System device and method for synchronously realizing organic waste disposal and synthesis gas quality improvement

A technology for organic waste and system devices, applied in biological water/sewage treatment, waste fuel, anaerobic digestion treatment, etc., can solve problems such as expensive catalysts, incomplete utilization, and complex gas components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

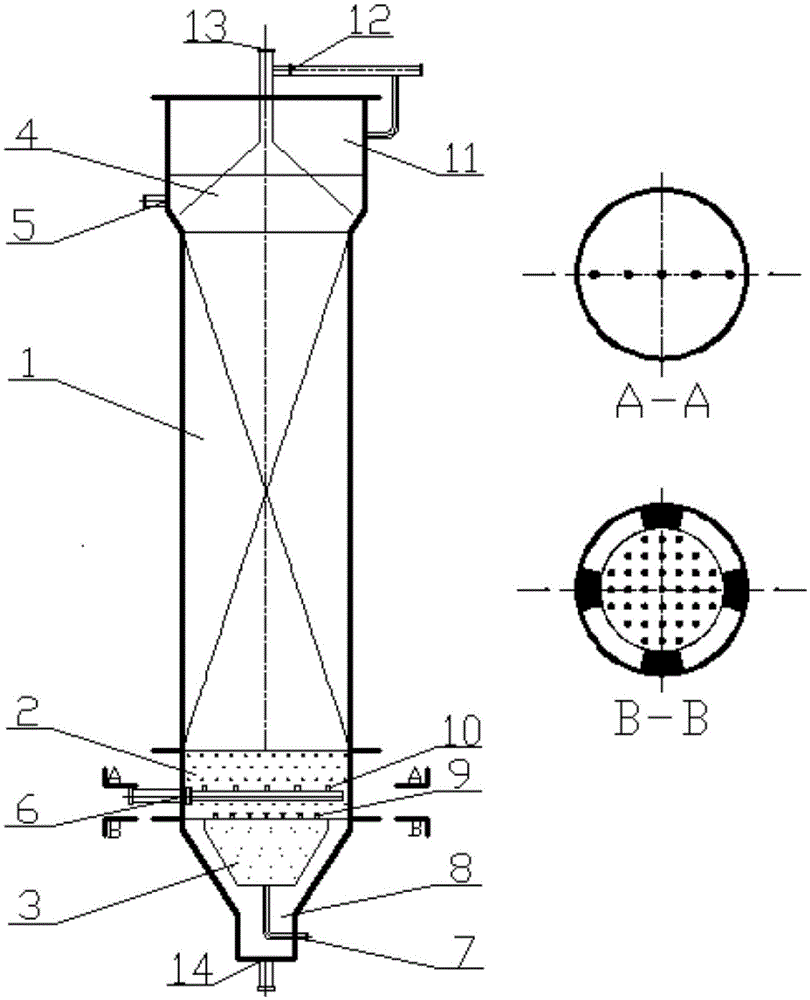

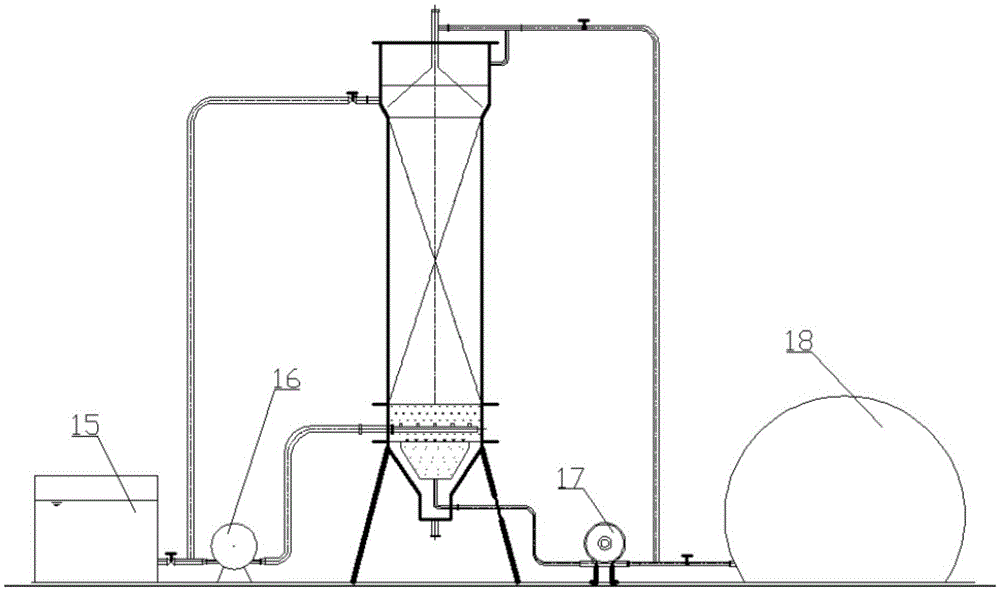

[0067] A system device for synchronously realizing organic waste treatment and syngas upgrading. The schematic diagram of the system device is shown in figure 2 As shown, the internal structure diagram of the core part of the anaerobic synthesis integrated reactor in the system device is shown in figure 1 as shown, figure 1 and figure 2 The meanings represented by the numbers in each part are as follows:

[0068] 1-microbial synthesis reaction zone, 2-gas-liquid mixing zone, 3-aeration buffer zone, 4-gas-solid-liquid separation zone, 5-liquid circulation pipe, 6-organic waste mixed liquid inlet, 7-synthesis gas inlet Outlet, 8-mud discharge area, 9-aeration device, 10-uniform water distribution device, 11-gas phase pressure stabilization area, 12-gas circulation pipe, 13-biological natural gas outlet, 14-mud discharge port, 15-organic Waste mixed liquid storage tank, 16-inlet pump, 17-intake pump, 18-synthesis gas storage tank.

[0069] The core part of the system device...

Embodiment 2

[0076] The system device described in Example 1 is used to treat the anaerobic reaction of the excess sludge in the sewage plant. The ratio of the diameter of the aeration disc to the inner diameter of the reactor is set to 0.7, the hole diameter of the aerator is 80 