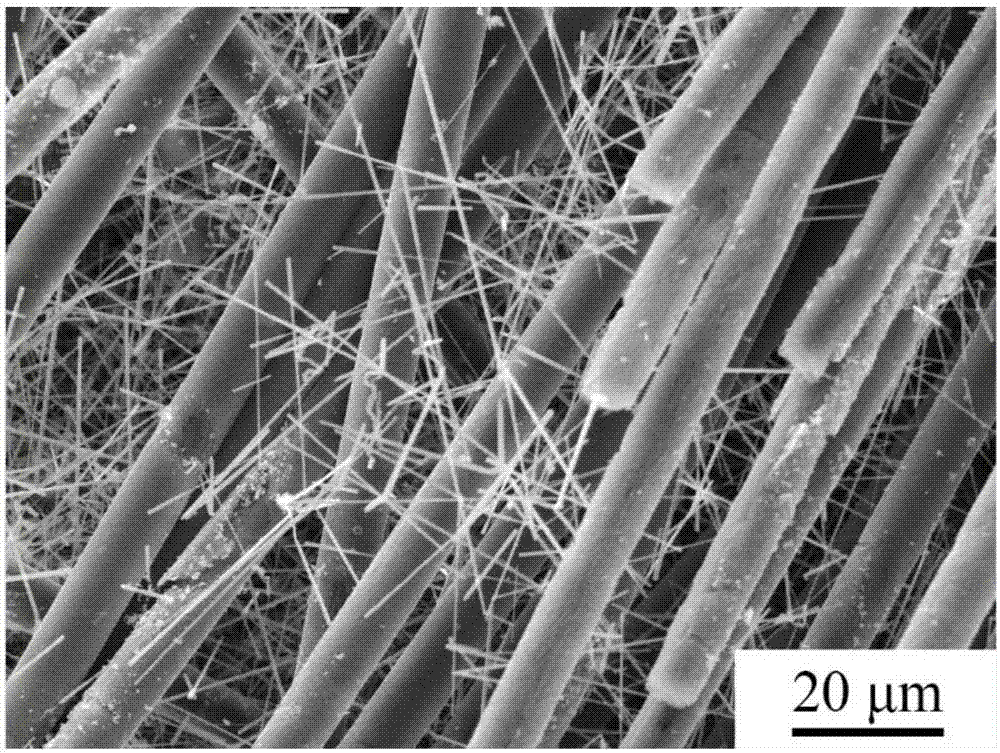

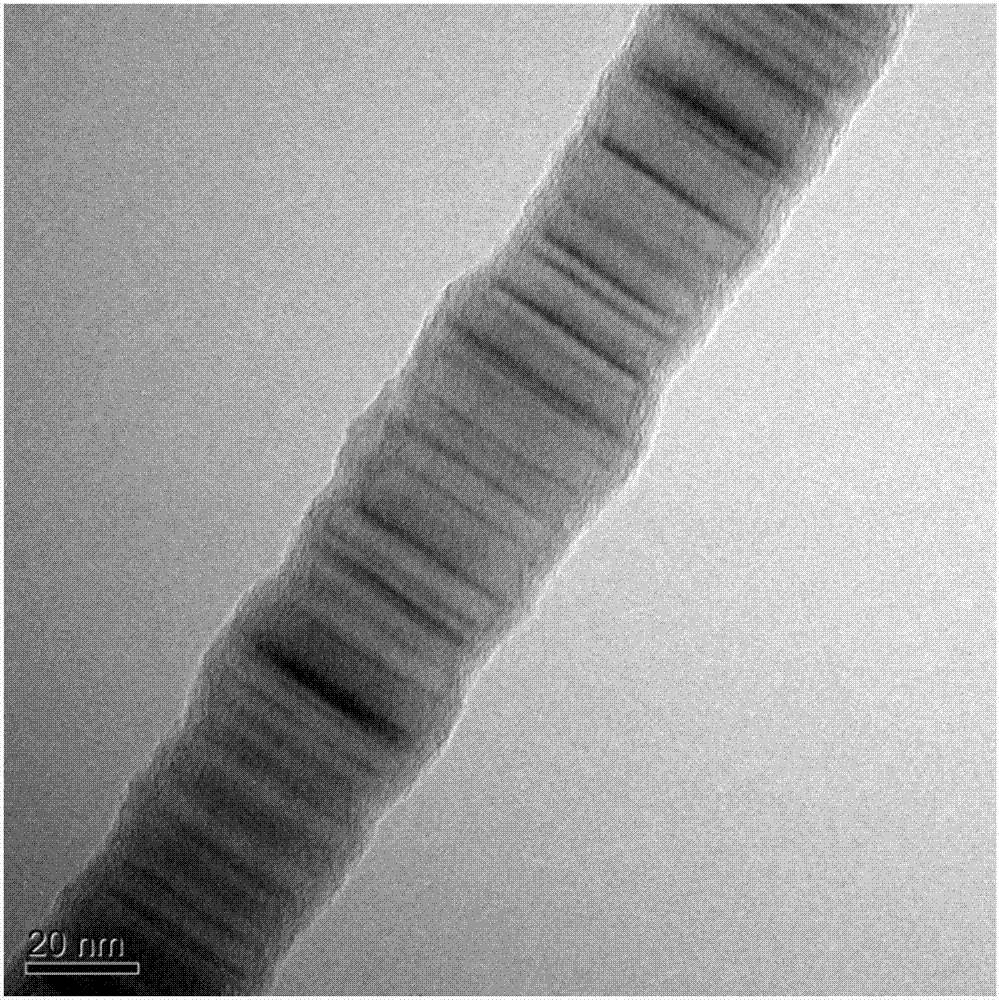

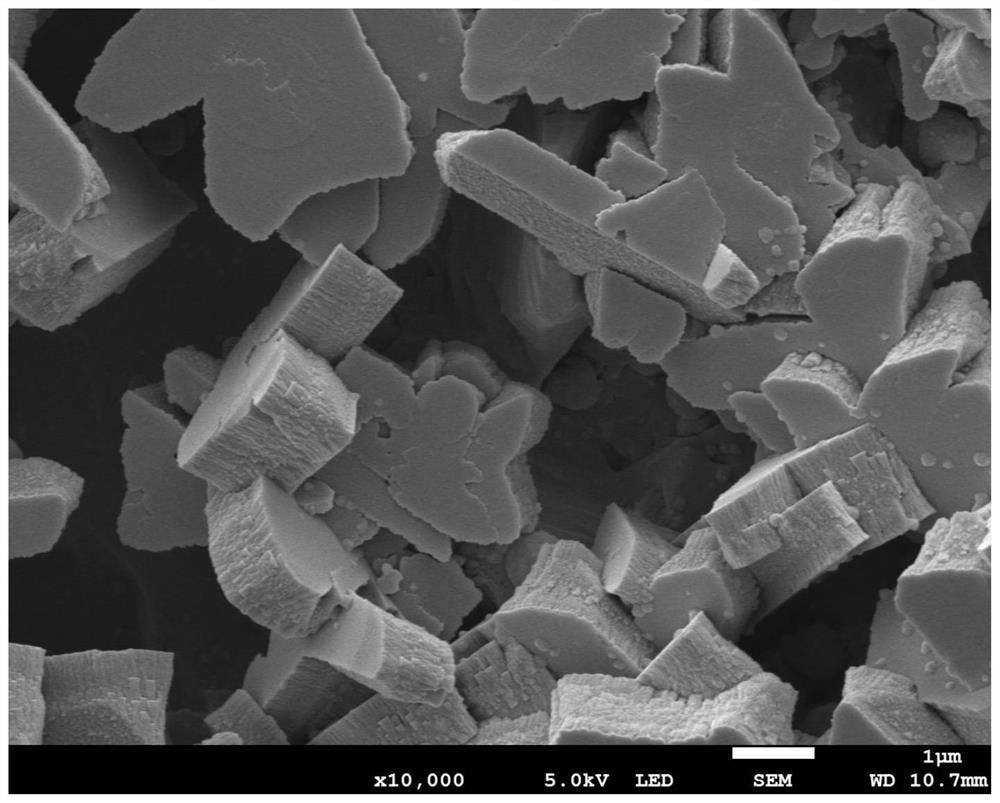

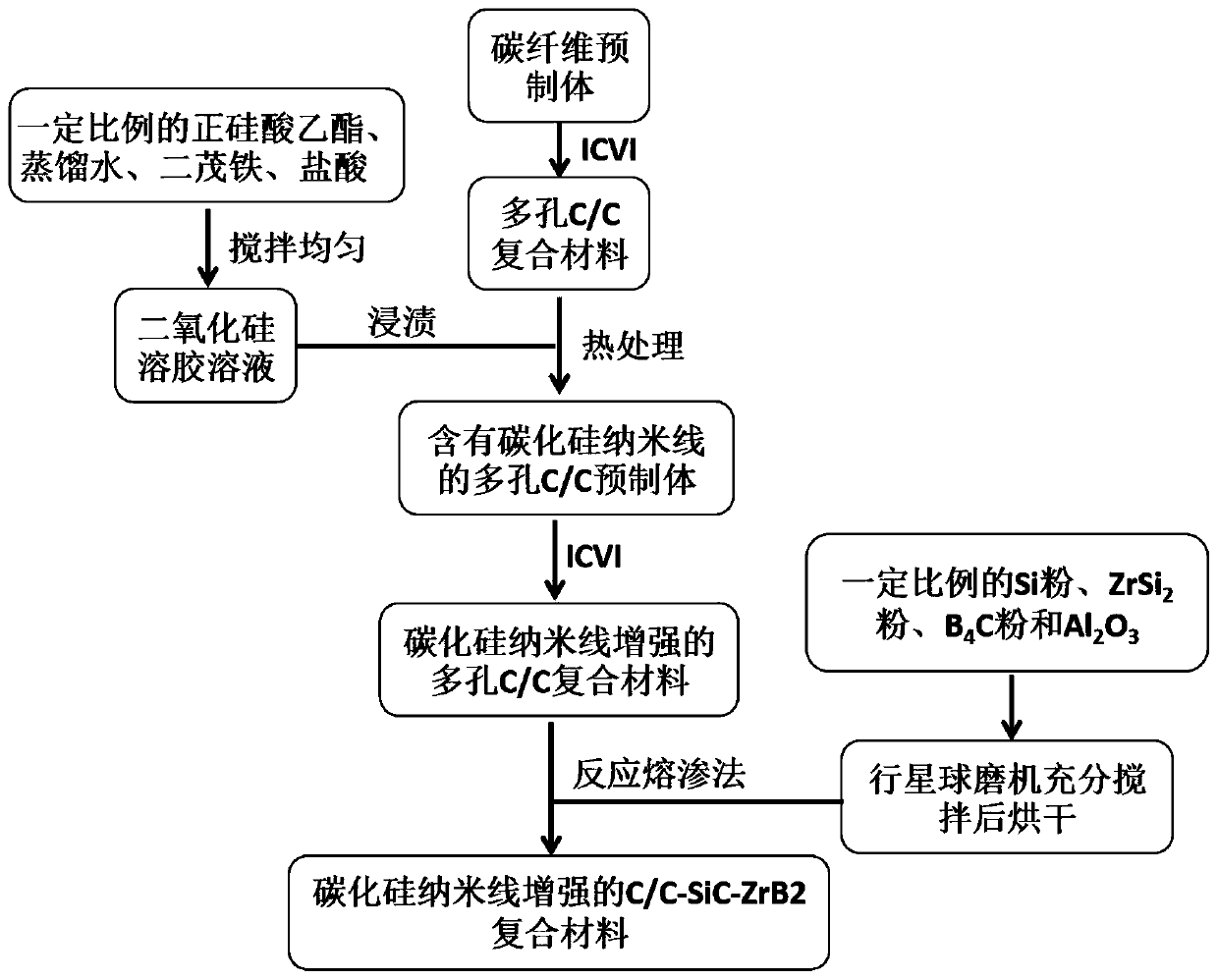

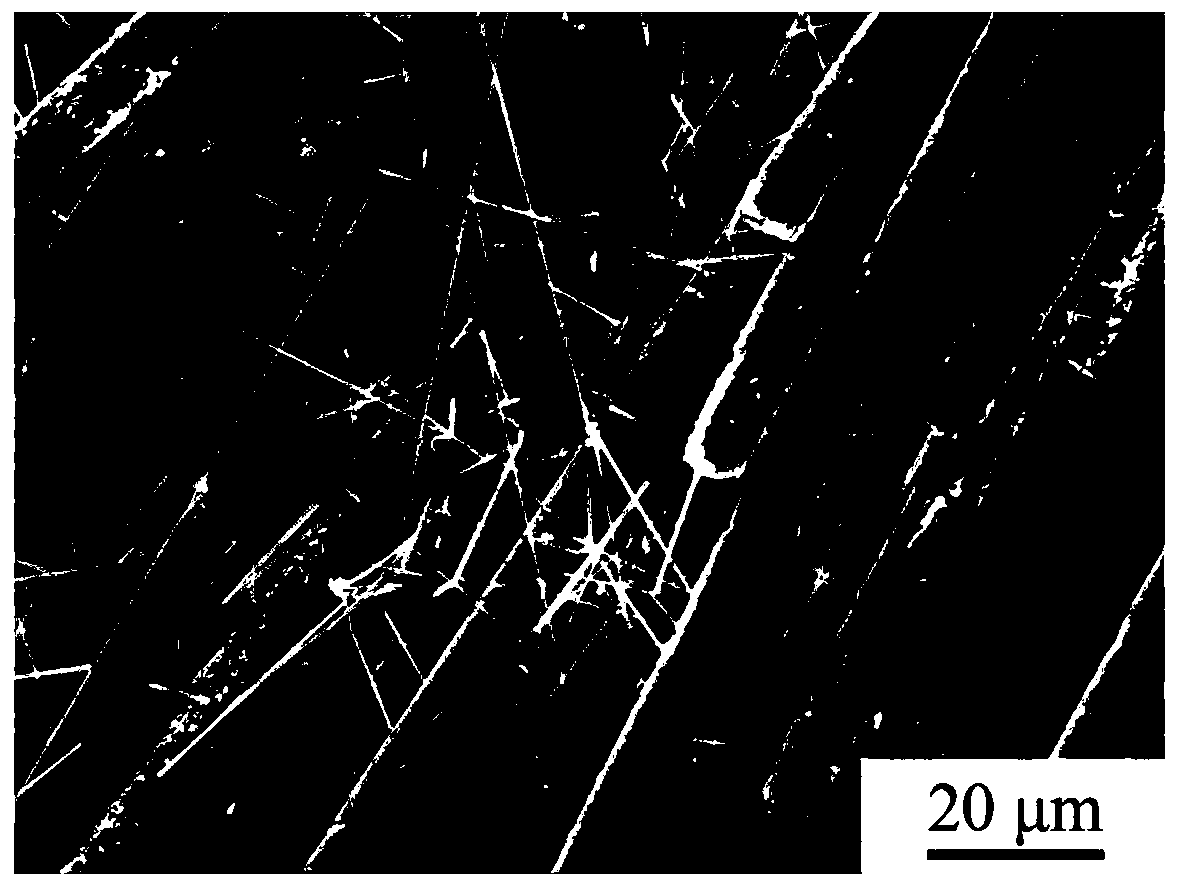

Preparation method of silicon carbide nanowire enhanced C/C-SiC-ZrB2 ceramic-based composite material

The invention relates to a preparation method of a silicon carbide nanowire enhanced C / C-SiC-ZrB2 ceramic-based composite material. A pretreated carbon fiber prefabricating body is thermally treated to obtain a silicon carbide nanowire. The silicon carbide nanowire prepared by a sol-gel carbon-thermal reaction method is evenly distributed at the inner part of a porous carbon / carbon composite material. Subsequently, pyrolytic carbon deposited in an isothermal chemical vapor deposition furnace is coated at the surface of the silicon carbide nanowire, thus the dropping, growing and rupture of the silicon carbide nanowire in the following reaction and infiltration processes are effectively avoided. A ceramic-based composite material carbon fiber, a silicon carbide nanowire and a pyrolytic carbon middle layer after reaction and infiltration are not eroded by a high-temperature metal bath and are well preserved; thus the physical performance of the composite material can be improved. Compared with the C / C-SiC-ZrB2 ceramic-based composite material without adding the silicon carbide nanowire, the bending strength and the fracture toughness property of the silicon carbide nanowire enhanced C / C-SiC-ZrB2 ceramic-based composite material are improved by 26.9-41.3% and 45.2-59.1% respectively.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

