Porous copper current collector, preparation method thereof and application of porous copper current collector in zinc/sodium ion battery

A zinc-ion battery and current collector technology, which is applied in secondary batteries, electrode carriers/current collectors, circuits, etc., can solve the problems of excessive use of metal zinc, large volume, and low Coulombic efficiency, and achieve uniform deposition and growth effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0028] A typical embodiment of the present invention provides a method for preparing a porous copper current collector, which is obtained by using a bronze alloy as a precursor in an acidic solution by electrochemical dealloying;

[0029] The acidic solution is one or a mixture of two or more of hydrochloric acid, acetic acid, sulfuric acid, citric acid, and oxalic acid;

[0030] The concentration of the acidic solution is 0.01~5mol L -1 .

[0031] The bronze alloy of the present invention is used as a raw material, and is prepared by an electrochemical dealloying method under acidic conditions, which can regulate the microscopic appearance and tin content in the bronze alloy, thereby inducing the uniform deposition of metal zinc and improving the deposition and stripping efficiency of zinc . In addition, the present invention adopts specific acid and concentration to ensure the control of tin content in the porous copper current collector.

[0032] Among them, the pickling...

Embodiment 1

[0048]A kind of preparation method of porous copper current collector:

[0049] Take a 2cm*2cm piece of bronze and dip it into 0.125moL L -1 Hydrochloric acid solution, using electrochemical dealloying method, the current density is 1mA cm -2 , the time is 2h. After the reaction is completed, the porous copper-based current collector can be prepared after washing with deionized water and drying.

[0050] Battery assembly: the above product is used as a current collector, the negative electrode is made of zinc foil, the electrolyte is made of 2M zinc sulfate aqueous solution, and the diaphragm is made of glass fiber.

[0051] The parameters for testing Coulombic efficiency are: the discharge current is 0.5mA, the discharge time is 1h, the charge current is 0.5mA, and the charge voltage is 0.5V.

[0052] The parameters of the test cycle are: the charge and discharge current is 0.5mA, and the charge and discharge time is 1h.

