Assembled type solid wood door leaf

A solid wood door, assembled technology, applied in the direction of the door leaf, etc., can solve the problems of short service life, bumps during transportation, inconvenient transportation, etc., and achieve the effect of high internal structure strength, increased structural strength and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

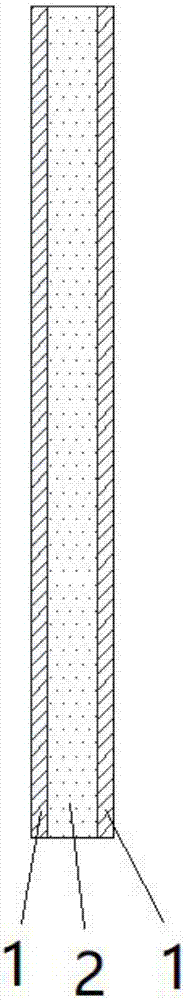

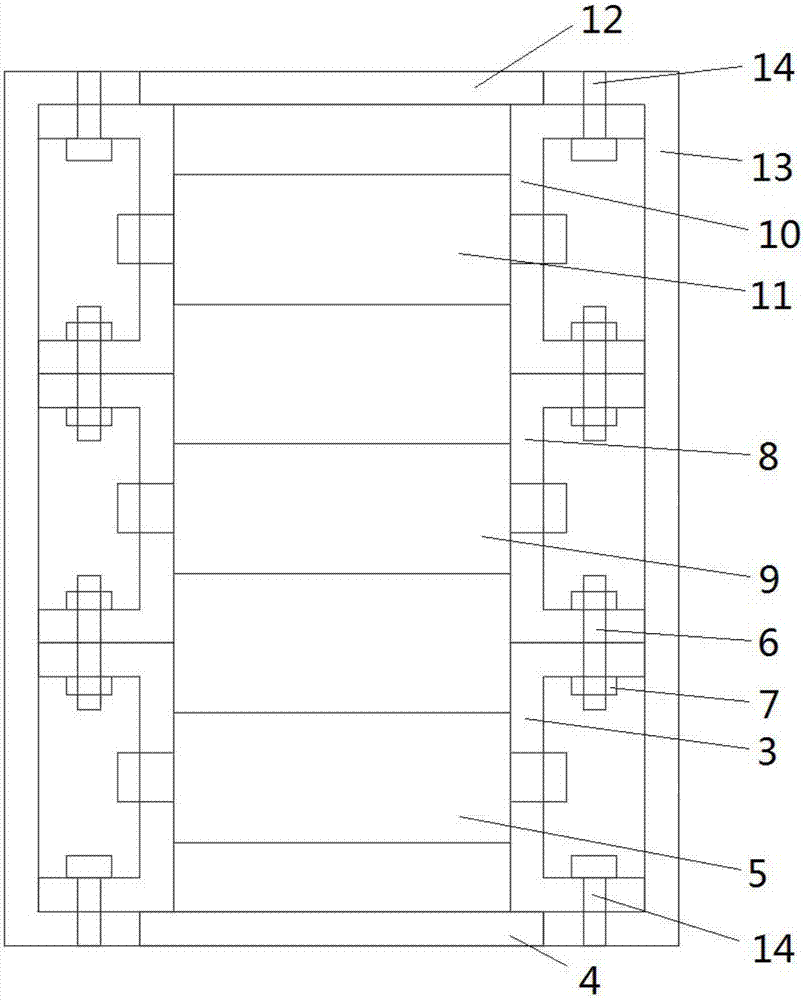

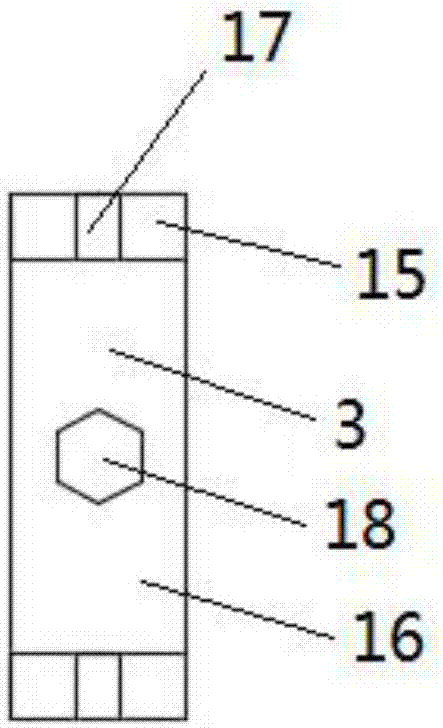

[0018] Embodiment: a kind of assembled solid wood door leaf, structure such as Figures 1 to 5 As shown, it includes a three-layer solid wood structure, wherein both sides are veneer layers 1, and an assembly layer 2 is sandwiched between the veneer layers 1; the assembly layer 2 includes a pair of symmetrically arranged first C-shaped planks 3, the second The lower end of a C-shaped plank 3 is connected with a base plate 4, the first C-shaped plank 3 is tenon-jointed with a bottom beam 5, and the top of the first C-shaped plank 3 is connected with a second C-shaped plank 8 via stud bolts 6 and nuts 7 , the second C-shaped planks 8 are mortised and joined with an intermediate crossbeam 9, and the upper part of the second C-shaped planks 8 is connected with a third C-shaped plank 10 via stud bolts 6 and nuts 7, and the third C-shaped planks 10 are tenoned A top beam 11 is connected, and a top plate 12 is connected above the third C-shaped plank 10; a fourth C-shaped plank 13 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com