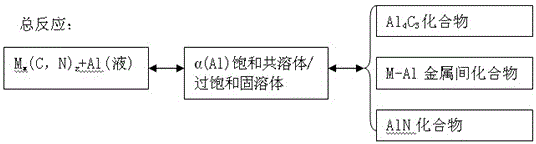

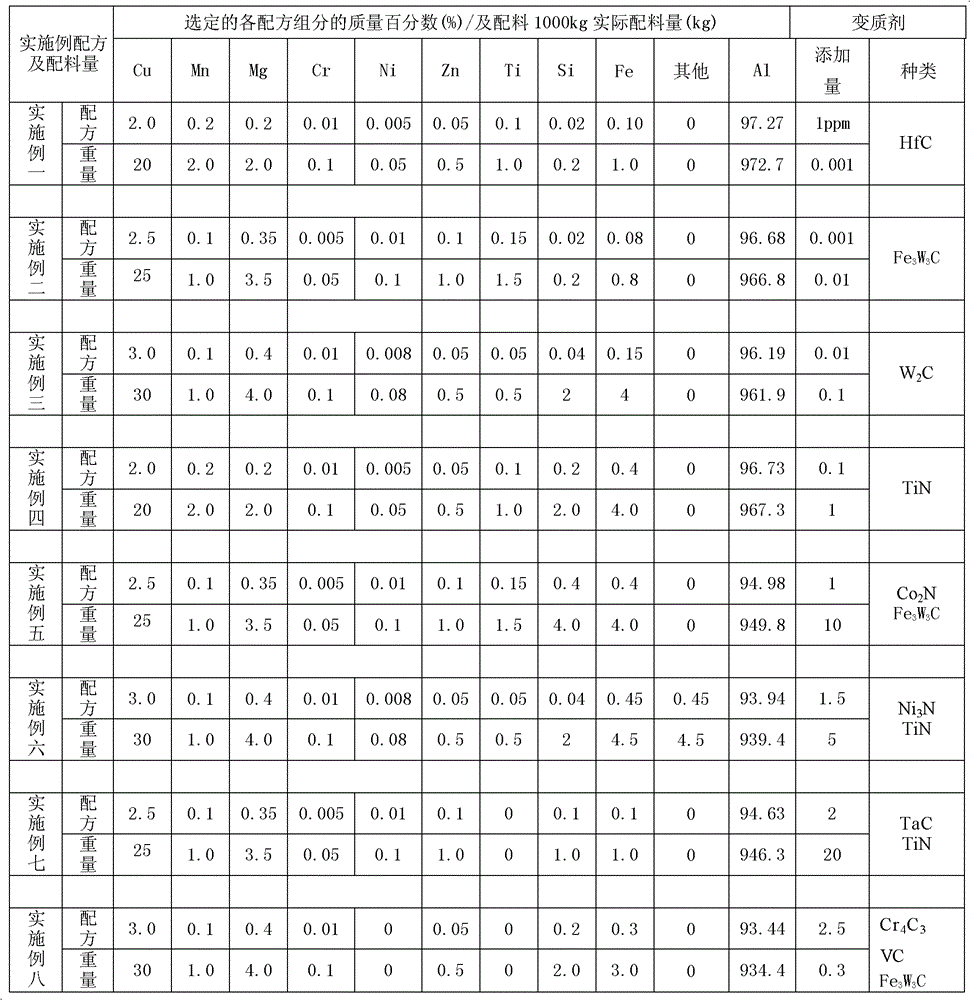

High-strength aluminum alloy subjected to carbonitride complex treatment and preparation method thereof

The invention discloses a high-strength aluminum alloy subjected to carbonitride complex treatment and a preparation method thereof. The alloy comprises the following components in percentage by weight: 2.0-3.2 percent of Cu, less than or equal to 0.2 percent of Mn, 0.2-0.5 percent of Mg, less than or equal to 0.01 percent of Cr, less than or equal to 0.01 percent of Ni, less than or equal to 0.1 percent of Zn, less than or equal to 0.15 percent of Ti, less than or equal to 0.5 percent of Si, less than or equal to 0.5 percent of Fe, and the balance of Al and inevitable trace impurities, wherein the carbonitride MX(C,N)Y is 0.05-2.5 percent of total mass of the furnace burden. The aluminum alloy has the characteristics of high strength and good casting performance.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

Polyvinylidene fluoride anti-pollution membrane and preparation method thereof

ActiveCN107149882AEasy to makeLow preparation equipment requirementsMembranesSemi-permeable membranesPhase conversionUltraviolet

The invention discloses a polyvinylidene fluoride anti-pollution membrane and a preparation method thereof, and belongs to the field of environmental functional membrane materials. The preparation method comprises: (1) self-polymerizing dopamine on the surface of polyvinylidene fluoride powder, and adhering the generated poly dopamine functional layer onto the surface of the polyvinylidene fluoride powder; (2) preparing a poly dopamine modified polyvinylidene fluoride membrane by using a phase conversion method; and (3) depositing a nano-TiO2 functional layer on the membrane prepared in the step (2) through a liquid phase deposition method to prepare the polyvinylidene fluoride anti-pollution membrane. According to the present invention, by combining the strong adhesion and the polyfunctional group of poly dopamine, the ultraviolet resistance and stable chemical performance of polyvinylidene fluoride, and the advantages of hydrophilicity, high photocatalytic activity and the like of nano-TiO2, the polyvinylidene fluoride anti-pollution membrane is developed; and the prepared polyvinylidene fluoride anti-pollution membrane has excellent pollution resistance, and can be used in various membrane separation fields.

Owner:天津鼎芯膜科技有限公司

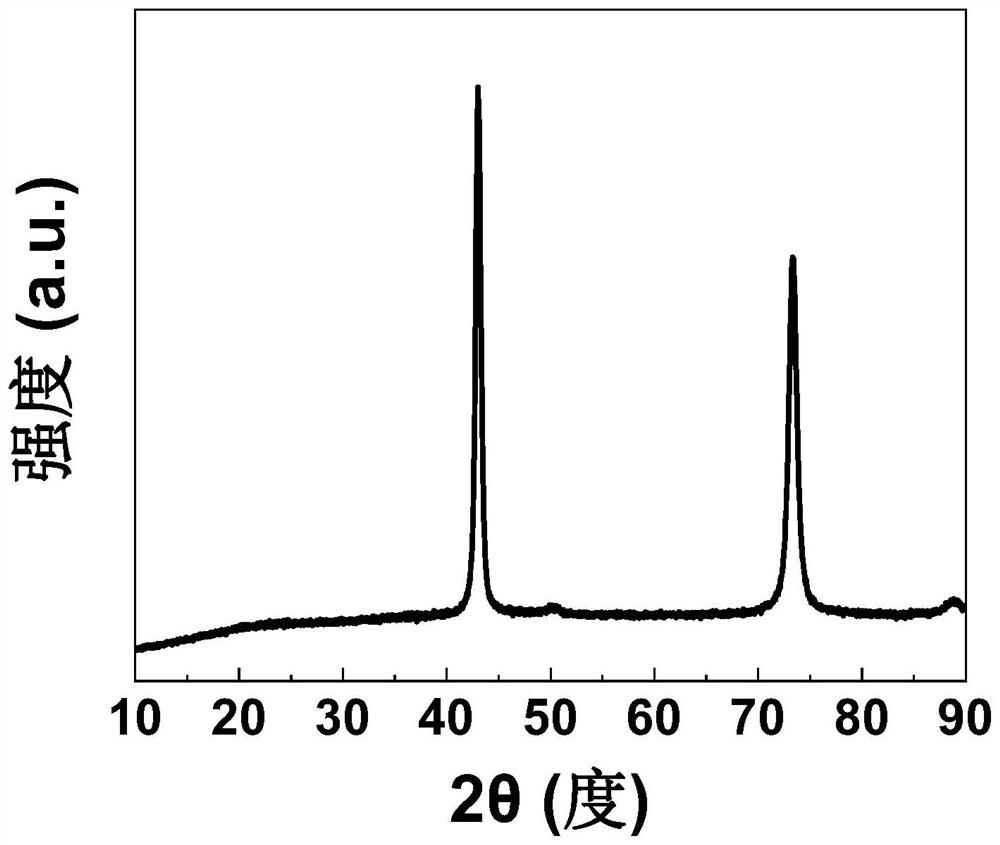

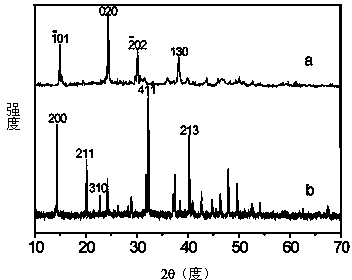

Method for preparing SSZ-39 molecular sieve by taking fluorine-modified Y-type molecular sieve as raw material

ActiveCN110950354AImprove pore structureIncrease the rate of crystallizationMolecular sieve catalystsHydrocarbon from oxygen organic compoundsDispersityPtru catalyst

The invention discloses a method for preparing an SSZ-39 molecular sieve by taking a fluorine-modified Y-type molecular sieve as a raw material. The method comprises the following steps: dipping a Y-type molecular sieve in a fluorine-containing aqueous solution, and drying and roasting the Y-type molecular sieve to obtain a fluorine-doped Y-type molecular sieve; mixing and stirring deionized water, an alkali source, a template agent and a silicon source well in proportion, and adding the fluorine-doped Y-type molecular sieve to prepare sol; and transferring the sol into a crystallization kettle, filtering, washing and drying the crystallization product after complete crystallization, carrying out ion exchange, and carrying out roasting to obtain a hydrogen type SSZ-39 molecular sieve. According to the invention, the Y-type molecular sieve raw material is modified by a fluorine doping method, so that the SSZ-39 molecular sieve can be prepared by complete crystal transformation in a short time under the condition of relatively low silica-alumina ratio, and the raw material and production costs can be obviously reduced. The SSZ-39 molecular sieve prepared by the method has the characteristics of short crystallization time, high crystallinity, controllable grain size, good grain dispersity and the like, and can be applied to the fields of methanol-to-olefin reaction, carriers of selective catalytic reduction catalysts and the like.

