High-efficiency automatic disassembling device for mobile phone fixing screw

A fixed screw and efficient technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problem of low efficiency of manual disassembly, and achieve the effects of diversified disassembly and utilization, cost reduction, and accurate disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

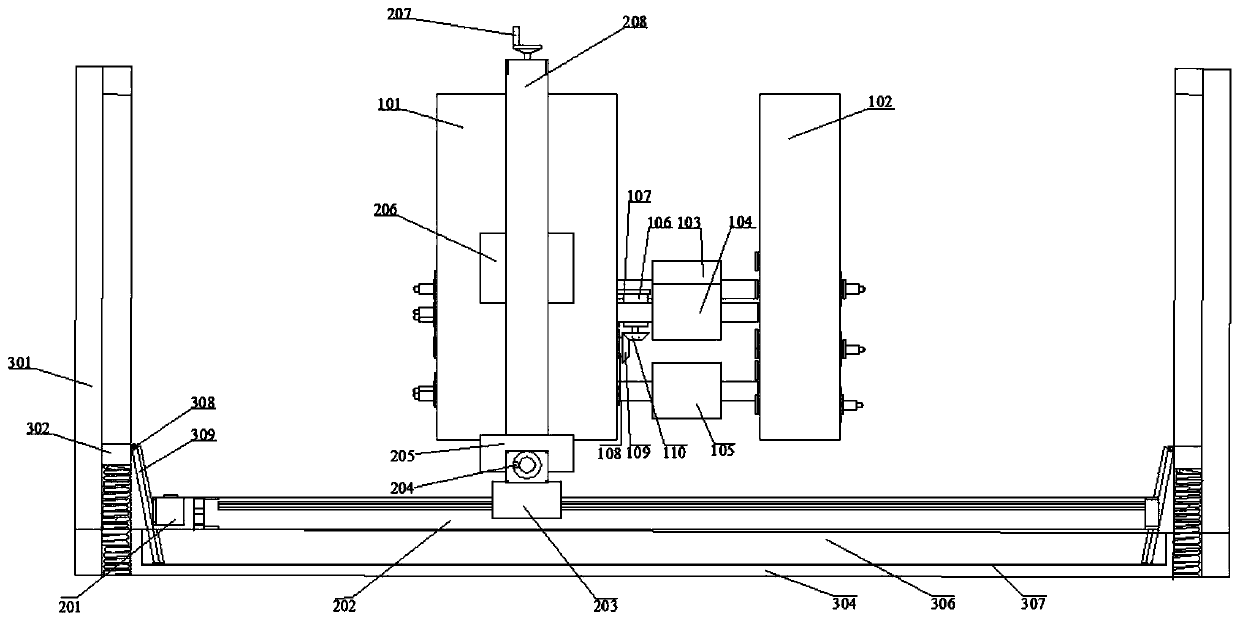

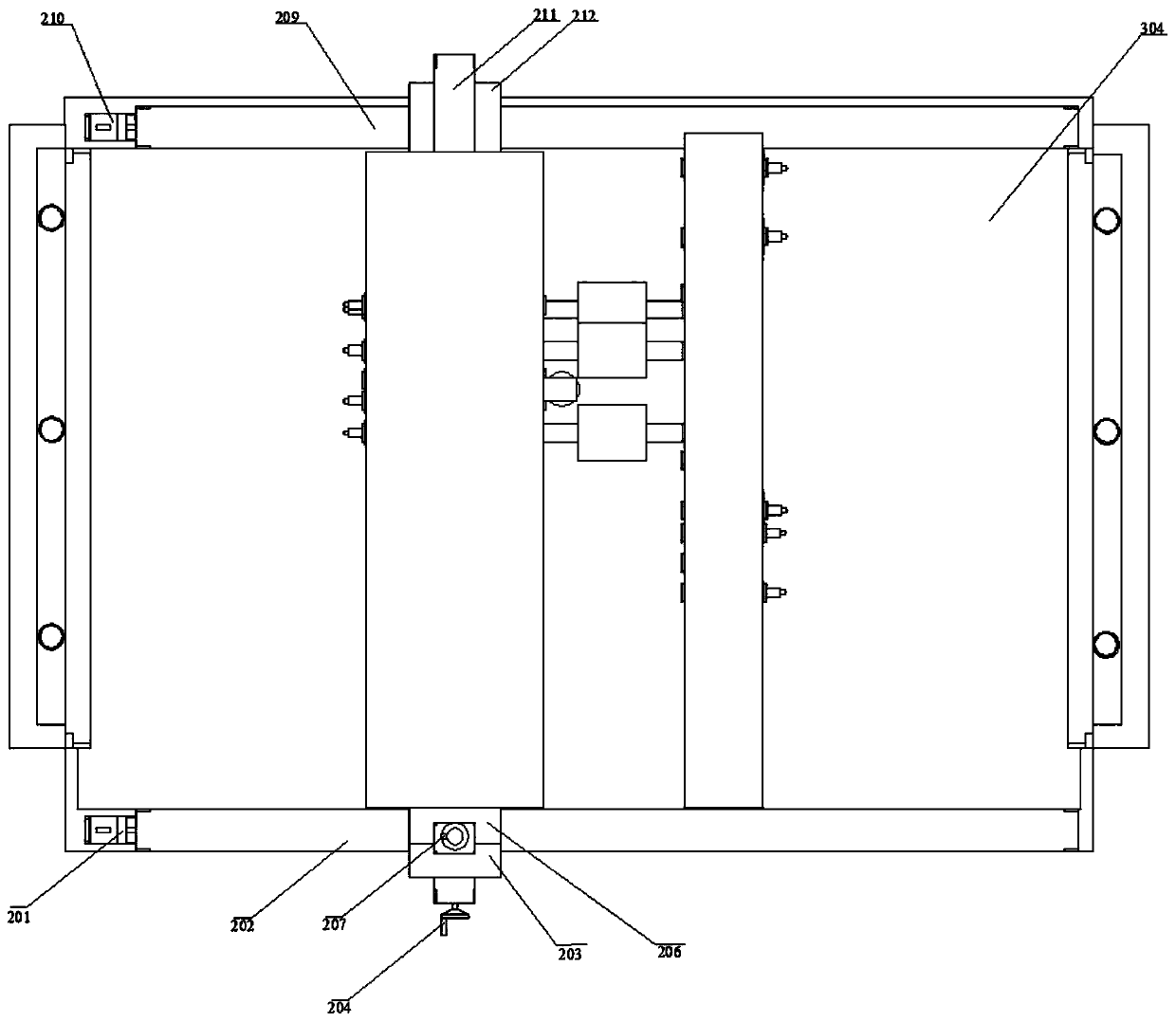

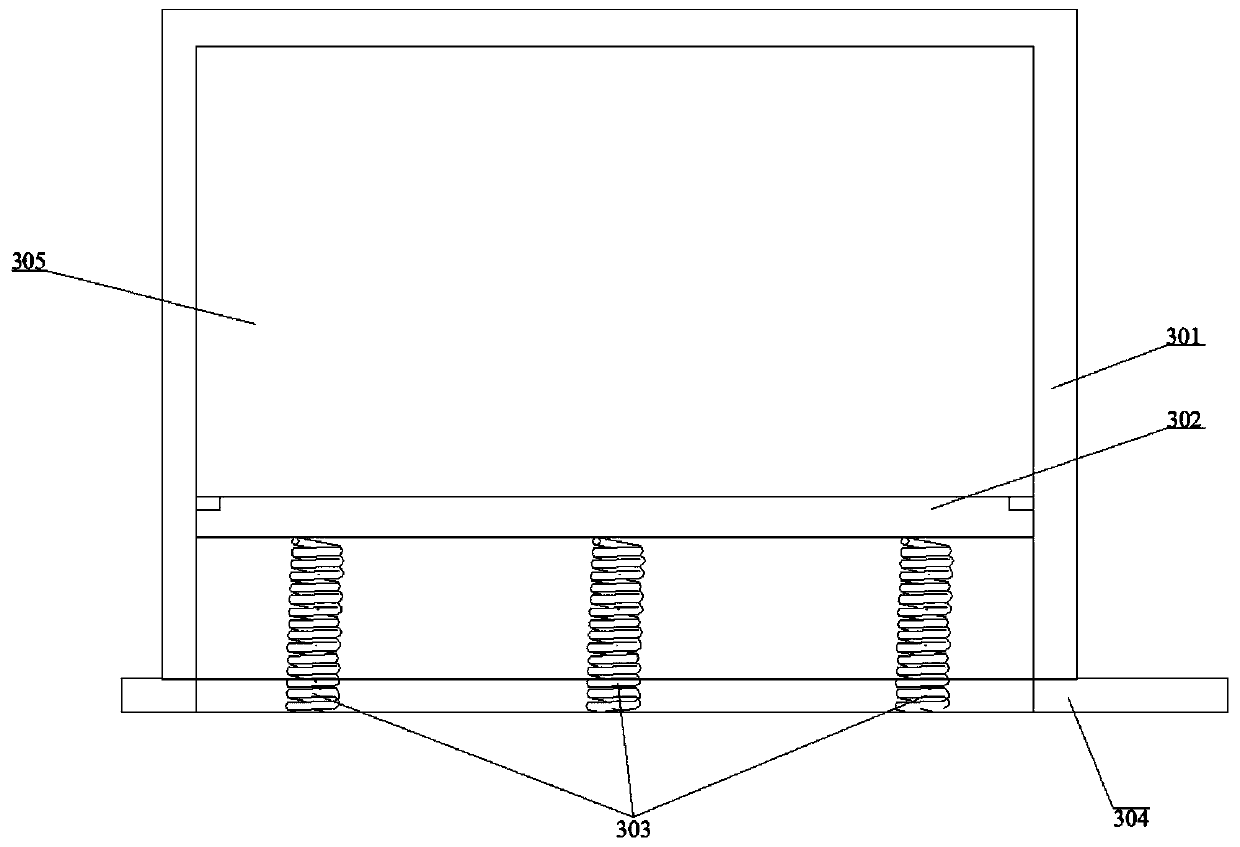

[0028] Such as Figure 1-8 As shown, in the embodiment of the present invention, a high-efficiency automatic dismantling device for mobile phone fixing screws includes a dismantling mechanism, a moving mechanism, a knife shaft connection mechanism and a clamping mechanism, the disassembly mechanism and the knife shaft connection mechanism are fixedly connected, and the clamping mechanism The mechanism is fixedly connected with the moving mechanism. The dismantling mechanism includes a first gear box 101 and a second gear box 102. The first gear box 101 is provided with a first rotating shaft 108. The first rotating shaft 108 is a power input shaft. The first rotating shaft 108, The