Preparing method of bamboo fiber winding composite tube

A bamboo fiber and composite pipe technology, applied in the pipeline field, can solve the problems of oil resource consumption, environmental pollution, etc., and achieve the effects of saving oil resources, high strength, and improving compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

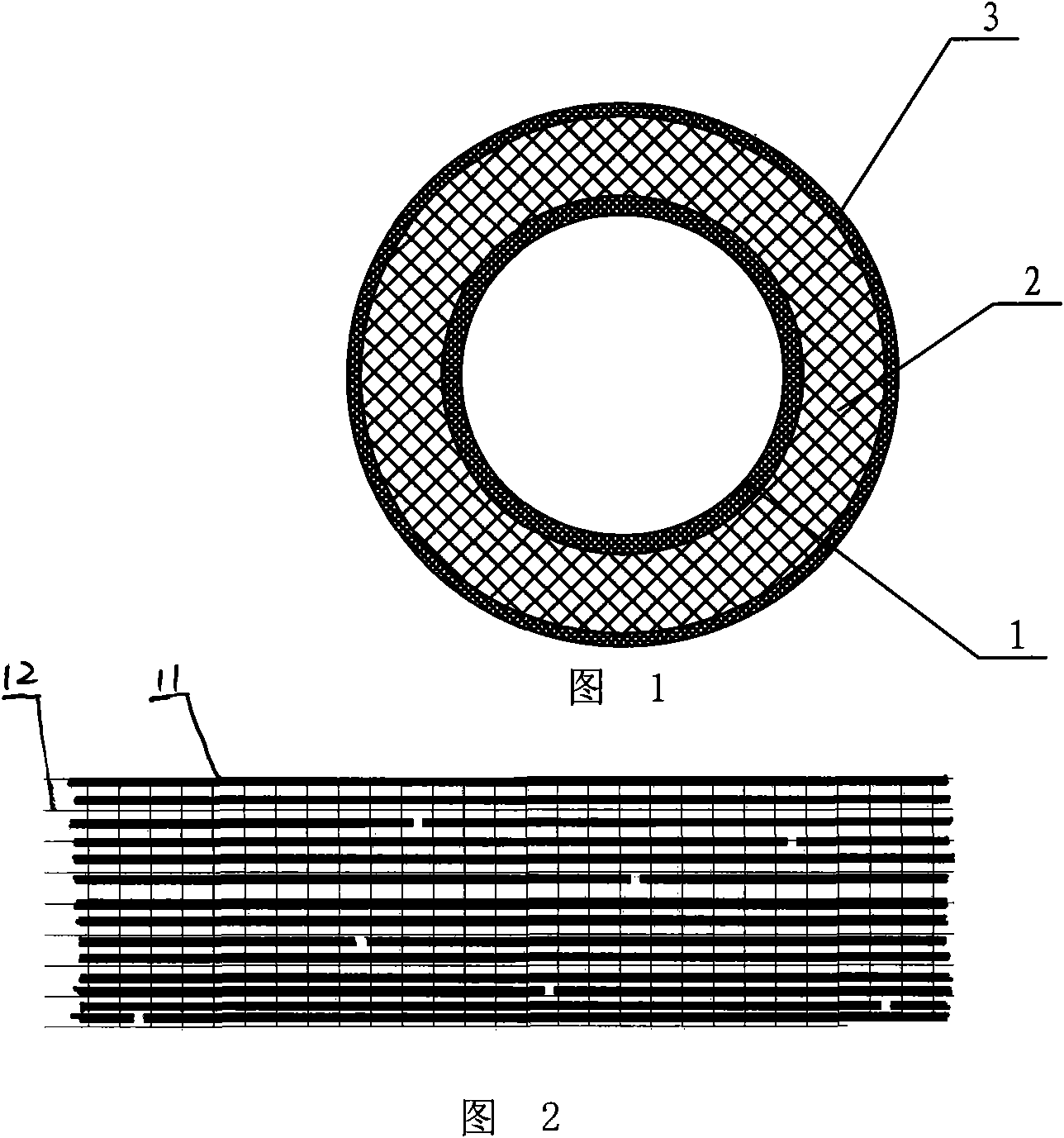

[0020] Taking the production of a bamboo composite pipe with a diameter of 200mm as an example, the specific steps are as follows:

[0021] a) bamboo chip pretreatment:

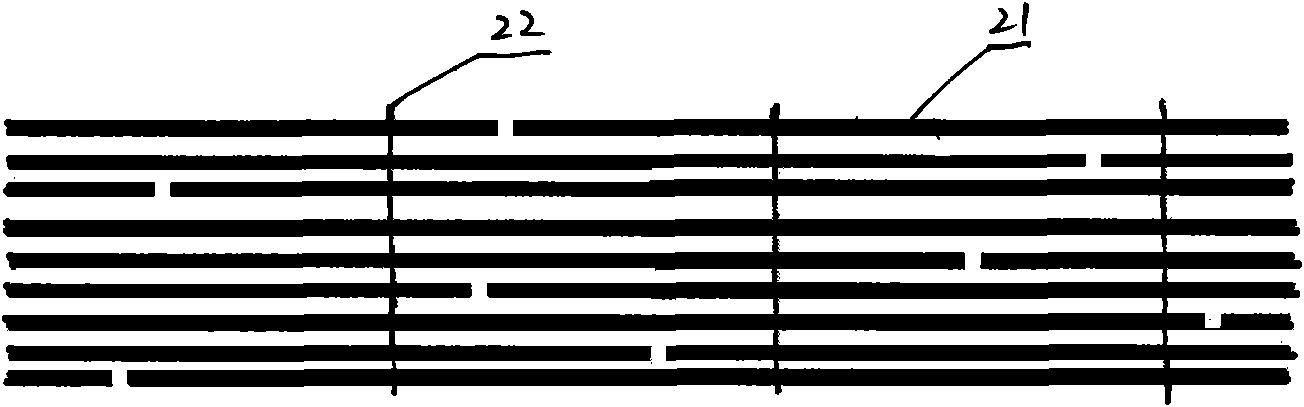

[0022] Open the fresh moso bamboo into 5 meters long, 0.7mm thick and 10mm wide bamboo slices, soak them in 5% NaOH solution for 6 hours, rinse them with water, and after drying, arrange them in a row with 9 bamboo slices 11 in parallel. The longitudinal direction is arranged in several rows successively, and the cotton yarn mesh cloth 12 (60g / m2) coated with urea-formaldehyde resin is lined on the back 2 ), solidified by pressing at 120°C for 5 minutes to form a bamboo strip with a width of 90 mm and a thickness of 0.8 mm (see figure 2 ), forming an uninterrupted strip of bamboo strips with a length of more than 50 meters, and rolled onto a reel for use;

[0023] b) Preparation of inner lining layer 1:

[0024] A 0.029mm thick polyester film is coated on a polished steel straight pipe mold with an outer ...

Embodiment 2

[0031] Taking the production of a bamboo composite pipe with a diameter of 300mm as an example, the specific steps are as follows:

[0032] a) bamboo chip pretreatment:

[0033] Fresh moso bamboo is opened into 5 meters long, 1.3mm thick, 14mm wide bamboo chips, soaked with 8% NaOH solution at 60°C for 8 hours, rinsed with water, and dried. Arrange in parallel with 8 bamboo slices 21 into a row, arrange multiple rows successively along the longitudinal direction, sew up with sutures 22 at every 30cm distance in the longitudinal direction, and the suture stitches become perpendicular to the bamboo slices (see image 3 ). After the bamboo slices are stitched, form a continuous strip of bamboo slices with a width of 120mm, a thickness of 1.3mm, and a length of more than 50 meters, and roll it onto a roll for use;

[0034] b) Preparation of inner lining:

[0035] Coated a layer of 0.029mm thick polyester film on a polished steel straight tube mold with an outer diameter of 300m...

Embodiment 3

[0042] Taking the production of a bamboo composite pipe with a diameter of 300mm as an example, the specific steps are as follows:

[0043]a) bamboo chip pretreatment:

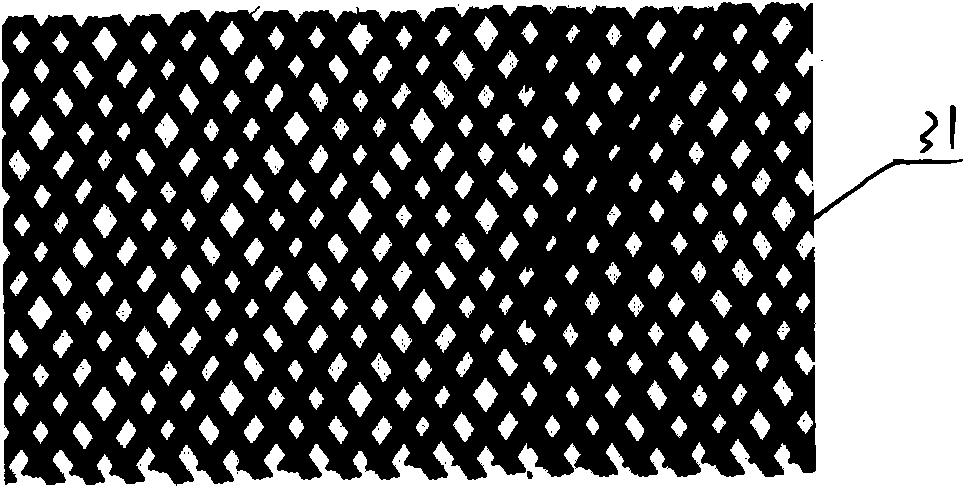

[0044] Cut fresh moso bamboo into 140 mm long, 1.0 mm thick, and 12 mm wide bamboo slices, soak them in 5% NaOH solution for 6 hours, rinse them with water, and dry them. Weave into the wide bamboo mat band of 110mm in the mode that bamboo sheet 31 intersects each other, and in this bamboo mat band, latitude and longitude bamboo sheet and bamboo mat band are the angle of 45 ° (see Figure 4 ). The woven bamboo mat is in the form of a continuous strip with a thickness of 2mm and a length of more than 50 meters, and rolled onto a drum for use;

[0045] b) Preparation of inner lining:

[0046] Coated a layer of 0.029mm thick polyester film on a polished steel straight tube mold with an outer diameter of 300mm, with food grade resin and polyester surface felt (30g / m 2 ) making an inner liner with a thickness o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com