Owner:CHINA CATALYST HLDG CO LTD

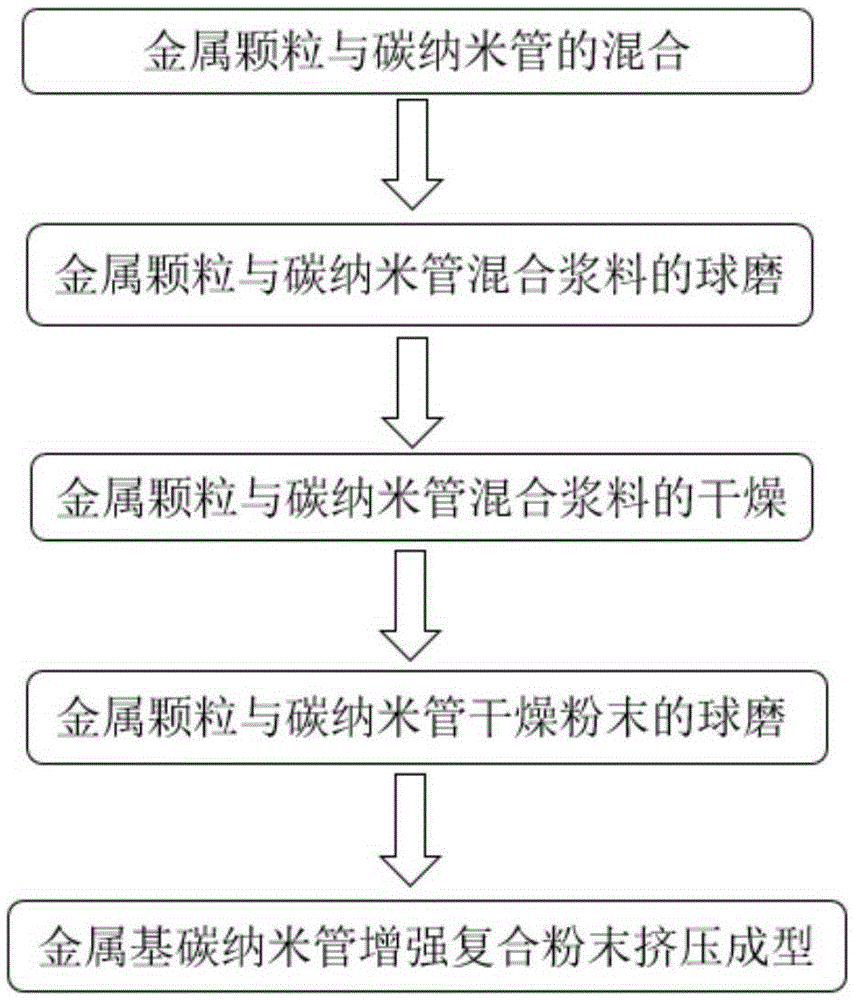

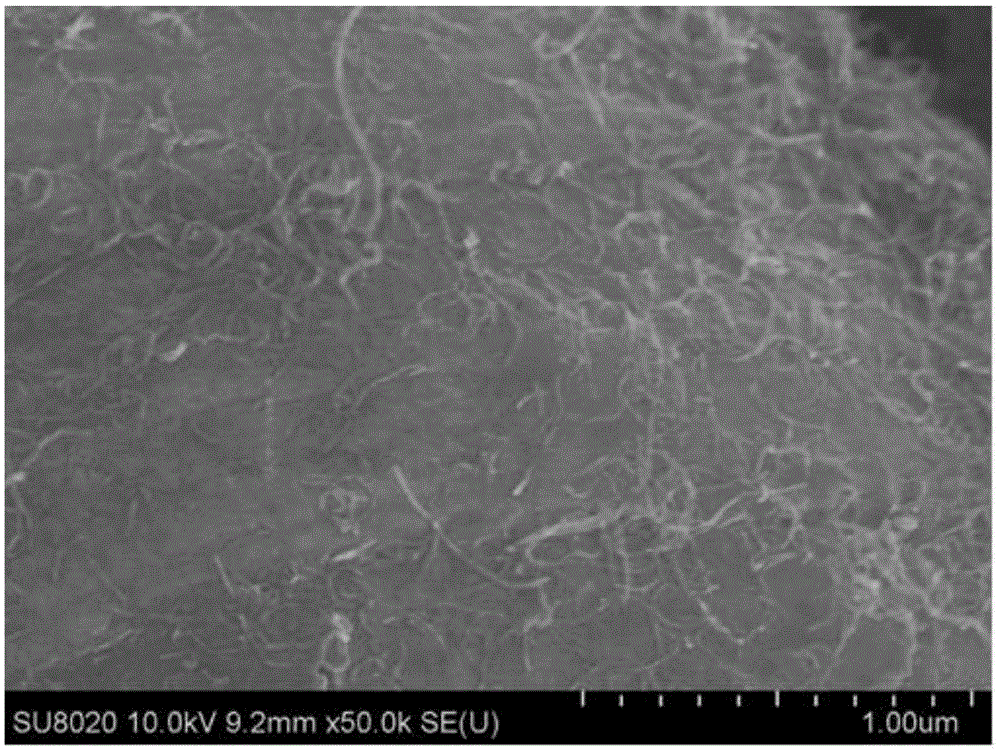

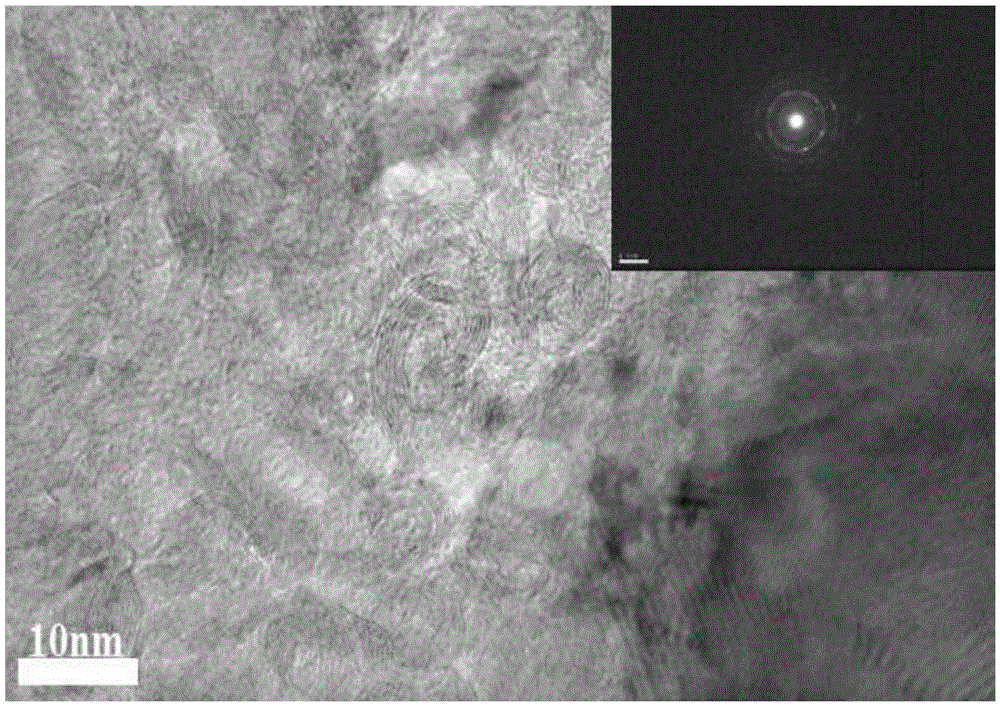

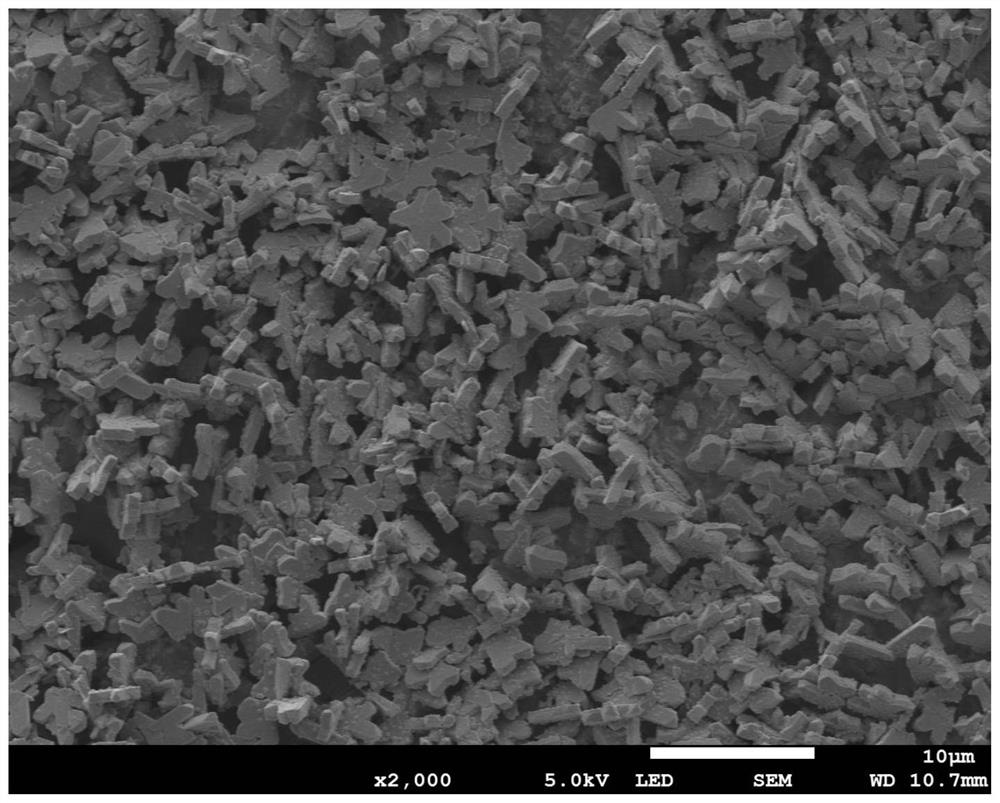

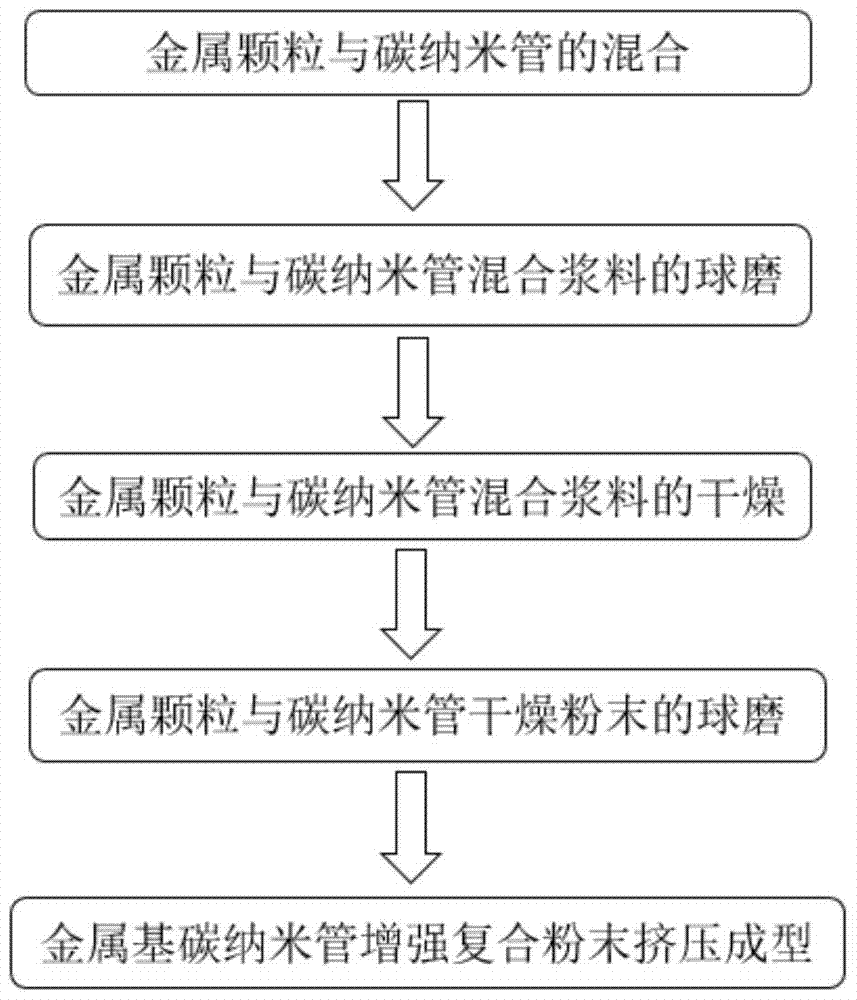

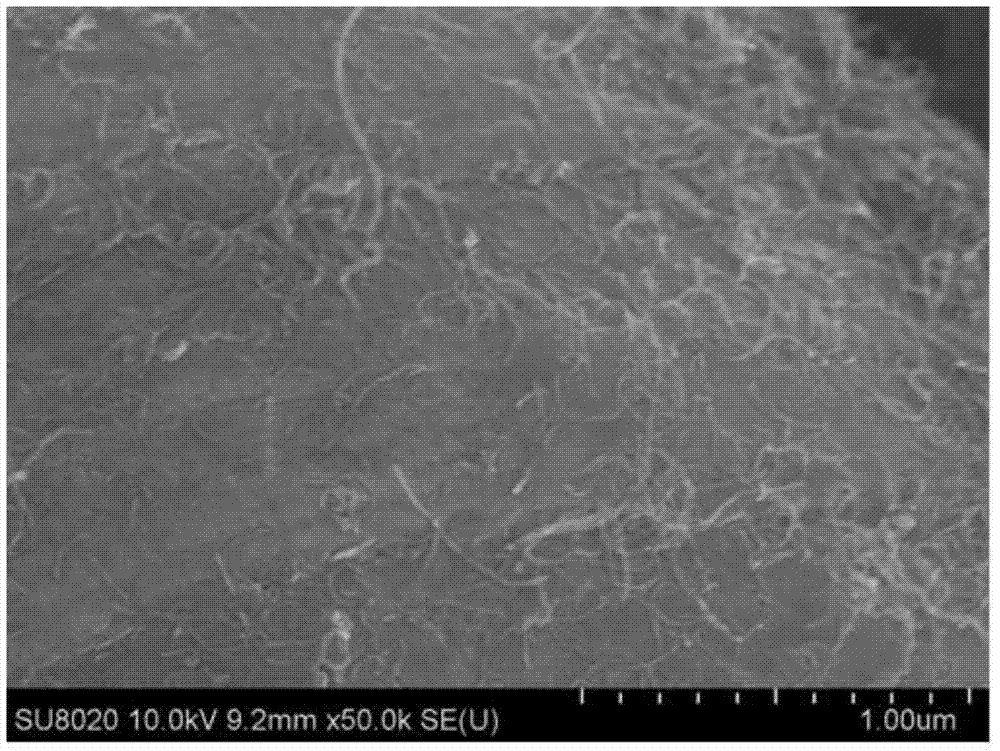

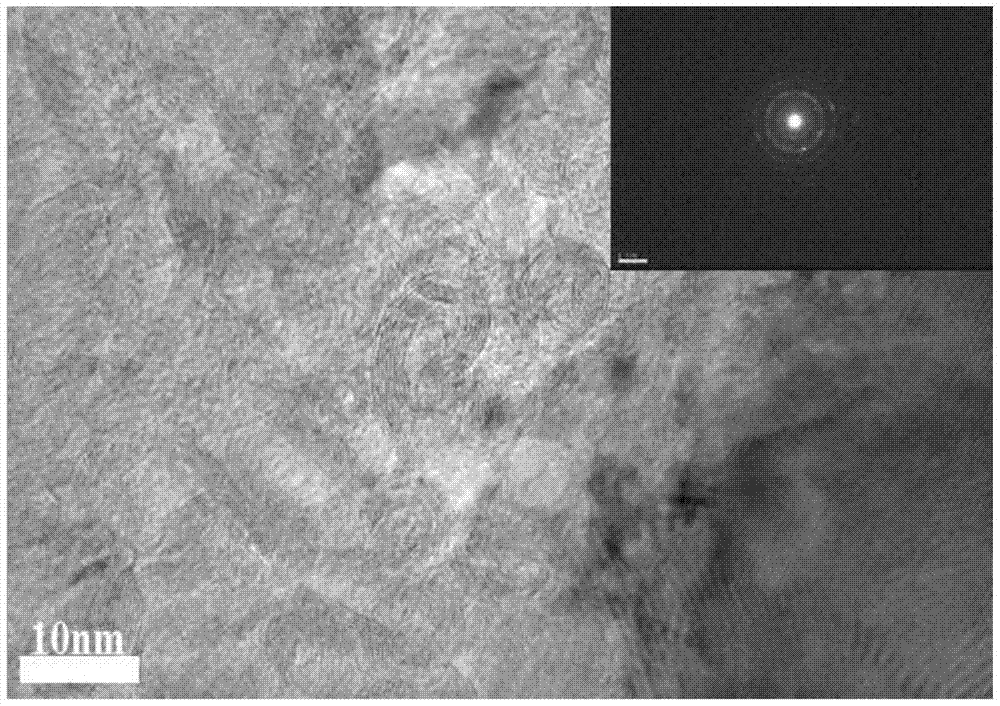

Preparation method of metal-based carbon nanotube reinforced composite material

The invention discloses a preparation method of a metal-based carbon nanotube reinforced composite material, and belongs to the field of preparation of metal-based composite materials. The method uses a series of process flows for uniformly dispersing carbon nanotubes and metal particles to obtain the metal-based carbon nanotube reinforced composite material. The method comprises the following specific steps: (1) the metal particles and the carbon nanotubes are mixed; (2) the ball grinding is performed for metal particle and carbon nanotube mixed slurry; (3) the metal particle and carbon nanotube mixed slurry is dried; (4) the ball grinding is performed for metal particle and carbon nanotube dried powder; and (5) metal-based carbon nanotube reinforced composite powder is molded through extruding. The method has such characteristics as simple preparation process, environmental protection and possession of large-scale application potential, and is suitable for such fields as aerospace and vehicle manufacturing having the high-mass and high-strength material demands.

Owner:BEIJING UNIV OF TECH

Diary product good for brain and reproduced food

The present invention is dairy product and reprocessed food with some health components and thus health function. The present invention features that each kilogram of the said dairy product contains the following components: DHA 10-200 mg, AA 10-300 mg, vitamin E 30-30 mg, vitamin B1 0.5-2 mg and taurine 20-100 mg, and the milk components; and each kilogram of the said reprocessed food contains the following components: DHA 0.5-20 mg, AA 0.5-50 mg, vitamin E 100-200 mg, vitamin B1 3-8 mg and taurine 300-500 mg and other food components. The present invention makes the dairy product and the food contain rich DHA and AA, prevents the oxidation and rancidity of DHA and AA, the makes the dairy product and the food good for brain.

Owner:赵桂华

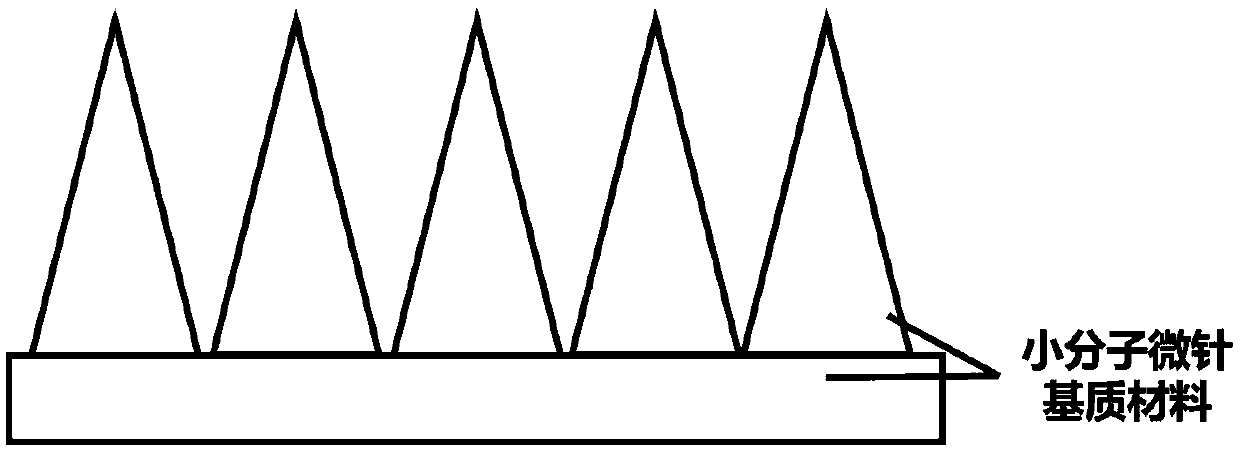

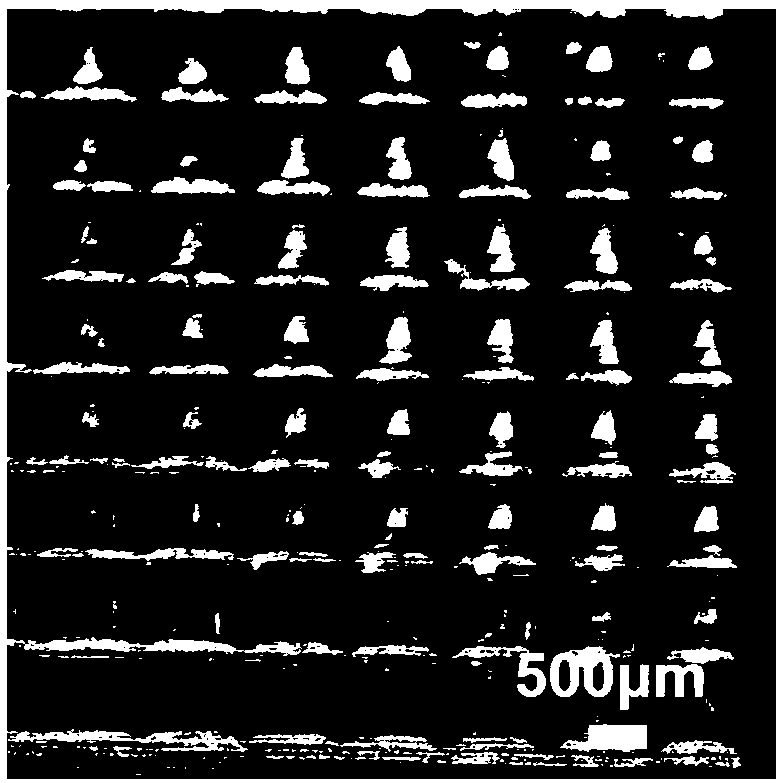

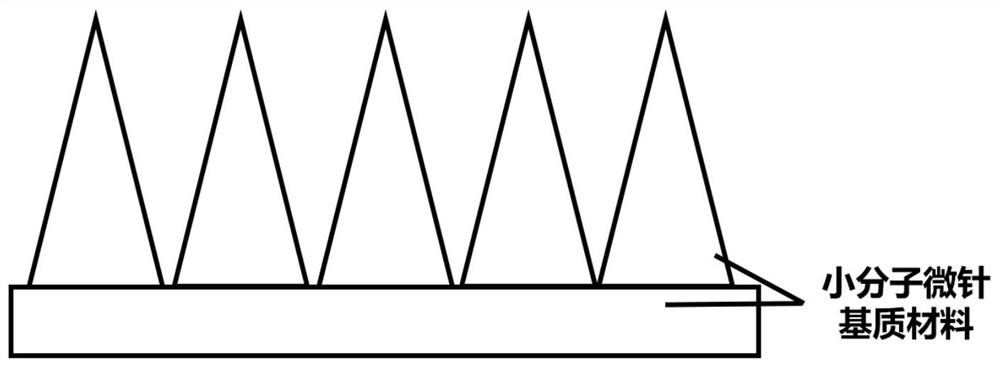

Micro-needle capable of being rapidly dissolved based on water-soluble small molecules as well as preparation and application of micro-needle

