Patents

Literature

45results about How to "Avoid risk of collapse" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

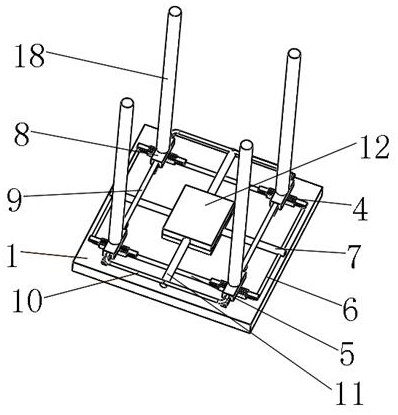

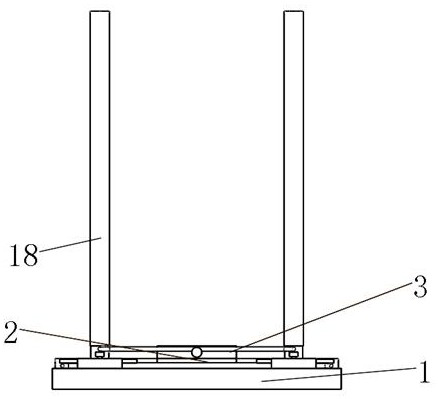

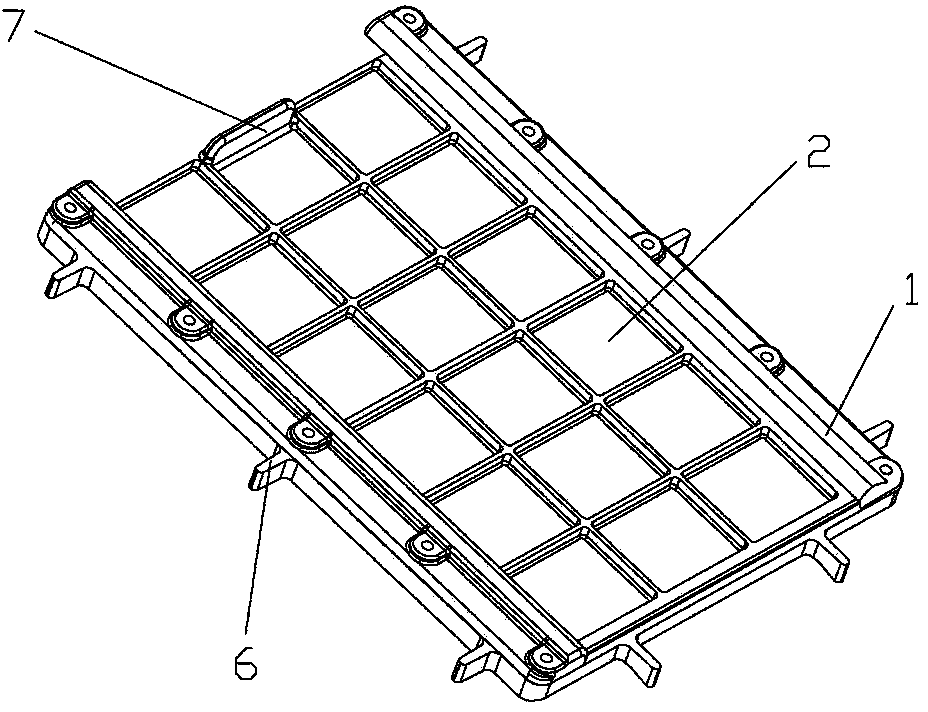

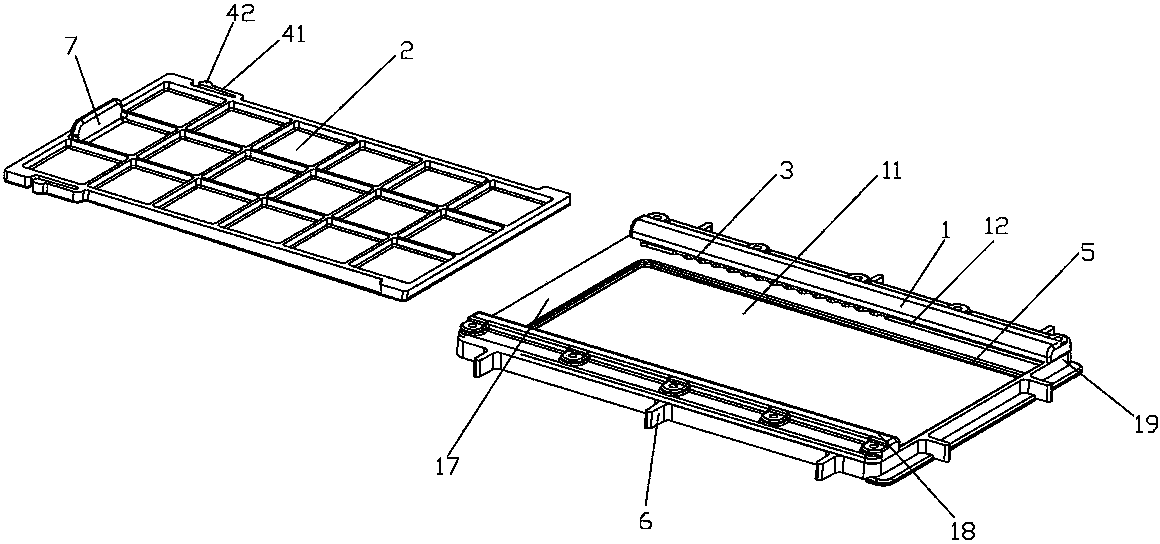

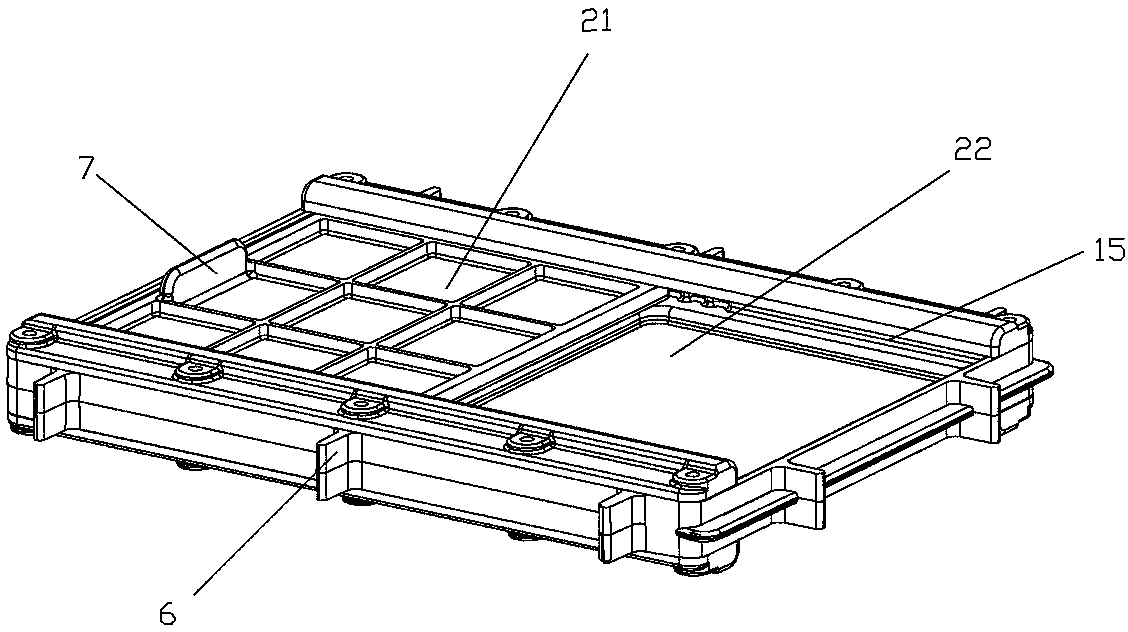

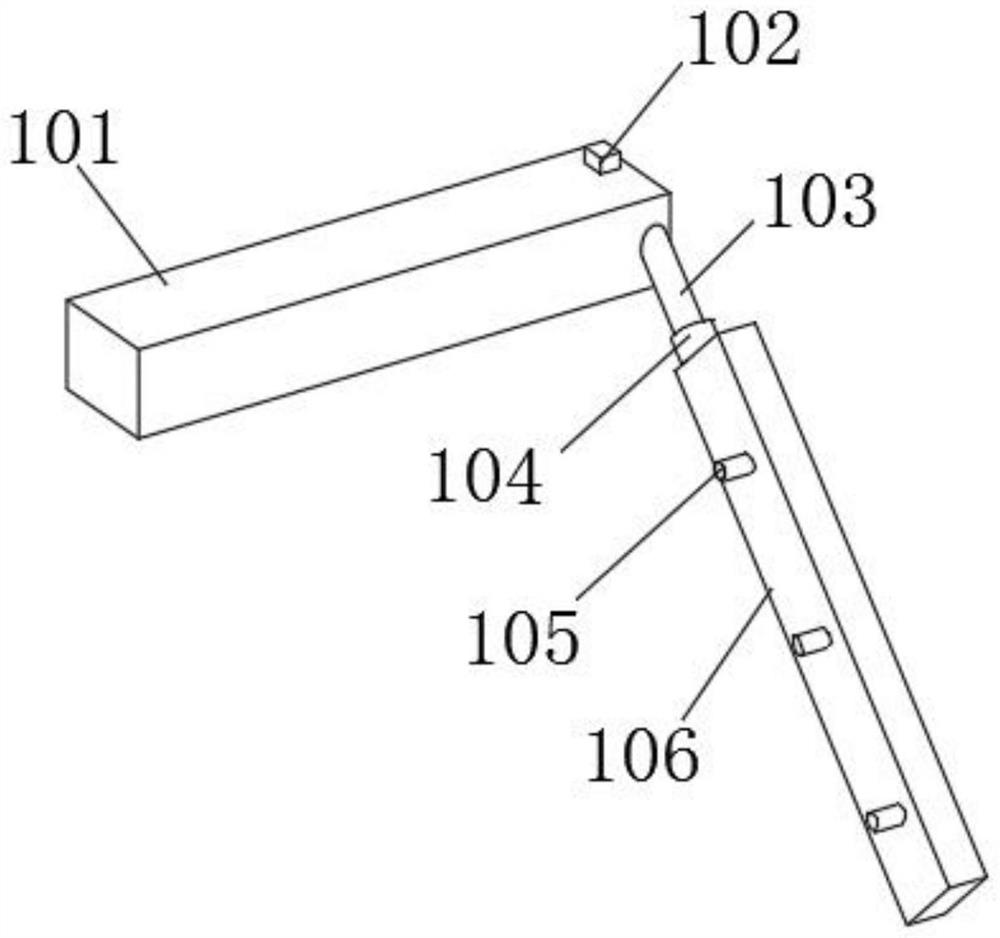

Single-step-type light single-side wall formwork trolley

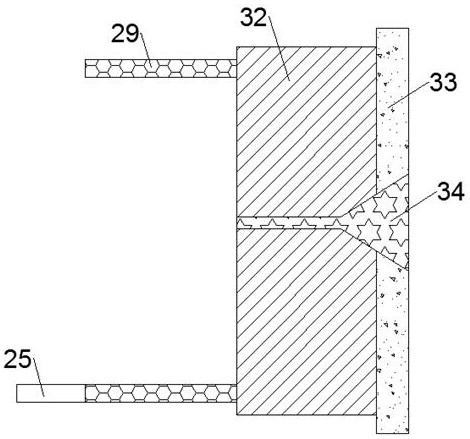

ActiveCN108533290AAvoid risk of collapseIncrease contact areaUnderground chambersTunnel liningPre embeddingSingle step

