A kind of propeller auxiliary disassembly tooling, disassembly method and installation method

A technology of propeller and tooling, applied in the field of auxiliary disassembly and assembly of propellers, can solve the problems of affecting the service life of the hull plate, a lot of manpower input, inconvenient disassembly and assembly, etc. The effect of assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

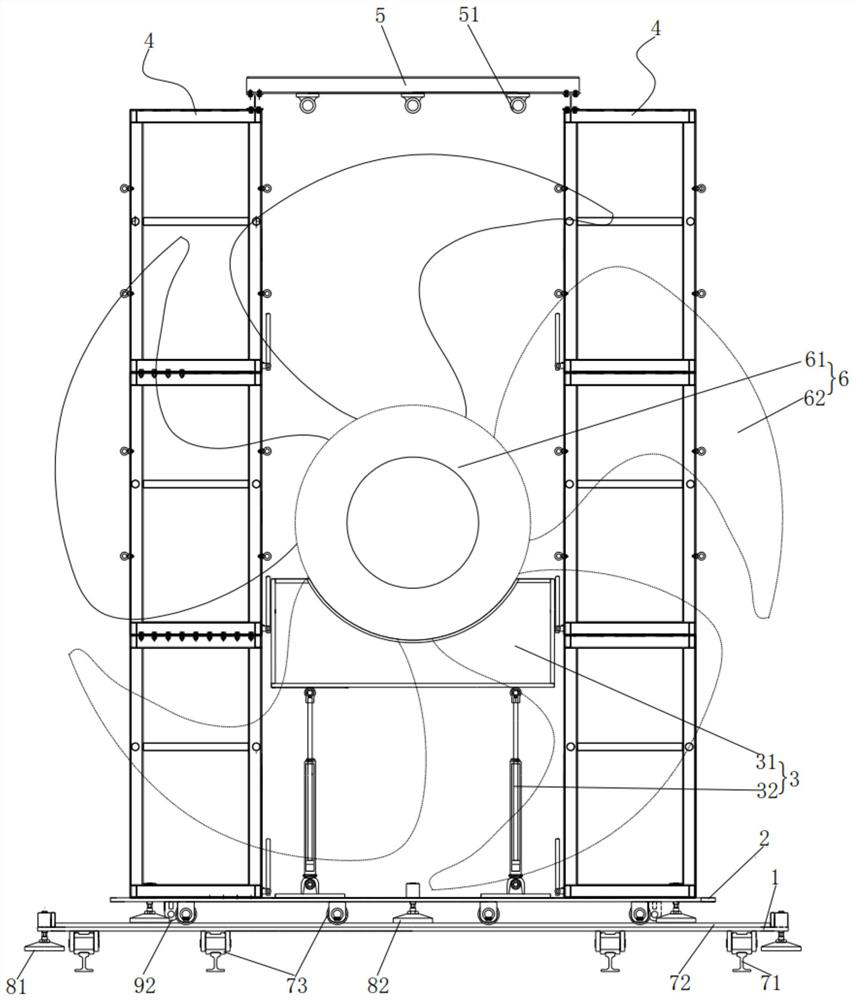

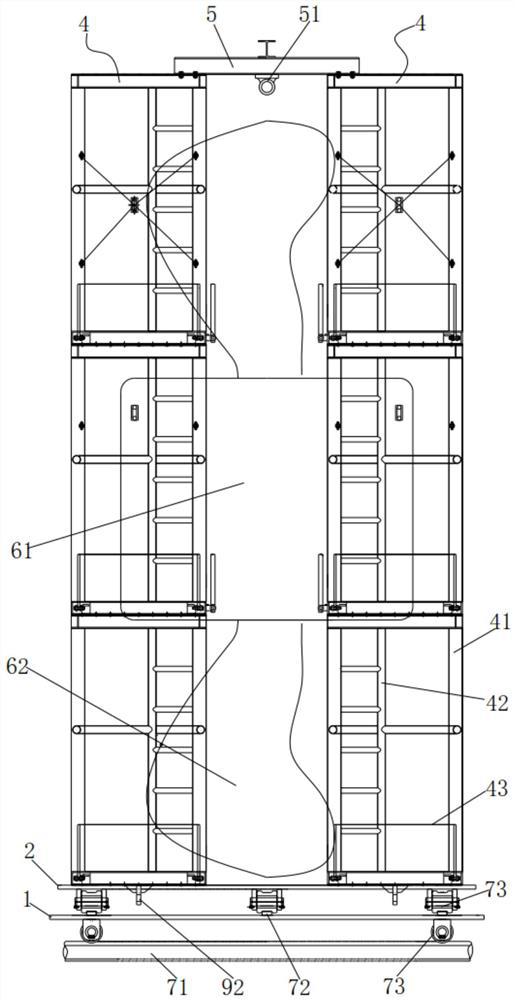

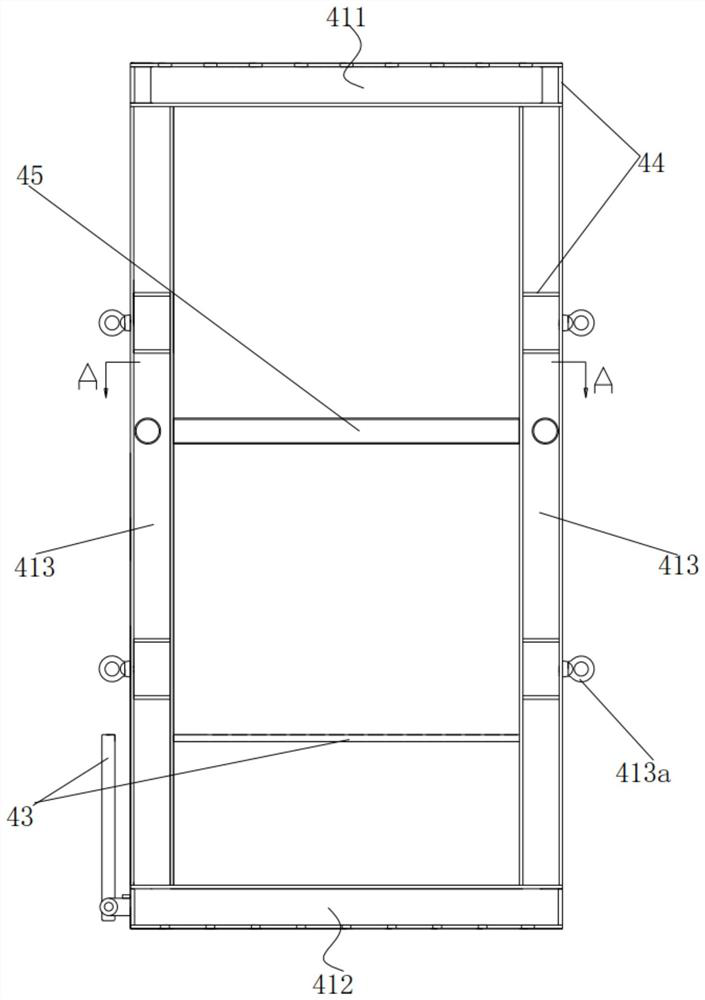

[0067] like figure 1 , figure 2 , Figures 8 to 14 As shown, a propeller auxiliary disassembly and assembly tool of the present invention includes a chassis I 1 that can move longitudinally on the ground, a chassis I 1 that can move laterally on the chassis I 1, and a jacking device 3 arranged on the chassis II 2. The device 3 includes a lifting platform 31 and a lifting driving device 32 that drives the lifting platform 31 to move up and down. The lifting driving device 32 is a hydraulic cylinder, a motor screw device or a cylinder and other linear driving devices; The concave arc-shaped groove 31a increases the contact area between the lift platform 31 and the propeller 61 of the propeller 6 and ensures the support stability of the propeller 61 .

[0068] like Figure 1 to Figure 2 As shown, the propeller auxiliary disassembly tool includes longitudinal guide rails 71, and the bottom of chassis I1 is provided with rollers 73 or sliders that can move on the longitudinal g...

no. 2 example

