Method for enhancing drilling torque and wear resistance of patio drill stem and patio drill stem

A wear-resistant and drill pipe technology, which is applied in the field of drilling tools, can solve problems such as not being able to adapt to development requirements, and achieve the effects of overall performance improvement, efficiency improvement, and quick installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings, but not as any limitation to the present invention.

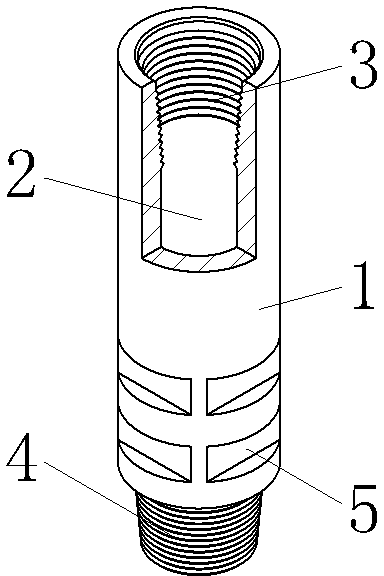

[0015] A method of increasing torque and wear resistance of raise drill pipe, such as figure 1 shown. The raise drill pipe of this method is processed into an integral drill pipe with an outer diameter φ of 287-292mm and an effective wall thickness of 45-50mm by using 4330V MOD alloy steel; After 6 hours, quenching; then tempering at 600~660°C to achieve the following comprehensive mechanical properties: tensile strength ≥ 1033Mpa, yield strength ≥ 964 Mpa, elongation ≥ 15%, reduction of area ≥ 45%, impact energy ≥ 90 J. The overall hardness value reaches 330 ~ 364HB; to improve the torque requirements and wear resistance requirements of the raise drill pipe.

[0016] The raise drilling pipe made by the aforementioned method, such as figure 1 shown. Including the rod body 1, the outer diameter φ ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com