first rotating shaft 108 is rotationally connected with the first gear box 101 through the second bearing 119, and the second bearing 119 is mounted on the first gear box 101 through an interference fit, and a motor base 107 is installed on the right outer wall of the first gear box 101, A dismantli...

Embodiment 2

[0042] Such as Figure 1-9As shown, in the embodiment of the present invention, a high-efficiency automatic dismantling device for mobile phone fixing screws includes a dismantling mechanism, a moving mechanism, a knife shaft connection mechanism and a clamping mechanism, the disassembly mechanism and the knife shaft connection mechanism are fixedly connected, and the clamping mechanism The mechanism is fixedly connected with the moving mechanism. The dismantling mechanism includes a first gear box 101 and a second gear box 102. The first gear box 101 is provided with a first rotating shaft 108. The first rotating shaft 108 is a power input shaft. The first rotating shaft 108, The first rotating shaft 108 is rotationally connected with the first gear box 101 through the second bearing 119, and the second bearing 119 is mounted on the first gear box 101 through an interference fit, and a motor base 107 is installed on the right outer wall of the first gear box 101, A dismantlin...

Embodiment 3

[0058] A dismantling method based on the efficient automatic dismantling device of the mobile phone fixing screw described in embodiment 2, the steps are as follows:

[0059] S1, first carry out the clamping of the mobile phone on the left and right sides, put the mobile phone to be disassembled into the clamping groove 305, press down the buffer spring 303, and press against the baffle 302 to complete the clamping of the mobile phone;

[0060] S2. Adjust the first adjustment knob 204 and the second adjustment knob 207, so that the disassembly mechanism is positioned before disassembly by the moving mechanism;

[0061] S3, after positioning, restore the dismantling mechanism to the middle position, start the dismantling motor 106, and the dismantling motor 106 rotates to drive the first bevel gear 110 and the second bevel gear 109 to rotate, and the power is input into the first gear box 101 and the second gear box 101. a gear box 102, so that the first gear box 101 and the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com