[0073] like Figure 1 to Figure 14 As shown, a propeller auxiliary disassembly and assembly tool of the present invention includes a chassis I 1 that can move longitudinally on the ground, a chassis I 1 that can move laterally on the chassis I 1, and a jacking device 3 arranged on the chassis II 2. The device 3 includes a lifting platform 31 and a lifting driving device 32 that drives the lifting platform 31 to move up and down. The lifting driving device 32 is a hydraulic cylinder, a motor screw device or a cylinder and other linear driving devices; The concave arc-shaped groove 31a increases the contact area between the lift platform 31 and the propeller 61 of the propeller 6 and ensures the support stability of the propeller 61 .

[0074] like figure 1 and figure 2 As shown, two sets of support frames are arranged on the chassis II 2 at intervals, and the tops of the two sets of support frames are connected by a hanger 5, and the hanger 5 is provided with a lifting ring ...

no. 3 example

[0086] The present invention also provides a disassembly method of the propeller, which uses the propeller-assisted disassembly and assembly tool in the first embodiment or the second embodiment to disassemble the propeller, and the disassembly method includes the following steps:

[0087] Move the chassis I 1 longitudinally to below the propeller 6 to be disassembled, adjust the position of the chassis II 2 on the chassis I 1, until the arc groove 31a of the lifting platform 31 is located directly below the propeller hub 61, through the lifting drive device 32 Drive the lift platform 31 to move up until the arc groove 31a of the lift platform 31 is fitted with the propeller hub 61;

[0088] Loosen the propeller 6 so that the hub 61 of the propeller 6 and the tail shaft are in a fixed release state;

[0089] Drive the chassis I1 to move away from the tail shaft, so that the propeller 6 is separated from the tail shaft; the chassis I1 continues to move until it reaches the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com