Non-hormone feed addictive and preparation method thereof

A technology of feed additives and hormones, which is applied in the field of non-hormone feed additives and its preparation, can solve the problems of human health and public health threats, large side effects of food animals, and low efficiency of selenium enrichment in plants, so as to improve feed conversion efficiency, growth promotion, and immune-boosting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The ingredients of the feed additive in this embodiment are organic selenium polysaccharides, seaweed polysaccharides, and cornstarch. The ingredients are: 0.05% organic selenium polysaccharides, 0.3% seaweed polysaccharides, and 99.65% fillers.

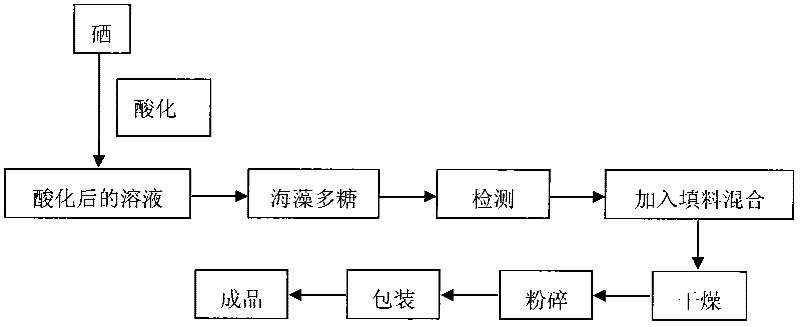

[0027] see figure 1 Shown, its preparation method: join 50 grams of selenium powders into 345.6 milliliters of concentrated nitric acid (concentration 65%, commercially available product), obtain selenous acid solution after dissolving completely, add 3456 milliliters of water, make solution I. The prepared solution I was added to the 30kg sodium chloride solution (0.2mol / L) that was dissolved with 1000 grams of red seaweed polysaccharide, mixed, reacted at 30°C for 20 hours, and detected the content of organic selenium polysaccharide and remaining seaweed polysaccharide, The reaction solution is mixed with cornstarch according to the weight ratio of organic selenium polysaccharide, remaining seaweed polysaccharide and cornsta...

Embodiment 2

[0035] In terms of weight percentage, the ingredients are: 0.1% organic selenium polysaccharide, 0.06% seaweed polysaccharide, and 99.84% filler.

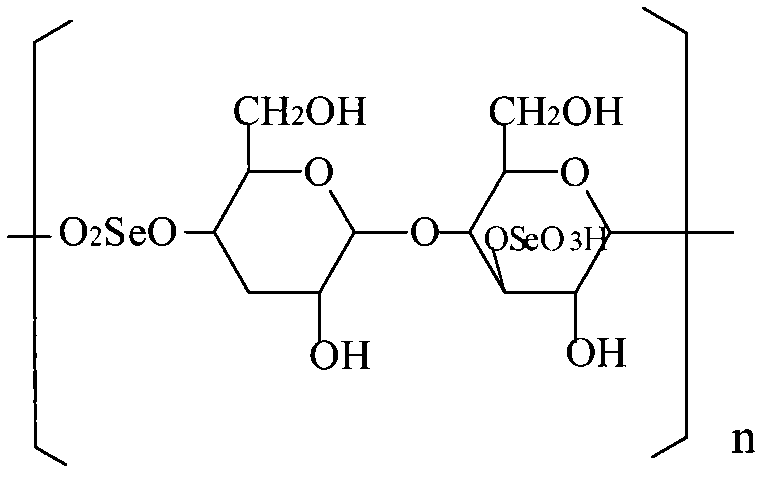

[0036] Add 10 grams of selenium powder into 30 milliliters of concentrated nitric acid (concentration 70%, commercially available product), add 600 milliliters of water after dissolving completely to obtain selenous acid solution, and make solution I. Solution I is added in the sodium chloride solution (0.6mol / L) of 400g that is dissolved with 40 grams of fucoidan, mixes, reacts at 60 ℃ for 18 hours, detects the content of organic selenium polysaccharide and unreacted seaweed polysaccharide, will Organic selenium polysaccharides, remaining seaweed polysaccharides and corn starch are mixed according to the ratio of 1:0.6:998.4 by weight, dried, and pulverized to obtain organic selenium polysaccharide feed additives, which are packaged to produce finished products (see Figure 2-2 ).

[0037] Feed this selenate polysaccharide feed a...

Embodiment 3

[0043] In weight percentage, the composition is: 0.5% organic selenium polysaccharide, 1.6% seaweed polysaccharide, 97.9% filler.

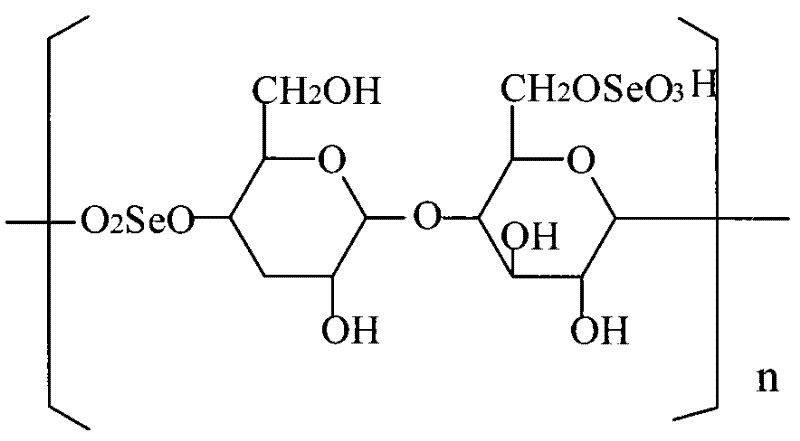

[0044] 30 grams of selenium powder was added to 70 milliliters of concentrated nitric acid, and after complete dissolution, 2.1 liters of water was added to obtain a selenous acid solution, and solution I was obtained. Solution I is added in the sodium chloride solution (1.0mol / L) of 8kg that is dissolved with 360 grams of green algae polysaccharides, mixes, reacts at 80 ℃ for 12 hours, detects the content of organic selenium polysaccharides and remaining seaweed polysaccharides, organic selenium polysaccharides Polysaccharides, remaining seaweed polysaccharides and cornstarch are mixed according to the ratio of 1:3.2:195.8 by weight, dried, and pulverized to obtain organic selenium polysaccharide feed additives, which are packaged to produce finished products (see Figure 2-3 ).

[0045] Feed this selenate polysaccharide feed additive production...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com