μm, and the diameter of the aerator is 250 mm. The aeration volume of the aerator is 2.5m 3 / h, the total aeration area of the aerator on the aeration plate accounts for 20%. Each process parameter is controlled as follows: the reactor is 100m 3 , the biogas production is 1m 3 / m 3 / d, CH in biogas 4The content is 60%, CO 2 The content is 40%. The converted coke oven gas is composed of H 2 Content 65%, CO content 5%, CH 4 Content 25%, CO 2 Content 3%. The flow rate of coke oven gas into the anaerobic synthesis integrated reactor is 400m 3 / d, the reactor adopts liquid circulation, and the circulation ascending flow rate is 1m / h. The amount of mixed gas produced is about 240m 3 / d, methane concentrati...

Embodiment 3

[0084] The system device described in Example 1 is used to process the anaerobic reaction of pig manure water in pig farms, the ratio of the diameter of the aeration disc to the inner diameter of the reactor is set to 0.6, the diameter of the aerator hole is 50 μm, and the diameter of the aerator is 20 mm. The aeration volume of the aerator is 0.5m 3 / h, the total aeration area of the aerator on the aeration plate accounts for 5%. Each process parameter is controlled as follows: the reactor is 80m 3 , the biogas production is 2.0m 3 / m 3 / d, CH in biogas 4 Content is 55%, CO 2 The content is 44.5%. The synthetic gas introduced is a mixture of coke oven gas and biomass pyrolysis gas. composed of H 2 Content 53%, CO content 14%, CH 4 Content 25%, CO 2 Content 6%. The flow rate of synthesis gas into the anaerobic synthesis integrated reactor is 650m 3 / d, the reactor adopts liquid circulation, and the circulation ascending flow rate is 1m / h. The resulting mixed gas ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com