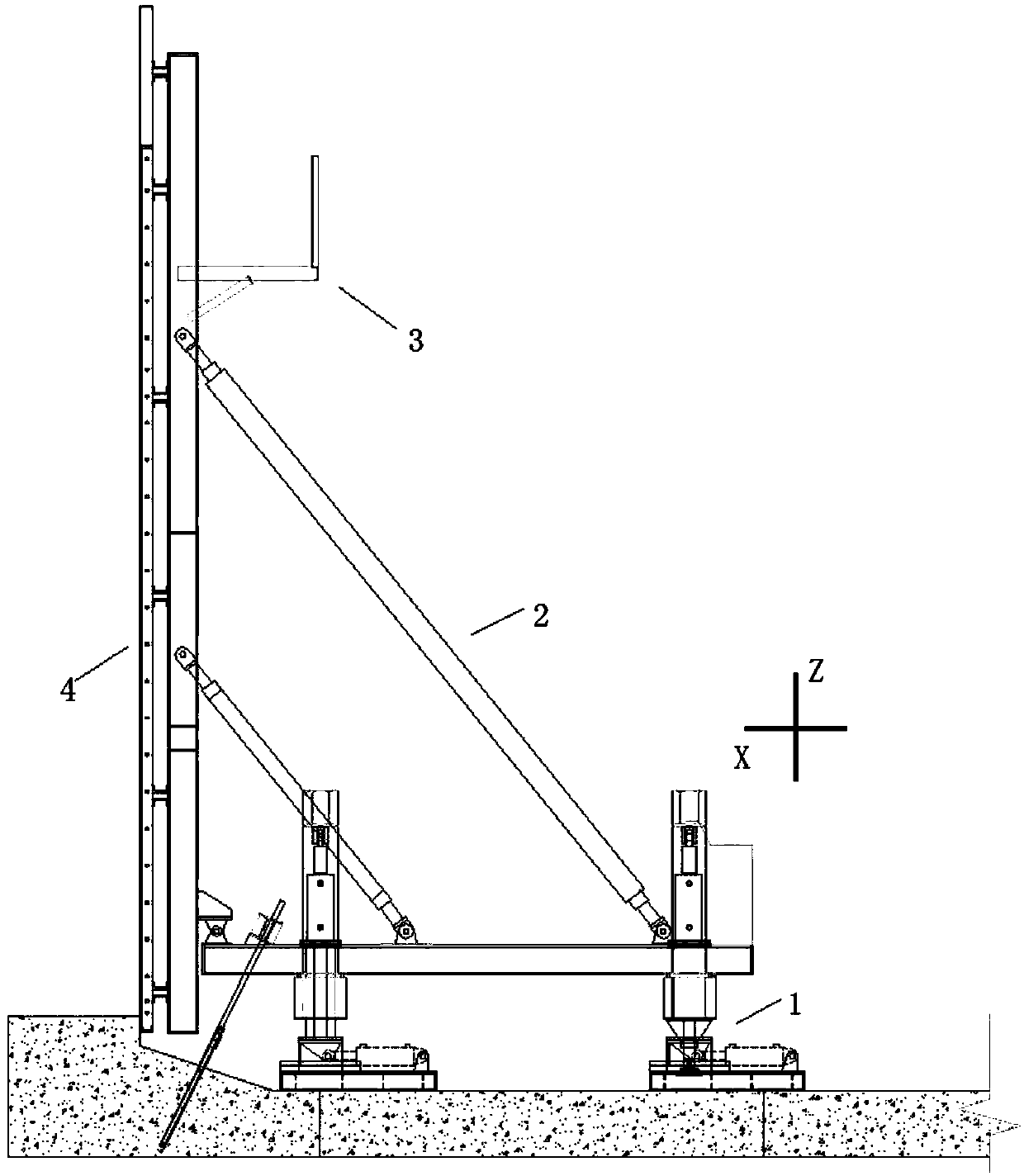

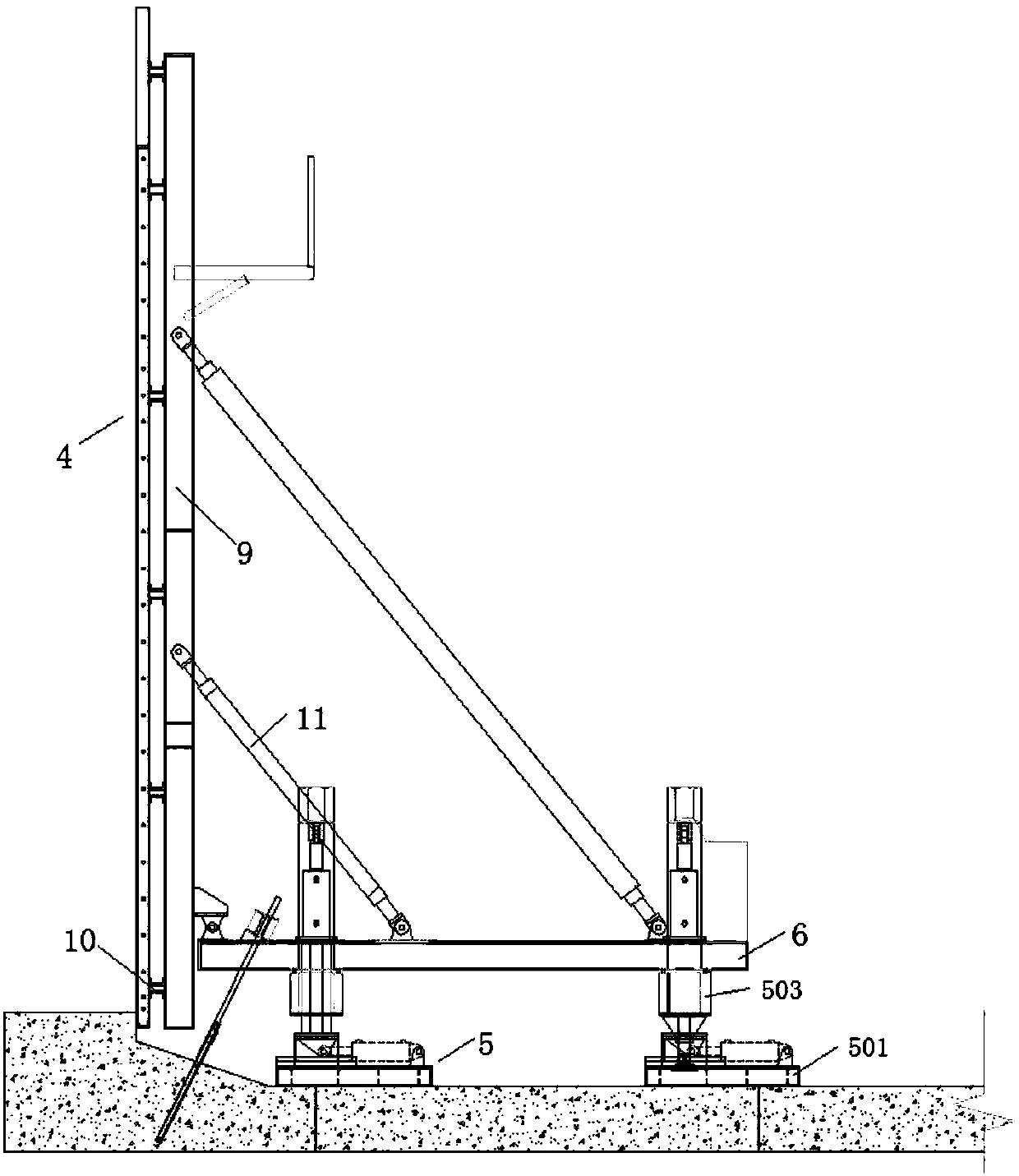

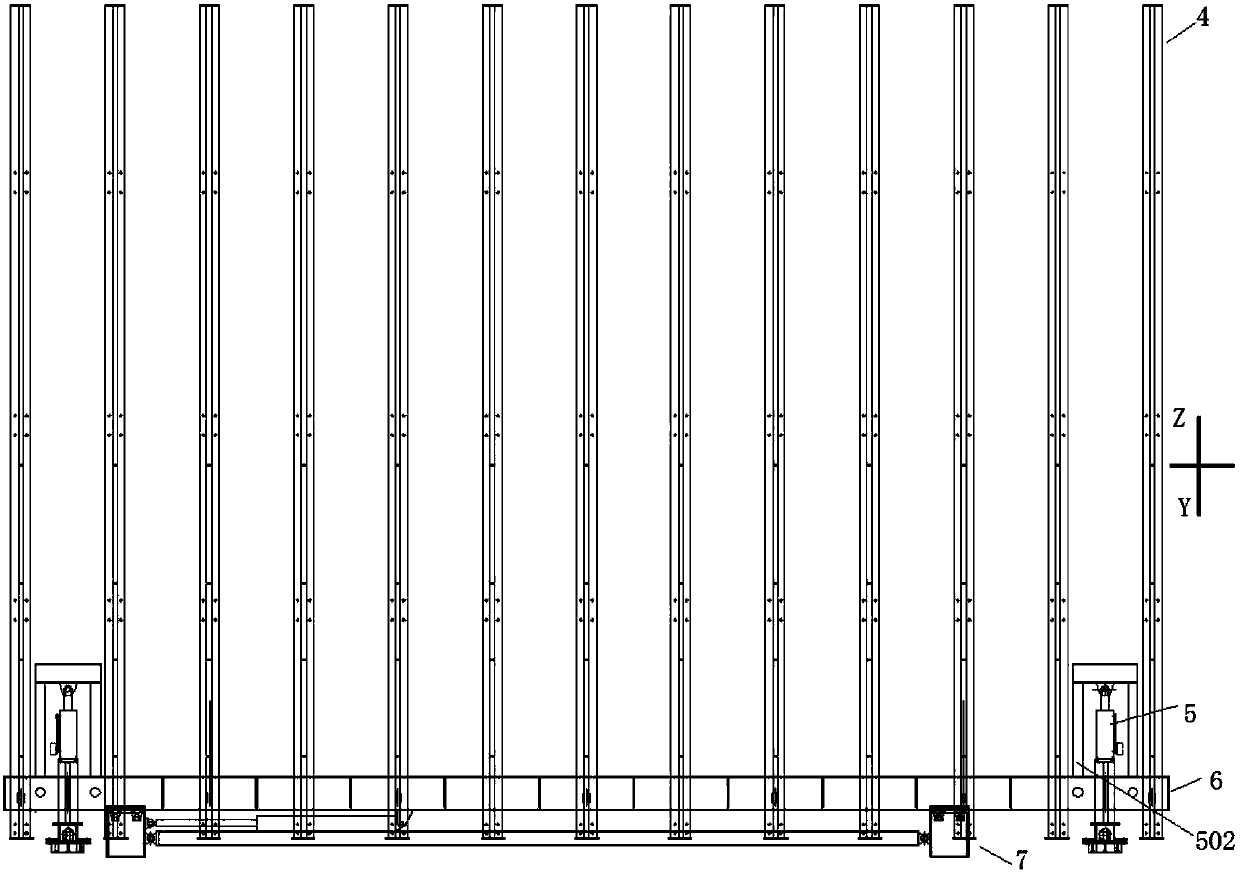

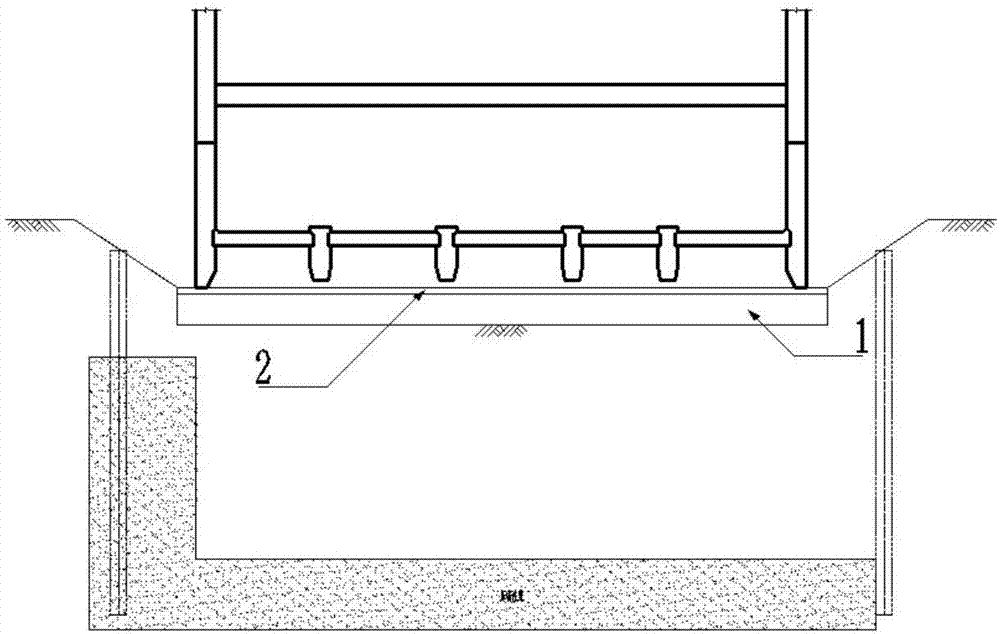

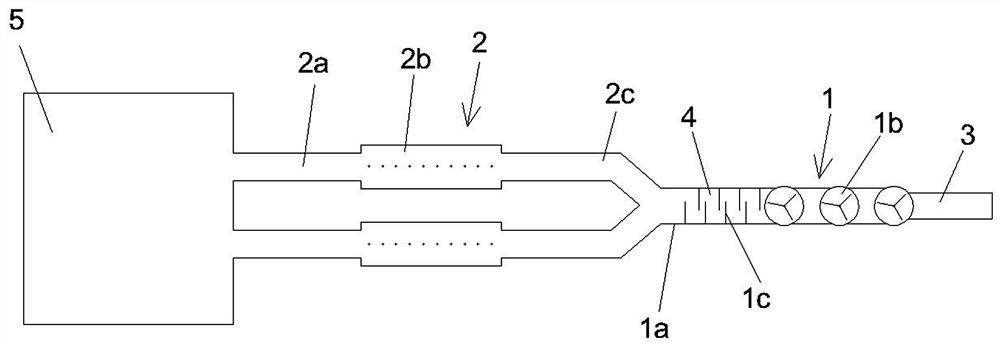

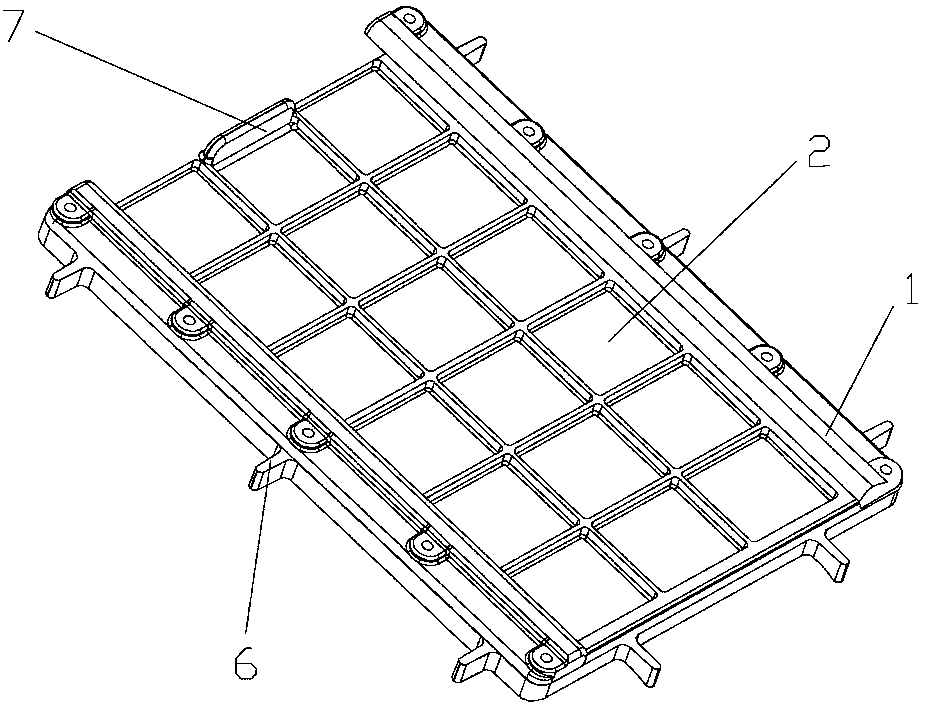

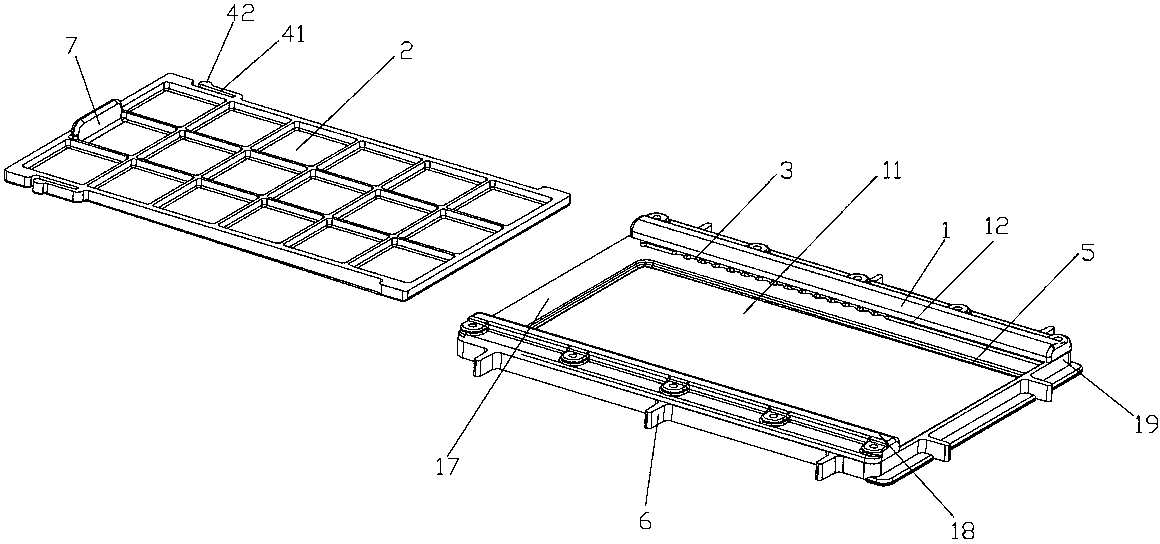

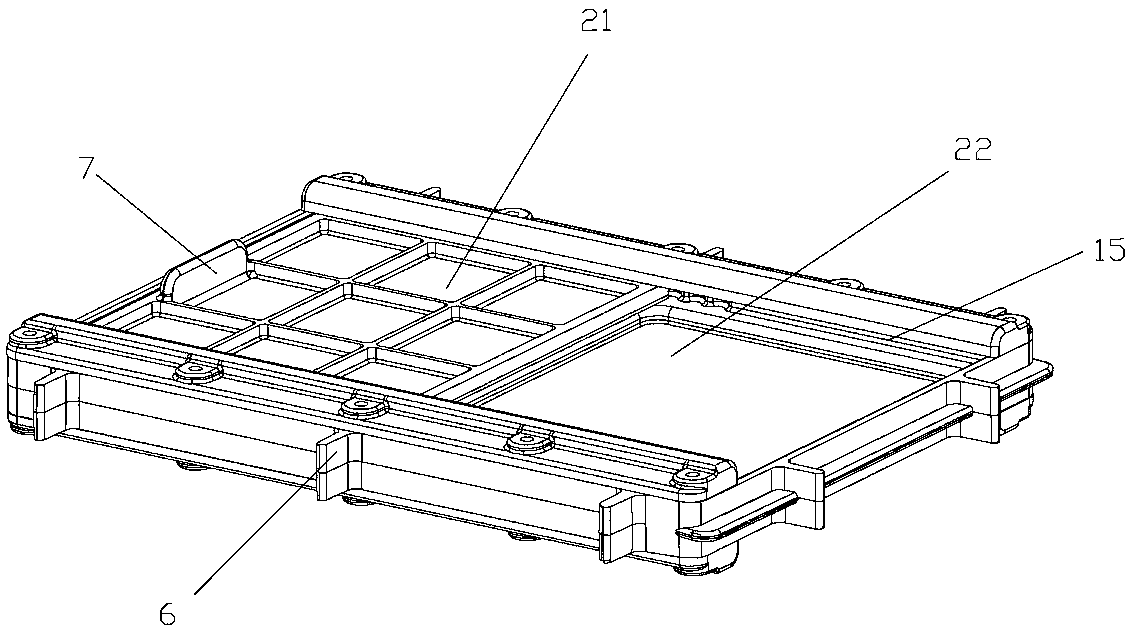

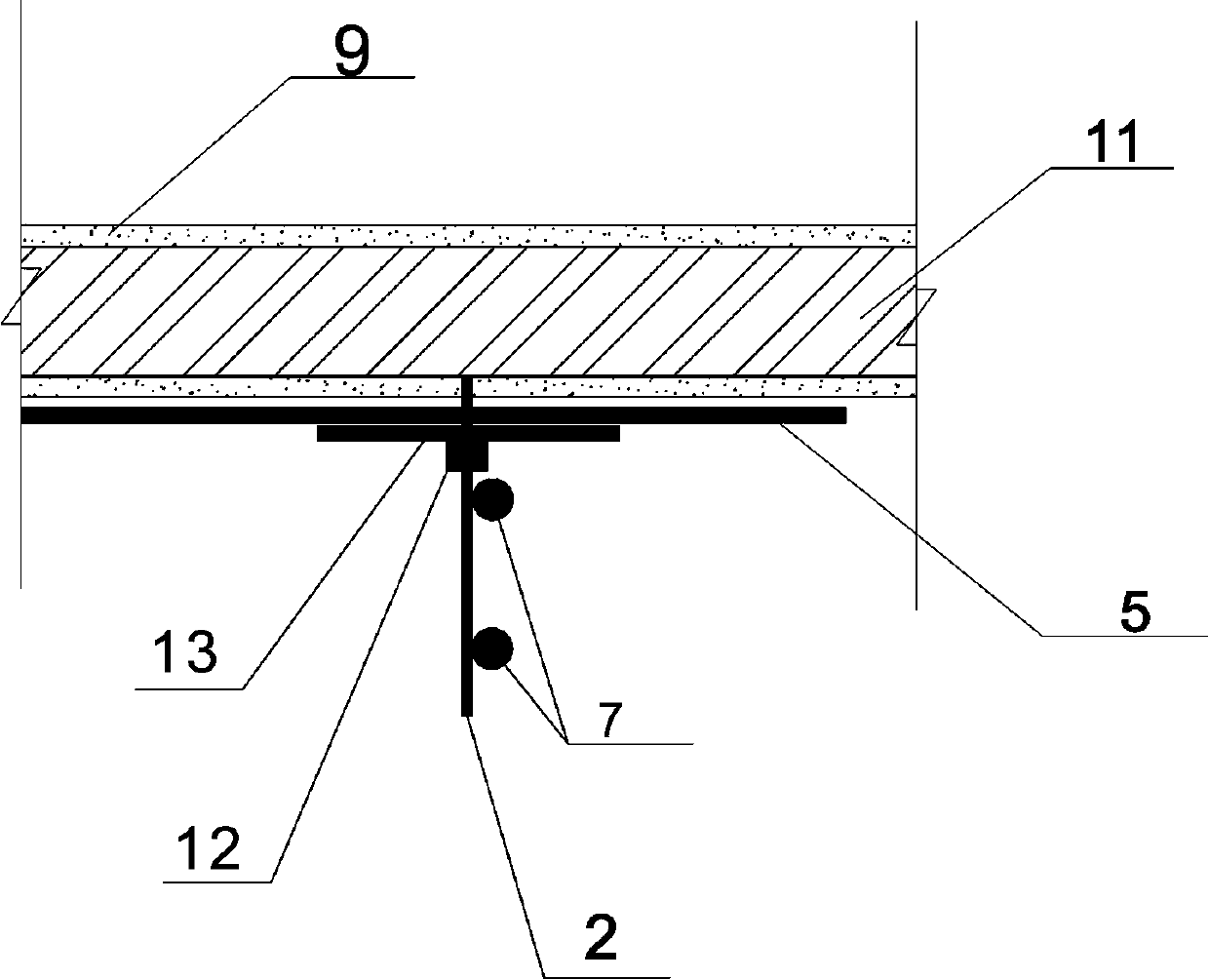

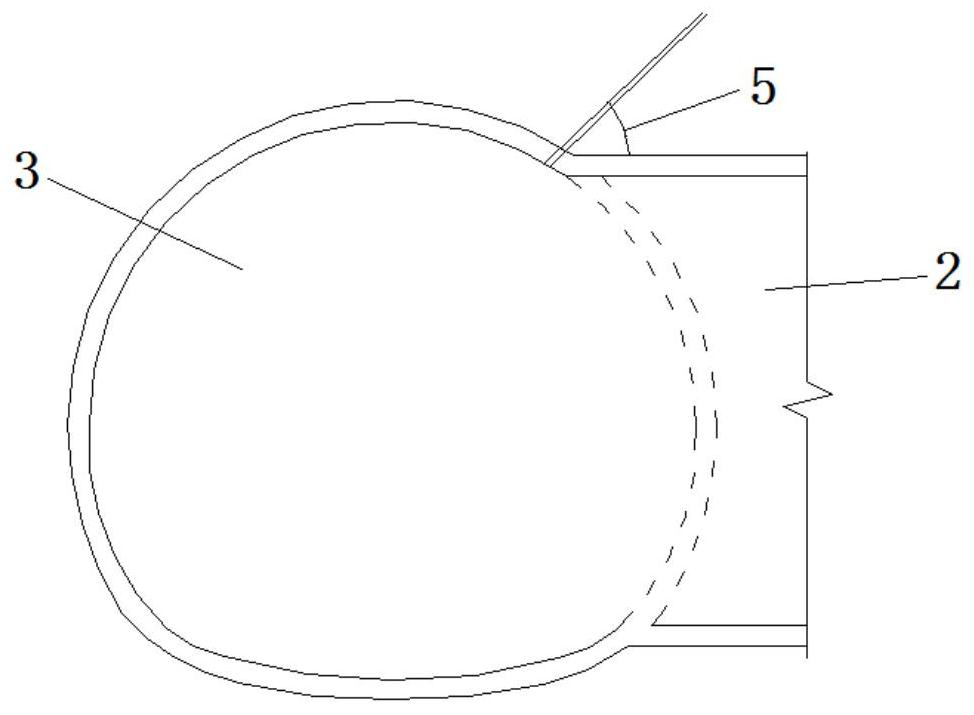

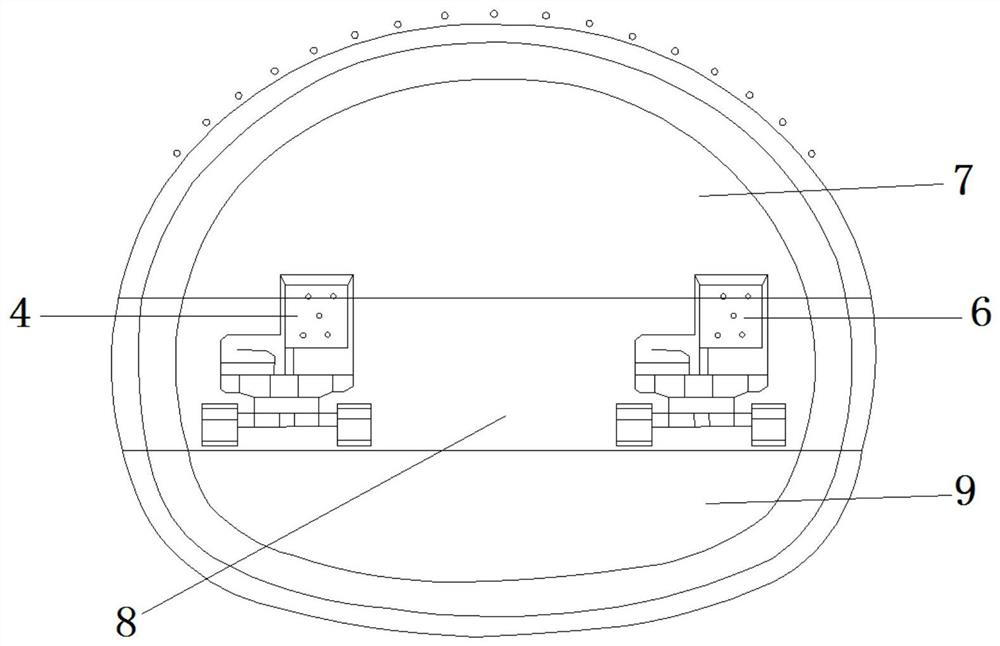

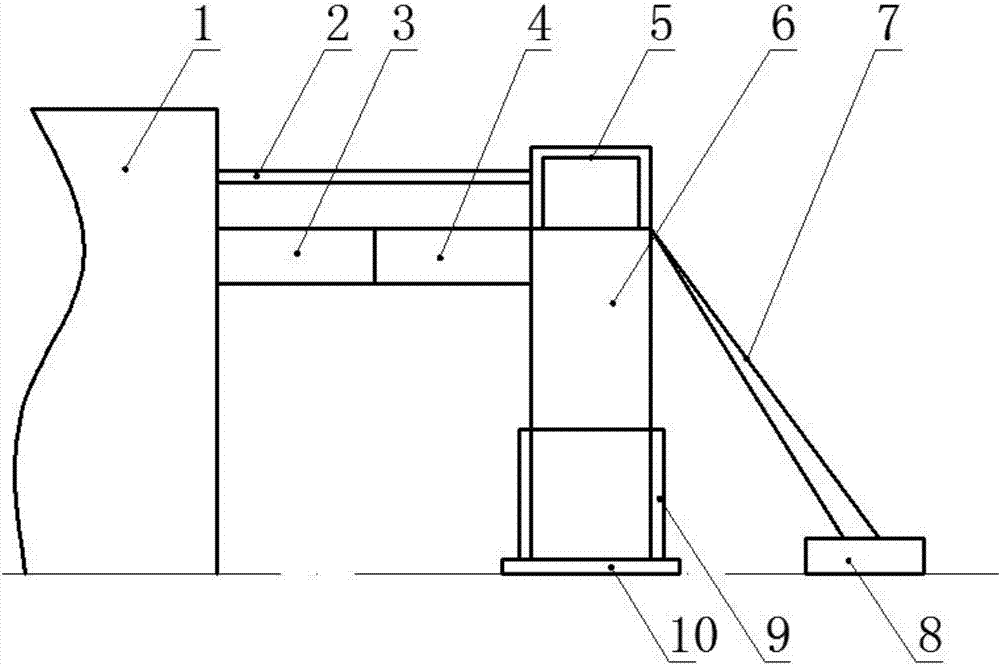

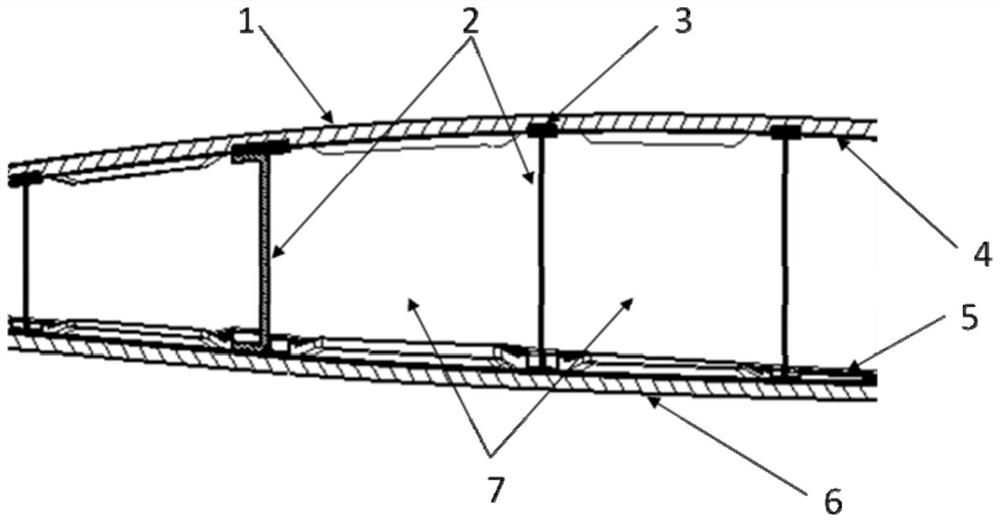

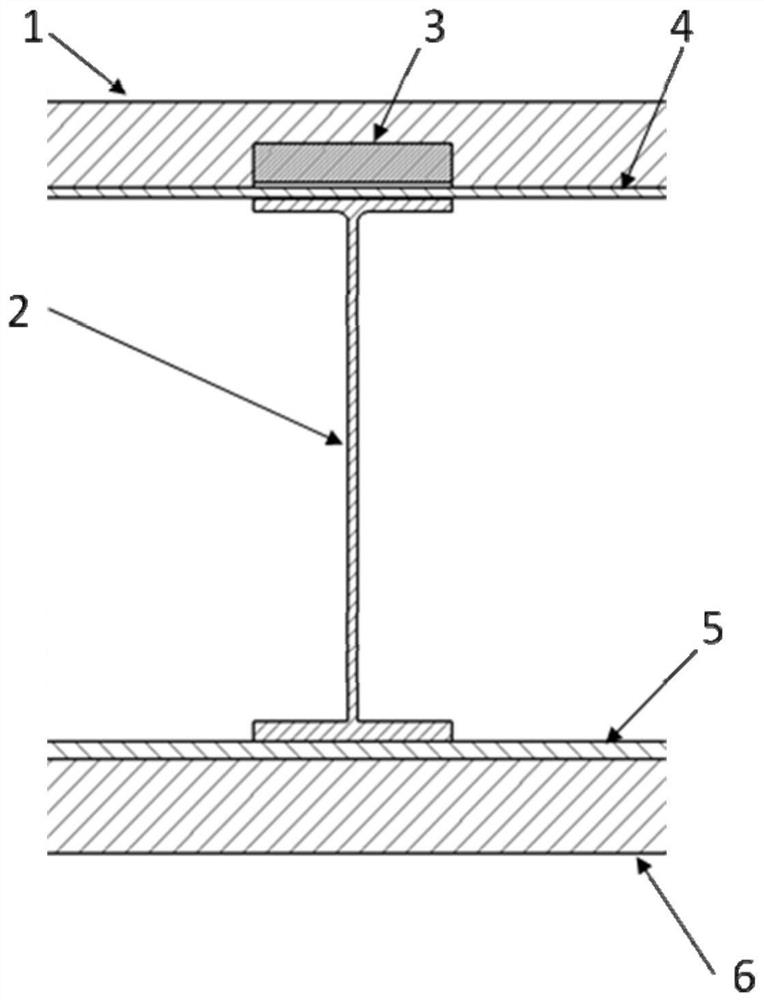

The invention provides a single-step-type light single-side wall formwork trolley, and belongs to the field of construction equipment. The single-step-type light single-side wall formwork trolley is composed of a travelling system (1), a standard triangular frame (2), an operating platform (3), a steel formwork (4) and a hydraulic system. The single-step-type light single-side wall formwork trolley is of a unilateral and asymmetric force structure, a transverse load needs to be borne through a side wall corner pre-embedded piece, thus transverse displacement of the trolley is prevented, formwork removing is achieved through the hydraulic system, 24 m of the side wall is poured at a time, and the efficiency is high.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

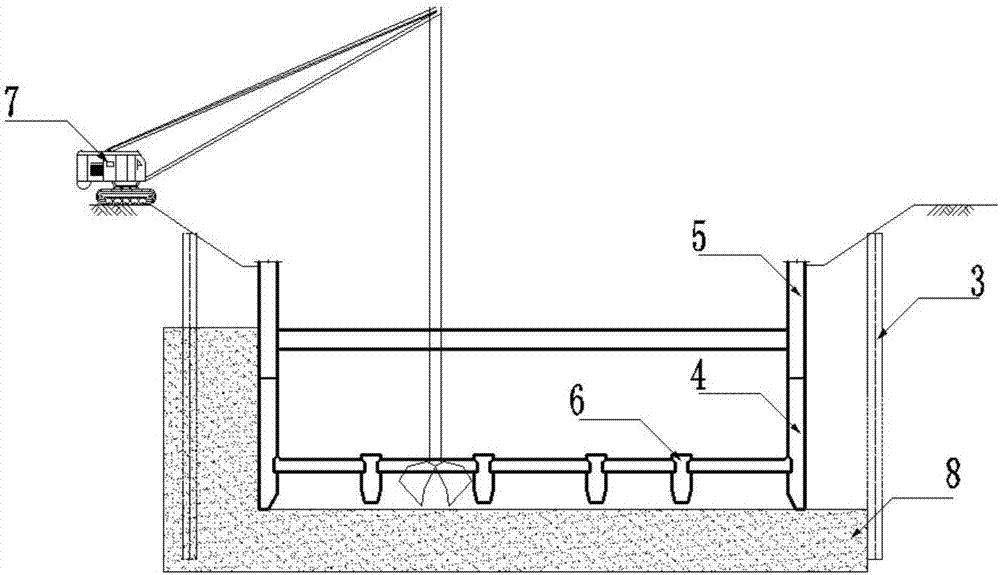

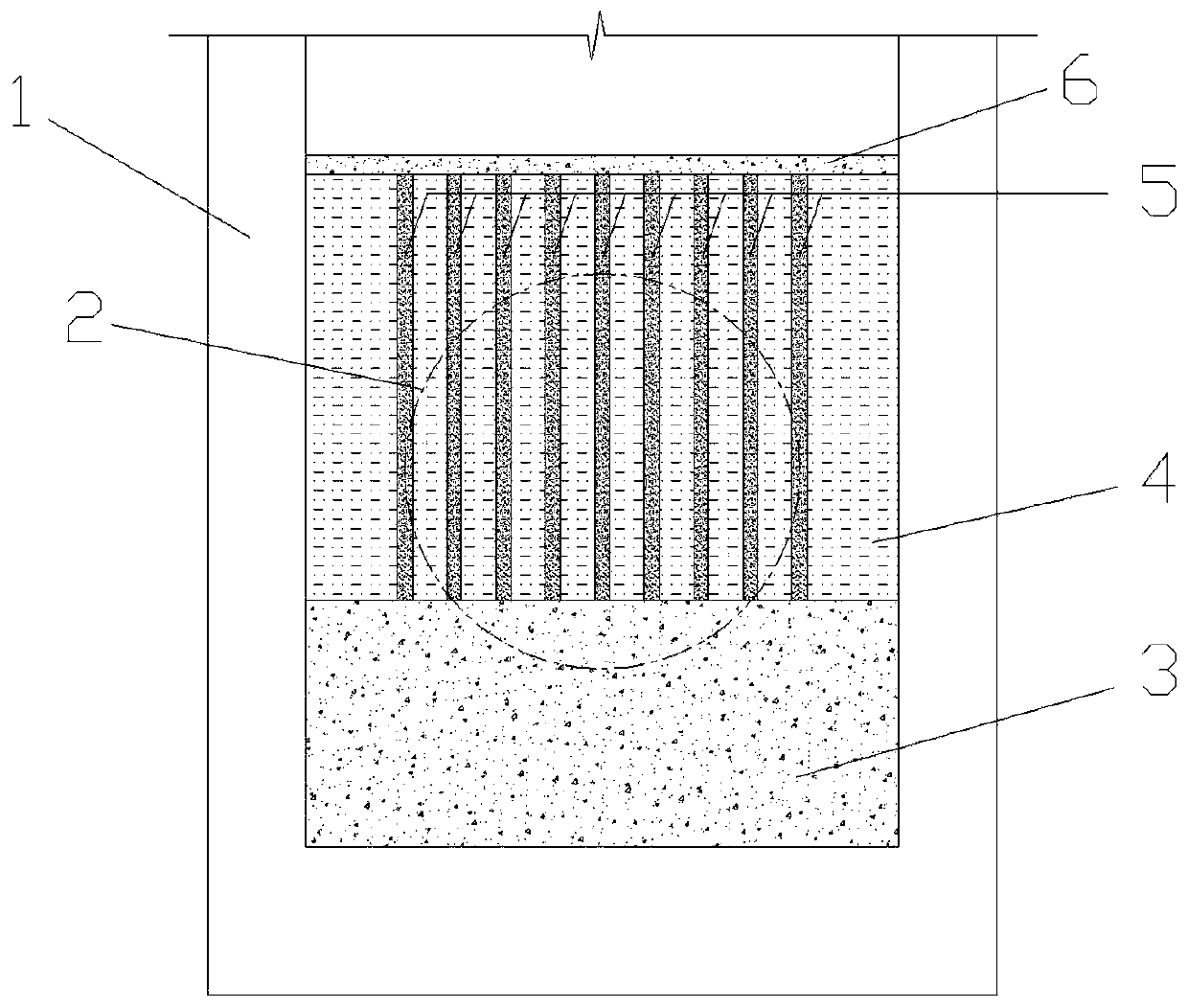

Ultrahigh ultra-large open caisson and construction method

PendingCN107447770AAvoid risk of collapseSave horizontal support systemCaissonsSupporting systemArchitectural engineering

The invention discloses an ultrahigh ultra-large open caisson and a construction method, and belongs to the technical field of municipal drainage, and aims to solve the problem that certain foundation pit collapse risk exists as an existing enclosure form of foundation pit construction is relatively high in cost and is long in construction period. The construction method for the ultrahigh ultra-large open caisson comprises the following steps of: firstly, arranging a waterproof curtain, a compaction grouting substrate and a cushion layer as preparatory measures, separately casting a first section of the open caisson and a second section of the open caisson in two steps until a complete open caisson structure is completed; then, performing open caisson construction; and finally, performing substrate concrete pouring. Through the construction method of manufacturing twice and performing open caisson construction once, a horizontal supporting system is saved, so that the foundation pit collapse risk is avoided; the open caisson is separately manufactured through two steps, so that the risk of a manufacturing process of manufacturing the ultrahigh ultra-large open caisson once is avoided, the construction period is shortened, and construction cost is reduced, and therefore, the popularization value is relatively high.

