Butt welding material and welding method for TA1-Q235 composite boards

A TA1-Q235, welding method technology, applied in the direction of welding/cutting medium/material, welding equipment, welding medium, etc., can solve the problems that TA1-Q235 layered composite boards cannot be directly welded and welded, and achieve excellent butt joints, The preparation process is simple, and the effect of improving the plasticity and toughness of the weld

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

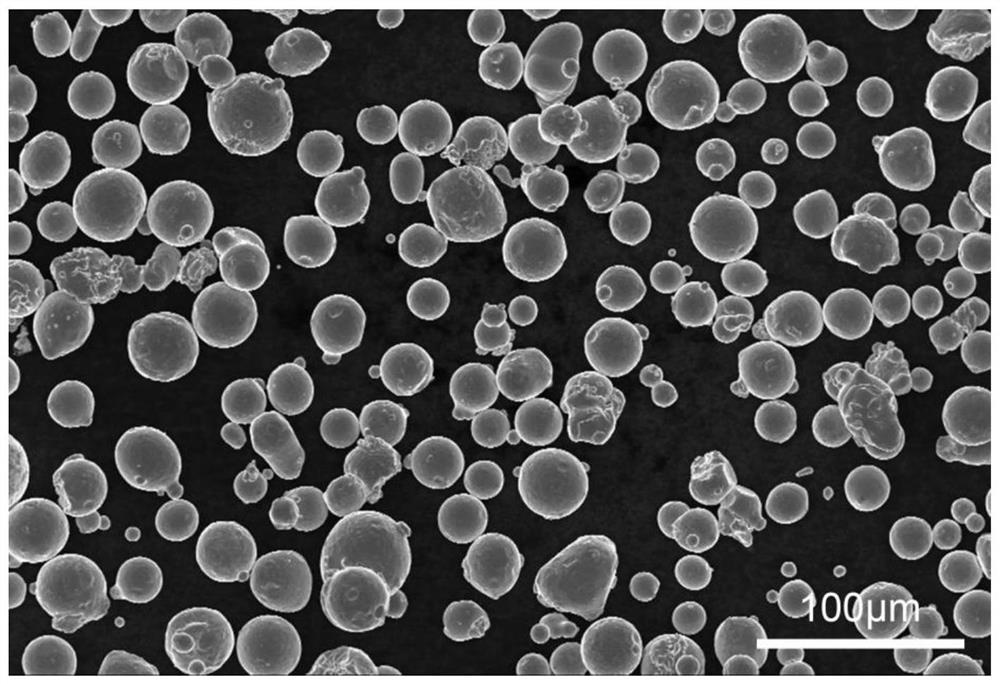

[0051] The preparation method of powder for laser cladding, the specific steps are as follows:

[0052] Step 1: Weigh 40% of Cu powder, 20% of V powder, 20% of Ni powder, 10% of Ag powder, and 10% of B powder according to mass percentage, and the sum of the mass percentages of the above components is 100%;

[0053] Step 2: Mix the powders of the raw materials in step 1, vacuum melt them, and use gas atomization to make powders; wherein, N 2 As an atomizing gas, the atomizing pressure is 6-8MPa, and the superheat of the melt is kept between 100 and 150°C during the atomizing process;

[0054] Step 3: performing particle size screening on the atomized alloy powder, so that the screened alloy powder is within the particle size range of 25-53 μm;

[0055] Step 4: vacuum pack the prepared powder for use.

[0056] The preparation method of copper-based flux-cored welding wire for TIG welding, the specific steps are as follows:

[0057] Step 1: Weigh 20-30% of Ag powder, 15-25% of...

Embodiment 1

[0074] Laser cladding powder preparation:

[0075] Step 1: Weigh 30% of Cu powder, 30% of V powder, 10% of Ni powder, 20% of Ag powder, and 10% of B powder according to mass percentage, and the sum of the mass percentages of the above components is 100%;

[0076] Step 2: Mix the alloy powders of the raw materials in step 1, melt them in vacuum, and make powder by gas atomization. Among them, with N 2 As an atomizing gas, the atomizing pressure is 6MPa, and the superheat of the melt is kept between 100 and 150°C during the atomizing process;

[0077] Step 3: Perform particle size screening on the atomized alloy powder, so that the screened alloy powder is within the particle size range of 25-53 μm.

[0078] Step 4: vacuum pack the prepared powder for use.

[0079] Flux cored wire preparation:

[0080] Step 1: Weigh 30% of Ag powder, 15% of V powder, 15% of Nb powder, 10% of Ni powder, 10% of Al powder, 10% of Co powder, 10% of B powder, and one of the above components by ma...

Embodiment 2

[0090] Laser cladding powder preparation:

[0091] Step 1: Weigh 40% of Cu powder, 20% of V powder, 20% of Ni powder, 10% of Ag powder, and 10% of B powder according to mass percentage, and the sum of the mass percentages of the above components is 100%;

[0092] Step 2: Mix the alloy powders of the raw materials in step 1, melt them in vacuum, and make powder by gas atomization. Among them, with N 2 As an atomizing gas, the atomizing pressure is 6MPa, and the superheat of the melt is kept between 100 and 150°C during the atomizing process;

[0093] Step 3: Perform particle size screening on the atomized alloy powder, so that the screened alloy powder is within the particle size range of 25-53 μm.

[0094] Step 4: vacuum pack the prepared powder for use.

[0095] Flux cored wire preparation:

[0096] Step 1: Weigh respectively 20% of Ag powder, 25% of V powder, 20% of Nb powder, 20% of Ni powder, 5% of Al powder, 5% of Co powder, 5% of B powder, and one of the above compon...

PUM

| Property | Measurement | Unit |

|---|---|---|

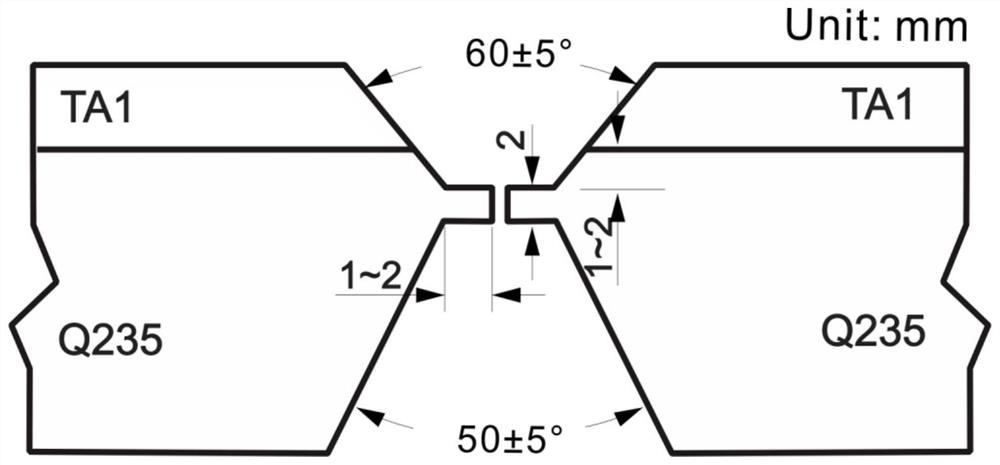

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com