ActiveCN109674737AEasy to prepareSuitable for mass productionOrganic active ingredientsPharmaceutical delivery mechanismWater solubleAqueous solution

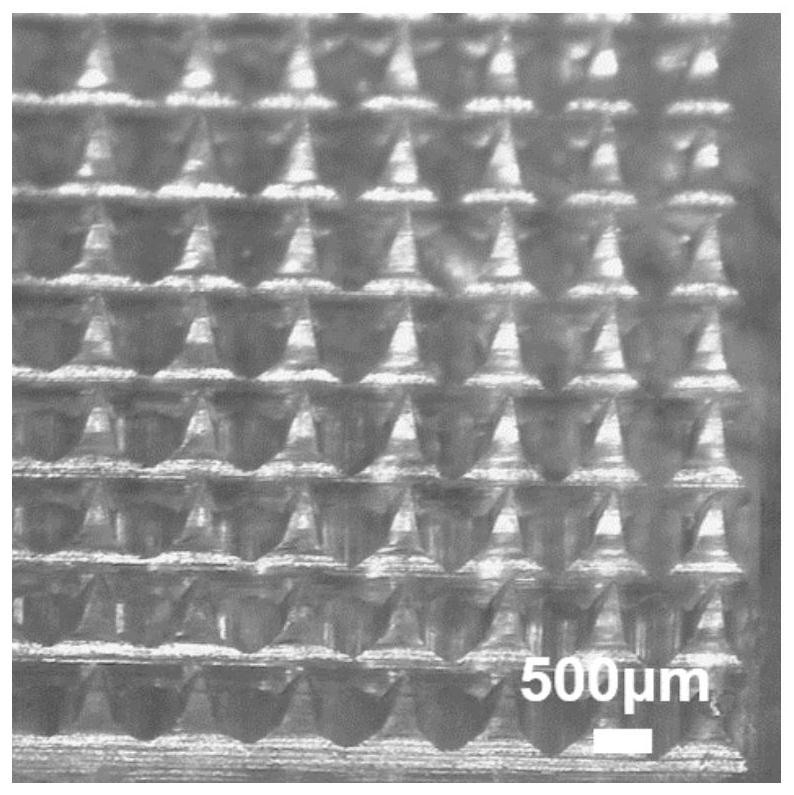

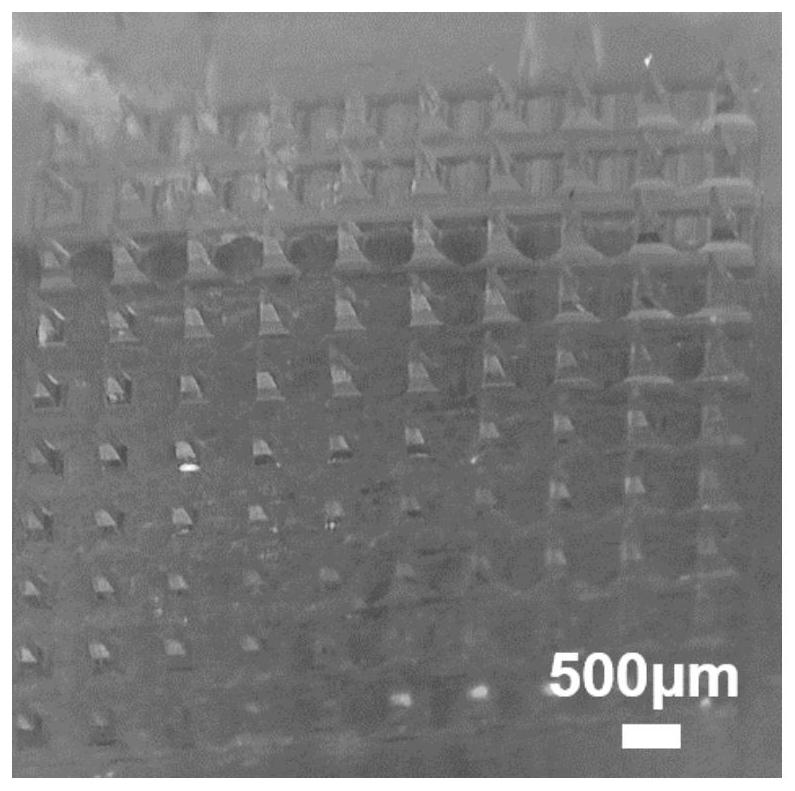

The invention belongs to the technical field of drug administration appliances and discloses a micro-needle capable of being rapidly dissolved based on water-soluble small molecules as well as a preparation and application of the micro-needle. The preparation method specifically comprises the following steps: firstly, taking a water-soluble small molecular material as a solute to prepare a small molecular water solution; then loading the small molecular water solution into a micro-needle mould; drying and de-molding so as to obtain the micro-needle capable of being rapidly dissolved based on the small molecules. According to the preparation method provided by the invention, a whole technological flow design and conditions and parameters (such as small molecule types and the concentration of water solutions of the small molecules) of each step are improved, so that the small molecular water-soluble micro-needle with an extremely rapid dissolving speed and good mechanical properties canbe prepared; compared with the prior art, the problems of a current high molecular water-soluble micro-needle that the time of a preparation process is long, the dissolving speed of the micro-needle is slow and the like can be effectively solved.