Owner:NO 2 CONSTR GRP CO LTD OF SHANGHAI CONSTR GRP

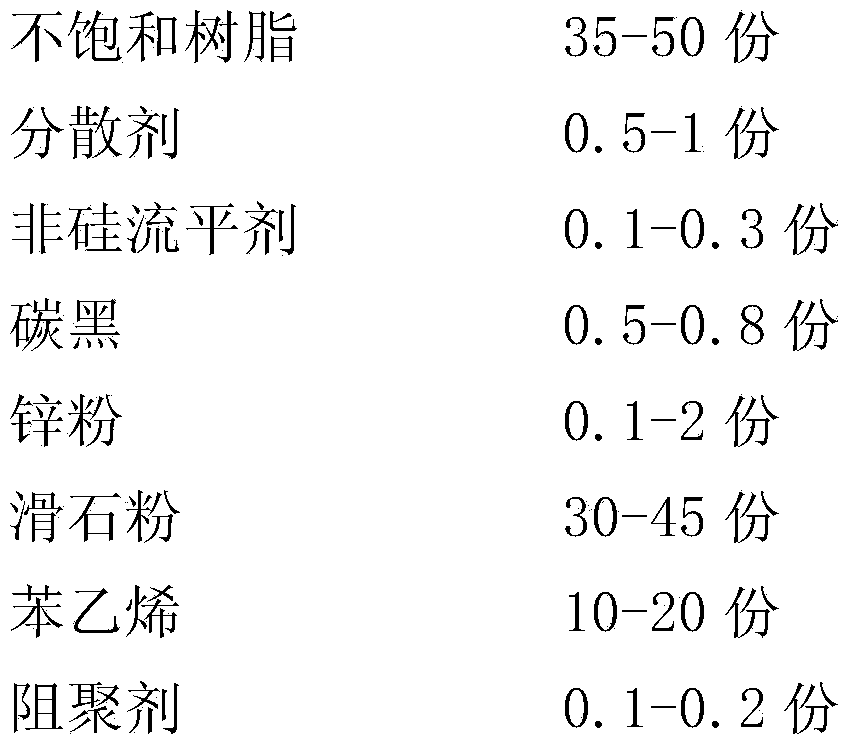

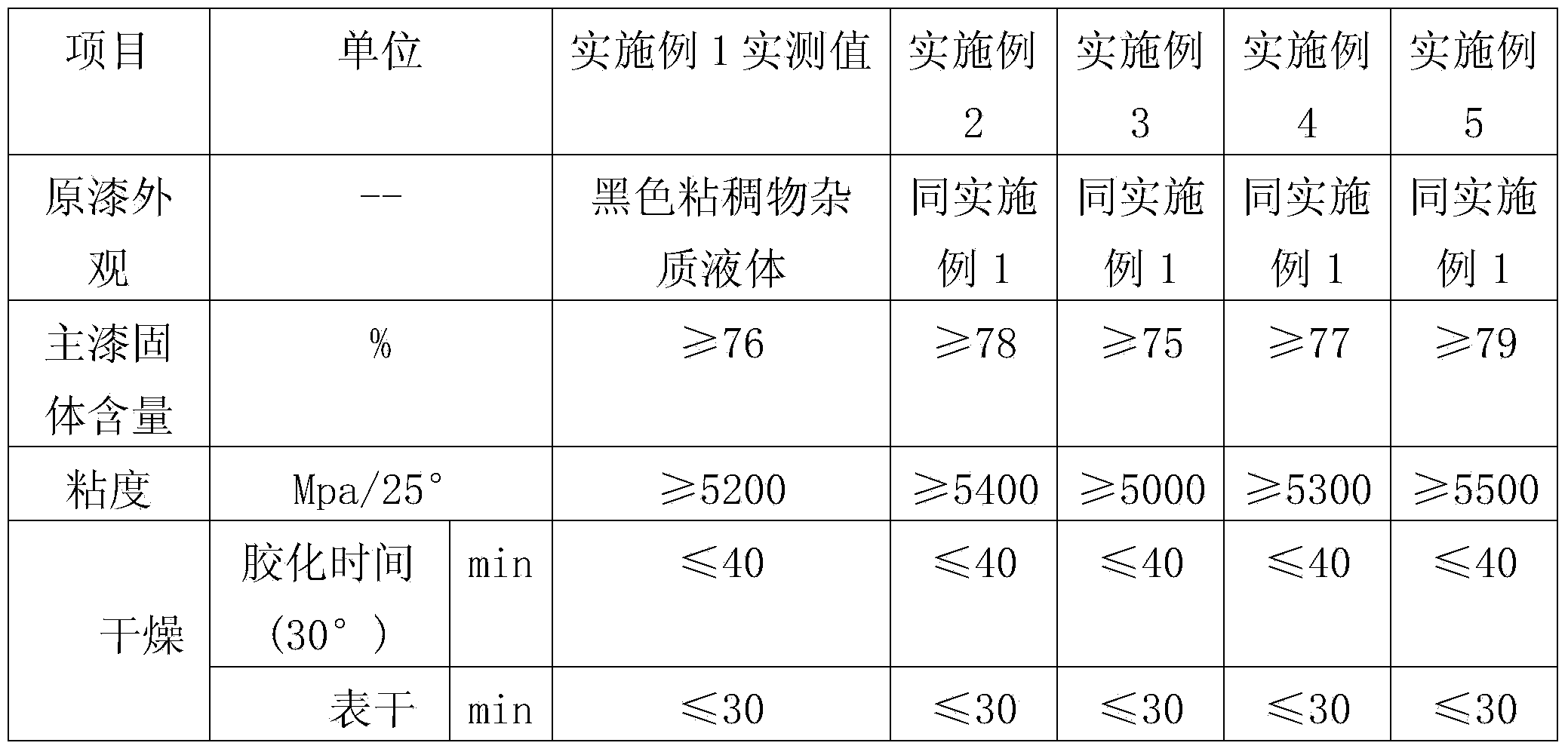

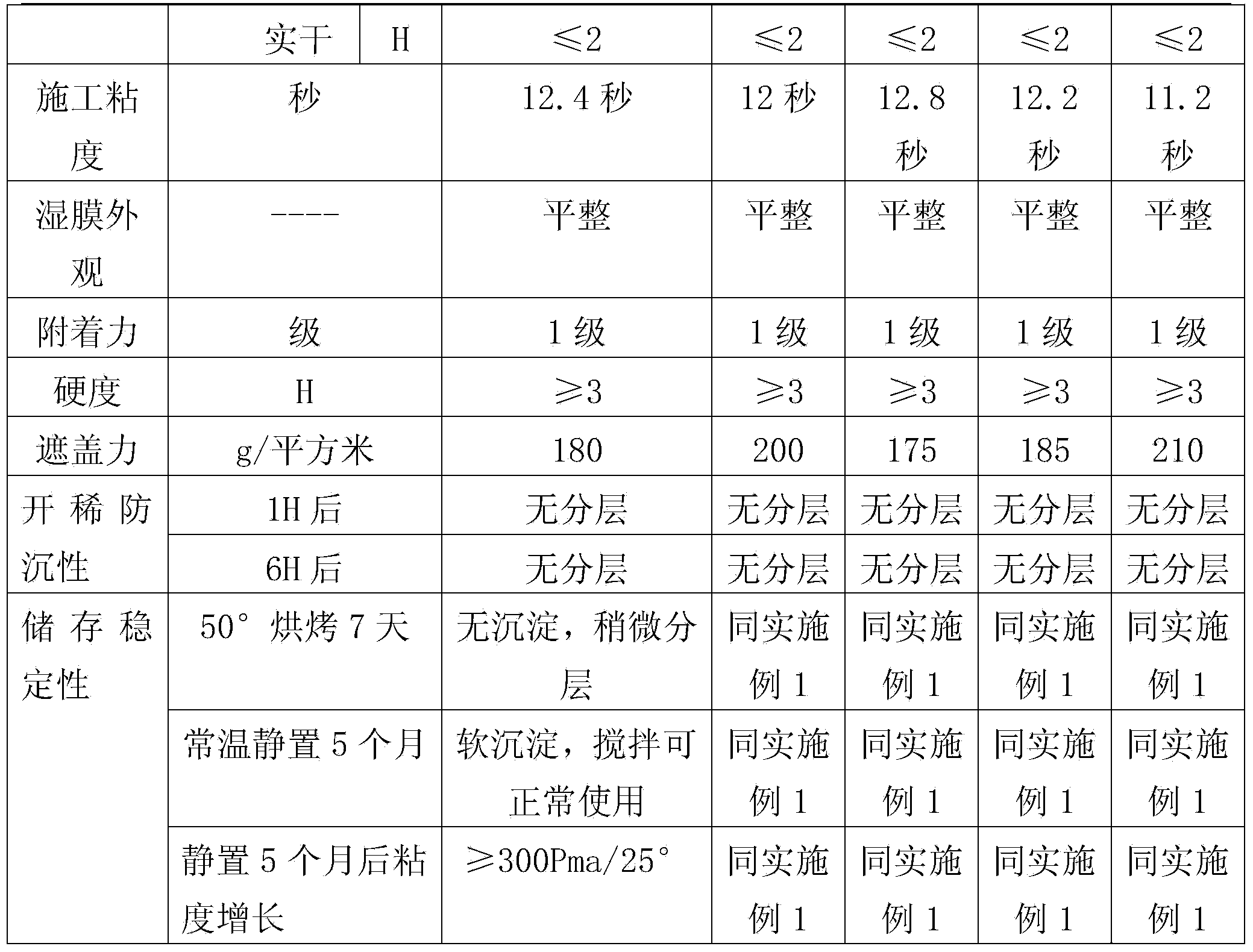

Unsaturated polyester black backing varnish with high fillibility and preparation method thereof

InactiveCN103483994AImprove the decorative effectGood filling effectPolyester coatingsPolyesterSolvent

The invention relates to unsaturated polyester black backing varnish with high fillibility and a preparation method thereof. The black backing varnish is prepared from a main agent, a promoter, an initiator and a diluent according to a weight ratio of (90-110): (0.9-1.1): (1.1-1.3): (25-30), wherein the main agent is prepared from the following raw materials in parts by weight: 35-50 parts of unsaturated resin, 0.5-1 part of dispersant, 0.1-0.3 part of non-silicon flatting agent, 0.5-0.8 part of carbon black, 0.1-2 parts of zinc powder, 30-45 parts of talcum powder, 10-20 parts of styrene and 0.1-0.2 part of polymerization inhibitor; the promoter is cobalt naphthenate; the initiator is cyclohexanone peroxide; the diluent is styrene. The unsaturated polyester black backing varnish prepared by the preparation method disclosed by the invention not only has high fillibility and high hardness, but also is capable of improving the fullness of finishing coat, and no solvent is rest on the varnish films after the construction, so that the environmental tolerance of the construction is large.

Owner:SKSHU PAINT

High-flow precious metal channel

ActiveCN111704347AGuaranteed service lifeGuaranteed use strengthForehearthsTank furnacesMaterials scienceGlass production

The invention provides a high-flow precious metal channel, which comprises a molten glass mixed-flow stirring section, at least two molten glass heating; clarifying and cooling sections are connectedin parallel to one end of the molten glass mixed-flow stirring section, and a liquid supply tank is further communicated with the other end of the molten glass mixed-flow stirring section. The methodis mainly used for clarification and homogenization of large-flow high-temperature molten glass in the production process of 8.5-generation or higher-generation TFT glass, and bubble-free and stripe-free high-quality molten glass is provided for the subsequent float forming or overflow forming process.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD +1

Irrigation and draining brake

InactiveCN103103967AAvoid the danger of being washed away by the currentAvoid the risk of collapseConstructionsSoil drainagePulp and paper industryWater level

The invention discloses an irrigation and draining brake which comprises a flashboard frame and a flashboard, wherein a water inlet through hole is formed in the flashboard frame. Guide grooves are formed in both sides of the flashboard frame. Both sides of the flashboard are contained in the guide grooves and can move along the guide grooves, positioning adjusting teeth are arranged on the inner wall of the guide grooves, and elastic clamping tongues which are matched with the positioning adjusting teeth are arranged on both sides of the flashboard. The irrigation and draining brake is fixed on an opening of a ridge, irrigation and draining work is controlled by moving the flashboard, and water level height can be adjusted. The irrigation and draining brake has the advantages of being convenient to use, safe and reliable.

Owner:顾积志 +2

Construction method for large-sized blast furnace foundation

ActiveCN102587404AAvoid risk of collapseTotal steel consumption savingFoundation engineeringRebarShape matching

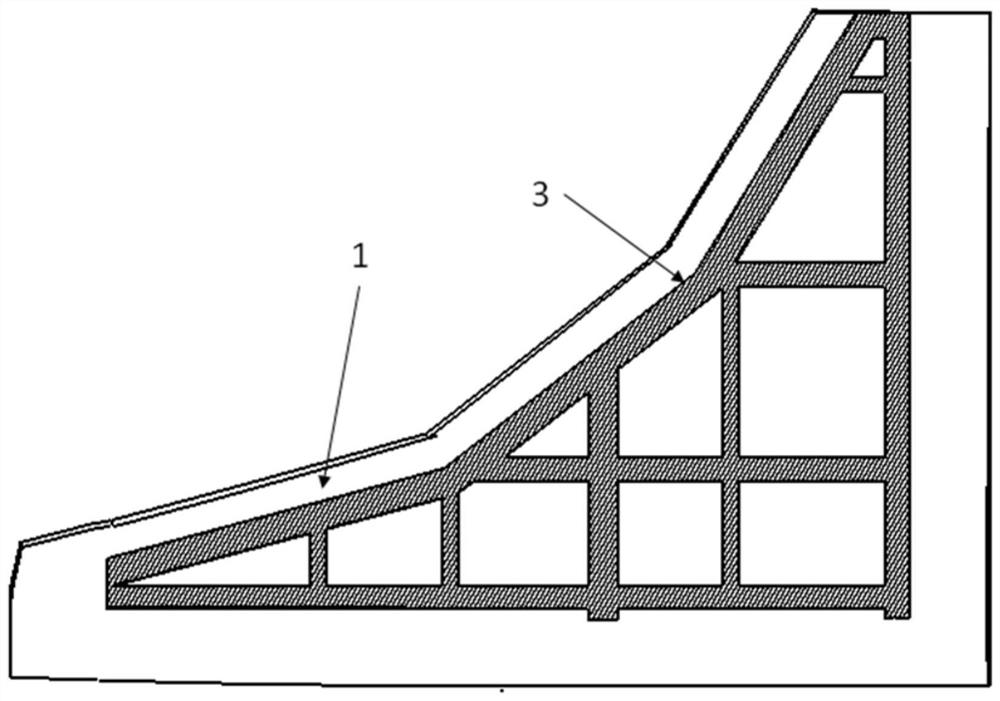

The invention discloses a construction method for a building foundation, and particularly relates to a construction method for a large-sized blast furnace foundation, which reduces utilization quantity of steel. The construction method for the large-sized blast furnace foundation comprises following steps: A, binding reinforcing steel bars of a bottom plate of the foundation; B, mounting upright columns on the basis of the reinforcing steel bars of the bottom plate, and leading the heights of the upright columns to be smaller than surface concrete; and mounting top horizontal rods and inclined surface rods at the tops of the upright columns, forming a supporting framework with the shape matching with that of the large-sized blast furnace foundation after the horizontal rods, the inclined surface rods and the upright columns are mounted, and leading the height of the supporting framework not to be larger than the surface concrete; C, binding reinforcing steel bars on the supporting framework; D, mounting formworks surrounding the outer surface of the supporting framework; and E; pouring to finish the large-sized blast furnace foundation. The upright columns, the top horizontal rods and the inclined surface rods are utilized to form the supporting framework, the reinforcing steel bars are then bound on the supporting framework, an additional platform is omitted, the reinforcing steel bars are directly bound on the supporting framework, and accordingly the total steel utilization quantity is greatly reduced.

Owner:CHINA 19TH METALLURGICAL CORP

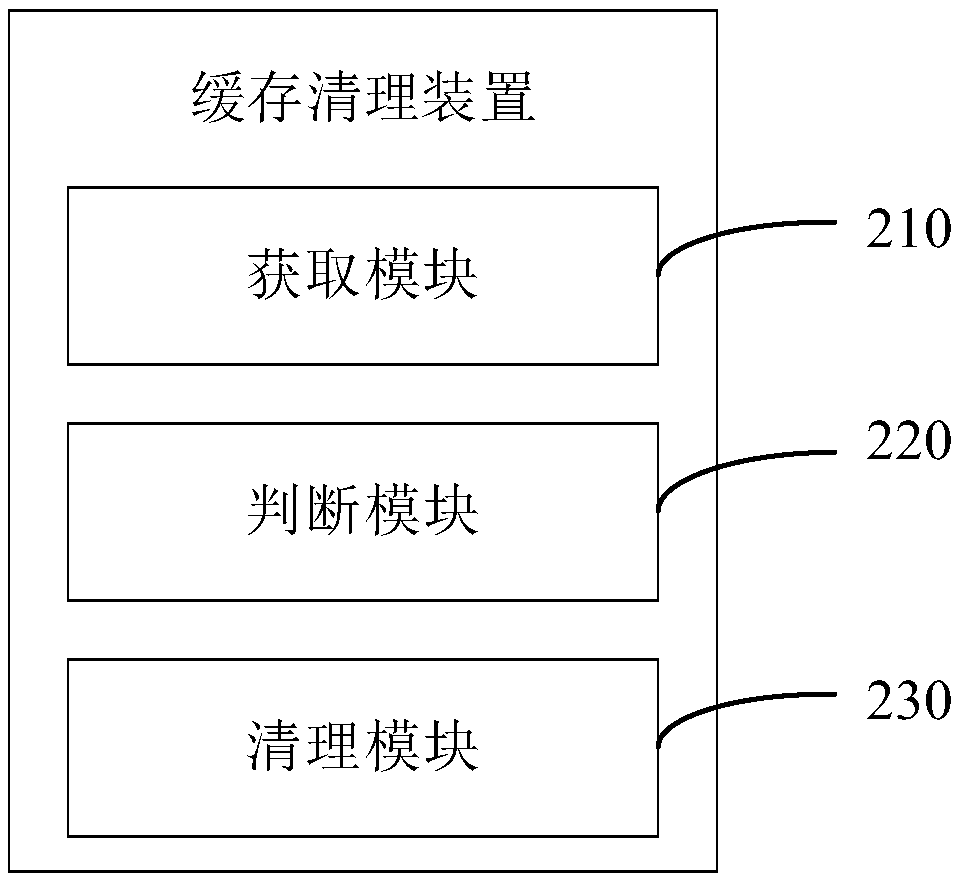

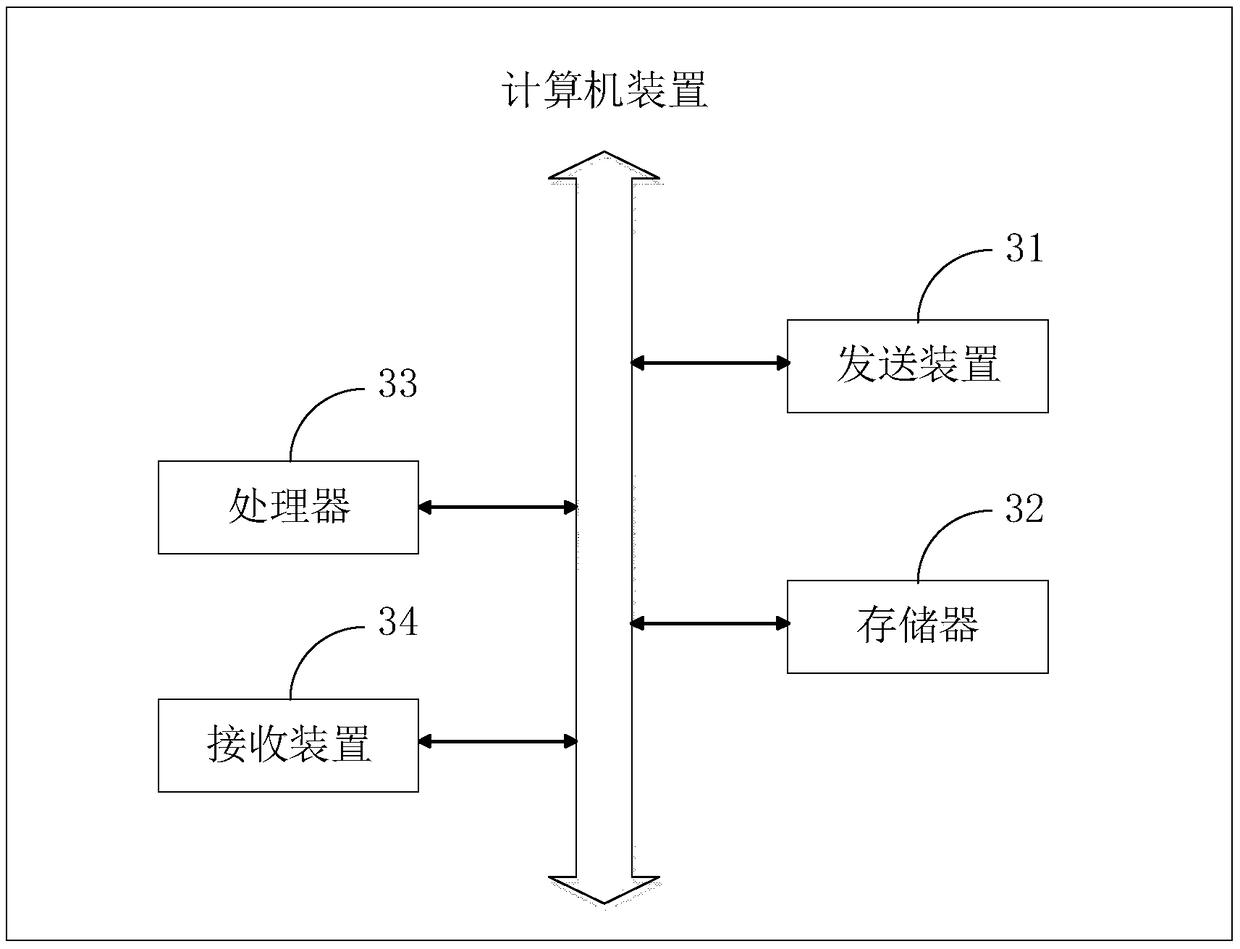

Cache cleaning method and device, computer device and storage medium

InactiveCN108647156AImprove space utilization and system operating efficiencyAvoid service exceptionsMemory systemsComputer deviceOperating system

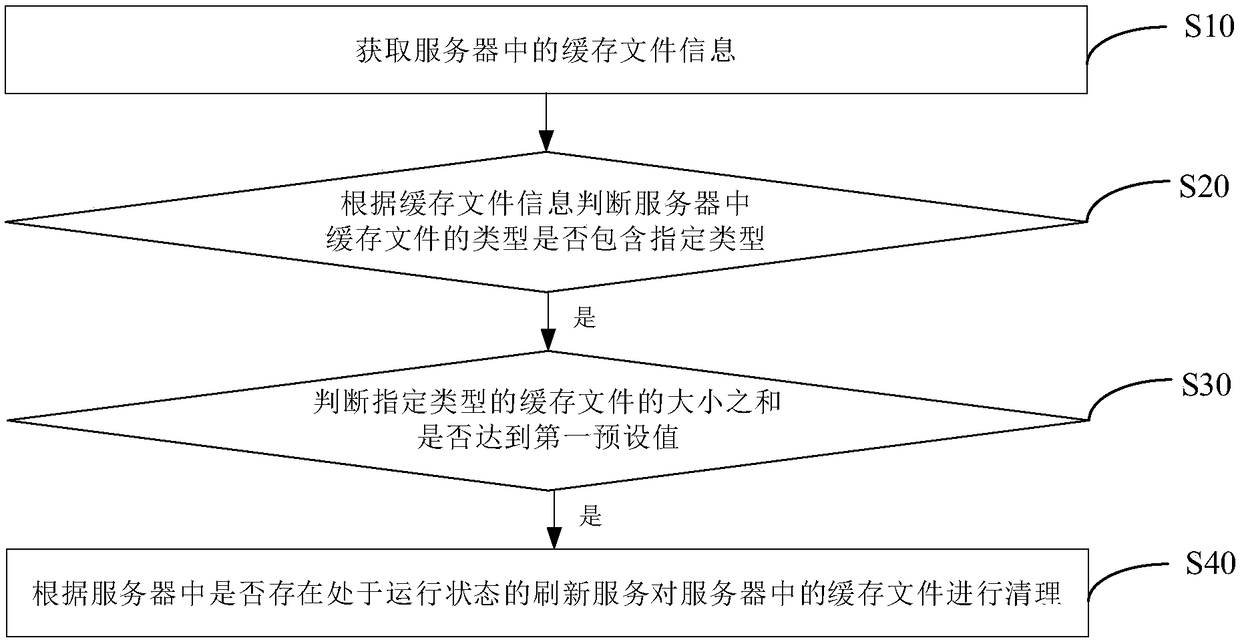

The invention provides a cache cleaning method, comprising the steps of: acquiring cache file information from a server; judging, according to the cache file information, whether the types of cache files in the server comprises a specified type; if yes, judging whether the size sum of the cache files of the specified type reaches a first preset value; if the size sum of the cache files of the specified type reaches the first preset value, cleaning the cache files in the server according to whether the server has a refresh service in a running state. The invention further discloses a cache cleaning device, a computer device and a computer readable storage medium. The method and the device can clean caches, thereby improving the space utilization of disks and the operating efficiency of thesystem, and avoiding the risk of service abnormality caused by the caches that are not cleaned.