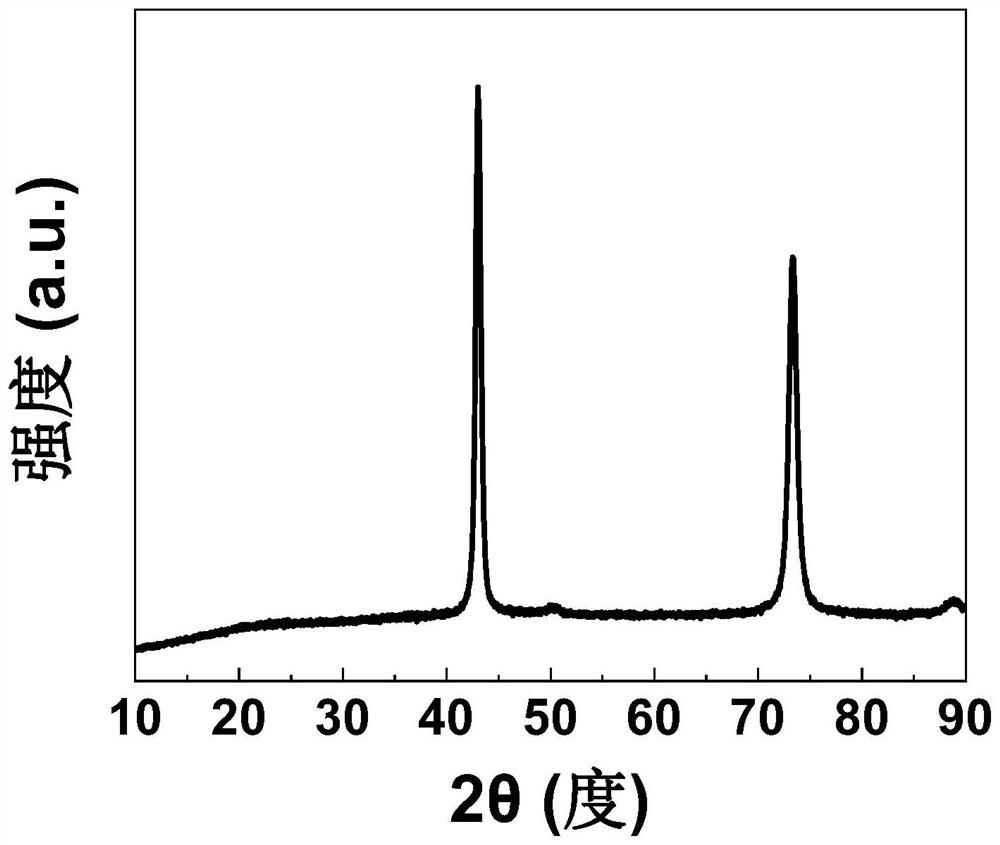

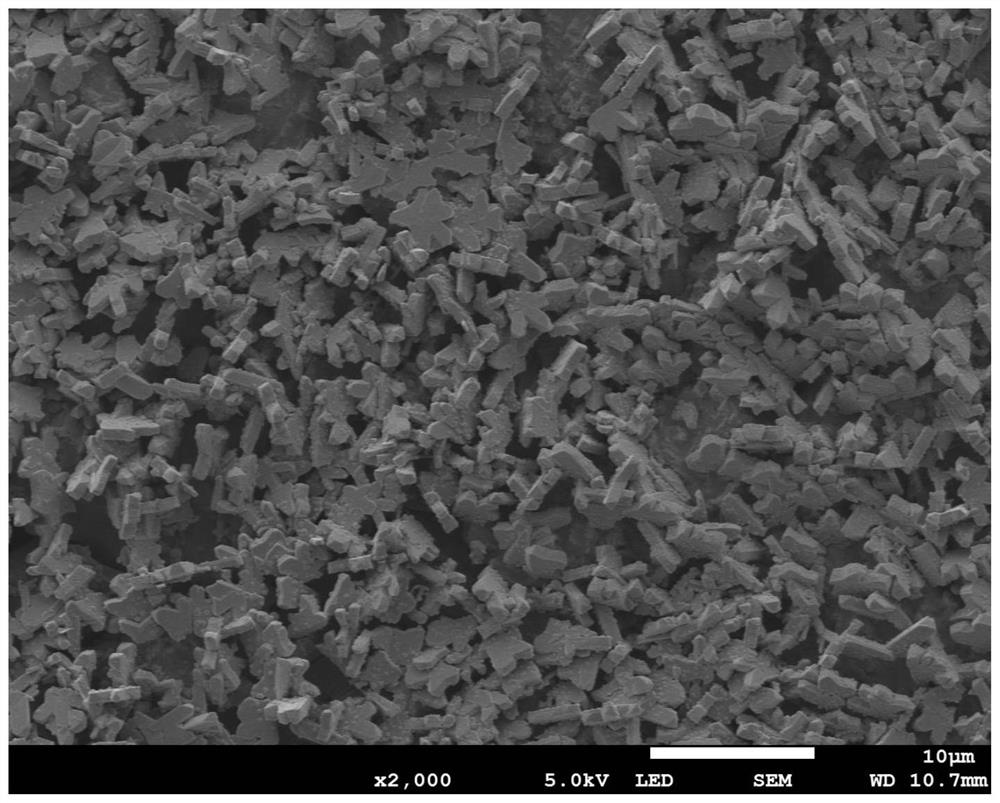

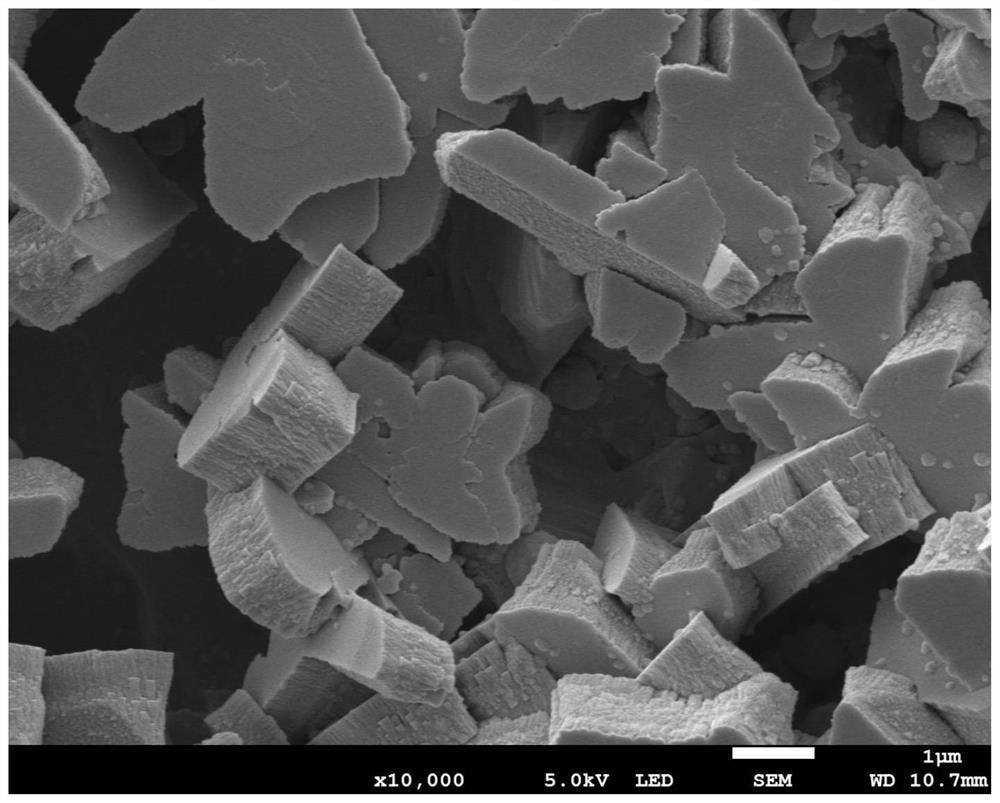

[0053] figure 1 The XRD pattern of the porous cop...

Embodiment 2

[0059] A kind of preparation method of porous copper current collector:

[0060] Take a 2cm*2cm piece of bronze and dip it into 0.05moL L -1 In the sulfuric acid solution, the electrochemical dealloying method was adopted, and the current density was 0.5mA cm -2 , the time is 4h. After the reaction is completed, the porous copper-based current collector can be prepared after washing with deionized water and drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com