Owner:武汉楚颜生物科技有限公司

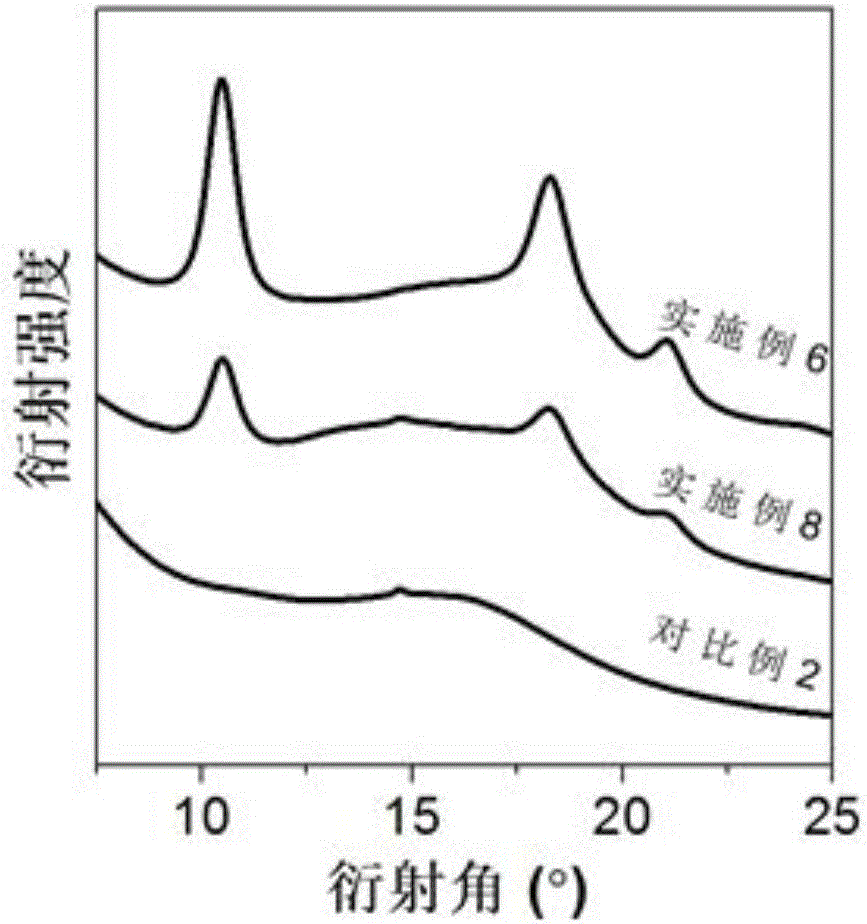

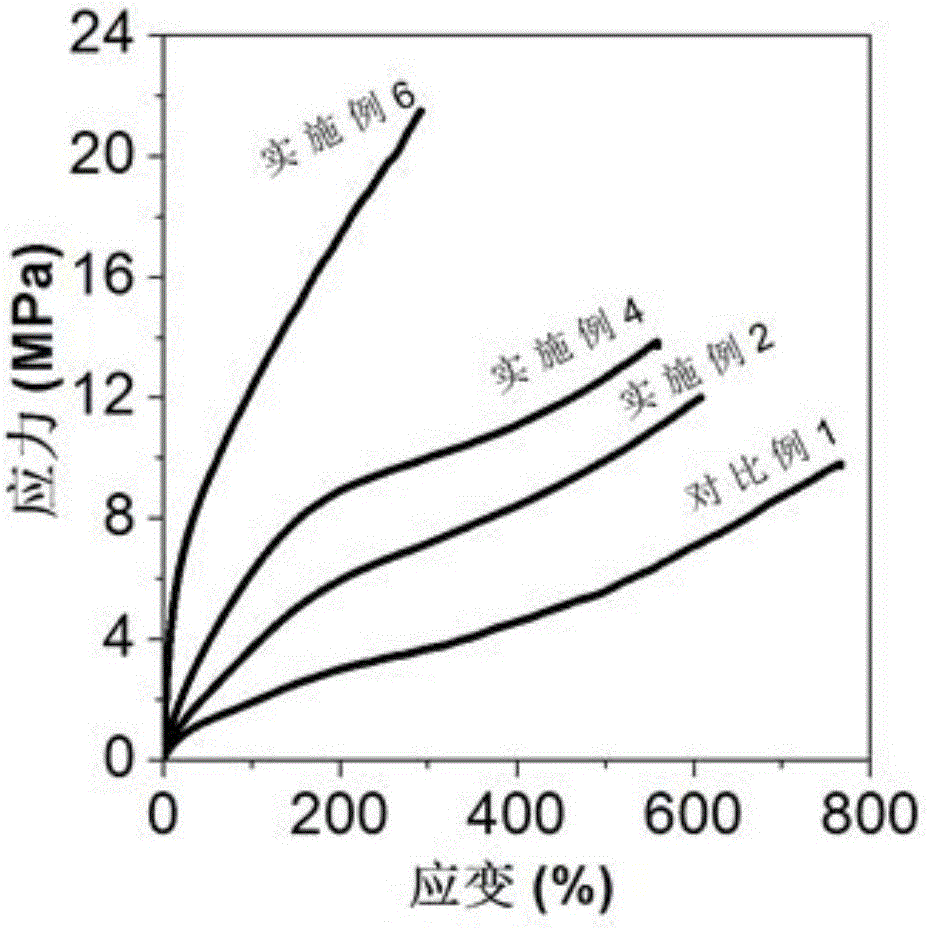

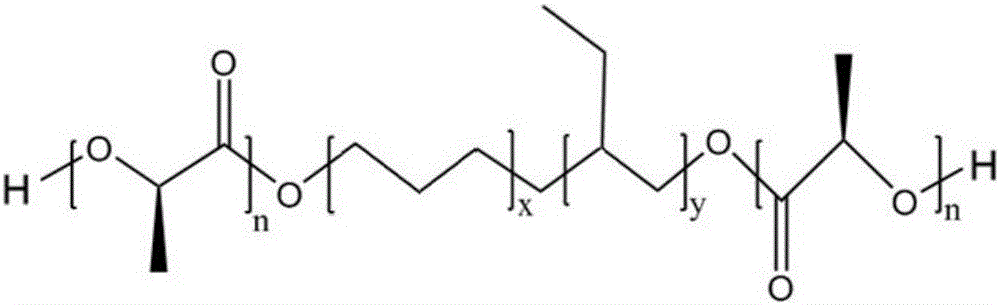

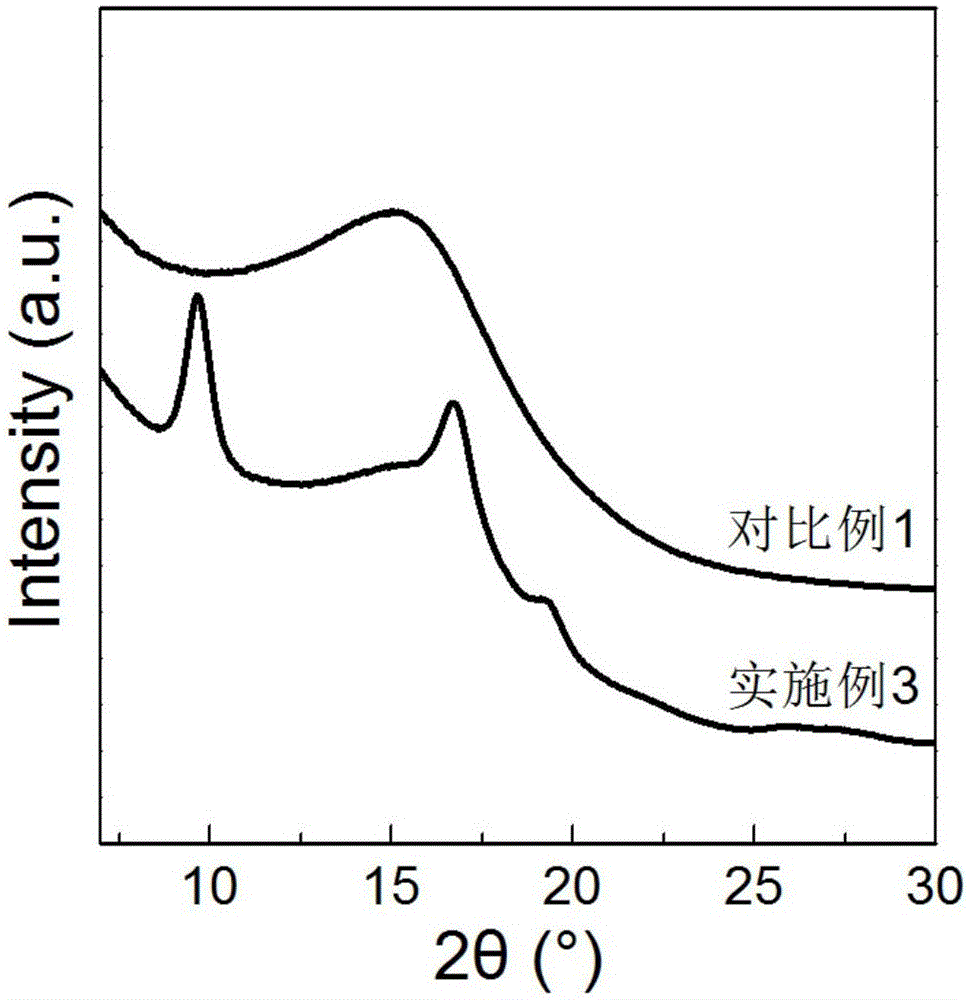

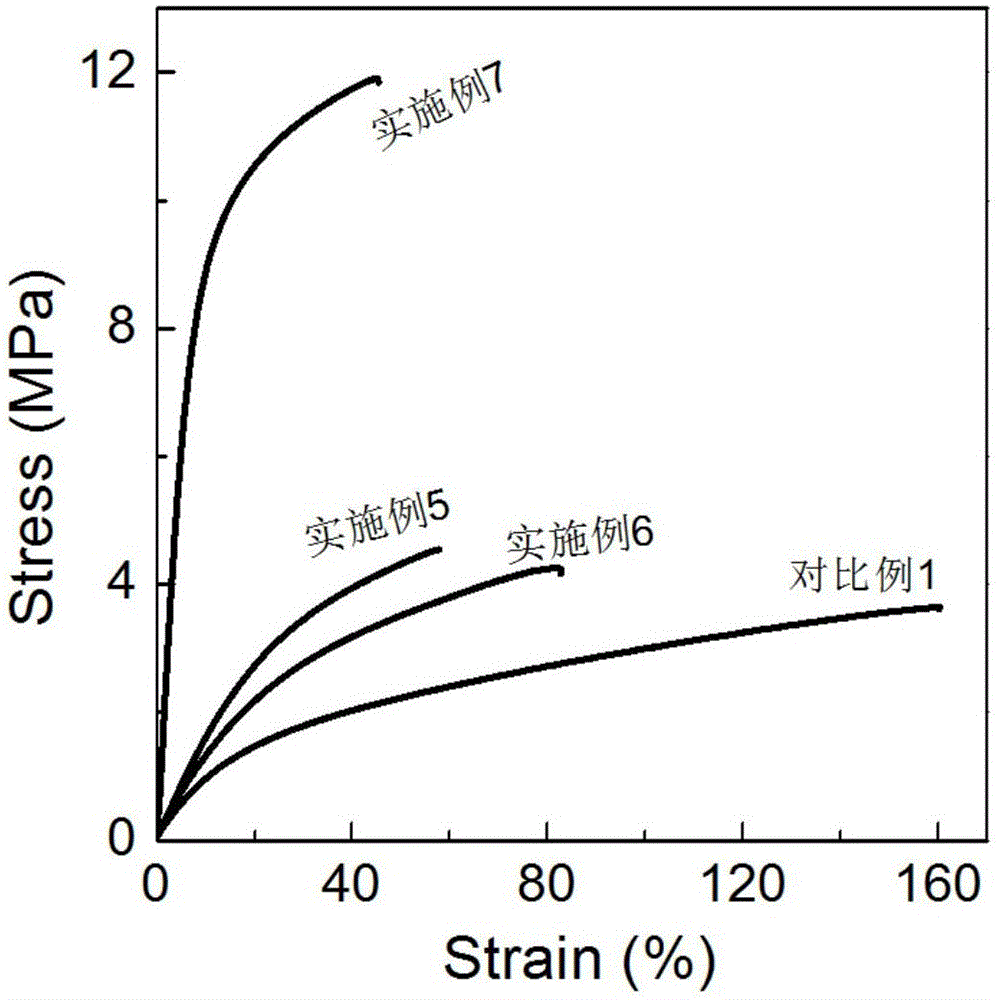

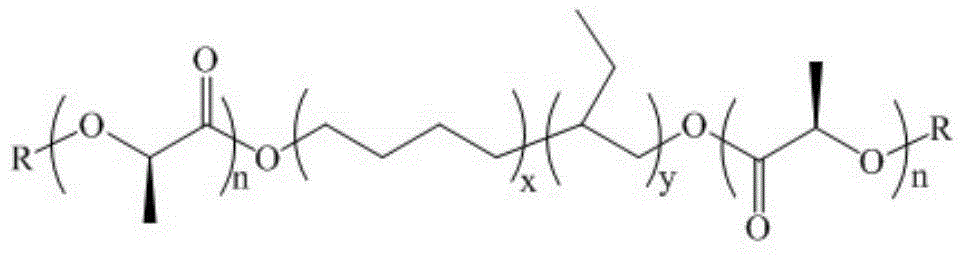

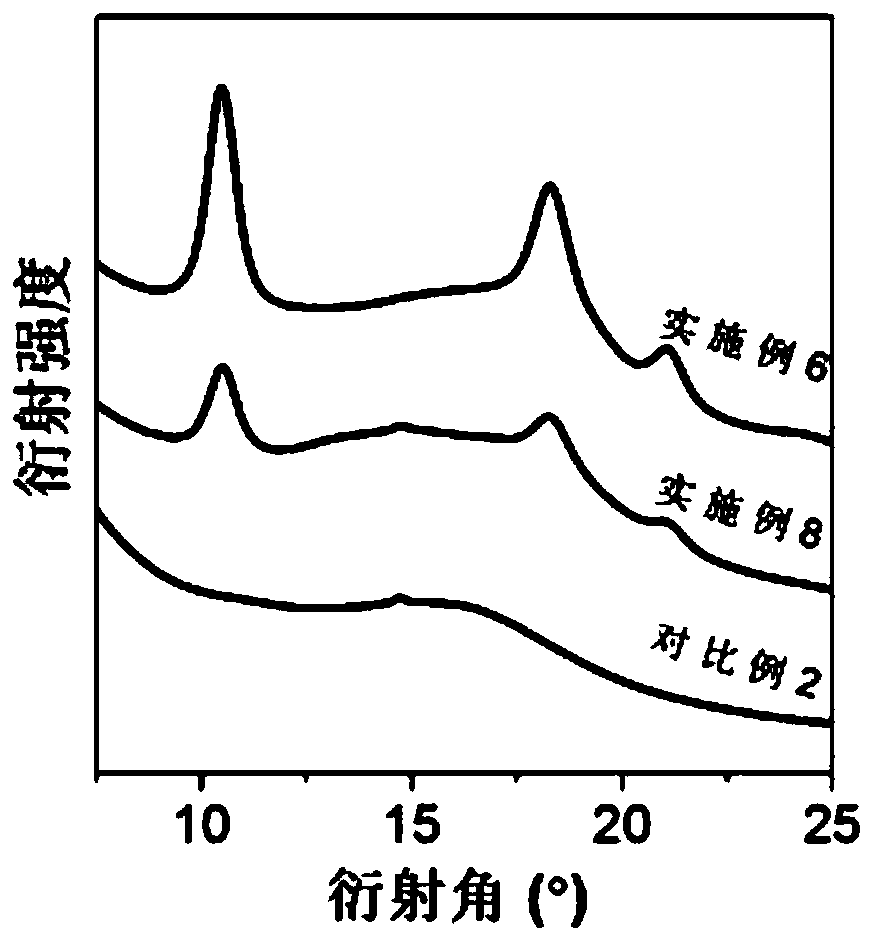

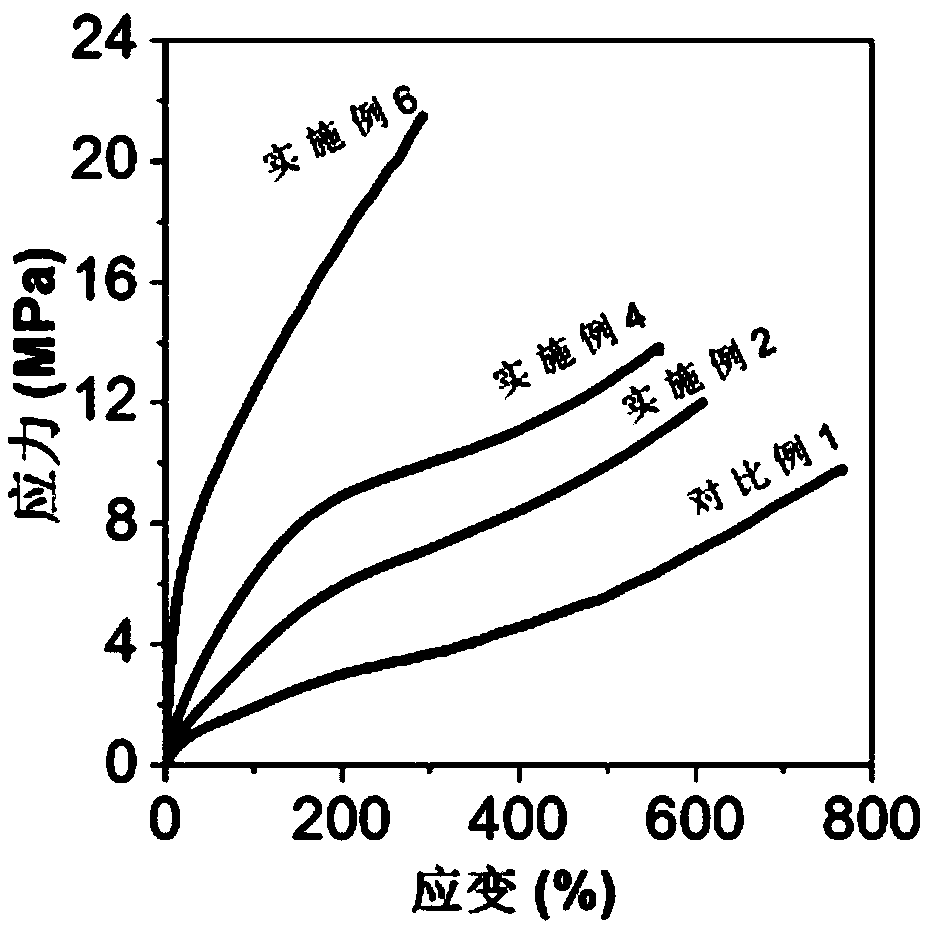

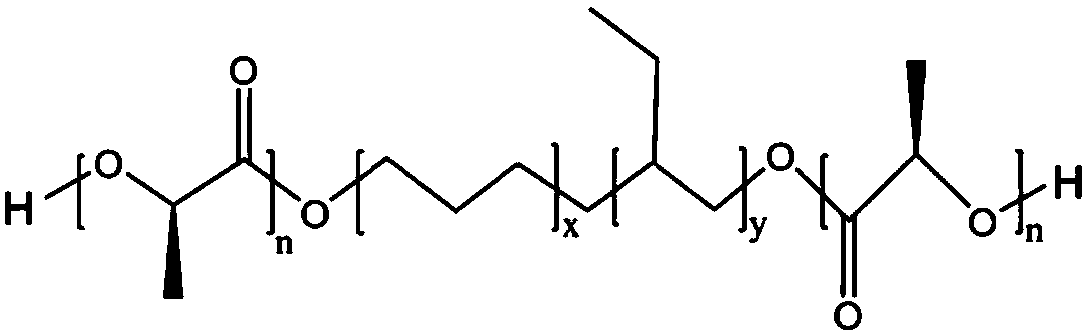

Preparation method of polyurethane elastomer containing stereoregular complex crystal

The present invention relates to a polyurethane elastomer technique and is intended to provide a preparation method of polyurethane elastomer containing stereoregular complex crystal. The preparation method includes steps of dissolving PLLA-PEB-PLLA and PDLA-PEB-PDLA in toluene and cooling to obtain prepolymer solution; injecting toluene solution containing catalyst and chain extender (or crosslinking agent) into prepolymer solution for uniformly stirring, after the reaction, heating the solution in a vacuum oven, drying to be constant weight, and then obtaining the polyurethane elastomer containing the stereoregular crystal. The hardness of the elastomer can be crystallized, the melting point is high, and the mechanical strength and the modulus are high. By changing the mixing ratio of the two components, the content of the stereoregular complex crystal can be adjusted to facilitate the regulation of the mechanical strength, modulus and heat resistance; the hard segments of the elastomer are bio-based and biodegradable PLLA and PDLA, which are environment friendly, green and resource saving.

Owner:ZHEJIANG UNIV

Steric compound crystal controlled polylactic acid/hydrogenated polybutadiene supermolecular elastomer

The invention relates to the technology of macromolecular thermoplastic elastomers, and aims to provide a steric compound crystal controlled polylactic acid / hydrogenated polybutadiene supermolecular elastomer. The product is composed of two compounds which are UPy-PLLA-PEB-PLLA-UPy and UPy-PDLA-PEB-PDLA-UPy respectively; in the UPy-PLLA-PEB-PLLA-UPy, chiral carbon in a PLLA block is of a left-handed structure; in the UPy-PDLA-PEB-PDLA-UPy, chiral carbon in a PDLA block is of a right-handed structure; and in the two compounds, the UPy-PLLA-PEB-PLLA-UPy occupies 10% to 90%, and the UPy-PDLA-PEB-PDLA-UPy occupies 90% to 10%. The UPy bonded PLA / PEB supermolecular polymer elastomer is prepared by adopting steric compound crystallized PLLA / PDLA as a hard area and PEB as a soft segment, and the hard segment of the obtained elastomer can be crystallized, and the elastomer is high in melting point, strength and modulus; the content of steric compound crystal can be adjusted by changing the mixed proportion of the two compound, so that the strength, modulus and heat resistance of the elastomer are convenient to control; and by adopting the biology base and biology degradable PLLA and PDLA as the hard segment of the supermolecular elastomer, the pollution generated to the environment is little, the elastomer is green and environment-friendly, and the resources are saved.