Owner:PING AN TECH (SHENZHEN) CO LTD

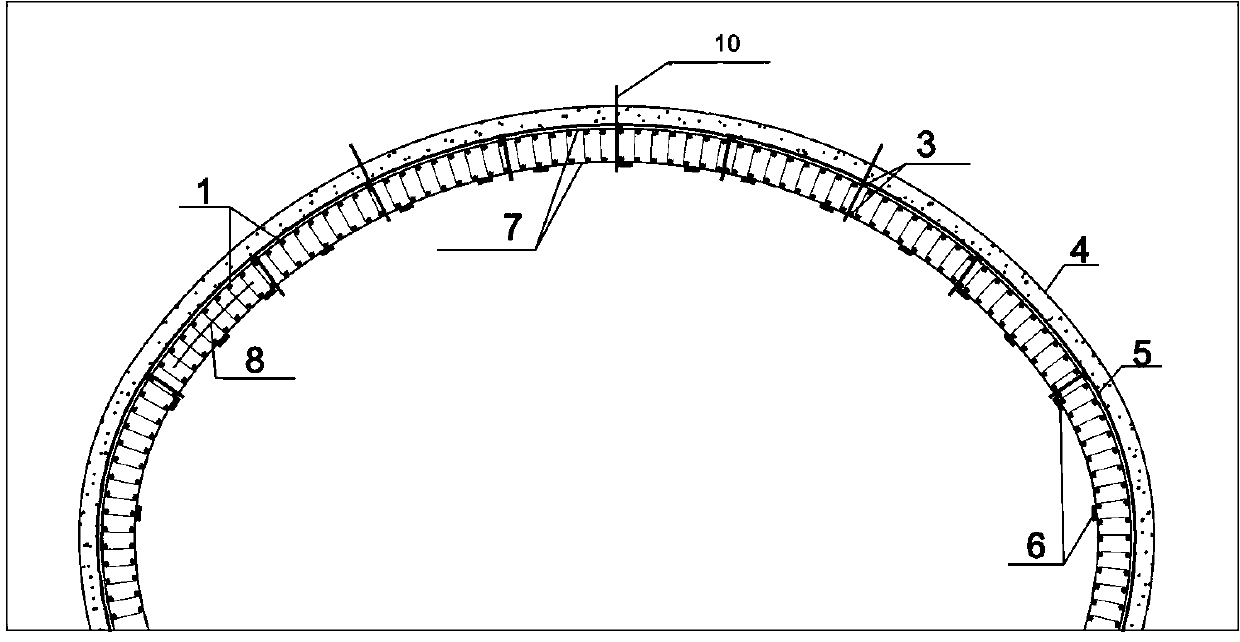

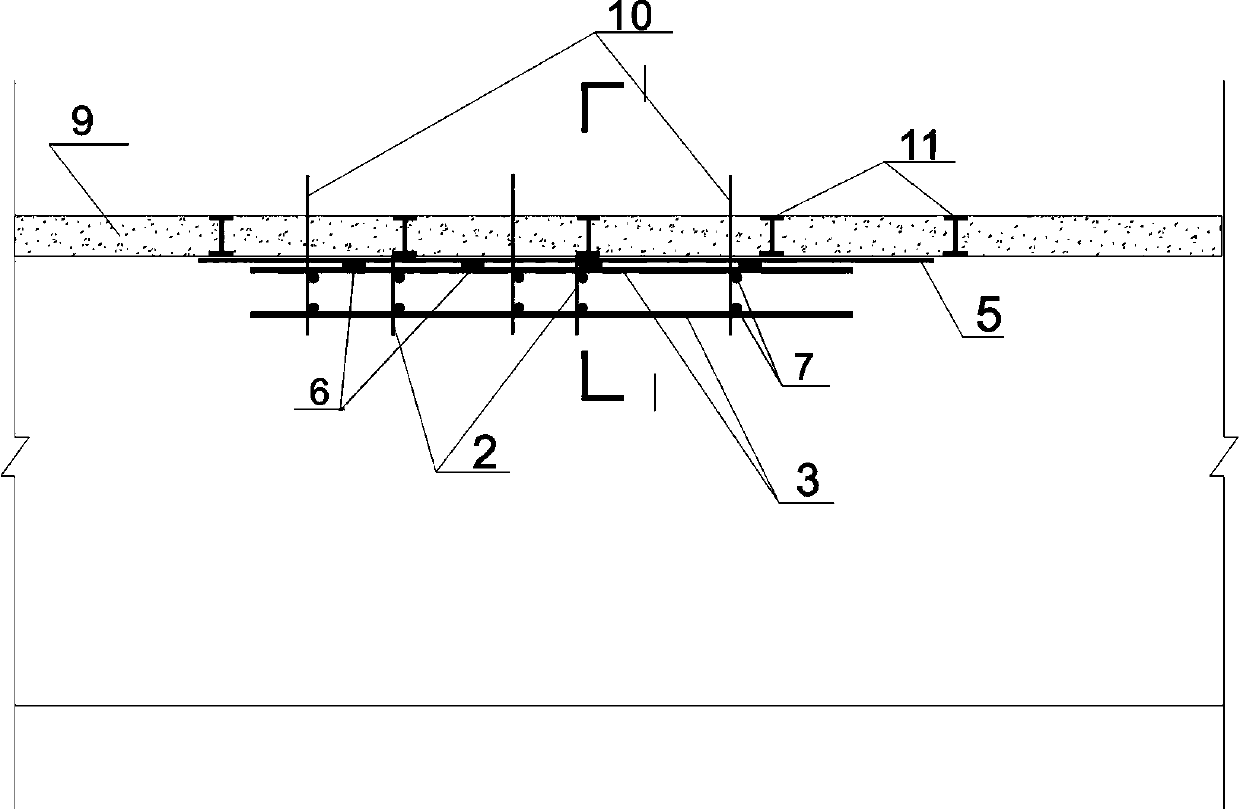

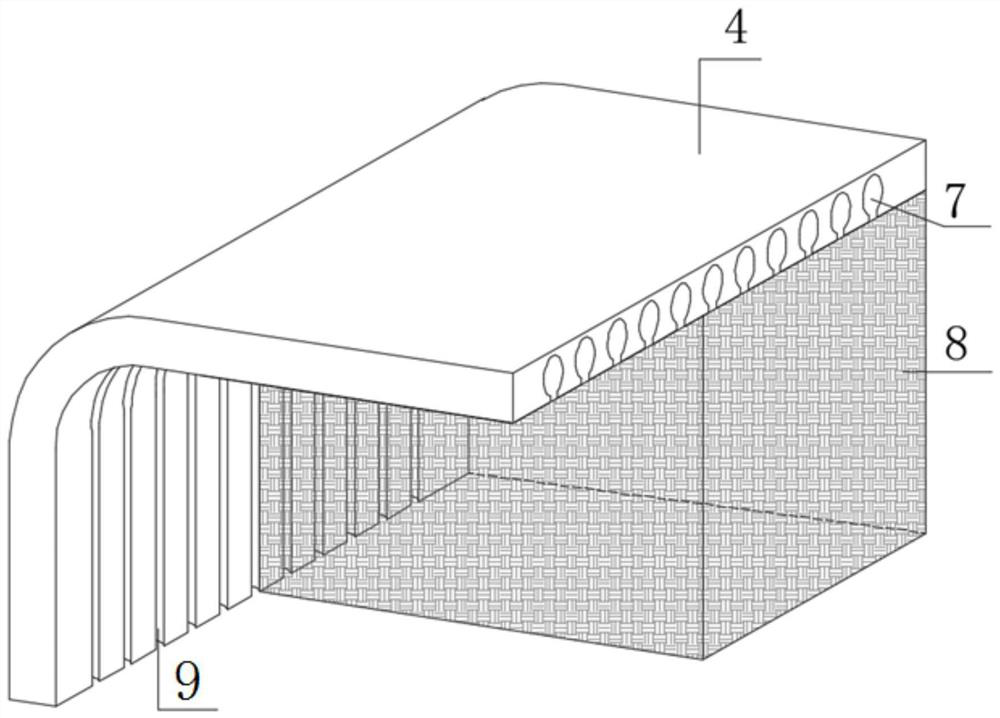

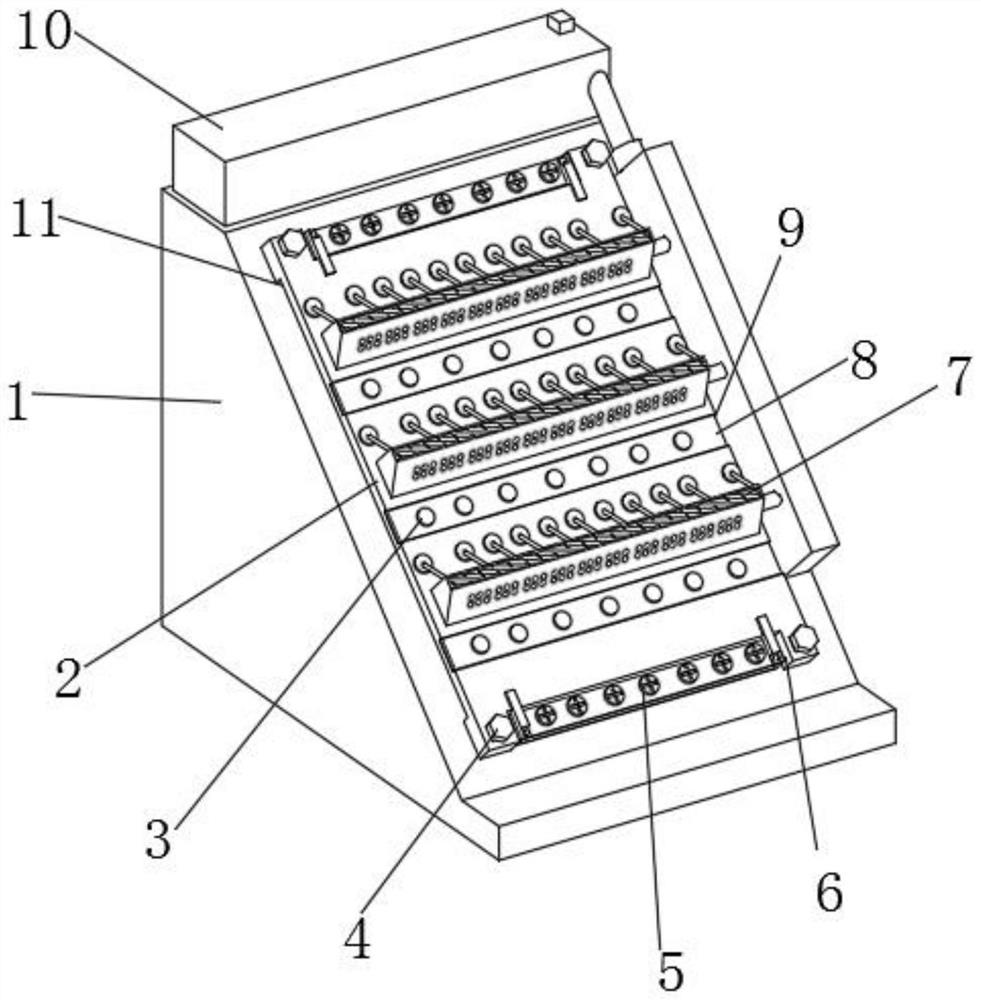

Construction method for preventing collapse of large-section tunnel lining reinforcing steel bars

ActiveCN111456757AGuaranteed spacingStable supportUnderground chambersTunnel liningArchitectural engineeringRebar

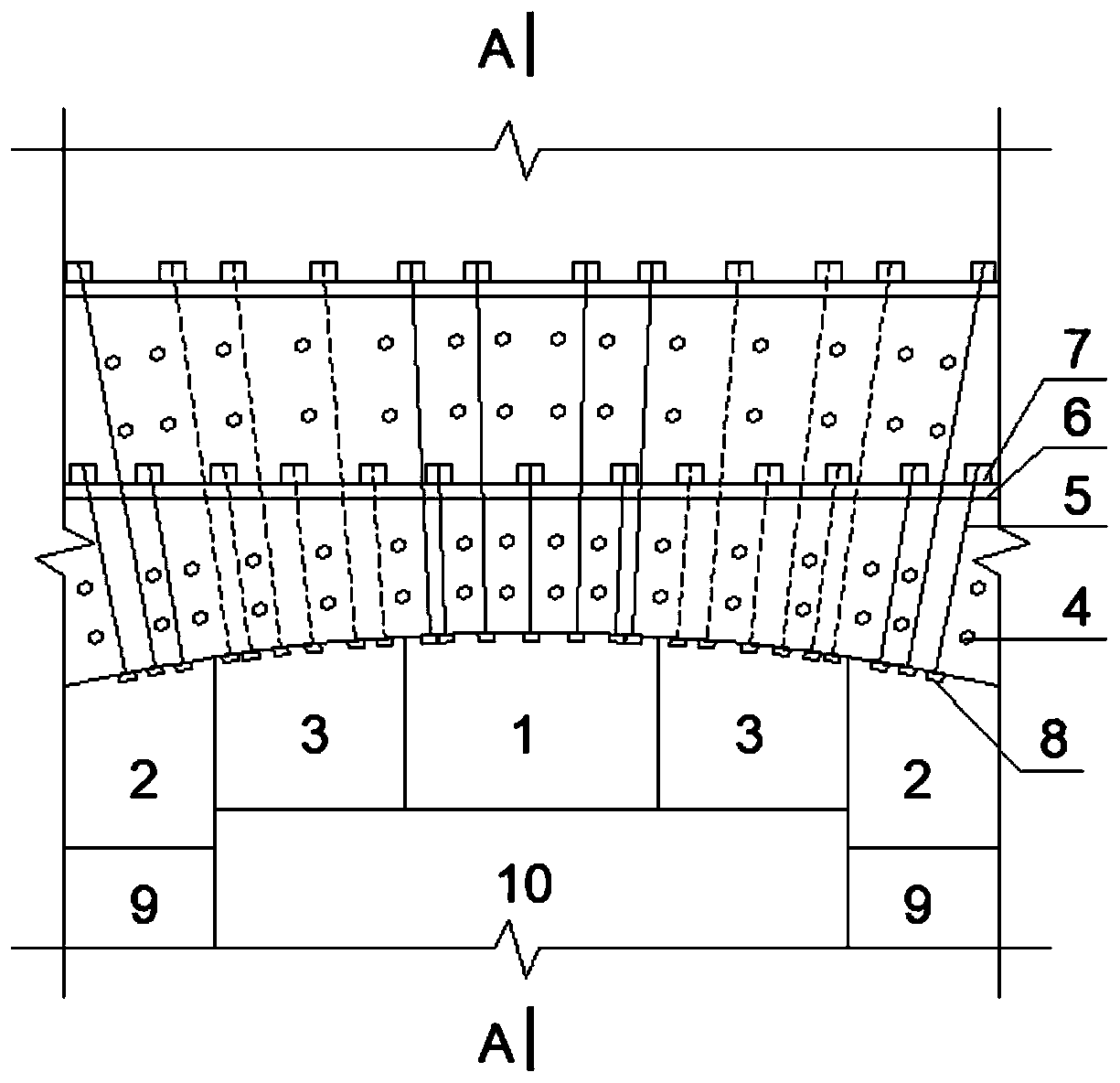

The invention provides a construction method for preventing collapse of large-section tunnel lining reinforcing steel bars, and relates to the technical field of tunnel construction. The constructionmethod comprises the steps that an opening hole is determined by the preliminary supporting of the first group of the lining reinforcing steel bars or the position of preliminary supporting profile steel is dig out; waterproof boards are paved; anchor rods are anchored or supporting ribs are welded; the penetrating positions of the waterproof boards are subjected to waterproof processing; positioning reinforcing steel bars are installed; external layer reinforcing steel bars are installed; internal layer reinforcing steel bars are installed; the reinforcing steel bars are trimmed; and protective layer supporting blocks are installed. The operation is simple and convenient, fixed supports are stable, and the collapse risk due to large deformation and poor supporting in the reinforcing steelbar construction process is effectively avoided.

Owner:ERCHU CO LTD OF CHINA RAILWAY TUNNEL GRP

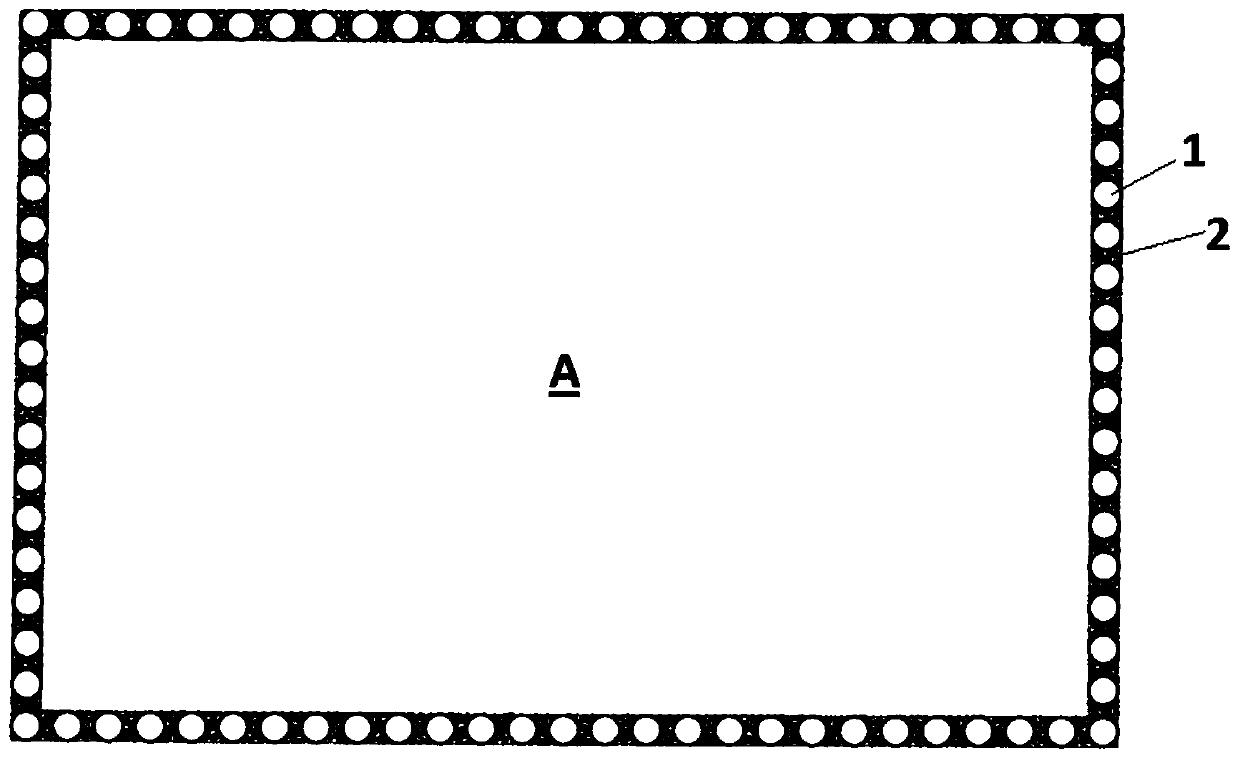

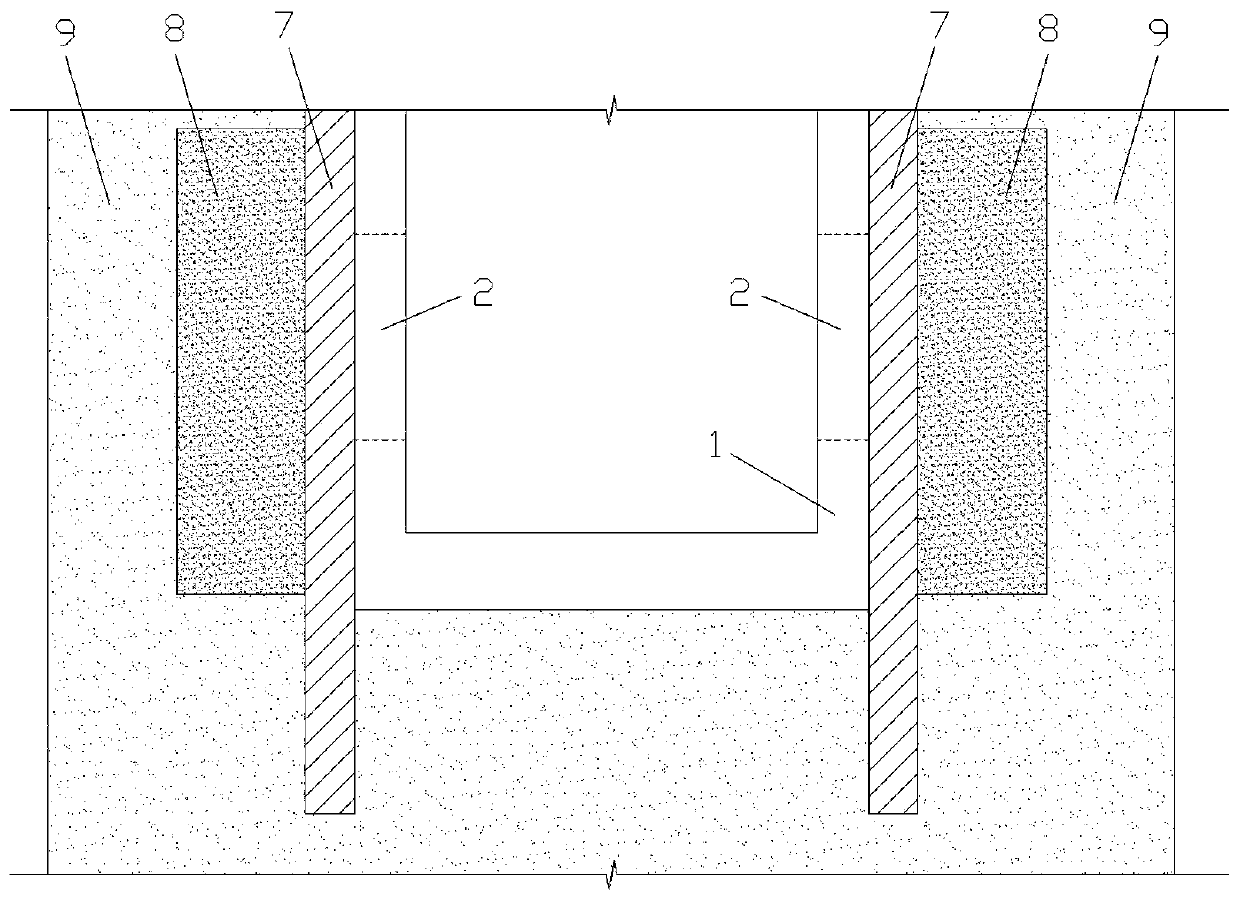

Foundation pit supporting composite retaining wall with water pumping and recharging function and construction method thereof

PendingCN109914427ASimple construction operationShort construction periodArtificial islandsExcavationsGroundwaterRetaining wall

The invention provides a foundation pit supporting composite retaining wall with water pumping and recharging functions. The foundation pit supporting composite retaining wall comprises a plurality ofpipe piles, connecting structures, a water pumping structure and a recharging structure. The plurality of pipe piles are arranged in the circumferential direction and are of hollow structures; the connecting structures are connected with the two adjacent pipe piles to form a circumferentially closed retaining wall; the water pumping structure is arranged on the pipe wall of at least one pipe pile, faces the inner side of the foundation pit, communicates with a soil body on the inner side of the foundation pit and the hollow structure, and is suitable for guiding underground water on the innerside of the foundation pit into the hollow structure of the pipe pile; the recharging structure is arranged on the pipe wall of the pipe pile provided with the water pumping structure, faces the outer side of the foundation pit, is located above the water pumping structure and communicates with the soil body and the hollow structure on the outer side of the foundation pit, is suitable for recharging the underground water in the hollow structure into the soil body on the outer side of the foundation pit. The invention further provides a construction method of the foundation pit supporting composite retaining wall.

