Electrochemical treatment method and device of carbon particles

A processing device and technology for carbon particles, which are applied in chemical instruments and methods, inorganic chemistry, fiber processing, etc., can solve the problems of grafting method that does not meet environmental protection standards, strong corrosiveness of equipment, etc., and achieve environmental friendliness, low cost, The effect of easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

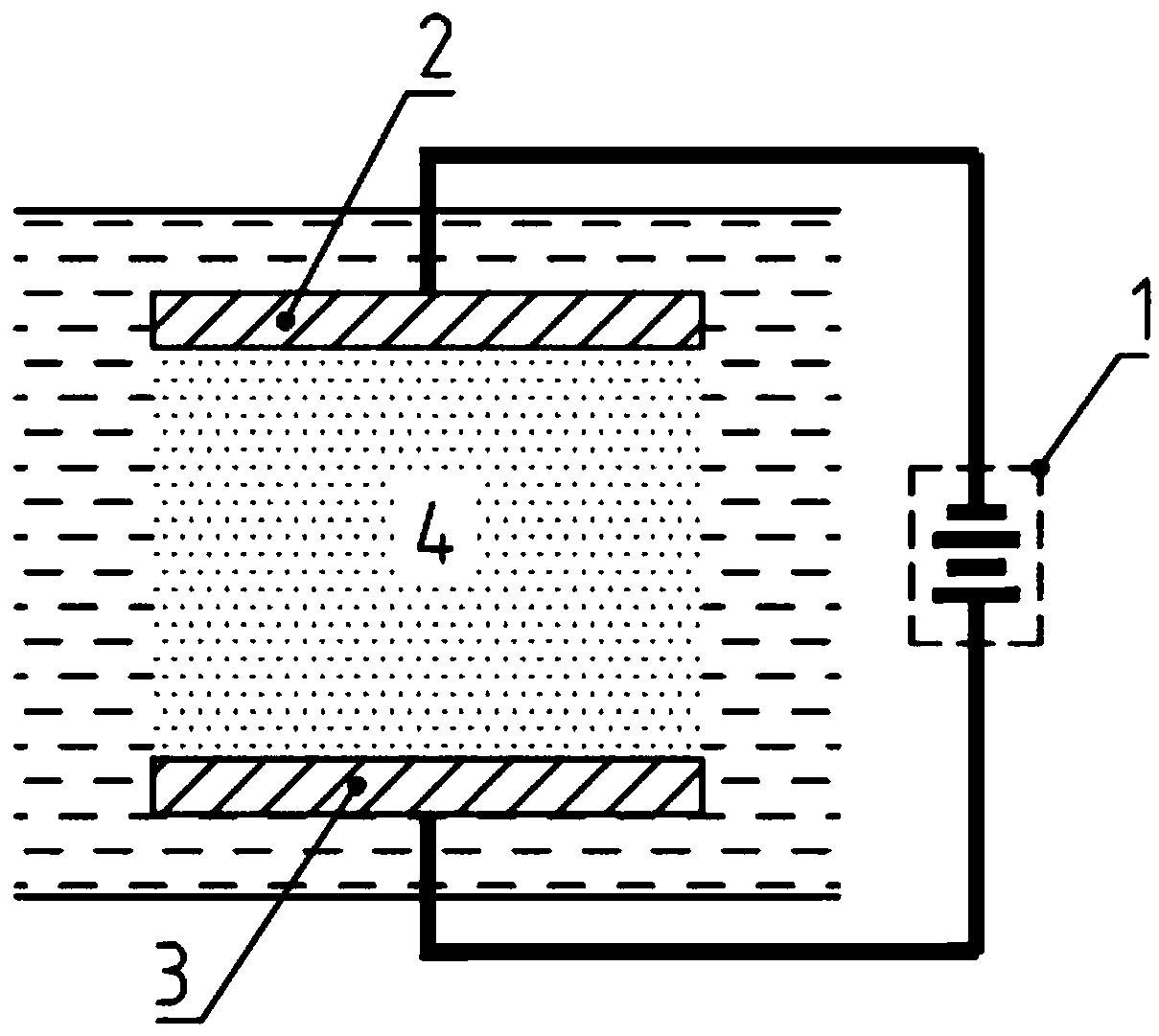

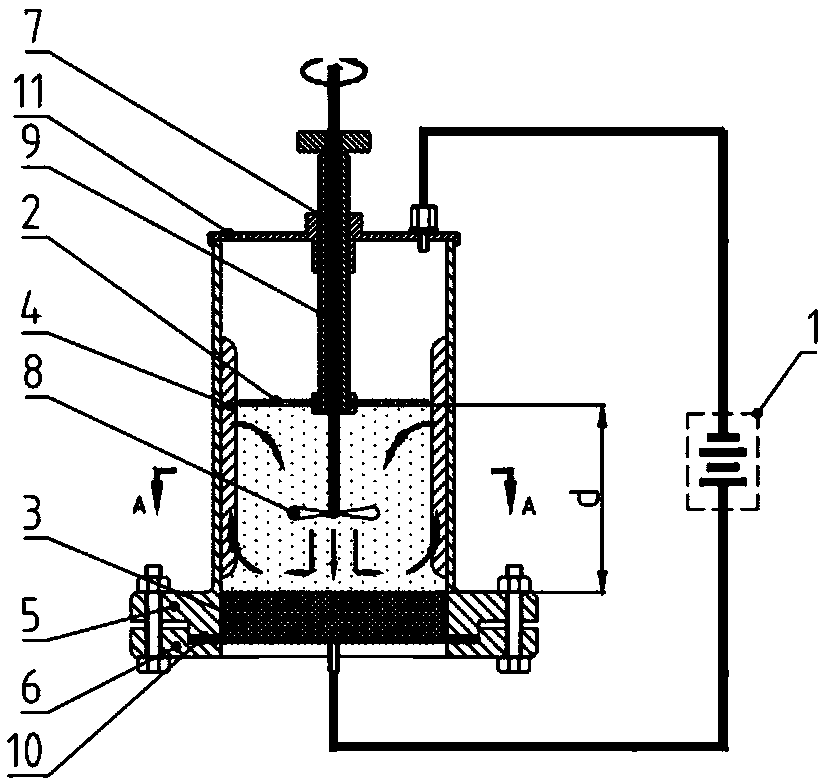

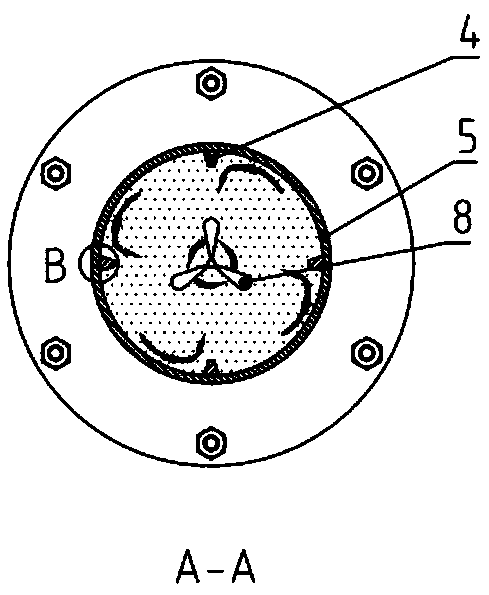

[0049] Such as Figure 2-4 As shown, a device for electrochemically treating carbon particles in this embodiment includes a power supply 1, a copper cathode plate 2, a graphite anode plate 3, and 4 separator columns 4 with a rectangular cross section (that is, θ is 90°). , the reactor shell 5, the base 6, the stirring rod 7, the stirring blade 8, the pole plate distance adjustment screw 9, the sealing ring 10 and the reactor cover plate 11, and the reactor shell 5 and the base 6 are connected by a flange , the reactor cover plate 11 is arranged on the upper port of the reactor housing 5, the anode plate 3 is arranged at the connection between the reactor housing 5 and the base 6, and is sealed by a sealing ring 10, and the pole plate distance adjustment screw rod 9 and The screw hole provided in the middle of the reactor cover plate 11 is threadedly connected, the cathode plate 2 is arranged at the lower end of the pole plate distance adjusting screw 9, and the pole plate dist...

Embodiment 2~3