Owner:ZHEJIANG UNIV

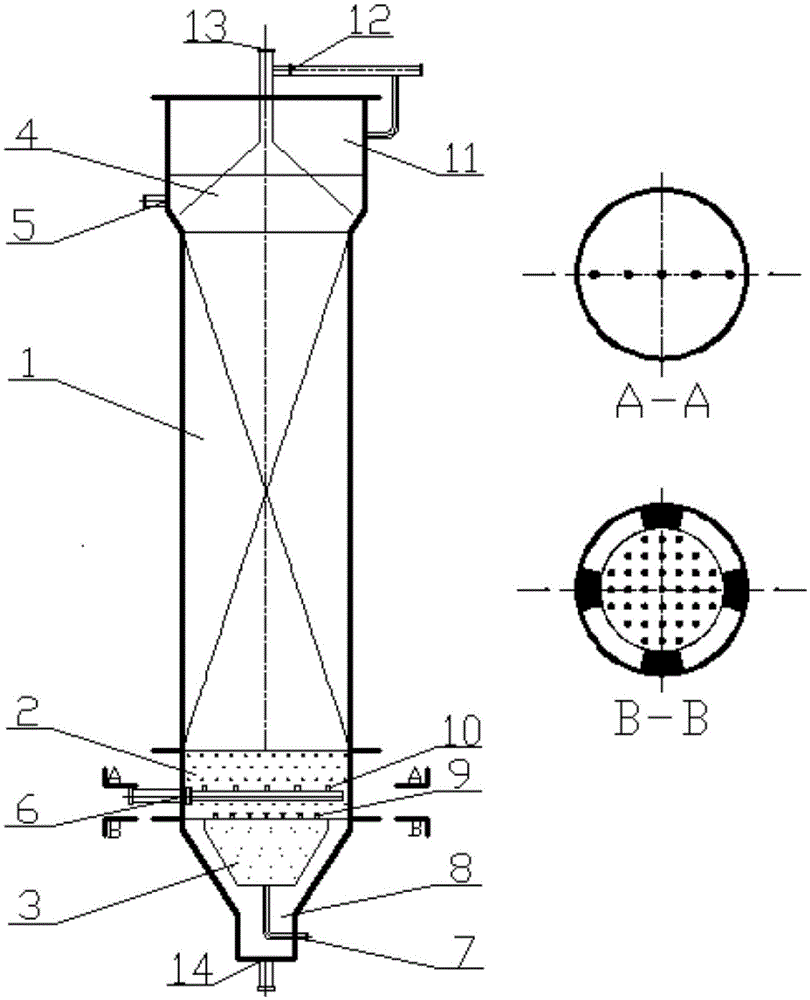

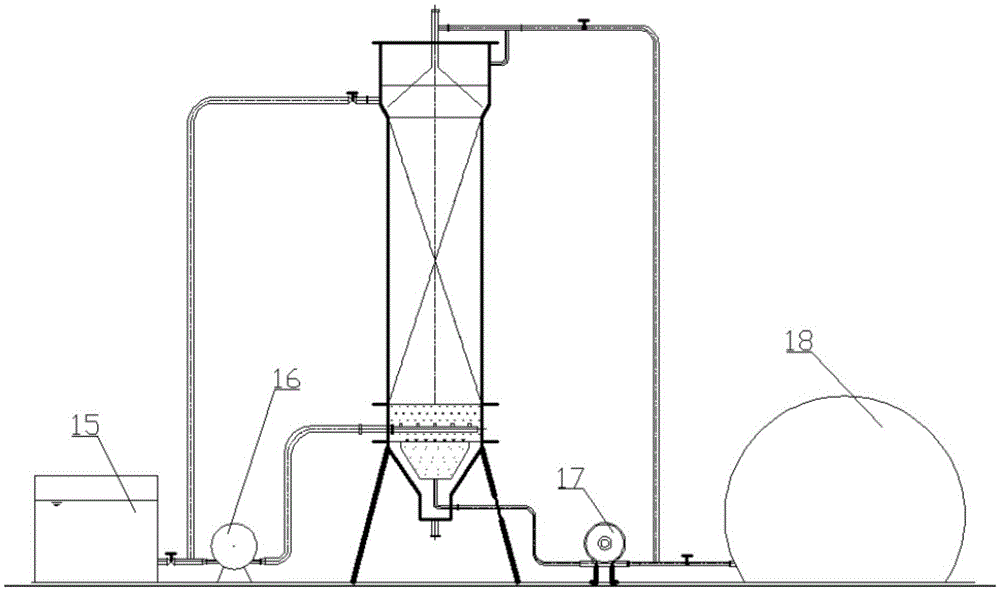

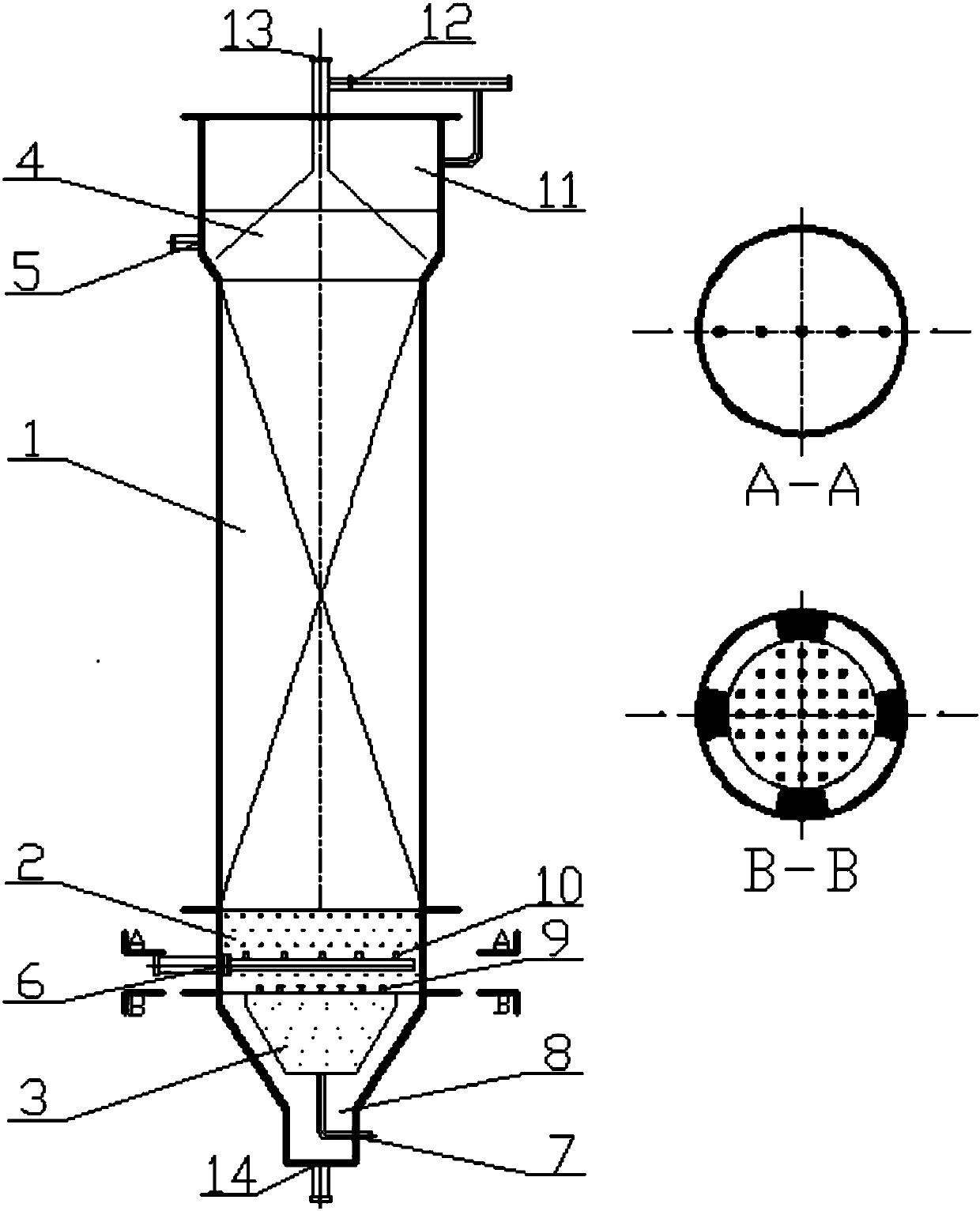

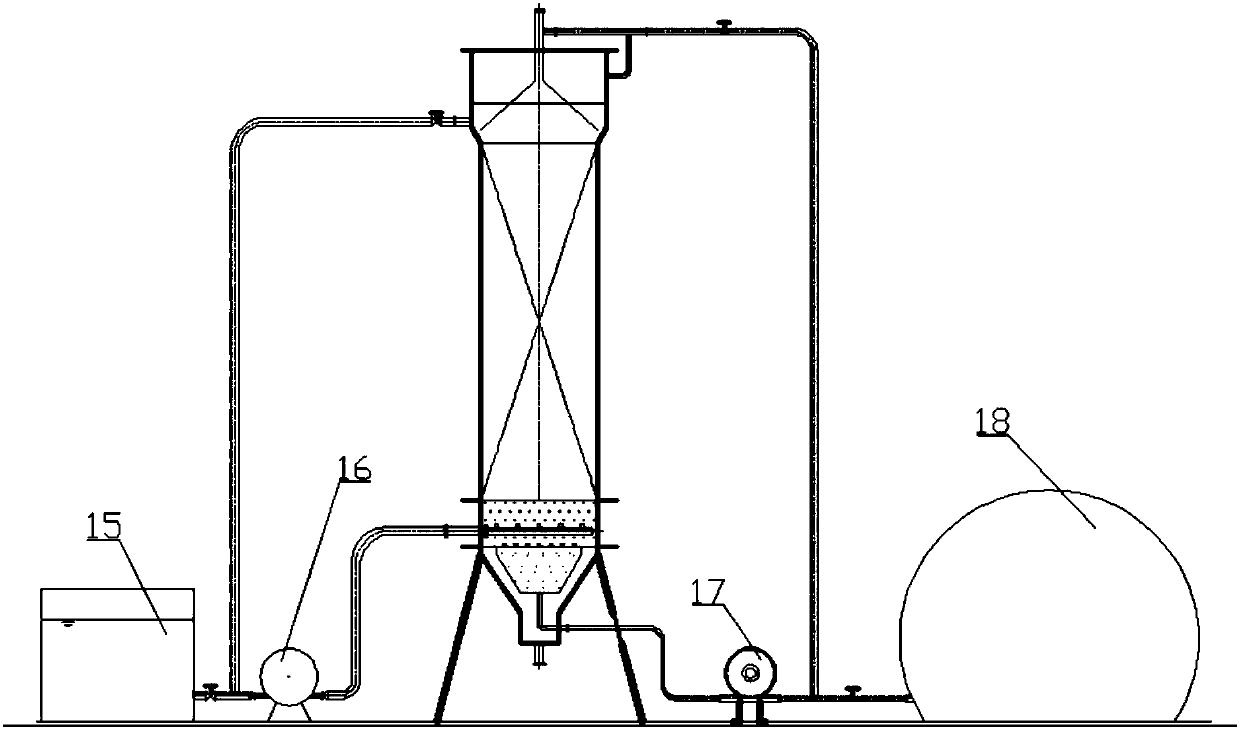

System device and method for synchronously realizing organic waste disposal and synthesis gas quality improvement

ActiveCN105645581AAchieve anaerobic digestionAchieve gas upgradingGaseous fuelsWaste based fuelSyngasMethanation

The invention discloses a system device and a method for synchronously realizing organic waste disposal and synthesis gas quality improvement. A core part of the system device is an anaerobic synthesis integrated reactor, wherein the anaerobic synthesis integrated reactor sequentially comprises a sludge discharge area, an aeration buffer area, a gas liquid mixing area, a microbial synthesis reaction area, a gas solid liquid separation area and a gas phase pressure stabilizing area from bottom to top. By adopting the system device, organic waste disposal and recycling production of methane in the anaerobic synthesis integrated reactor can be realized, and methanation quality improvement of synthesis gas also can be realized simultaneously. Compared with the prior art, the system device and the method have the advantages that by adopting a microbial technology, while the synthesis gas is led into the anaerobic synthesis integrated reactor to dispose organic waste, gas quality improvement and purification are realized, under normal temperature and normal pressure, most components, except methane, in the synthesis gas can be converted into methane, and a new method is provided for solving the problems of resource shortage, environment pollution, unreasonable energy structure, and the like in the energy field in China.

Owner:BEIJING UNIV OF CHEM TECH +1

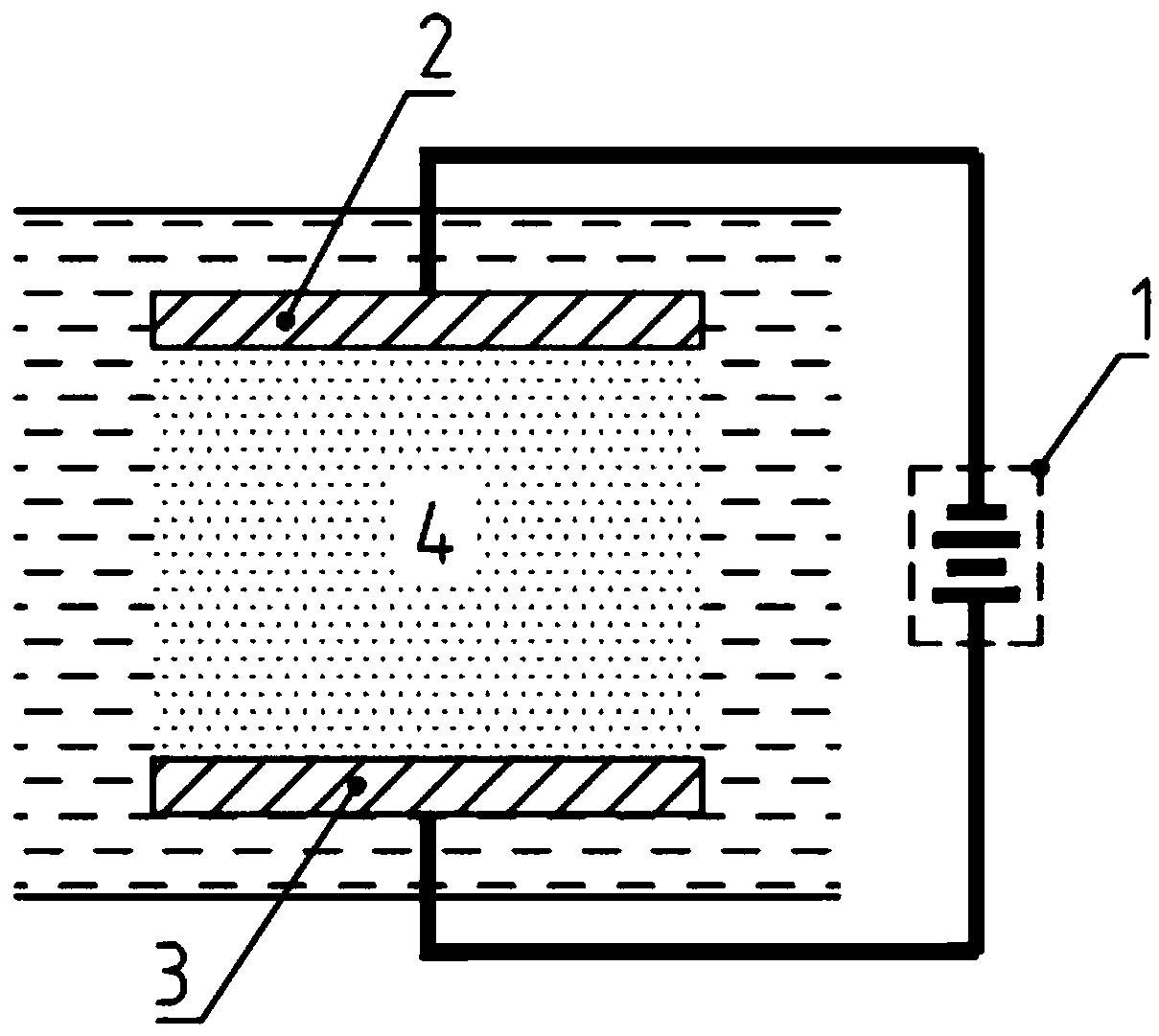

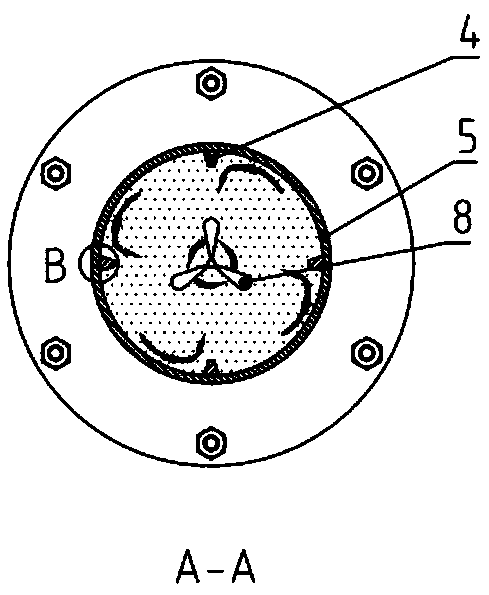

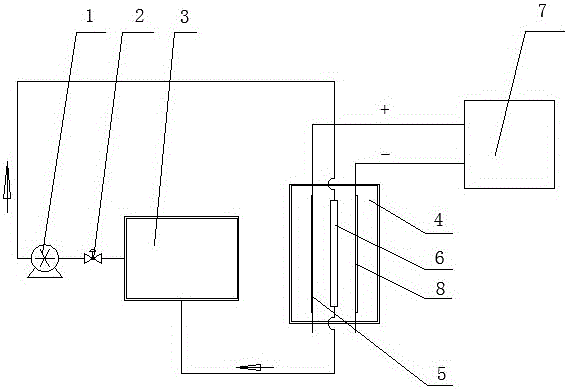

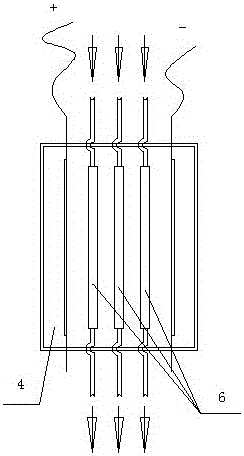

Electrochemical treatment method and device of carbon particles

ActiveCN109665513AGood dispersionImprove hydrophilicityAnodisationPhysical treatmentOxygenCarbon particle

The invention provides an electrochemical treatment method and device of carbon particles and mainly solves the technical problem that an existing acid oxidation process to treat carbon particles causes great corrosion on equipment and a grafting process fails to meet the environmental protection standard. A carbon particle suspension is placed between an anode and a cathode which are parallel andspaced; a constant voltage is applied between the cathode and the anode by an electrochemical method; by introducing current of constant strength or by means of cyclic voltammetry, the carbon particles are brought to contact with the surface of the anode, and oxygen-bearing nitrogen-bearing functional groups are generated by reacting. The method provided herein as a carbon particle surface treatment method, has the advantages that the raw material is easy to obtain, the cost is low, operation is simple, and large-scale preparation is available; the type, quantity and distribution of the functional groups are controllable.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

6082 aluminum alloy melted with cuh and preparation method of aluminum alloy

The invention discloses a 6082 aluminum alloy melted with CuH and a preparation method of the aluminum alloy. The method comprises the following steps of: heating aluminum ingots or molten aluminum till complete melting; adding Si, Fe, Mn, Mg, Cr, Zn and Ti, and completely dissolving and melting the elements; preserving the heat at the temperature of between 700 and 1,000 DEG C after refining, and obtaining an alloy melt; performing degassing purification operation on the alloy melt by using nitrogen or inert gas or mixed gas of the nitrogen and the inert gas in a random ratio, and continuously introducing the gas till the reaction is finished; adding CuH powder into the alloy melt in a fluidized form together with the gas; stirring to make the CuH distributed uniformly in the alloy melt and fully reacted with the alloy melt; and standing, regulating the temperature to 680-730 DEG C, and discharging the molten alloy for casting. By the method, the defects of the properties of the conventional aluminum alloy can be overcome, the toughness, the forming property and the hardening capacity of the aluminum alloy are improved, and a high-end base material is provided for efficient deep processing.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

Health preserving rice wine

InactiveCN106916709AGood health effectAdjustable contentDigestive systemAlcoholic beverage preparationTraditional Chinese medicineMedicine

The invention discloses a health preserving rice wine preparation method. According to the present invention, the rice wine prepared through the method has the sweet and delicious taste; the traditional Chinese medicine extraction liquid is added, and the content of the traditional Chinese medicine extraction liquid can be adjusted according to the specific situation of the drinker; and by adding euryale ferox shell and the like, the good health effect can be achieved.

