High-flow precious metal channel

A precious metal, high-flow technology, applied in glass production, feeding troughs, etc., can solve problems such as limited processing capacity, inability to achieve high-quality and stable clarification, and inability to guarantee high-temperature mechanical strength to achieve excellent results, ensure service life and high temperature Effect of mechanical strength and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

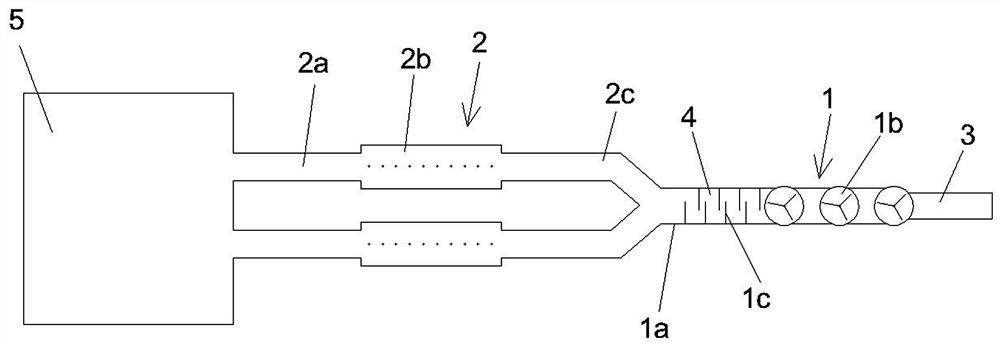

[0016] Such as figure 1 As shown, a large-flow noble metal passage includes a mixed-flow stirring section 1 of molten glass, and the mixed-flow stirring section 1 of molten glass includes a confluence channel 1a with a diameter of 400mm, and one end of the confluence channel 1a is connected to the two diameters of The cooling channel 2c with a length of 280mm and a length of 3000mm is connected, and a set of spoiler 1c is welded in the confluence channel 1a. The set of spoiler 1c includes eight spoilers 1c that are misplaced from each other. Through these eight spoilers The plate 1c divides a section of serpentine flow channel 4 in the confluence channel 1a.

[0017] The confluence channel 1a at one end of the serpentine flow channel 4 is also connected in turn with three molten glass stirring tanks 1b with a diameter of 400 mm, a rotating speed of 3 revolutions per minute, and stirring directions of counterclockwise, clockwise, and counterclockwise respectively. A liquid sup...

Embodiment 2

[0022] Such as figure 1 As shown, a large-flow noble metal passage includes a mixed-flow stirring section 1 of molten glass, and the mixed-flow stirring section 1 of molten glass includes a confluence channel 1a with a diameter of 300mm, and one end of the confluence channel 1a is connected to the two diameters of The 220mm cooling channel 2c with a length of 2000mm is connected, and a set of spoiler 1c is welded in the confluence channel 1a. The set of spoiler 1c includes five spoiler 1c that are misaligned with each other. Through these five spoiler The plate 1c divides a section of serpentine flow channel 4 in the confluence channel 1a.

[0023] On the confluent channel 1a at one end of the serpentine flow channel 4, there are also three molten glass stirring tanks 1b with a diameter of 350 mm, a rotating speed of 8 revolutions per minute, and stirring directions of clockwise, counterclockwise, and clockwise respectively. A liquid supply tank 3 with a diameter of 300 mm is...

Embodiment 3

[0028] Such as figure 1 As shown, a large-flow noble metal passage includes a mixed-flow stirring section 1 of molten glass, and the mixed-flow stirring section 1 of molten glass includes a confluence channel 1a with a diameter of 500mm, and one end of the confluence channel 1a is connected to the two diameters of The cooling channel 2c with a length of 360mm and a length of 6000mm is connected, and a set of spoiler 1c is welded in the confluence channel 1a. The spoiler 1c divides a section of serpentine flow channel 4 in the confluence channel 1a.

[0029] On the confluence channel 1a at one end of the serpentine flow channel 4, there are also three molten glass stirring tanks 1b with a diameter of 550 mm, a rotating speed of 18 revolutions per minute, and stirring directions of counterclockwise, clockwise, and counterclockwise respectively. A liquid supply tank 3 with a diameter of 500 mm is communicated with the liquid outlet of the last molten glass stirring tank 1b.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com