[0056] The device for electrochemically treating carbon particles with the same structure as in Example 1 is adopted, and the design of the separator column and the electrode plate are changed: the front bottom angle θ of the cross section of the separator column (4) whose cross section is rectangular (that is, θ is 90°) The angle can be adjusted in the range of 0.1-90°; the anode plate can be an inert material electrode such as gold electrode, platinum electrode or graphite electrode, and the cathode plate can be any iron electrode, copper electrode, aluminum electrode, gold electrode, platinum electrode or graphite electrode. Electrode; specific angle design and plate material are listed in Table 1.

[0057] Use the same method for electrochemically treating carbon particles as in Example 1, change the electrode material carbon particle type, electrolyte type and concentration, processing voltage, processing time, stirring mode, and carry out electrochemical processing. After...

Embodiment 4~6

[0059] The device for electrochemically treating carbon particles with the same structure as in Example 1 is adopted, and the design of the separator column and the electrode plate are changed: the front bottom angle θ of the cross section of the separator column (4) whose cross section is rectangular (that is, θ is 90°) The angle can be adjusted in the range of 0.1-90°; the anode plate can be an inert material electrode such as gold electrode, platinum electrode or graphite electrode, and the cathode plate can be any iron electrode, copper electrode, aluminum electrode, gold electrode, platinum electrode or graphite electrode. Electrode; specific angle design and plate material are listed in Table 1.

[0060] Use the same method for electrochemically treating carbon particles as in Example 1, use a DC stabilized power supply to process the carbon particles in a constant current mode, change the type of electrode material carbon particles, the type and concentration of the elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com