Owner:TIANCHANG HIGH TECH ENTREPRENEURSHIP SERVICE CENT

Porous copper current collector, preparation method thereof and application of porous copper current collector in zinc/sodium ion battery

PendingCN114284505AAdjustable contentUniform depositionElectrode carriers/collectorsSecondary cellsOXALIC ACID DIHYDRATEElectrical battery

The invention belongs to the technical field of advanced non-ferrous metal materials, and relates to a high-performance copper alloy for electronics, in particular to a porous copper current collector, a preparation method thereof and application of the porous copper current collector in a zinc / sodium ion battery, and the preparation method comprises the following steps: taking bronze alloy as a precursor, and obtaining the porous copper current collector in an acid solution by adopting an electrochemical dealloying method; the acidic solution is one or a mixture of more than two of hydrochloric acid, acetic acid, sulfuric acid, citric acid and oxalic acid; the concentration of the acid solution is 0.01 to 5 mol L <-1 >. The porous copper current collector provided by the invention can induce uniform deposition of metal zinc, and the deposition stripping efficiency of zinc is improved. And after the negative-electrode-free zinc battery is assembled, metal zinc is not used, so that the energy density of the battery can be greatly improved, the volume and the weight of the battery are reduced, and the application range of the battery is widened.

Owner:SHANDONG UNIV

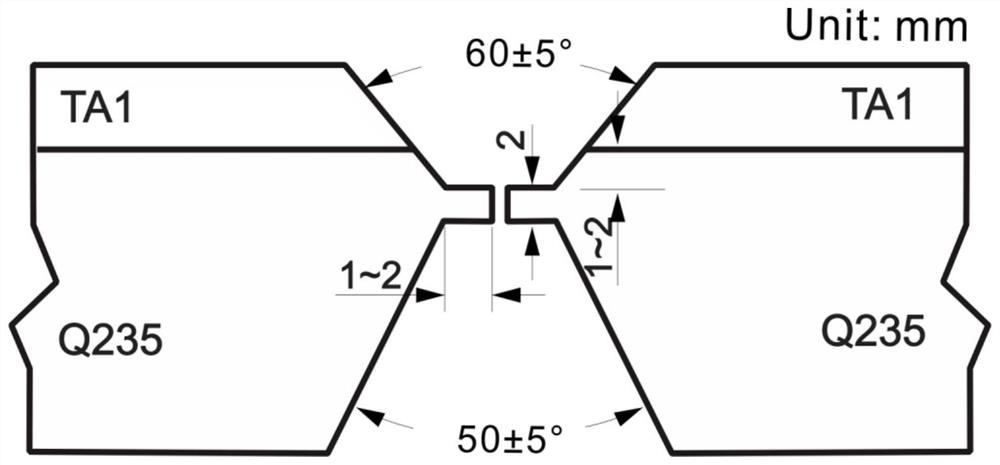

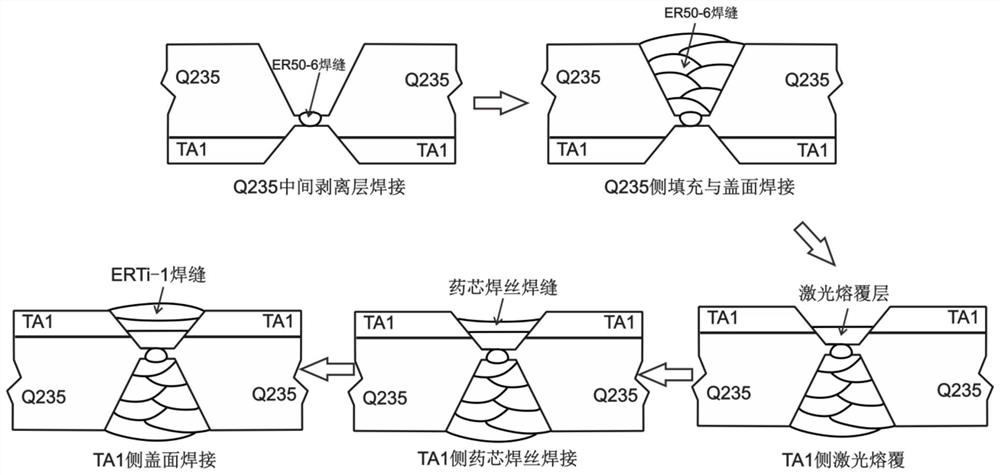

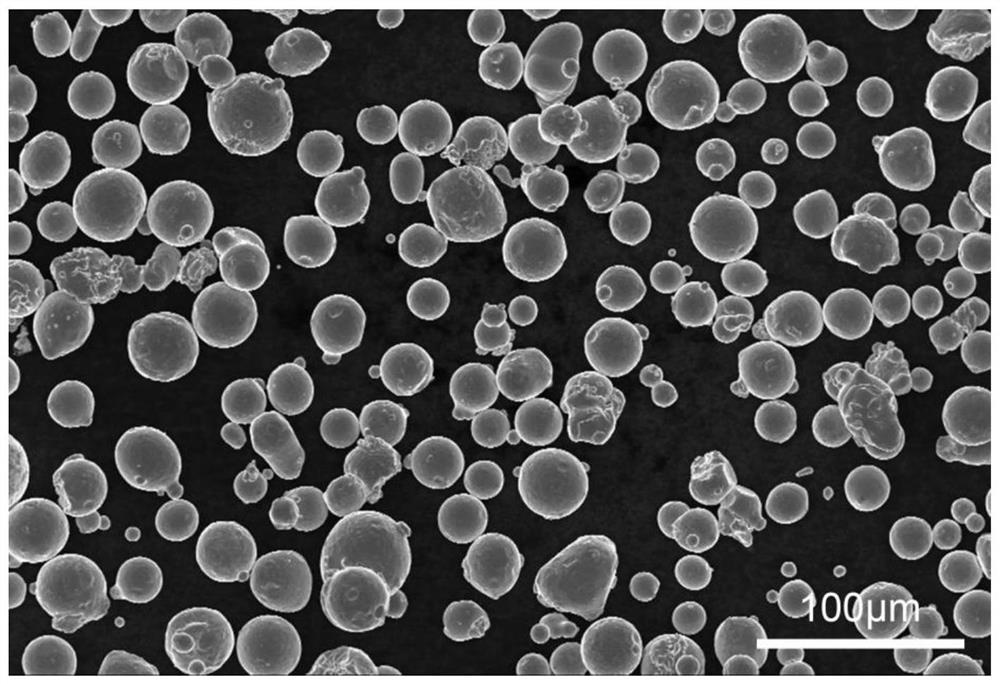

Butt welding material and welding method for TA1-Q235 composite boards

ActiveCN113953712AControl brittle phaseImprove toughnessWelding/cutting media/materialsSoldering mediaAl powderButt welding

The invention discloses a butt welding material and welding method for TA1-Q235 composite boards. The material comprises a laser cladding layer and a welding material for a copper base layer for TIG welding; a raw material of the laser cladding layer is laser cladding powder, wherein the laser cladding powder is composed of the following components of 30%-40% of Cu powder, 20%-30% of V powder, 10%-20% of Ni powder, 10%-20% of Ag powder and 5%-10% of B powder; a raw material of the copper-based layer for TIG welding is a copper-based flux-cored wire for TIG welding, wherein powder is composed of the following components of 20%-30% of Ag powder, 15%-25% of V powder, 15%-25% of Nb powder, 10%-20% of Ni powder, 5%-10% of Al powder, 5%-10% of Co powder and 5%-10% of B powder; and welding skin is a copper belt. The welding material solves the problem that the TA1-Q235 layered composite boards cannot be directly welded and butted. The invention further discloses a welding method for TA1-Q235 composite boards.

Owner:XIAN UNIV OF TECH

A rapidly dissolving microneedle based on water-soluble small molecules and its preparation and application

ActiveCN109674737BFast dissolutionEasy to manufactureOrganic active ingredientsPharmaceutical delivery mechanismAqueous solubilityAqueous solution

The invention belongs to the technical field of drug delivery devices, and discloses a rapidly dissolving microneedle based on water-soluble small molecules and its preparation and application. Then, the small molecule aqueous solution is filled into a microneedle mold, dried and demolded to obtain a rapidly dissolving microneedle based on the small molecule. In the present invention, by improving the overall process flow design of the preparation method and the conditions and parameters involved in each step (such as the type of small molecule and its aqueous solution concentration, etc.), it is possible to prepare a small molecule with an extremely fast dissolution rate and good mechanical properties. Compared with the existing technology, the soluble microneedles can effectively solve the problems of the time-consuming preparation process of the polymer soluble microneedles and the slow dissolving speed of the microneedles.

Owner:武汉楚颜生物科技有限公司

6082 aluminum alloy melted with cuh and preparation method of aluminum alloy

The invention discloses a 6082 aluminum alloy melted with CuH and a preparation method of the aluminum alloy. The method comprises the following steps of: heating aluminum ingots or molten aluminum till complete melting; adding Si, Fe, Mn, Mg, Cr, Zn and Ti, and completely dissolving and melting the elements; preserving the heat at the temperature of between 700 and 1,000 DEG C after refining, and obtaining an alloy melt; performing degassing purification operation on the alloy melt by using nitrogen or inert gas or mixed gas of the nitrogen and the inert gas in a random ratio, and continuously introducing the gas till the reaction is finished; adding CuH powder into the alloy melt in a fluidized form together with the gas; stirring to make the CuH distributed uniformly in the alloy melt and fully reacted with the alloy melt; and standing, regulating the temperature to 680-730 DEG C, and discharging the molten alloy for casting. By the method, the defects of the properties of the conventional aluminum alloy can be overcome, the toughness, the forming property and the hardening capacity of the aluminum alloy are improved, and a high-end base material is provided for efficient deep processing.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

Stomach nourishing rice wine preparation method

InactiveCN106916707AAdjustable contentGood health effectDigestive systemAlcoholic beverage preparationTraditional medicineChinese herbology

The invention discloses a stomach nourishing rice wine preparation method. According to the present invention, the rice wine prepared through the method has the sweet and delicious taste; the traditional Chinese medicine extraction liquid is added, and the content of the traditional Chinese medicine extraction liquid can be adjusted according to the specific situation of the drinker; and the good health effect can be achieved.

Owner:TIANCHANG HIGH TECH ENTREPRENEURSHIP SERVICE CENT

A kind of preparation method of polyurethane elastomer containing stereocomplex crystal

The present invention relates to a polyurethane elastomer technique and is intended to provide a preparation method of polyurethane elastomer containing stereoregular complex crystal. The preparation method includes steps of dissolving PLLA-PEB-PLLA and PDLA-PEB-PDLA in toluene and cooling to obtain prepolymer solution; injecting toluene solution containing catalyst and chain extender (or crosslinking agent) into prepolymer solution for uniformly stirring, after the reaction, heating the solution in a vacuum oven, drying to be constant weight, and then obtaining the polyurethane elastomer containing the stereoregular crystal. The hardness of the elastomer can be crystallized, the melting point is high, and the mechanical strength and the modulus are high. By changing the mixing ratio of the two components, the content of the stereoregular complex crystal can be adjusted to facilitate the regulation of the mechanical strength, modulus and heat resistance; the hard segments of the elastomer are bio-based and biodegradable PLLA and PDLA, which are environment friendly, green and resource saving.

Owner:ZHEJIANG UNIV

A method for preparing SSZ-39 molecular sieve using fluorine-modified Y-type molecular sieve as raw material

ActiveCN110950354BImprove pore structureIncrease the rate of crystallizationMolecular sieve catalystsHydrocarbon from oxygen organic compoundsPtru catalystIon exchange

The invention discloses a method for preparing SSZ‑39 molecular sieves by using fluorine-modified Y-type molecular sieves as raw materials. Y-type molecular sieve is impregnated with fluorine-containing aqueous solution, dried, and roasted to obtain fluorine-doped Y-type molecular sieve; mix and stir deionized water, alkali source, template agent, and silicon source according to the ratio, and add the above-mentioned fluorine-doped Y-type molecular sieve. Sol: transfer the sol to a crystallization kettle, after the crystallization is complete, the crystallized product is filtered, washed, dried, ion-exchanged, and then roasted to prepare a hydrogen-type SSZ‑39 molecular sieve. The present invention modifies the raw material of Y-type molecular sieve by fluorine doping method, so that it can completely transform crystal to prepare SSZ-39 molecular sieve in a relatively short period of time under the condition of relatively low silicon-aluminum ratio, so that the raw material and Cost of production. The SSZ-39 molecular sieve prepared by the invention has the characteristics of short crystallization time, high crystallinity, controllable grain size, good grain dispersion, etc., and can be applied to the fields of methanol-to-olefin reaction, carrier of selective catalytic reduction catalyst, and the like.

Owner:CHINA CATALYST HLDG CO LTD

Preparation method of metal matrix carbon nanotube reinforced composite material

Owner:BEIJING UNIV OF TECH

A silicon carbide nanowire reinforced c/c-sic-zrb 2 Preparation method of ceramic matrix composite material

The invention relates to a preparation method of a silicon carbide nanowire enhanced C / C-SiC-ZrB2 ceramic-based composite material. A pretreated carbon fiber prefabricating body is thermally treated to obtain a silicon carbide nanowire. The silicon carbide nanowire prepared by a sol-gel carbon-thermal reaction method is evenly distributed at the inner part of a porous carbon / carbon composite material. Subsequently, pyrolytic carbon deposited in an isothermal chemical vapor deposition furnace is coated at the surface of the silicon carbide nanowire, thus the dropping, growing and rupture of the silicon carbide nanowire in the following reaction and infiltration processes are effectively avoided. A ceramic-based composite material carbon fiber, a silicon carbide nanowire and a pyrolytic carbon middle layer after reaction and infiltration are not eroded by a high-temperature metal bath and are well preserved; thus the physical performance of the composite material can be improved. Compared with the C / C-SiC-ZrB2 ceramic-based composite material without adding the silicon carbide nanowire, the bending strength and the fracture toughness property of the silicon carbide nanowire enhanced C / C-SiC-ZrB2 ceramic-based composite material are improved by 26.9-41.3% and 45.2-59.1% respectively.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