Owner:刘小檀 +1

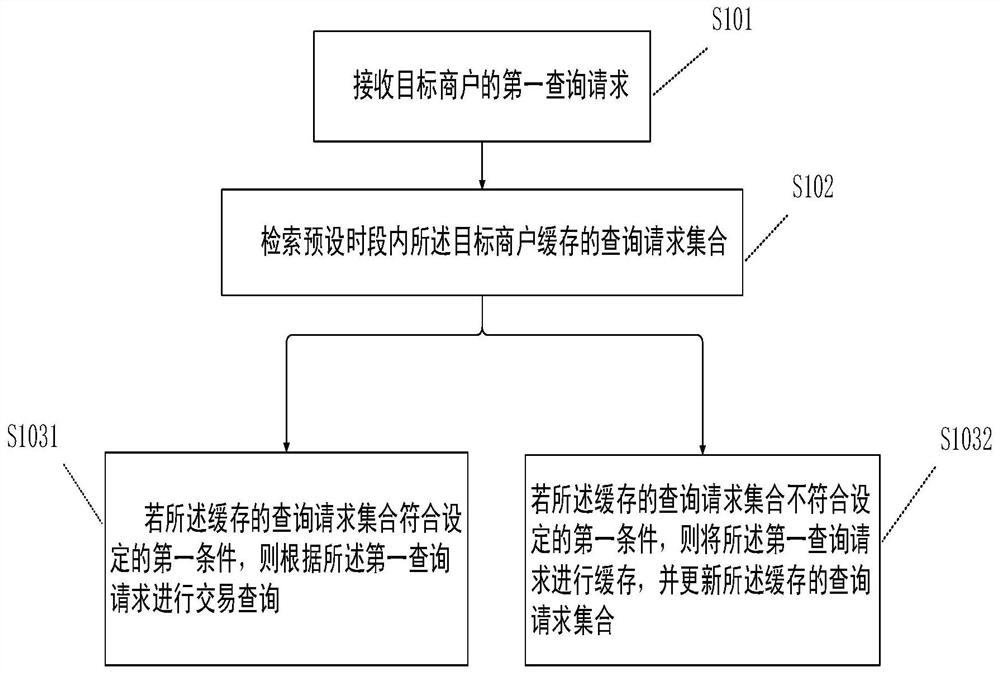

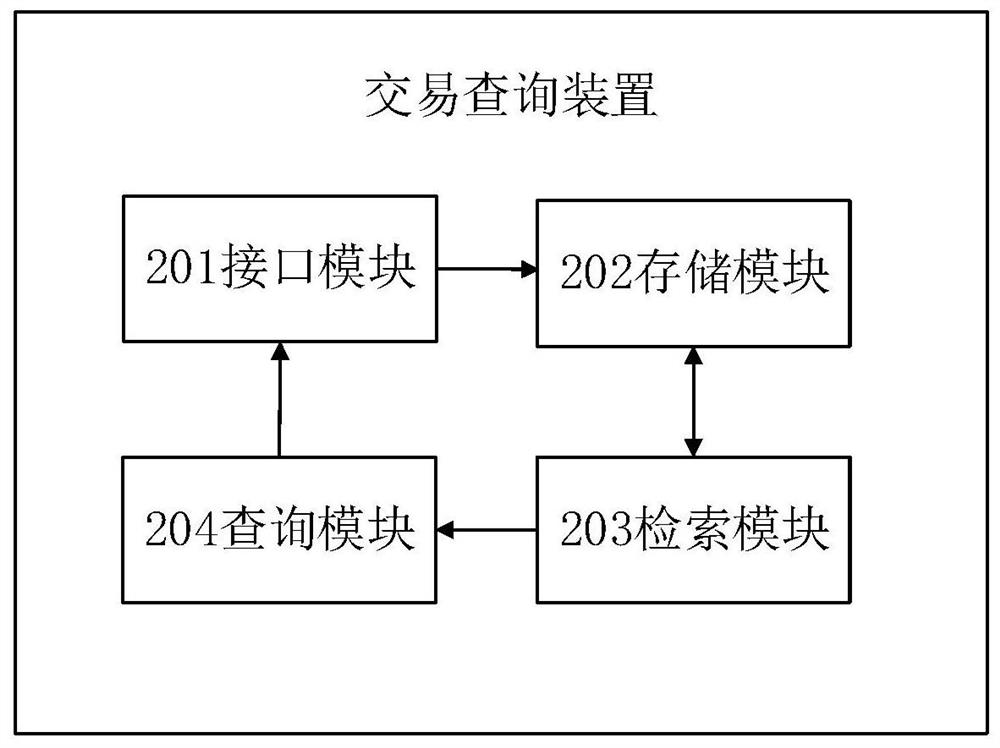

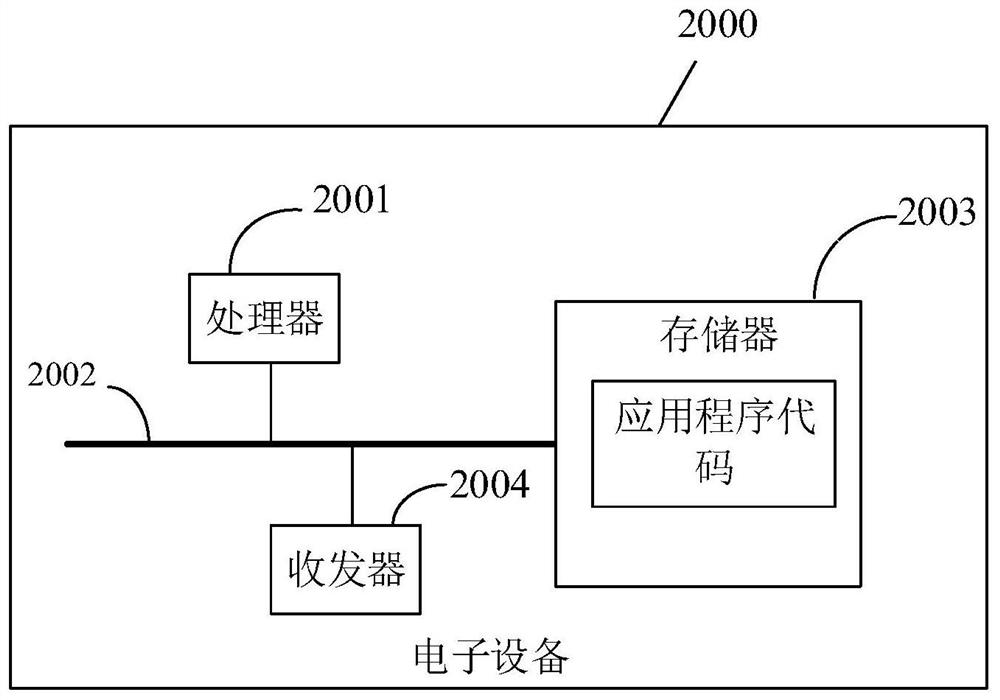

Transaction query method and device, electronic equipment and readable storage medium thereof

PendingCN111897838AReduce riskAvoid risk of collapseDigital data information retrievalError avoidanceEngineeringFinancial transaction

The invention relates to the field of bank transactions, in particular to a transaction query method and device, electronic equipment and a readable computer storage medium. The transaction query method comprises the following steps: receiving a first query request of a target merchant; retrieving a query request set cached by the target merchant in a preset time period; if the cached query request set meets a set first condition, performing transaction query according to the first query request; and if the cached query request set does not meet the set first condition, caching the first queryrequest, and updating the cached query request set. Based on the scheme disclosed by the invention, the query request in the cache can be queried according to the set query frequency to control the query of the database, so that the risk of slow query or query system crash caused by query hotspots due to a large number of queries is avoided.

Owner:CHINA CONSTRUCTION BANK

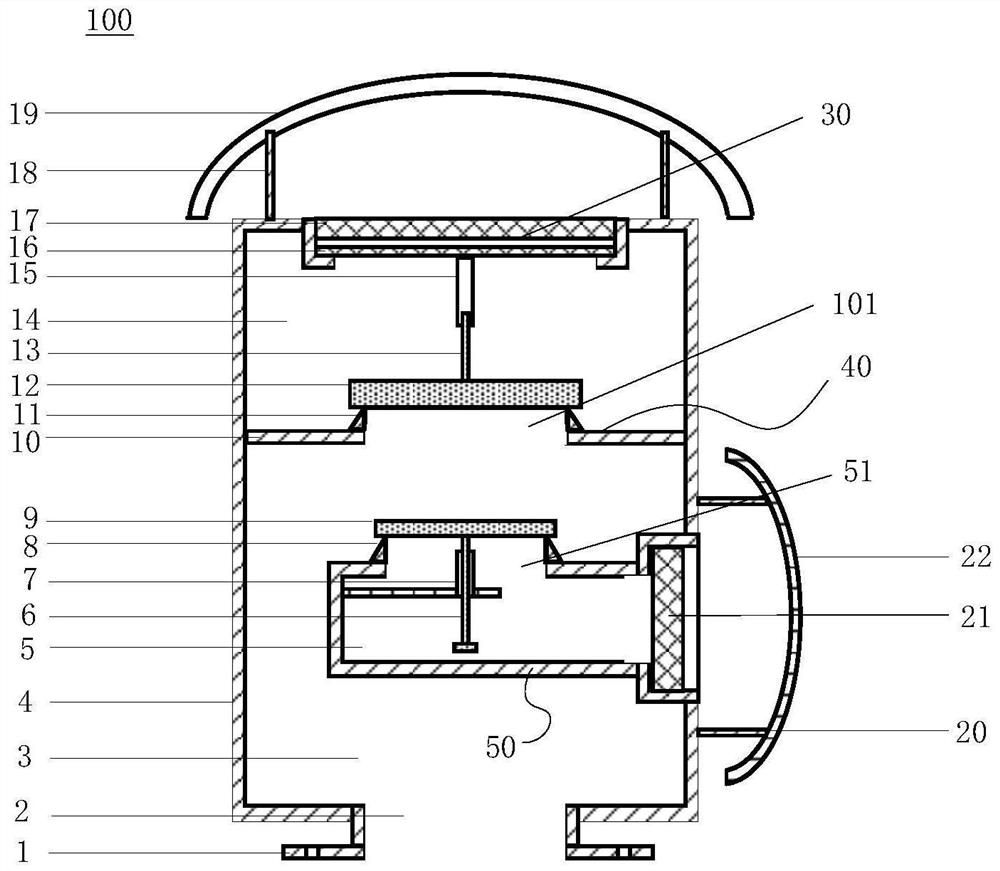

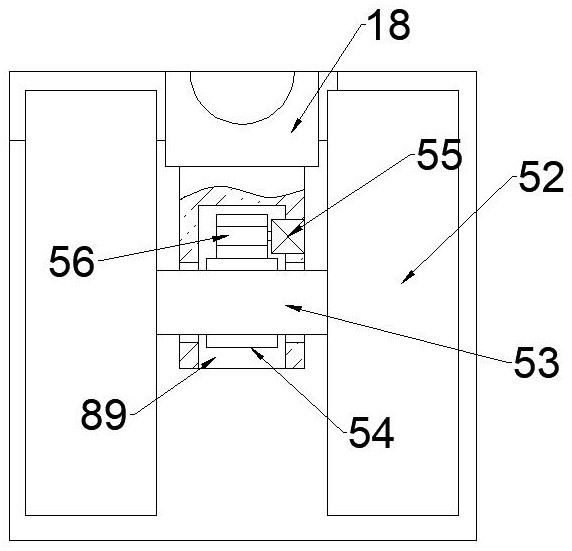

Damping device for light steel integrated housing

ActiveCN112609853AAvoid breakingAvoid risk of collapseProtective buildings/sheltersShock proofingStructural engineeringMechanical engineering

The invention discloses a damping device for light steel integrated housing. The damping device for the light steel integrated housing comprises a base; a vertical buffering mechanism is installed at the top of the base; a horizontal buffering mechanism is installed at the top of the vertical buffering mechanism; the vertical buffering mechanism comprises vertical buffering assemblies welded to the four corners of the top of the base; light steel keel supporting columns are installed at the four corners of the tops of the vertical buffering assemblies correspondingly; a first vertical buffering pipe is welded between the ends, close to each other, of two vertical buffering assemblies located on the same side of the base in a butt clamping and penetrating mode; and a second vertical buffering pipe is welded between the other ends of the two vertical buffering assemblies located on the two sides of the base in a butt clamping and penetrating mode. A control mechanism is arranged to be connected with the vertical buffer mechanism and the horizontal buffer mechanism, and when no severe external force is applied, hydraulic oil in a shell is blocked by a sealing plug, so that circulation of the hydraulic oil is prevented, fixing of the light steel keel supporting columns is achieved, and the housing can be prevented from shaking.

Owner:安徽省佳业集成房屋科技发展有限公司

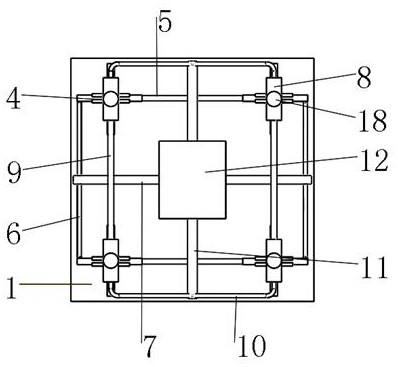

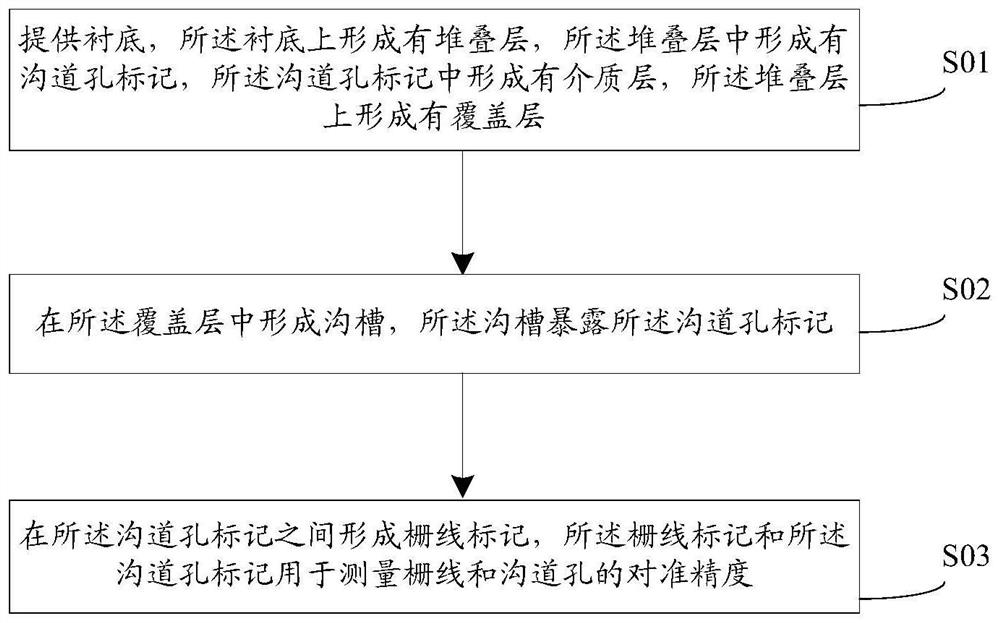

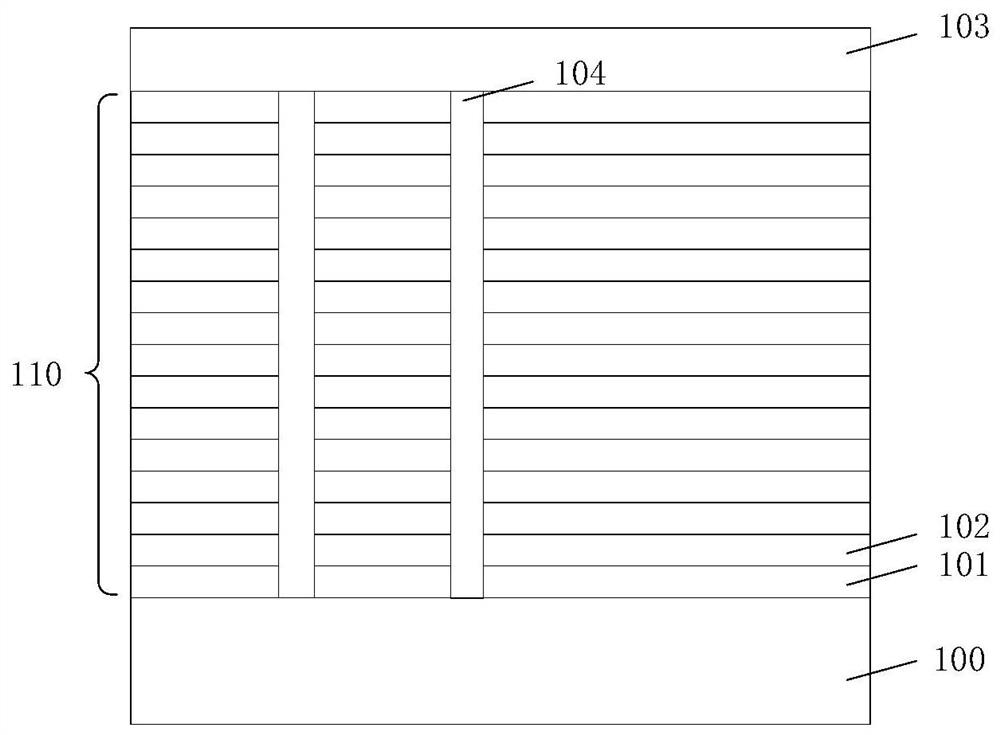

Overlay precision detection method and semiconductor structure

ActiveCN112435936ARealization of overlay precision detectionAvoid risk of collapseSemiconductor/solid-state device testing/measurementSolid-state devicesSemiconductor structureEngineering

The invention provides an overlay precision detection method and a semiconductor structure. The overlay precision detection method comprises the steps of: providing a substrate, forming a stacking layer on the substrate, forming a channel hole mark in the stacking layer, forming a dielectric layer in the channel hole mark, and forming a covering layer on the stacking layer; forming a groove in thecovering layer, wherein the groove exposes the channel hole mark; and forming grid line marks between the channel hole marks, wherein the grid line marks and the channel hole marks are used for detecting the overlay precision of the grid lines and the channel holes. Thus, the grid line marks are formed among the channel hole marks, and the dielectric layer is formed in the channel hole marks andcan support the stacked layer, so that the risk of collapse of the area around the grid line marks after the sacrificial layer in the stacked structure is removed is avoided, and the reliability of the stacked structure is improved. Therefore, overlay precision detection of the grid lines and the channel holes can be directly realized through the grid line marks and the channel hole marks.

Owner:YANGTZE MEMORY TECH CO LTD

Assembly type supporting drainage structure

PendingCN112323769AAvoid risk of collapseExcavationsSoil preservationGeotechnical engineeringCapillary water

The invention provides an assembly type supporting drainage structure. The assembly type supporting drainage structure specifically comprises a capillary drainage plate, wherein a capillary water guide channel is arranged in the capillary drainage plate; grooves are formed in the side surface of the capillary drainage plate; the plurality of capillary water guide channels are arranged in the capillary drainage plate side by side; the plurality of grooves are formed in the surface of the capillary drainage plate side by side; and each groove is distributed on the surface of the capillary drainage plate along the corresponding capillary water guide channel and communicates with the corresponding capillary water guide channel. According to the assembly type supporting drainage structure, thesoil body drainage structure is assembled, supersaturated water and the like in soil can be effectively removed, and the collapse risk caused by long-term water immersion of the foundation pit supporting soil body is avoided.

Owner:CHINA CONSTR FIRST BUILDING GRP CORP LTD

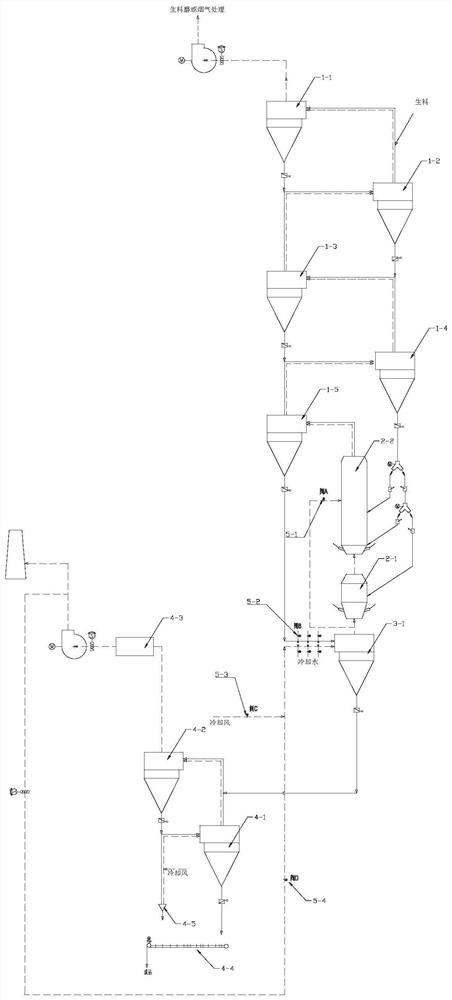

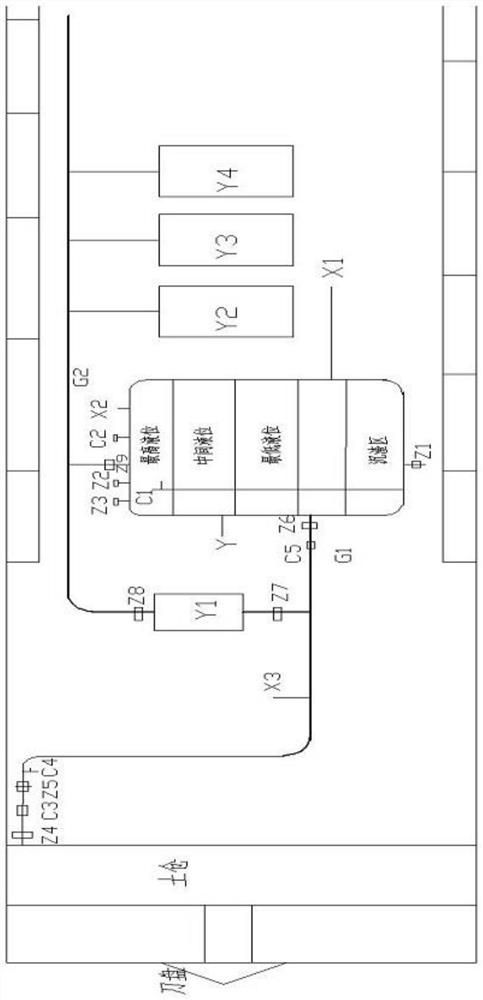

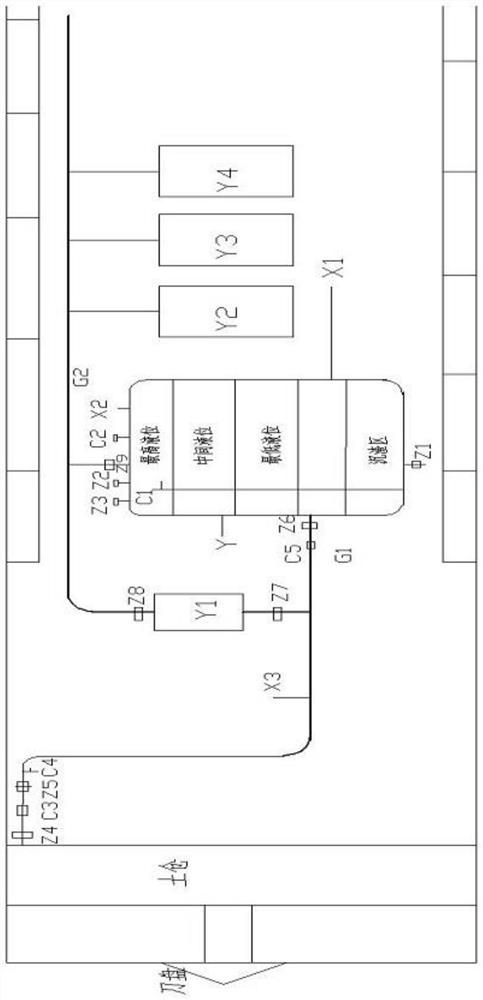

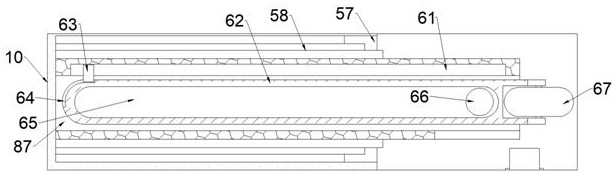

Flexibly-adjustable high-activity metakaolin preparation system and method

ActiveCN112939002AFully burnt outAchieve recyclingFurnace typesFurnace coolingKaolin clayProcess engineering

