Multifunctional valve element dismounting device and application method

A technology of multi-functional valve and disassembly method, which is applied in the field of mechanical assembly, and can solve the problems that disassembly and assembly cannot be carried out, the sealing surface of the valve seat cannot be ground and repaired, and the weight of the valve stem and valve core assembly of the safety valve is large, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with embodiment the present invention is further introduced:

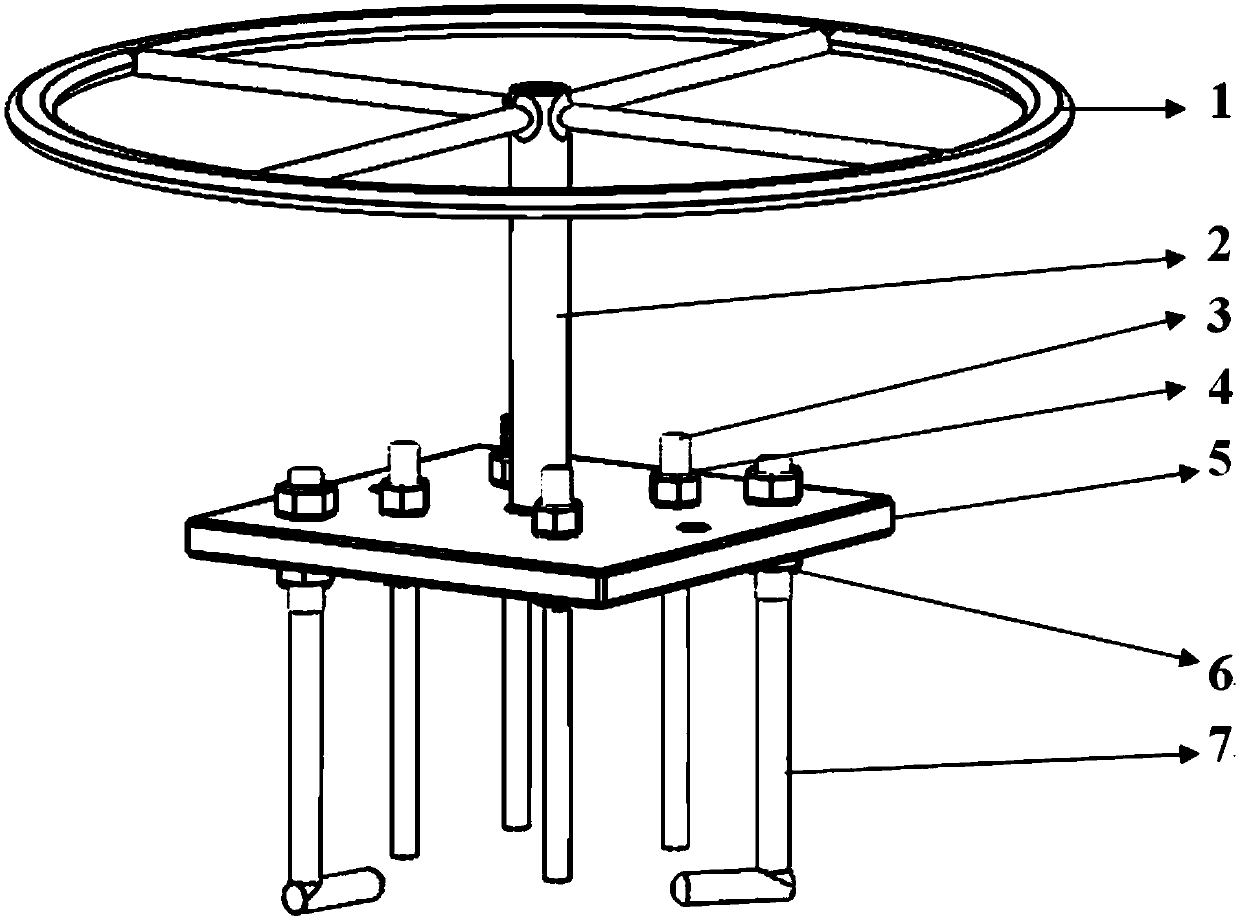

[0022] A multifunctional valve core dismounting device, comprising a grinding hand wheel 1, a connecting rod 2, a positioning rod 3, an upper fastening nut 4, a motherboard 5, a lower fastening nut 6 and a hook 7; the upper end of the connecting rod 2 Grinding handwheel 1 is welded, and the lower end is welded on the motherboard 5; four positioning rods 3 and two suspension hooks 7 pass through the motherboard 5; each positioning rod 3 and suspension hook 7 pass through an upper fastening nut 4 and A lower fastening nut 6 is fixed on the motherboard 5 .

[0023] A valve core dismounting method, which is realized based on the multifunctional valve core dismounting device

[0024] Include the following steps:

[0025] [1] After the valve is removed, rotate it 180°, and the valve core is above the valve stem;

[0026] [2] Insert the bent ends of the two hooks 7 into two self-retaining ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com