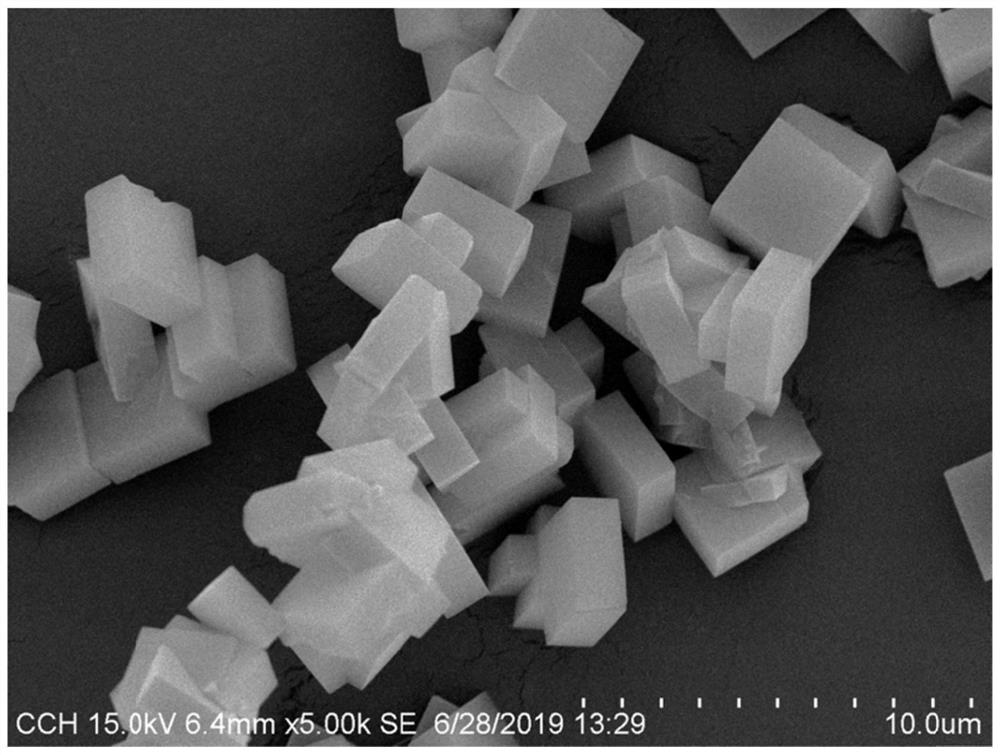

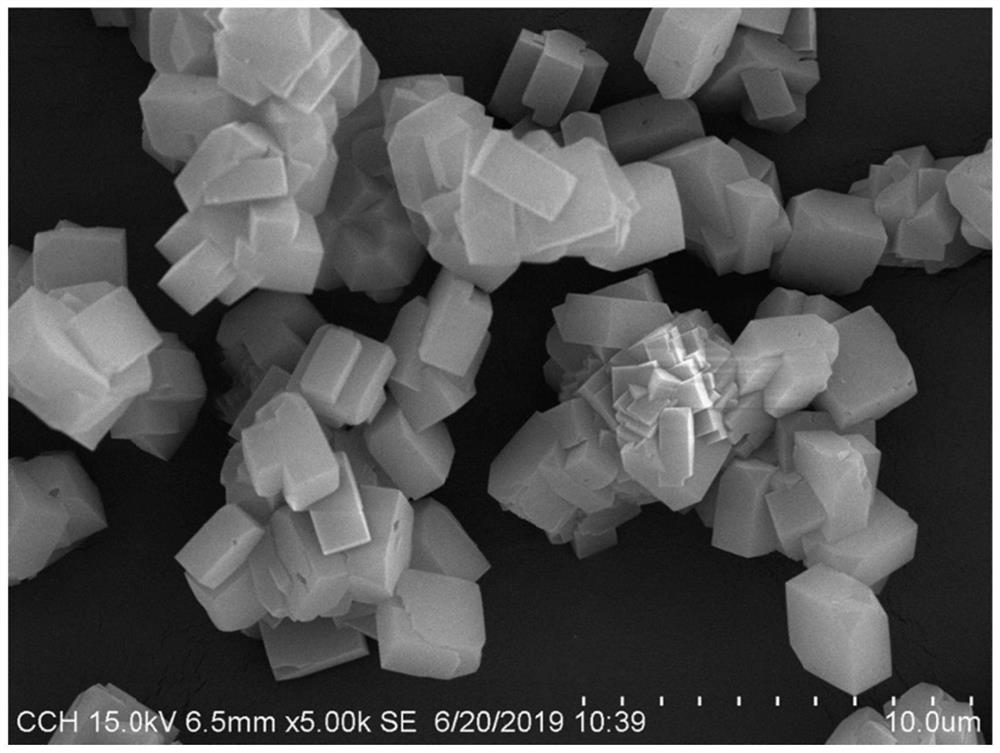

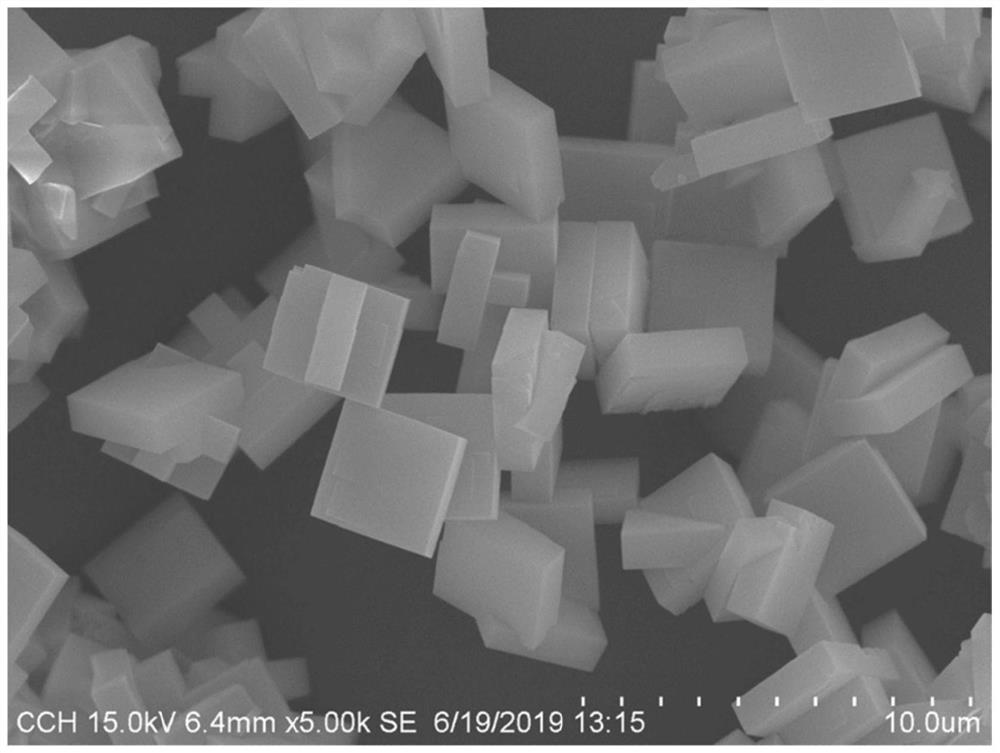

Method for adjusting and controlling structure and shape of calcium oxalate crystals by using colibacillus secretion

InactiveCN103113214BUniform sizeConsistent shapeMicroorganism based processesCarboxylic acid salt preparationCalcium oxalate monohydrate crystalsMatrix solution

The invention relates to a method for adjusting and controlling the structure and shape of calcium oxalate crystals by using colibacillus secretion. The method comprises the following steps of: mixing the colibacillus secretion with a matrix solution of which the ratio of [Ca2<+>] to [C2O4<2->] is (19.5-20.5):1, wherein the volume ratio is 1:(8-80); performing constant temperature incubation, and staying overnight; and washing and drying to obtain pure acalculous type calcium oxalate dehydrate crystals or a mixture of the calcium oxalate dehydrate crystals and calcium oxalate monohydrate crystals, wherein the colibacillus secretion is prepared through the steps of inoculating TOP10 single colonies of colibacillus to an LB liquid culture medium, performing low-speed oscillation on the culture medium at a constant temperature, staying the culture medium overnight, and performing high-speed centrifugation on the original bacterium liquid to obtain the colibacillus secretion. The method has the advantages that the calcium oxalate dehydrate crystals formed through colibacillus secretion adjustment and control have the characteristics of uniform size and consistent shape, the content of the calcium oxalate dehydrate crystals can be adjusted according to different additions, and the preparation condition is simple and non-hazardous, so that the method can be widely used in various fields.

Owner:TONGJI UNIV

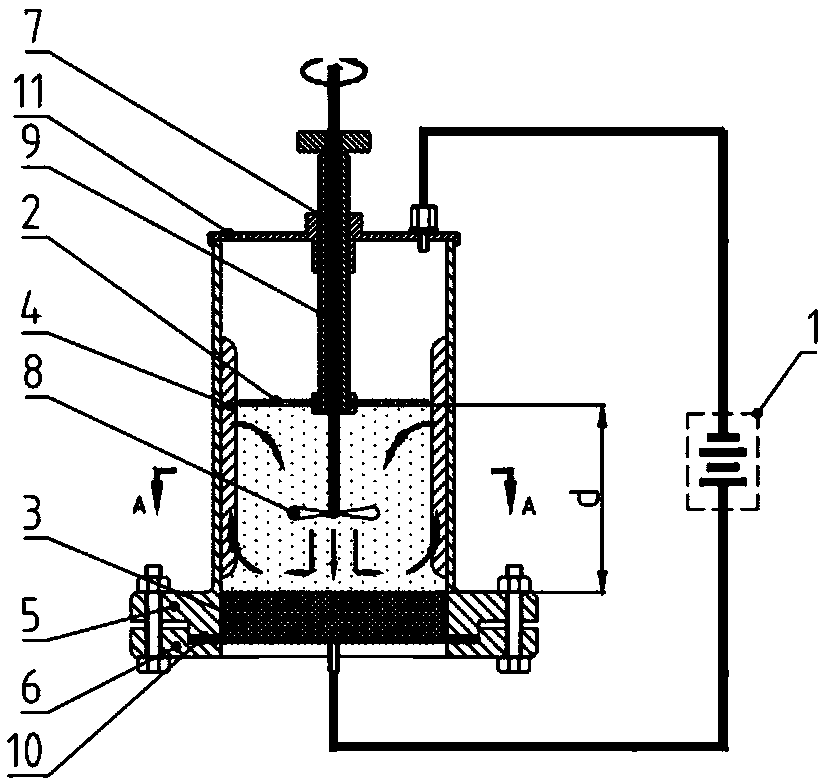

A kind of purification method and device of graphene oxide/graphene solution

InactiveCN104118872BHigh speedImprove efficiencyCarbon compoundsMaterials scienceAnalytical chemistry

The invention discloses a method and a device for purifying an oxidized graphene / graphene solution. The method comprises the following steps: pumping the oxidized graphene / graphene solution to be purified into a channel consisting of at least one filtering and discharging pipe, arranging the at least one filtering and discharging pipe between at least one group of negative and positive electrodes of an electrolytic tank, and forming auxiliary liquid channels between the negative and positive electrodes and the at least one filtering and discharging pipe; performing electrode migration on ions and charged particles in the oxidized graphene / graphene solution to be purified under the action of an electrical field between the negative and positive electrodes, filtering impurities out of the filtering and discharging pipes, taking away the impurities by auxiliary liquid, and pumping the residual purified oxidized graphene / graphene solution into another water tank from the at least one filtering and discharging pipe to form filtering circulation. According to the method and the device, the process is simple, the cost is low, the speed that the impurities are filtered out of the at least one filtering and discharging pipe can be increased, efficient purification of the oxidized graphene / graphene solution is realized, and the method is very suitable for industrial production.

Owner:CHANGSHA SAIWEI ENERGY TECH

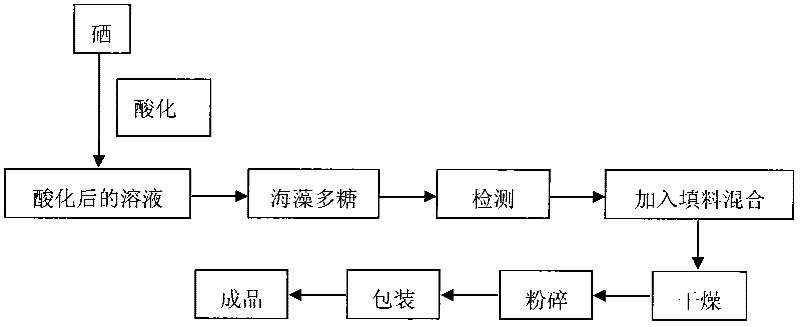

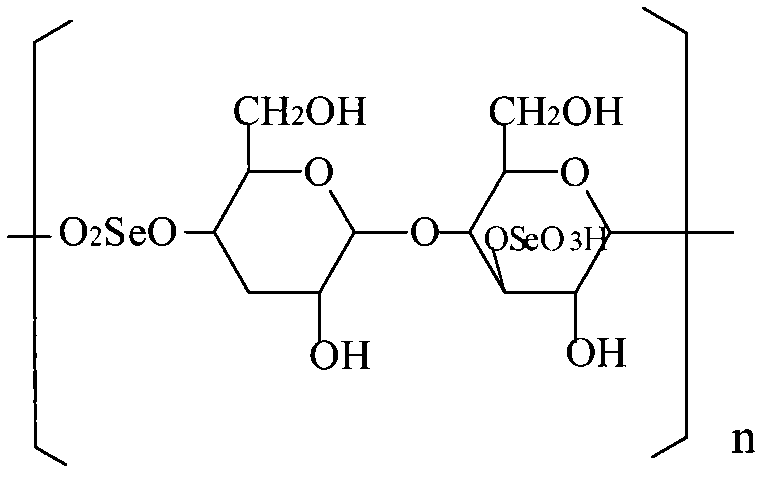

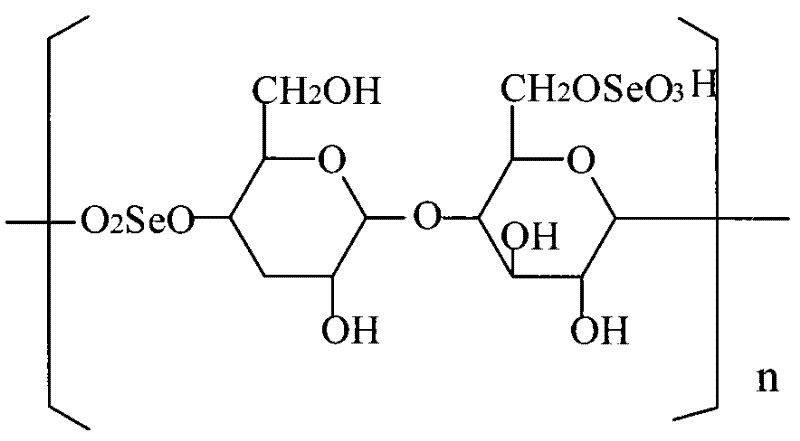

Non-hormone feed addictive and preparation method thereof

InactiveCN101461454BEasy to synthesizeHigh activityAnimal feeding stuffAccessory food factorsSide effectAntibiotic Y

The invention relates to a non-hormone type feed additive containing organic selenium polysaccharide and preparation method thereof, belonging to the feed industry field. The preparation method comprises: adding selenium powder into concentrated nitric acid, diluting by water to obtain selenious acid solution which is called as solution I; adding the prepared solution I into sodium chloride solution dissolved with algal polysaccharides; reacting under 30-80 degrees centigrade for 12-20 hours; mixing the reaction residue- organic selenium polysaccharide and algal polysaccharides with filling material according to the weight percentages of 0.05%-0.5% of organic selenium polysaccharide, 0.06%-1.6% of algal polysaccharides and balanced amount of filling material; drying, grinding and obtaining the feed additive containing organic selenium polysaccharide. The feed additive of the invention is green, has no residue or pollution, can substitute antibiotics; also has high production efficiency, short cycle, and high selenium utilization rate, is safe and reliable for animal body without side effect.

Owner:YANTAI INST OF COASTAL ZONE RES CHINESE ACAD OF SCI

CuH-doped 6181 aluminum alloy and smelting and casting method thereof

The invention discloses a CuH-doped 6181 aluminum alloy and a smelting and casting method thereof. The method comprises the following steps of: heating aluminum ingots or molten aluminum till complete melting; adding Si, Fe, Cu, Mn, Mg, Zn and Ti, and completely dissolving and melting the elements; preserving the heat at the temperature of between 700 and 1,000 DEG C after refining, and obtainingan alloy melt; performing degassing purification operation on the alloy melt by using nitrogen or inert gas or mixed gas of the nitrogen and the inert gas in a random ratio, and continuously introducing the gas till the reaction is finished; adding CuH powder into the alloy melt in a fluidized form together with the gas; stirring to make the CuH distributed uniformly in the alloy melt and fully reacted with the alloy melt; and standing, regulating the temperature to 680-730 DEG C, and discharging the molten alloy for casting. By the method, the defects of the properties of the conventional aluminum alloy can be overcome, the toughness, the forming property and the hardening capacity of the aluminum alloy are improved, and a high-end base material is provided for efficient deep processing.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

Face nourishing rice wine preparation method

InactiveCN106916705AAdjustable contentGood health effectSkeletal disorderAlcoholic beverage preparationTraditional medicineHealth effect

The invention discloses a face nourishing rice wine preparation method. According to the present invention, the rice wine prepared through the method has the sweet and delicious taste; the traditional Chinese medicine extraction liquid is added, and the content of the traditional Chinese medicine extraction liquid can be adjusted according to the specific situation of the drinker; and the good health effect can be achieved.

Owner:TIANCHANG HIGH TECH ENTREPRENEURSHIP SERVICE CENT

Bone strengthening rice wine

InactiveCN106916700AAdjustable contentGood health effectSkeletal disorderAlcoholic beverage preparationMedicineEuryale ferox

The invention discloses a bone strengthening rice wine preparation method. According to the present invention, the bone strengthening rice wine prepared according to the method has sweet and delicious taste; the traditional Chinese medicine extraction liquid is added, and the content of the traditional Chinese medicine extraction liquid can be adjusted according to the specific situation of the drinker; and by adding euryale ferox shell and the like, the good health effect can be achieved.

Owner:TIANCHANG HIGH TECH ENTREPRENEURSHIP SERVICE CENT

Stomach nourishing rice wine

InactiveCN106916708AAdjustable contentGood health effectDigestive systemAlcoholic beverage preparationTraditional medicineHealth effect

Owner:TIANCHANG HIGH TECH ENTREPRENEURSHIP SERVICE CENT

A system device and method for synchronously realizing organic waste treatment and syngas upgrading

ActiveCN105645581BRealize in-situ upgrading and purificationAddress resource shortagesGaseous fuelsWaste based fuelGas solidSyngas

Owner:BEIJING UNIV OF CHEM TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com