The invention belongs to the field of high-activity metakaolin preparation, and particularly relates to a flexibly-adjustable high-activity metakaolin preparation system and method. The flexibly-adjustable high-activity metakaolin preparation system comprises a suspension preheating system, wherein the suspension preheating system comprises multiple stages of cyclone preheaters, raw powder is subjected to preheating and gas-solid separation in the cyclone preheaters, and the raw powder having been subjected to multiple times of heat exchange and gas-solid separation enters a calcining furnace system from the penultimate-stage cyclone preheater of the suspension preheating system. According to the flexibly-adjustable high-activity metakaolin preparation system and method, the requirements of different industries for the color of a finished metakaolin product are fully considered, high-activity metakaolin is produced, and meanwhile the problems that a conventional metakaolin preparation system is high in energy consumption, small in processing capacity, difficult in product quality control and the like are solved.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

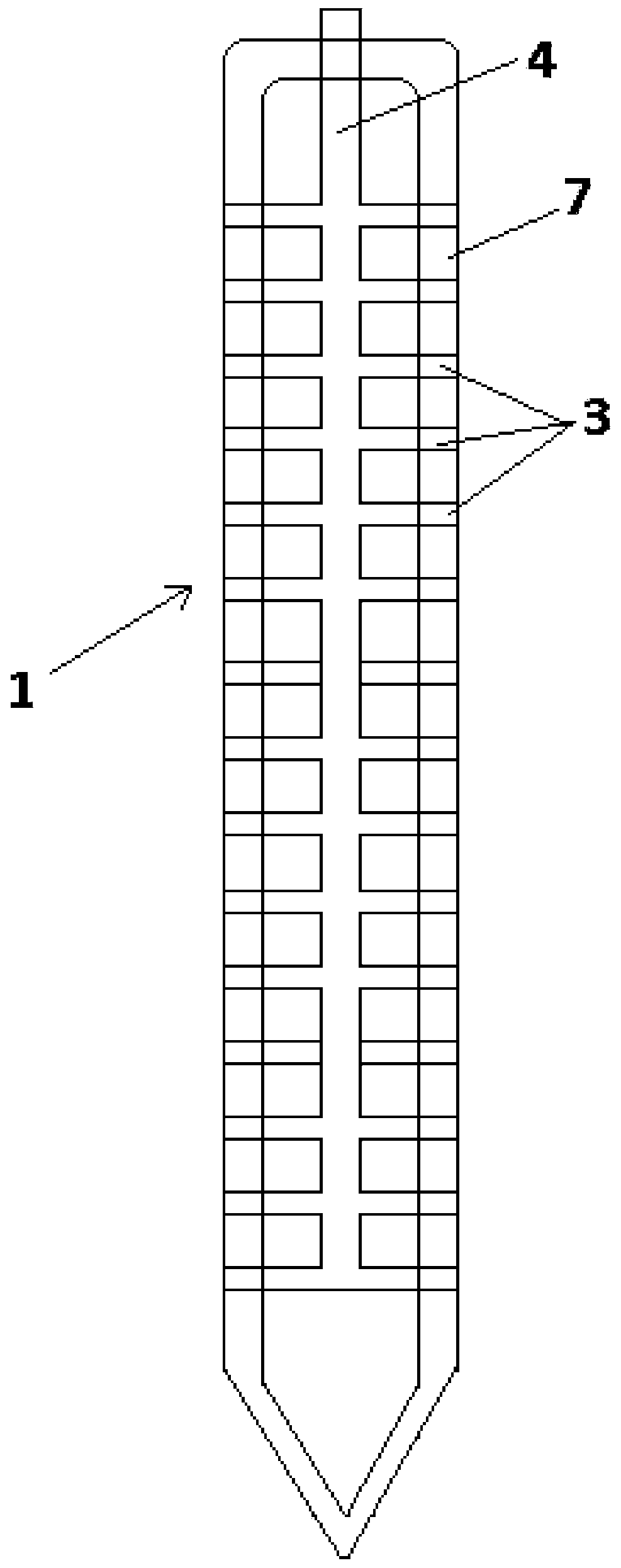

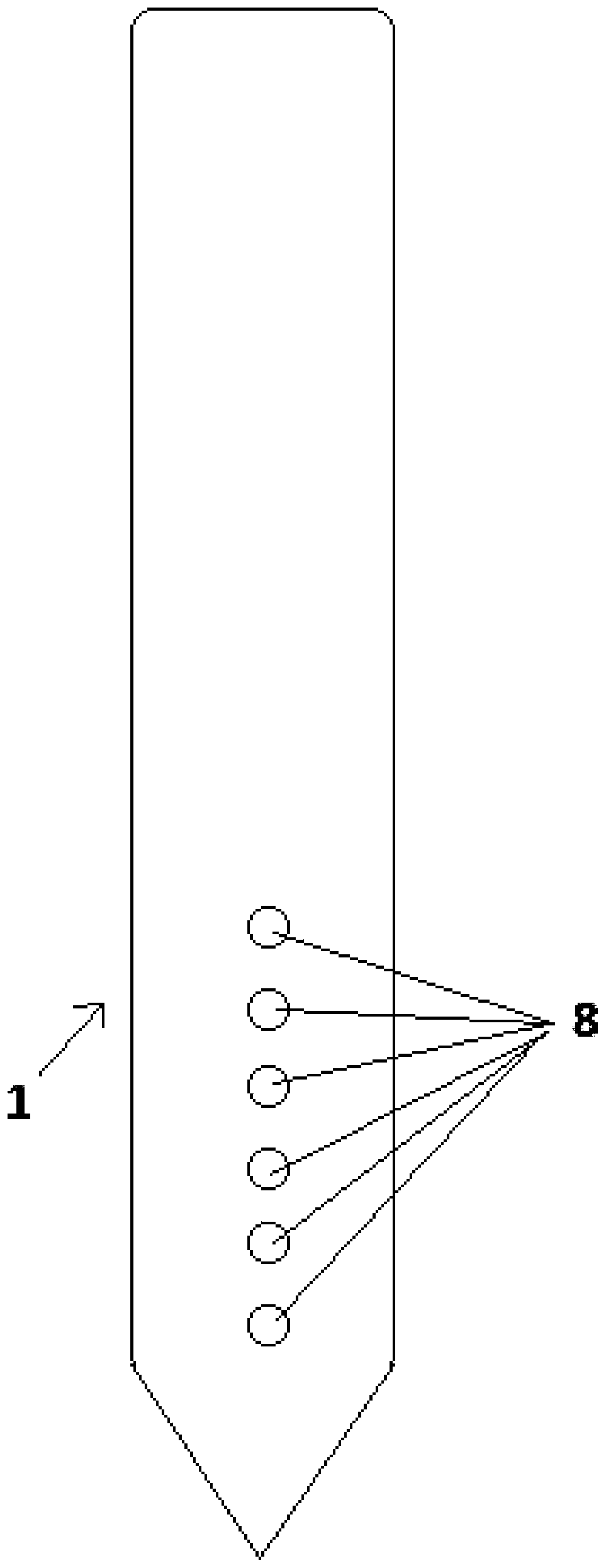

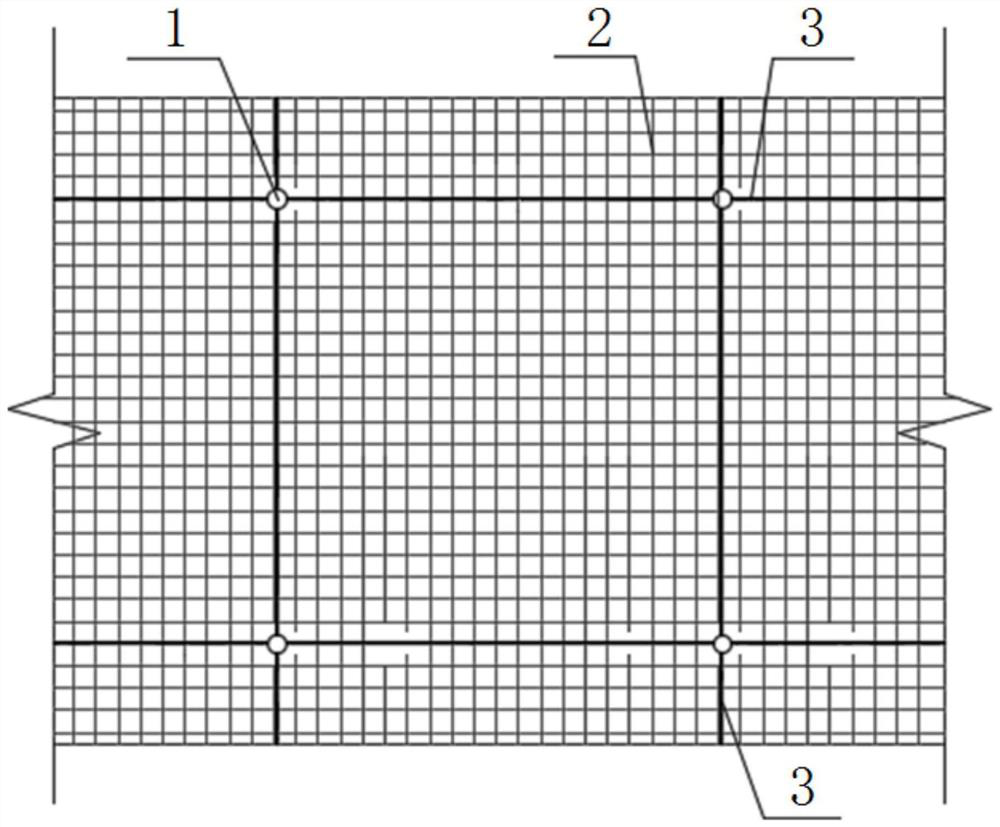

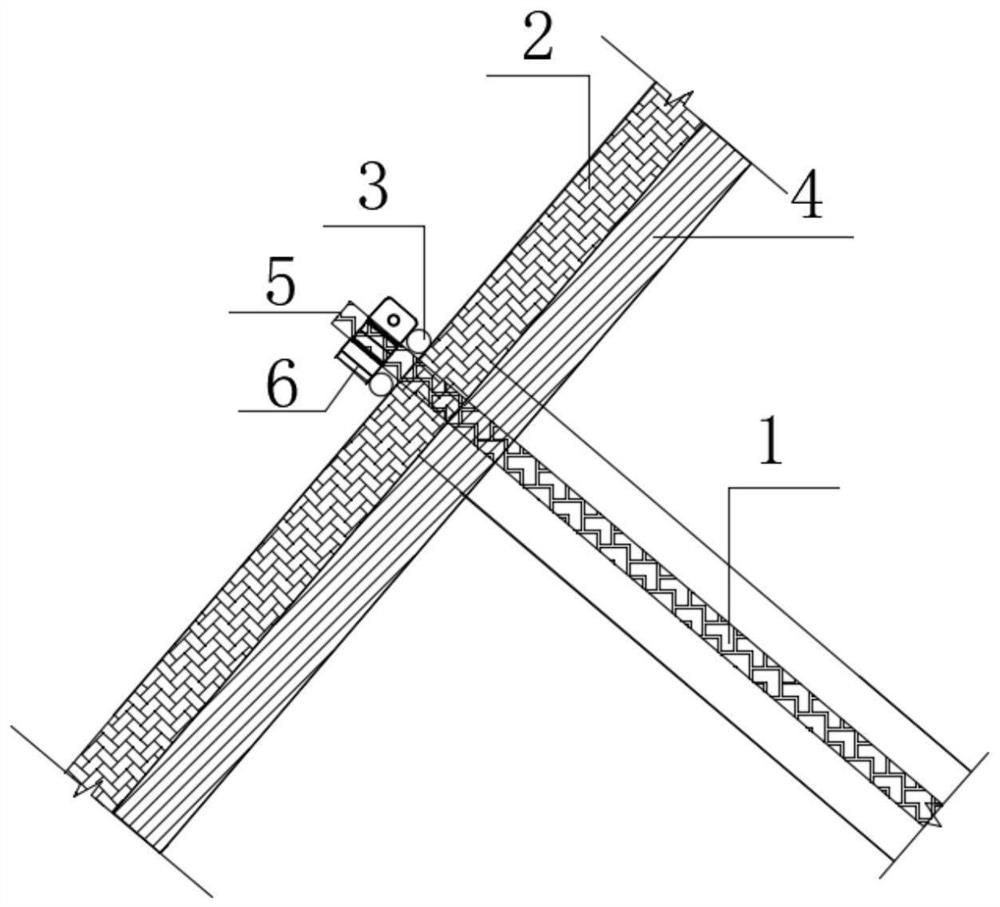

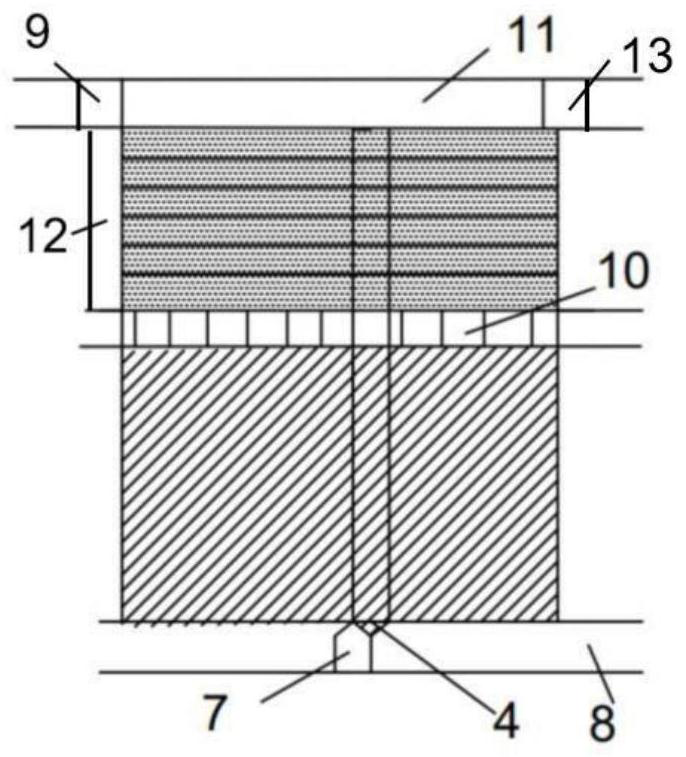

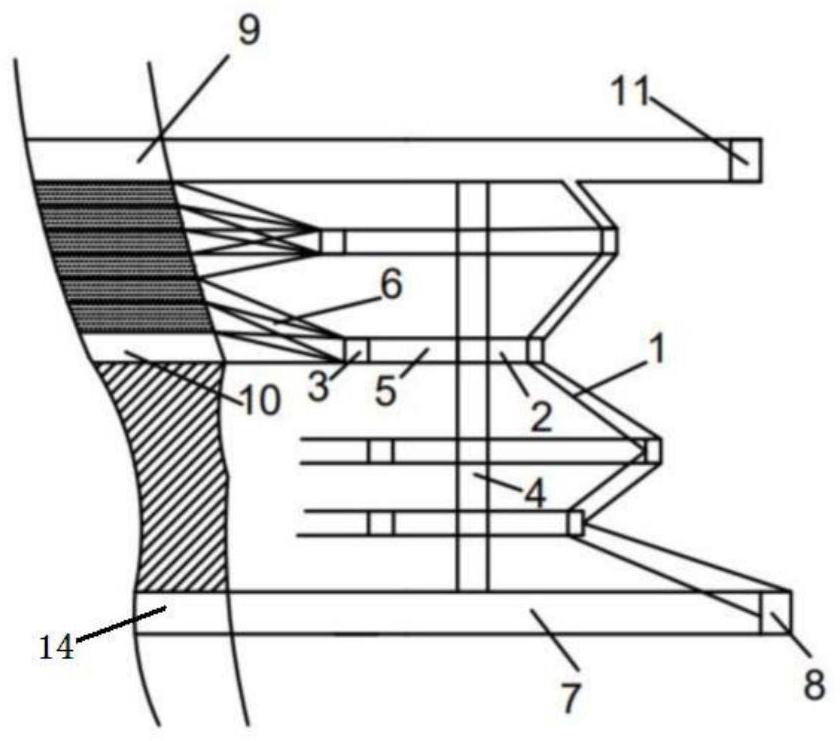

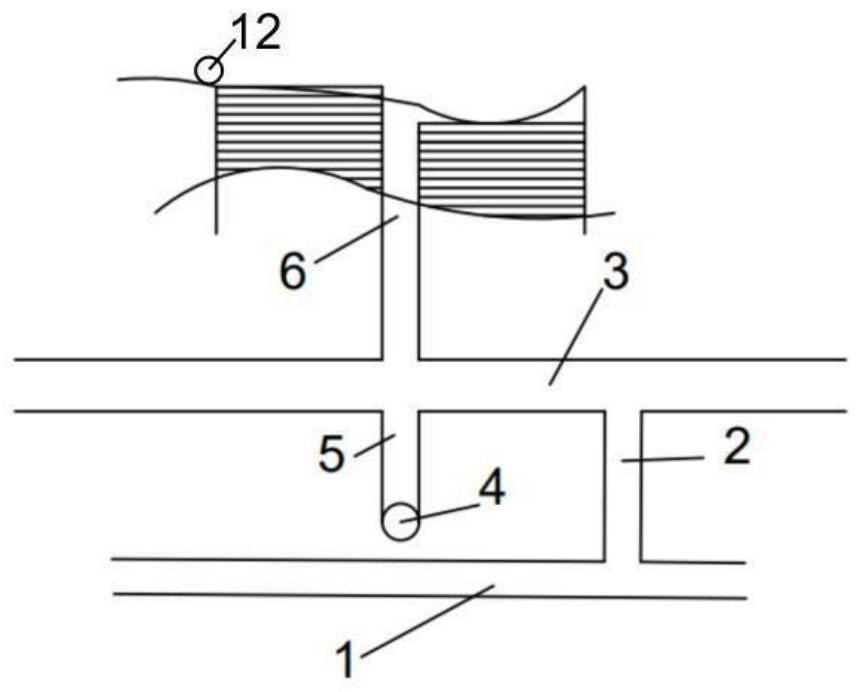

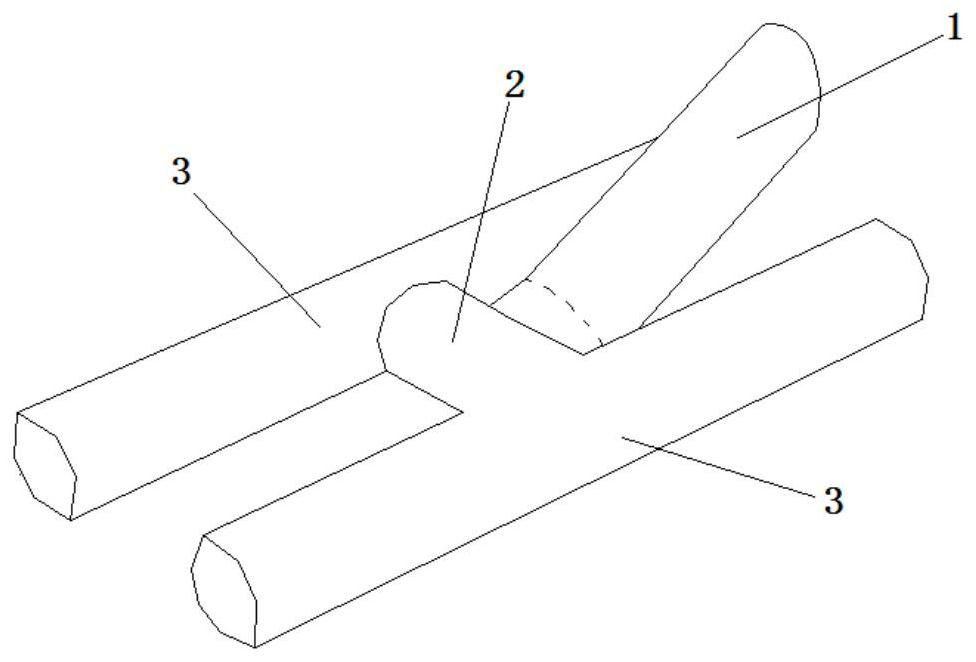

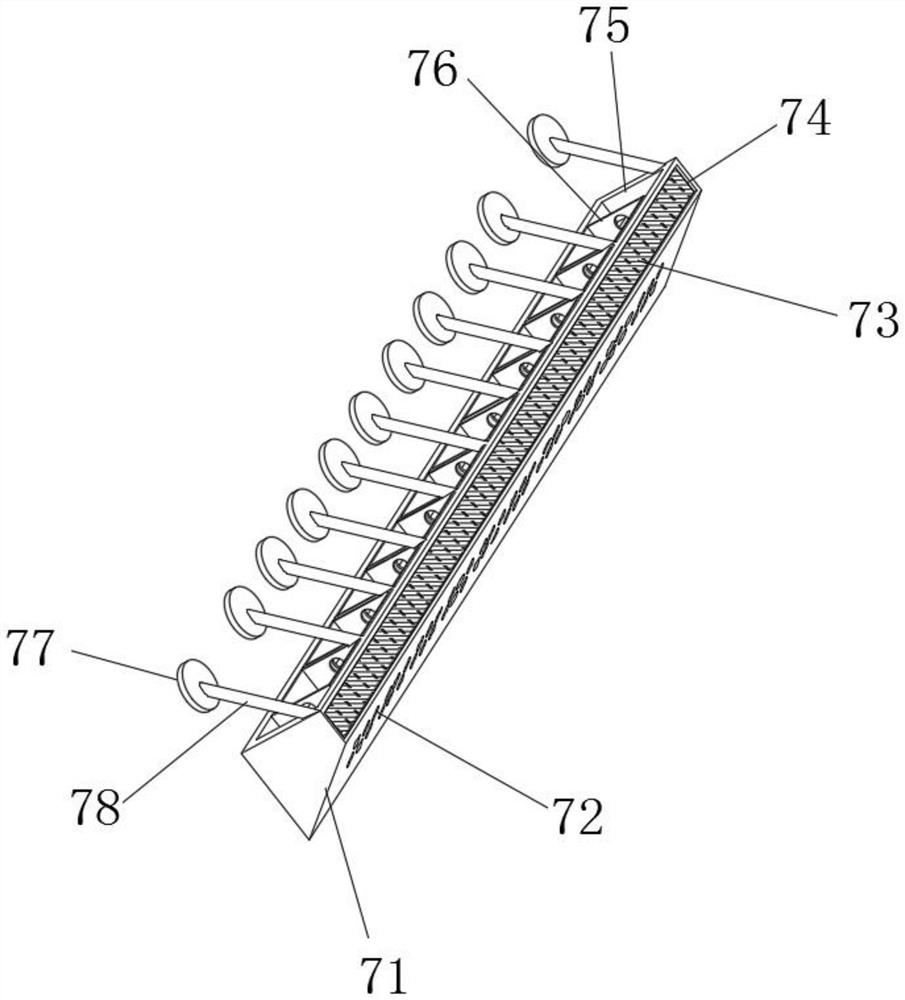

Downward layered drift filling mining method for extremely-broken thick and large ore body

PendingCN114592909AFull recoveryReduce loss dilution rateUnderground miningClimate change adaptationMining engineeringMechanical engineering

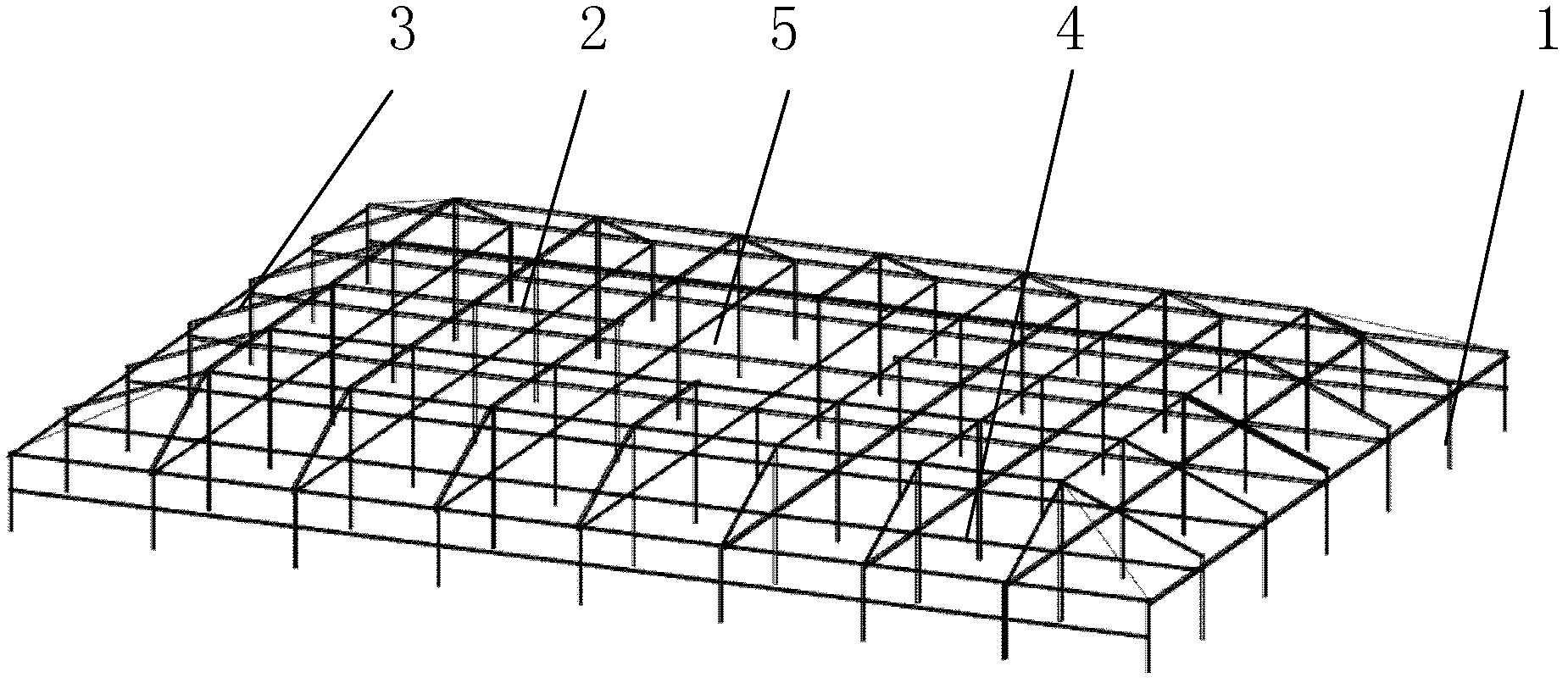

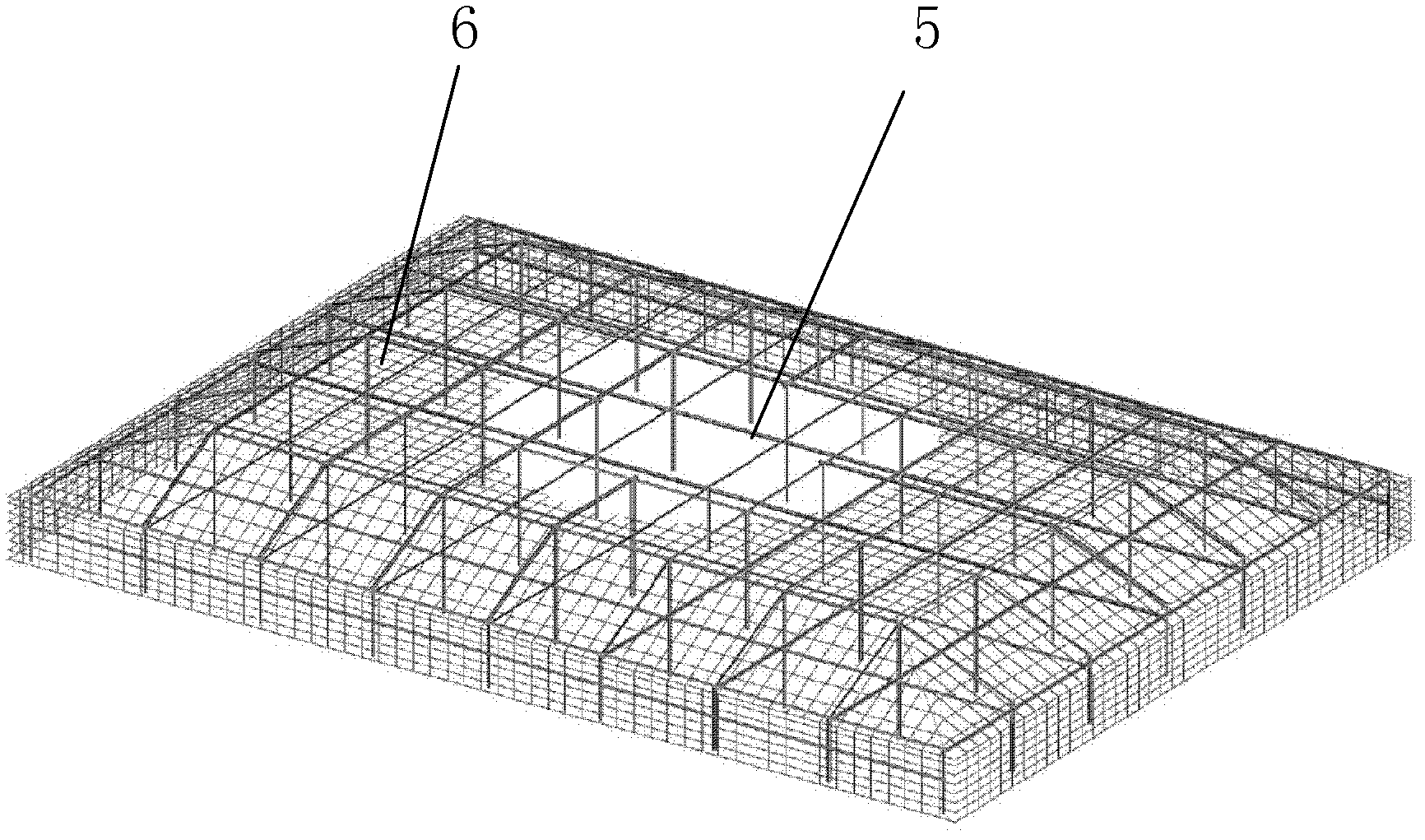

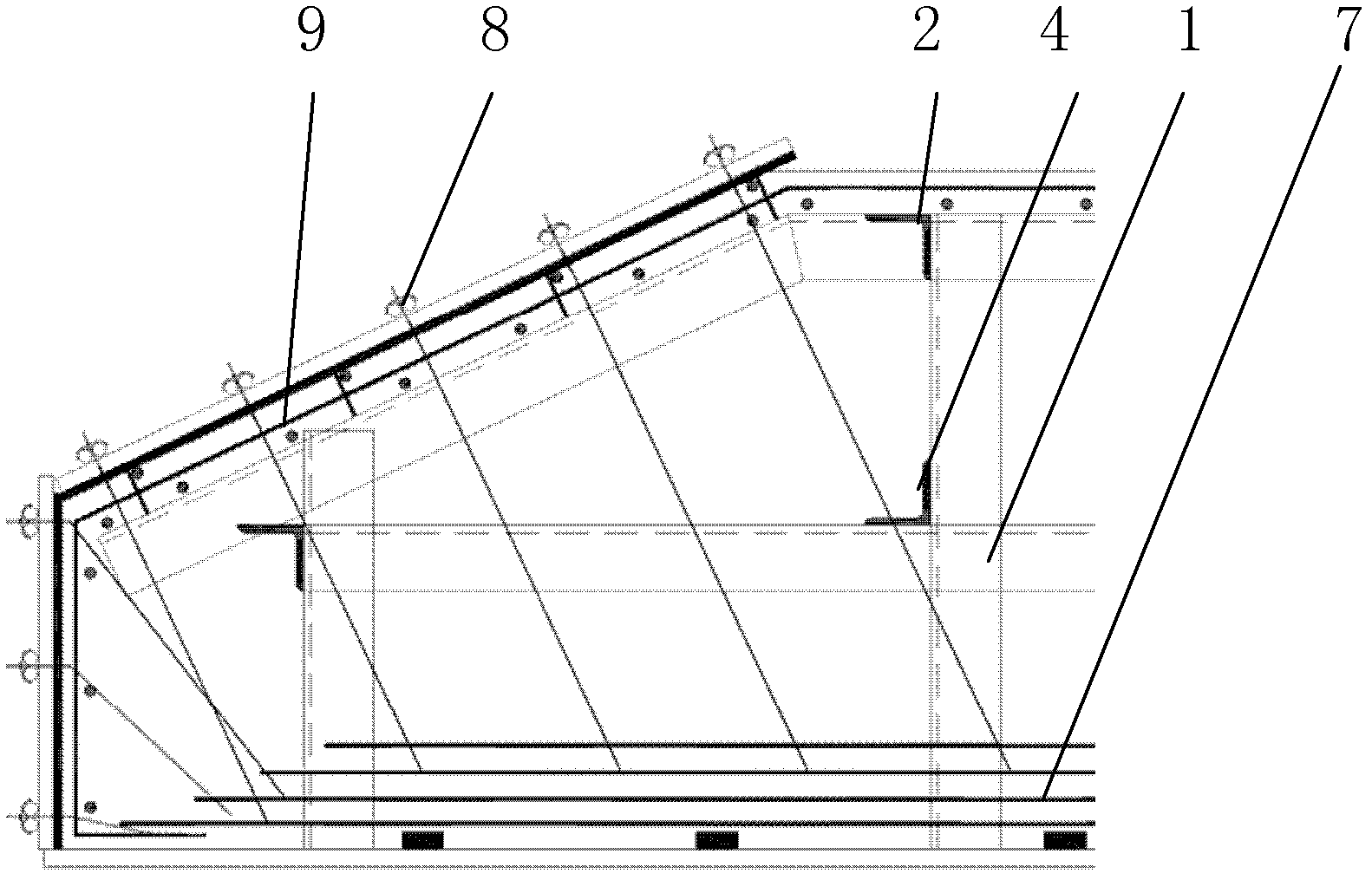

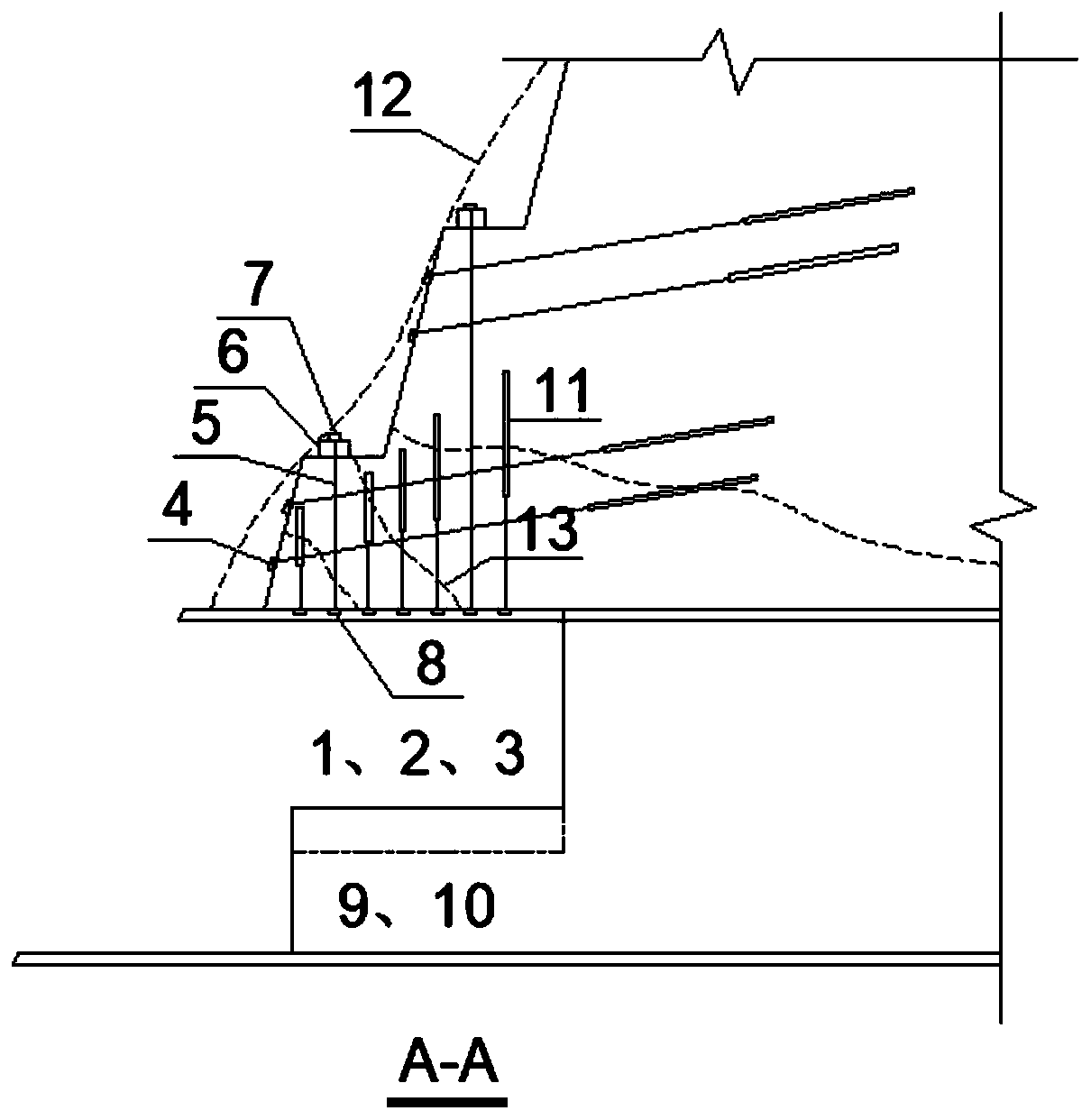

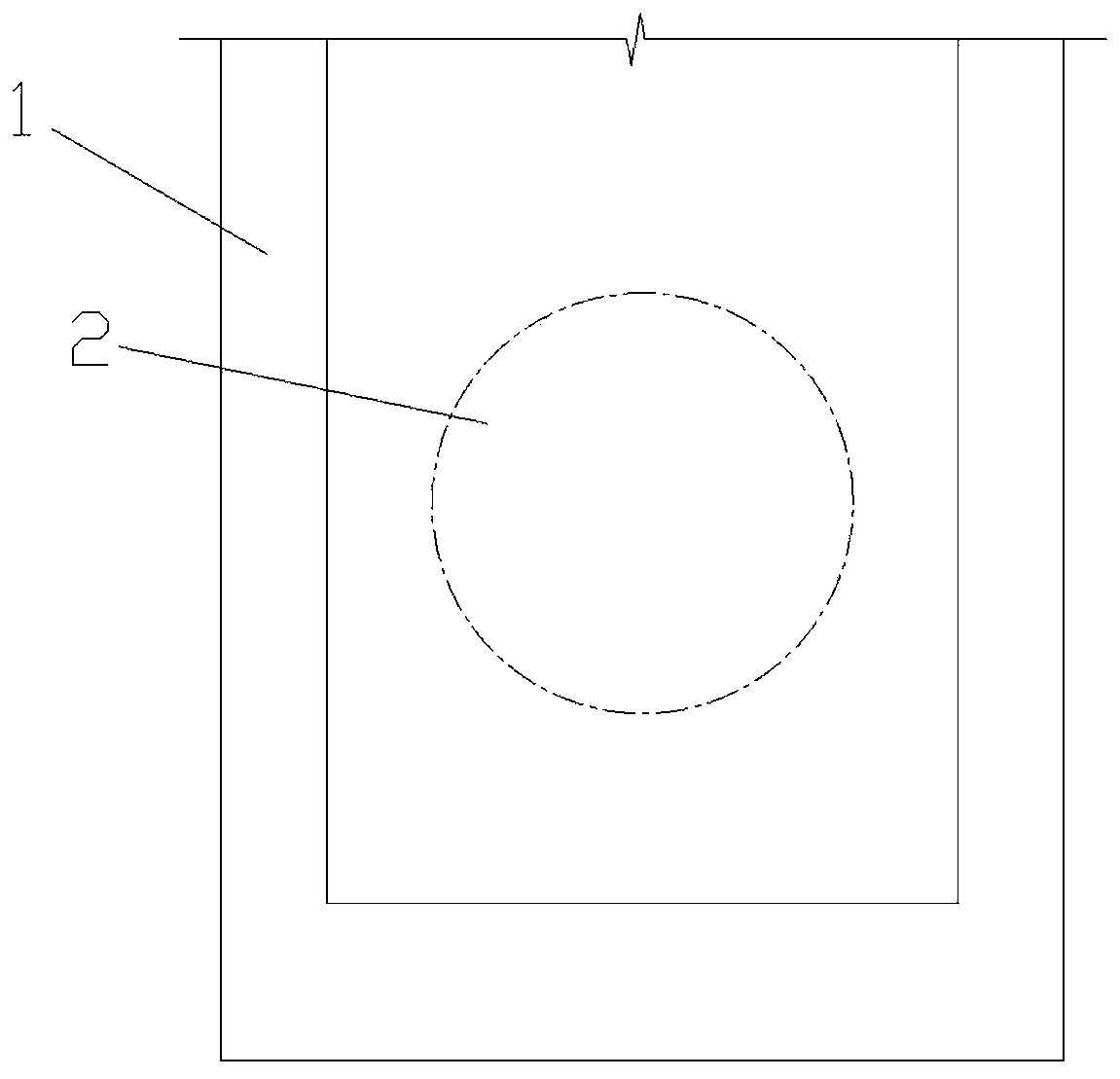

A downward layered drift filling mining method for extremely-broken thick and large ore bodies comprises the steps of stope arrangement and mining preparation cutting, specifically, outside-vein slope ramps (1) communicated with roadways (7) of all stages are tunneled between adjacent middle sections perpendicular to a vein; the method comprises the following steps of: excavating a slope ramp outside a vein, excavating a segmented connection way (2) from the slope ramp outside the vein, excavating a segmented gate way (3) communicated with the segmented connection way, sequentially excavating two or more layered connection ways (6) from the segmented gate way, excavating a layered connection gate way (5) communicated with the layered connection ways, and excavating a stoping drift (10) from the layered connection gate way; an ore pass (4) is arranged in a layered connection gate way (5), a filling return air raise (12) is tunneled, a filling return air roadway (11) is tunneled at the upper part of the filling return air raise, and a current-stage haulage roadway (8) and an upper-stage haulage roadway (13) are respectively tunneled at the joints between the outside-vein ramp and the current-stage transverse drift (14) and between the outside-vein ramp and the upper-stage transverse drift (9); and blasting, ventilating a stope, stoping and filling a goaf. The tunneling and mining efficiency is improved, the mining safety is improved, and the loss and dilution rate of ore is effectively reduced.

Owner:生态环境部固体废物与化学品管理技术中心

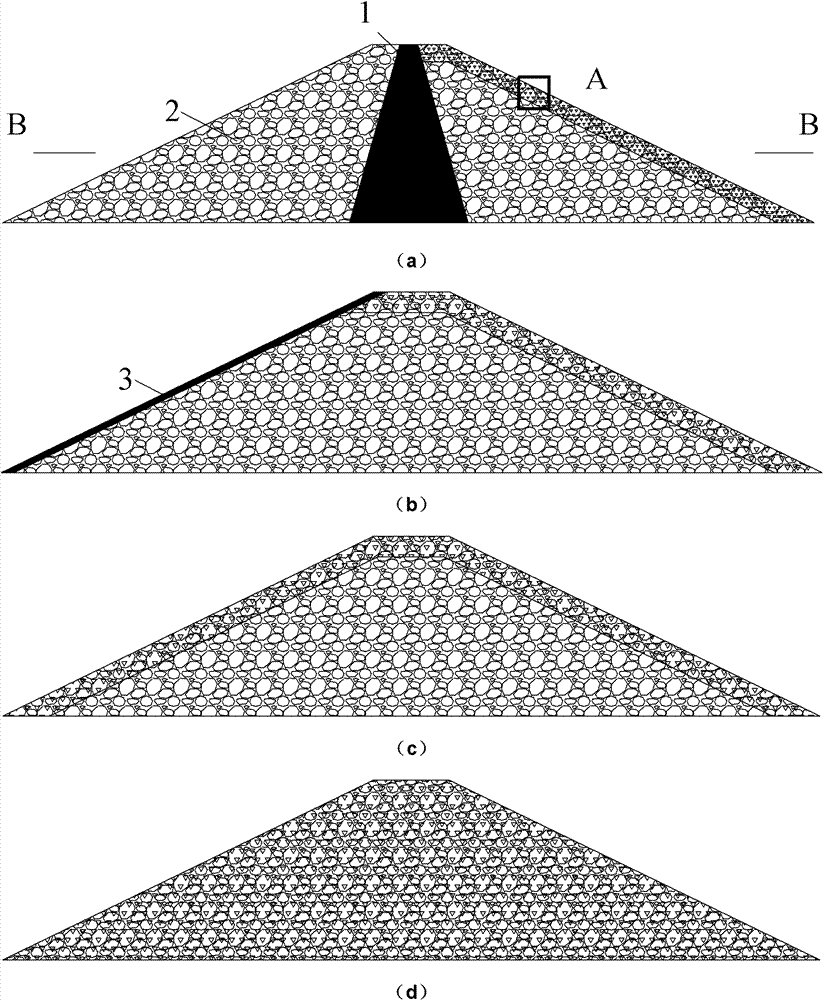

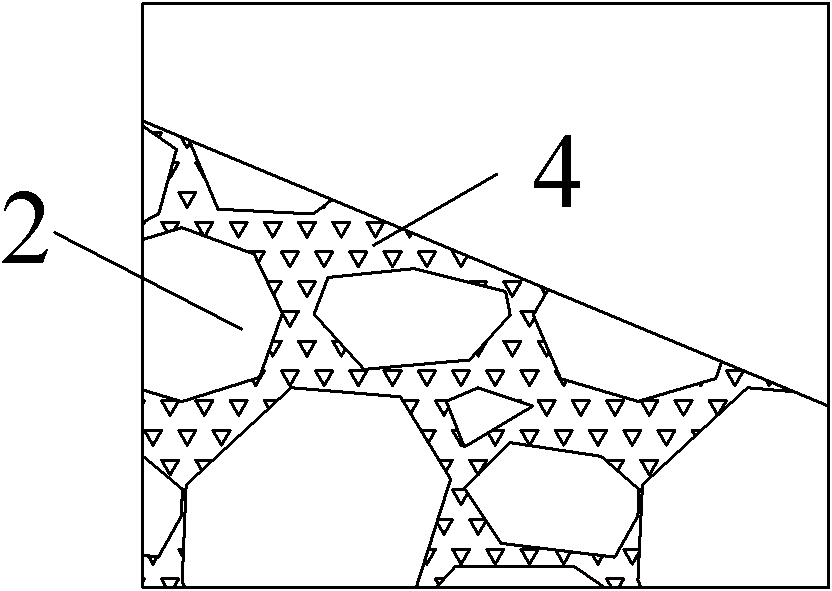

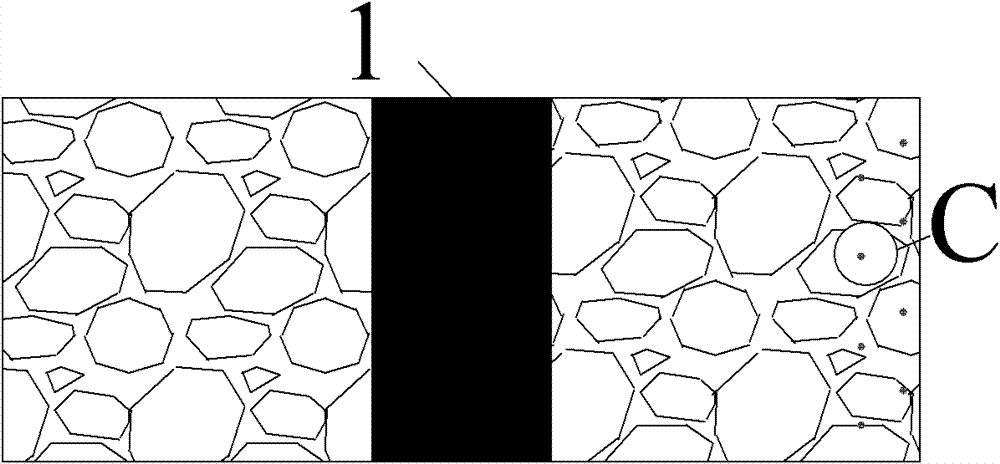

Polymer grout injected earth-rock dam and construction method thereof

ActiveCN102561271BAvoid risk of collapseTo achieve overflow functionFoundation engineeringEarth-fill damsStructure of the EarthMaterials science

The invention discloses a polymer grout injected earth-rock dam and a construction method thereof. The polymer grout injected earth-rock dam comprises rockfill, polymer grout injected rockfill and a face slab. A dam body is built with the rockfill, with the rockfill and a clay core wall or with the face slab and the rockfill by filling. Overall dam grouting or grouting on the upstream surface and the downstream surface of the dam body are performed during filling. The problems that conventional earth-rock dam allows no passage of water, accelerations at the top of the dam are high, the rockfill mass is easy to loosen and the like are solved, and the polymer grout injected earth-rock dam is simple in structure and convenient in construction, has evidently improved seismic stability, has wide application prospect and is an economical and practical dam.

Owner:HOHAI UNIV

Earth pressure shield external air bag combined mud pressure balancing method

ActiveCN112664214AAvoid the risk of ground subsidenceMinor changesUnderground chambersTunnel liningEngineeringEnvironmental geology

The invention discloses an earth pressure shield external air bag combined mud pressure balancing method. The earth pressure shield external air bag combined mud pressure balancing method comprises the steps that a mud pressure bin with an air bag or a combination of a plurality of air bags is connected with the top of a shield soil bin through a pipeline, in the shield tunneling process, the pipeline is unblocked all the time, the high compressibility or elasticity of the air bags is utilized, and mud is used as a transmission medium to keep in contact with the soil pressure in the soil bin to form a stable balance mode. By means of the mode, the conditions of ultrahigh pressure (the ultrahigh pressure can cause ground upheaval, slag outlet or shield tail spewing and shield tail sealing breakdown) or ultralow pressure (the ultralow pressure can cause stratum collapse and ground collapse) in the soil bin can be eliminated, the pressure of the soil bin is stabilized within a reasonable range, and micro-disturbance tunneling of the stratum around the tunnel is achieved.

Owner:GUANGZHOU RAIL TRANSIT CONSTR SUPERVISION CO LTD

Irrigation and draining brake

InactiveCN103103967BAvoid the danger of being washed away by the currentAvoid the risk of collapseConstructionsSoil drainagePulp and paper industryWater level

The invention discloses an irrigation and draining brake which comprises a flashboard frame and a flashboard, wherein a water inlet through hole is formed in the flashboard frame. Guide grooves are formed in both sides of the flashboard frame. Both sides of the flashboard are contained in the guide grooves and can move along the guide grooves, positioning adjusting teeth are arranged on the inner wall of the guide grooves, and elastic clamping tongues which are matched with the positioning adjusting teeth are arranged on both sides of the flashboard. The irrigation and draining brake is fixed on an opening of a ridge, irrigation and draining work is controlled by moving the flashboard, and water level height can be adjusted. The irrigation and draining brake has the advantages of being convenient to use, safe and reliable.

Owner:顾积志 +2

Construction method of deep-buried intersecting tunnel group in semi-diagenetic area

ActiveCN112983431AReduce the impactPrevent subsidenceUnderground chambersHydro energy generationArchitectural engineeringTunnel construction

The invention discloses a construction method of a deep-buried intersecting tunnel group in a semi-diagenetic area. The construction method comprises the following steps that firstly, an escalator tunnel is constructed, and an escalator tunnel arch frame is reinforced when the escalator tunnel reaches the intersection of transverse channels; the transverse channels are synchronously excavated and constructed from the intersection of the escalator tunnel and the transverse channels to the left side and the right side; after the transverse channels are constructed, synchronous excavation is conducted on the left side and the right side of a left line and a right line through a top-lifting conversion construction method to conduct main line tunnel construction, foot-locking anchor pipes are reinforced in the transverse channels and the corresponding primary support arch frame ranges on the two sides in time, and the escalator tunnel serves as a ballast outlet channel; and after excavation and primary support are completed, secondary lining construction is conducted. The construction sequence is arranged reasonably, the construction progress is effectively accelerated, and the cost is reduced; and meanwhile, the high risk of vault settlement and collapse caused by uneven structural stress of the multi-node three-dimensional intersecting tunnel is controlled, and the problem that the structure is unstable during construction of the deep-buried intersecting tunnel group in the semi-diagenetic area is solved.

Owner:GUANGZHOU METRO DESIGN & RES INST

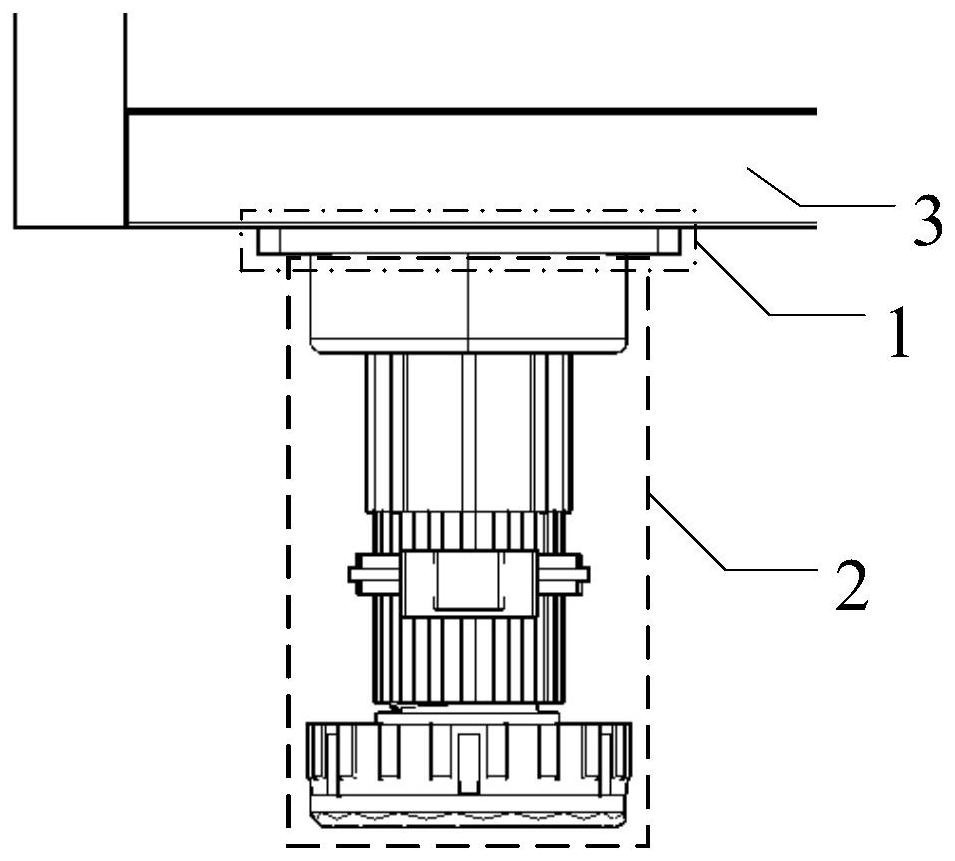

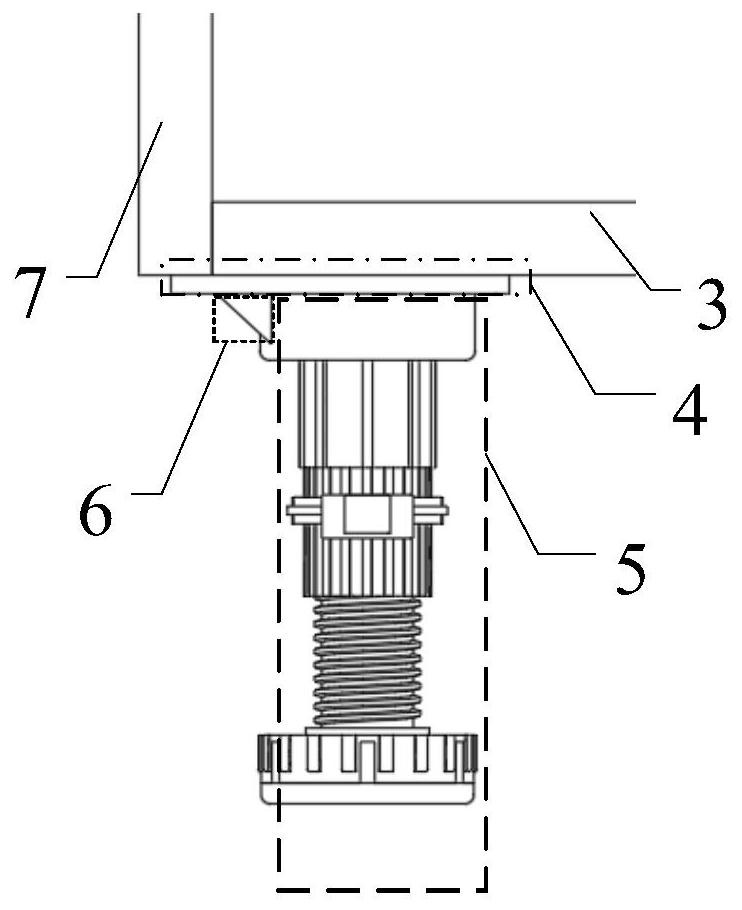

Lower jacking fast installation type lifting platform and construction method

ActiveCN107327148AReduce preparation timePrevent dumpingBuilding material handlingButt jointArchitectural engineering

The invention relates to a lower jacking fast installation type lifting platform. An assembly type steel structure foundation is fixed on a ground foundation on one side of an original bearing platform of a building in a spaced mode. A jacking system is fixedly installed at the upper end of the assembly type steel structure foundation. A plurality of standard knots are installed on the jacking system coaxially in the longitudinal direction in a stacked mode. The height of the upper ends of the standard knots is the same as that of the original bearing platform of the building. A lifting bearing frame is fixedly installed at the upper ends of the standard knots. A stretching type bearing table is installed on one sides of the upper portions of the standard knots in a cantilever type mode. The cantilever end of the stretching type bearing table is connected with the upper end of the original bearing platform of the building in a flush butt-joint mode. A pull rod is connected between one side of the lifting bearing frame and the building. After the fast installation type lifting platform is used for site-in construction of indoor substation electrical equipment, the risks of equipment toppling and platform collapsing are avoided, meanwhile, construction efficiency is improved greatly, original platform preparation time of 10 hours is shortened to 2 hours, the lower jacking fast installation type lifting platform can be repeated used and is suitable for lifting transfer of various heights, and construction cost is lowered greatly.

Owner:TIANJIN ELECTRIC POWER TRANSMISSION & TRANSFORMATION ENG CORP +1

Rock stratum super-large tunnel spanning high-side slope tunnel portal supporting structure and construction method thereof

PendingCN111236996APrevent collapseAvoid risk of collapseExcavationsBulkheads/pilesSupporting systemPre stress

The invention discloses a rock stratum super-large tunnel spanning high-side slope tunnel portal supporting structure and a construction method thereof. The supporting structure comprises upward slopeground beams, annular upward slope anchor cables, vertical high-strength prestressed steel cables and in-tunnel system anchor rods or anchor cables, wherein the upward slope ground beams are externalstress structures of a tunnel portal supporting system; the annular upward slope anchor cables are arranged on a side slope of a tunnel portal, and unstable blocks formed by rock fractures and fracture zones at the top of a tunnel portal section structure are fixed on peripheral stable blocks through the annular upward slope anchor cables, or the unstable blocks are connected in series to form the stable blocks; the vertical high-strength prestressed steel cables are arranged in lowering holes of the upward slope ground beams and are arrange in crossed with the annular upward slope anchor cables; and the in-tunnel system anchor rods or anchor cables are arranged above a top middle tunnel and top side tunnels. According to the rock stratum super-large tunnel spanning high side slope tunnelportal supporting structure and the construction method thereof, rapid and safe tunnel entering construction of a hard rock stratum high-side slope ultra-large-span underground structure is achieved,a tunnel portal side slope self-stabilization reinforcing body is formed, and the risk that rock mass on the upper portion of a tunnel forms a slip surface, the unstable blocks or rock mass wedges onthe top of the cavern range collapse due to excavation is avoided.

Owner:CHINA RAILWAY TUNNEL SURVEY & DESIGN INST +1

Cache design management method, device and equipment and computer readable storage medium

ActiveCN112799978AAvoid system crashWon't hurtMemory systemsEnergy efficient computingWhole systemsOperating system

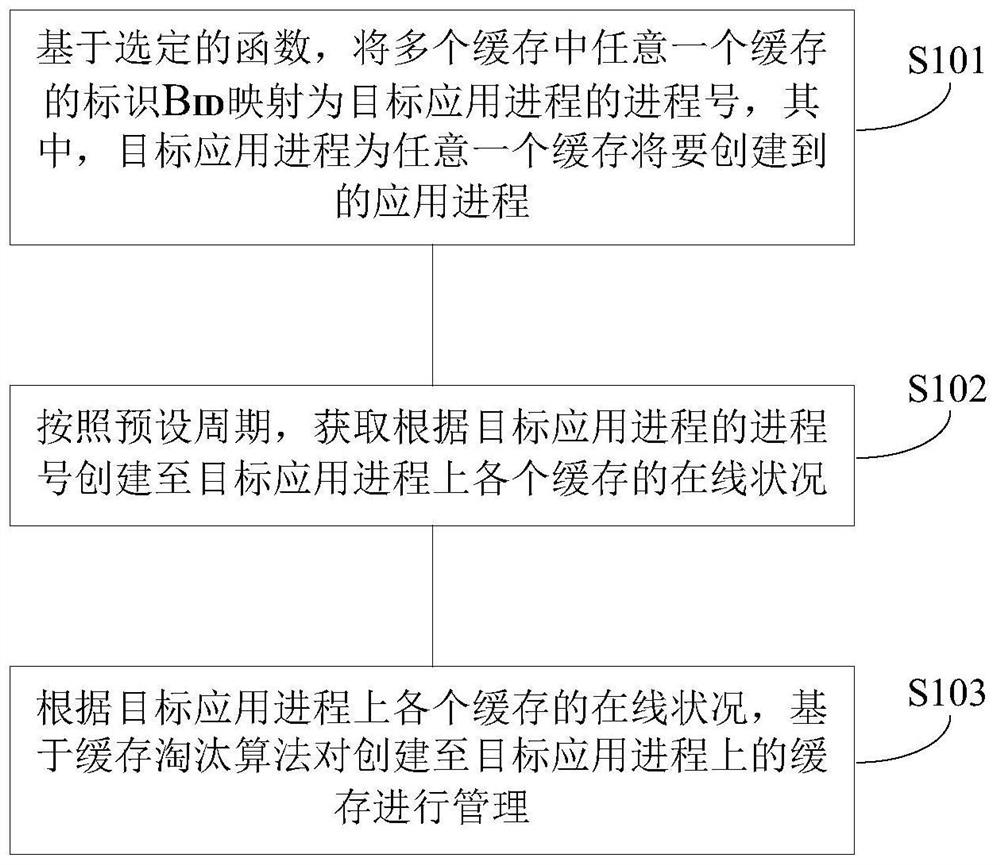

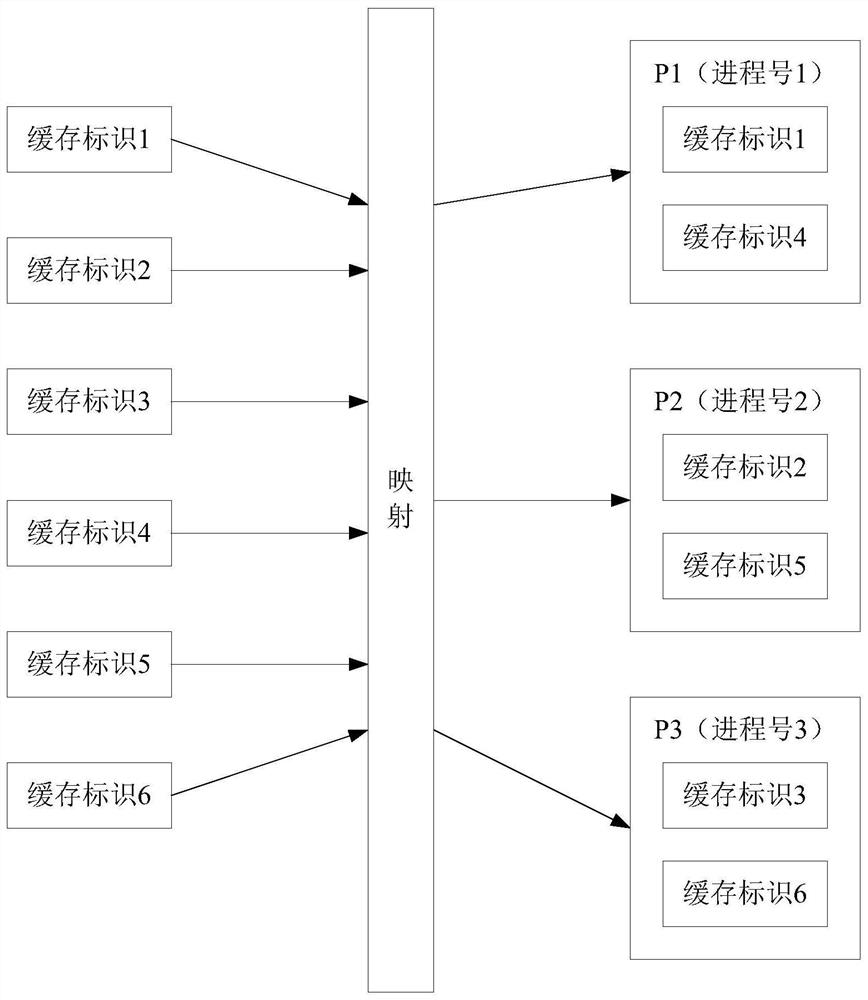

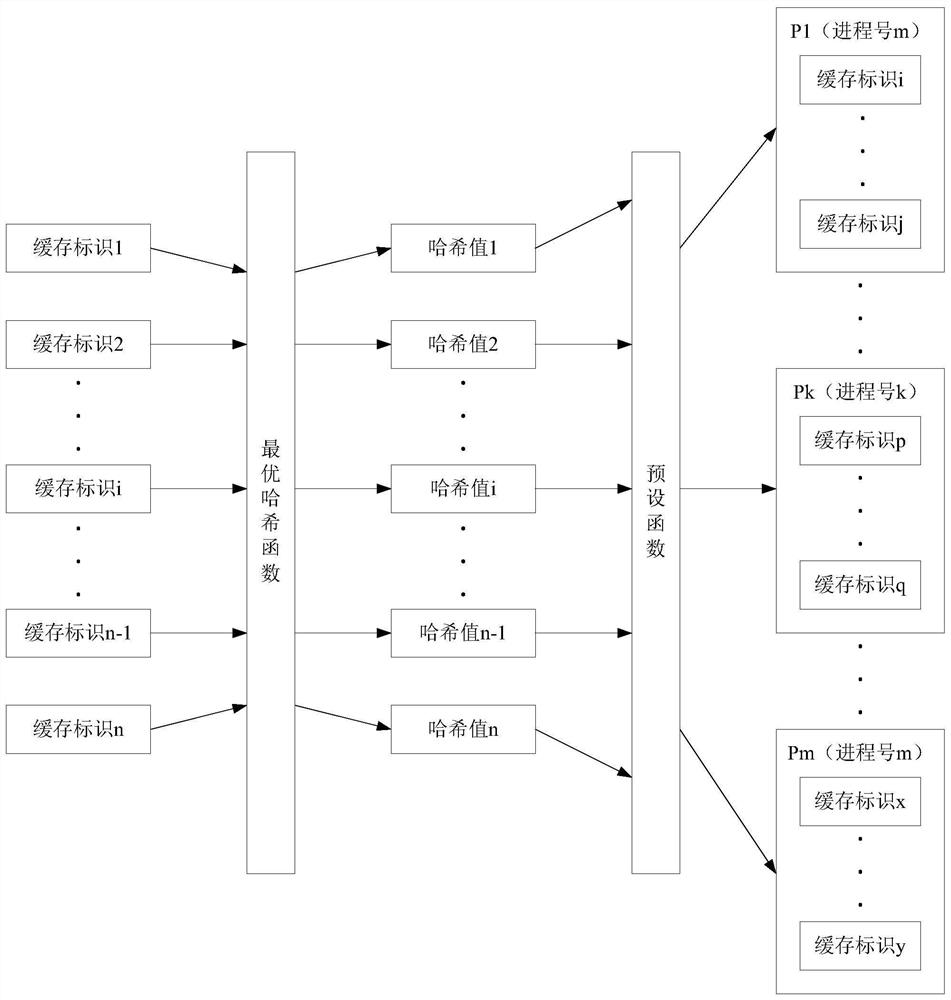

The invention relates to the field of computer networks, provides a cache design management method, device and equipment and a computer readable storage medium, and aims to accurately position a cache with a problem and avoid overall collapse of a system caused by collapse of a central node. The method comprises the following steps: mapping an identifier BID of any cache in a plurality of caches into a process number of a target application process based on a selected function; according to a preset period, obtaining an online condition of each cache created to the target application process according to the process number of the target application process; and managing the caches created to the target application process based on a cache elimination algorithm according to the online condition of each cache on the target application process. According to the technical scheme, on one hand, the application process where the cache with the problem is located can be rapidly positioned according to the mapping relation, and on the other hand, the risk of collapse of the whole system caused by collapse of one center node in the prior art can be avoided.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

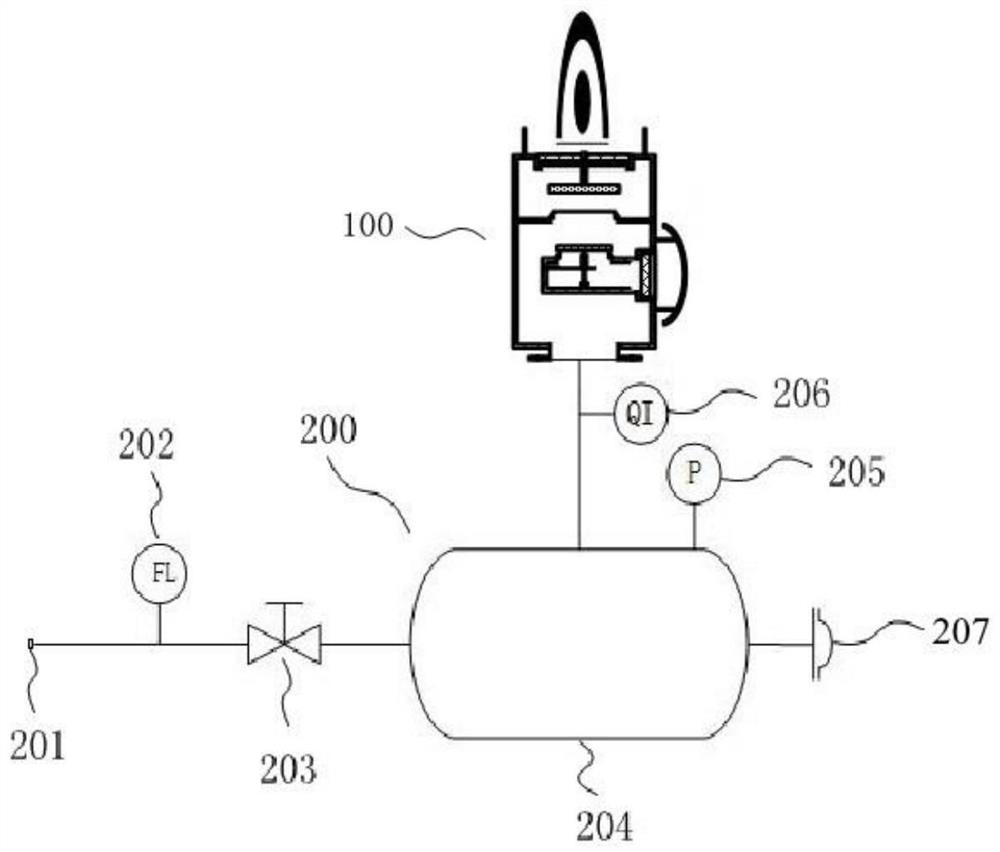

All-weather burning-resistant breather valve device

PendingCN114427618AEnsure safetyAvoid the hazards of vibration instabilityThermal insulationLarge containersEngineeringMechanics

The invention provides an all-weather burning-resistant breather valve device. The all-weather burning-resistant breather valve device comprises a main valve body; the burning-resistant fire-retardant assembly is arranged at an opening in the upper end of the main valve body; the pressure valve is formed in the main valve body, and a pressure valve air chamber and a common air chamber are formed on the upper side and the lower side of the pressure valve respectively; the vacuum valve is arranged in the common air chamber and fixedly connected to the side wall of the main valve body, the vacuum valve comprises a vacuum valve air chamber, and a detonation fire-retardant disc is arranged on the side portion of a vacuum valve body; according to the all-weather burning-resistant breather valve device, when the pressure of gas in the storage tank exceeds the preset pressure of the pressure valve, the pressure valve is opened, so that the gas in the storage tank sequentially enters the common gas chamber and the pressure valve gas chamber and then is discharged through the burning-resistant fire-retardant assembly, and when the pressure of the gas in the storage tank is negative and is lower than the preset pressure of the vacuum valve, the pressure valve is opened. The vacuum valve is opened, so that outside air is sucked into the vacuum valve air chamber from the detonation fire-retardant disc and then enters the common air chamber through the vacuum valve to enter the storage tank, and therefore the gas pressure of the storage tank is supplemented.

Owner:CHINA PETROLEUM & CHEM CORP +1

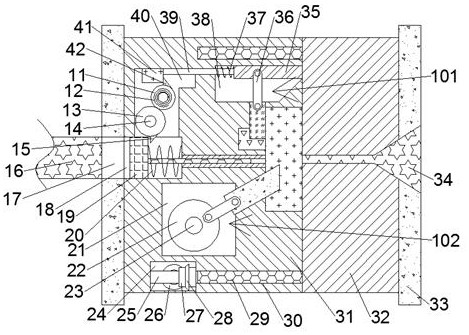

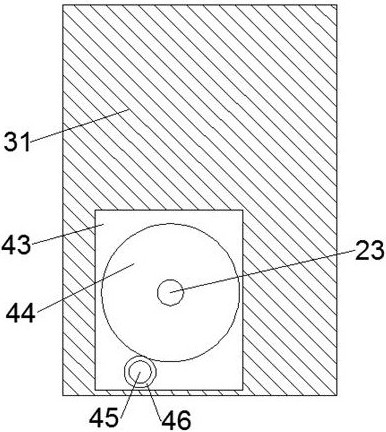

A plastic forming mold for solving the inverted structure

ActiveCN111633924BSimple production processAvoid risk of collapseStructural engineeringInjection molding machine

The invention discloses a plastic forming mold for solving an undercut structure, which comprises a forming template, an auxiliary template and a plastic part. The plastic part is provided with an undercut cavity opening to the left, and the left side of the plastic part is An upside-down button body is fixed on the top, a clamping template is fixed on the left side of the forming template and the right side of the auxiliary template, and a cavity with an opening to the right is provided inside the molding template. The upper side of the cavity is provided with a transmission mechanism that can realize the formation of the inverted button body structure. The present invention uses the auxiliary formwork to press the top column to move to the left, and the slide rod drives the screw to penetrate the screw sleeve and drive the screw sleeve to rotate. Both the vertical insert block and the oblique insert block are controlled to be inserted into the mold cavity, so that when the injection molding machine injects plastic raw materials, the raw materials can be formed into plastic parts, undercut bodies and undercut cavity structural characteristics in the cavity.

Owner:深圳市美域同润实业有限公司

A pressure balance method of earth pressure shield with external airbag combined with mud

ActiveCN112664214BEliminate gushingEliminates breakdown difficultiesUnderground chambersTunnel liningThermodynamicsUltra high pressure

Owner:GUANGZHOU RAIL TRANSIT CONSTR SUPERVISION CO LTD

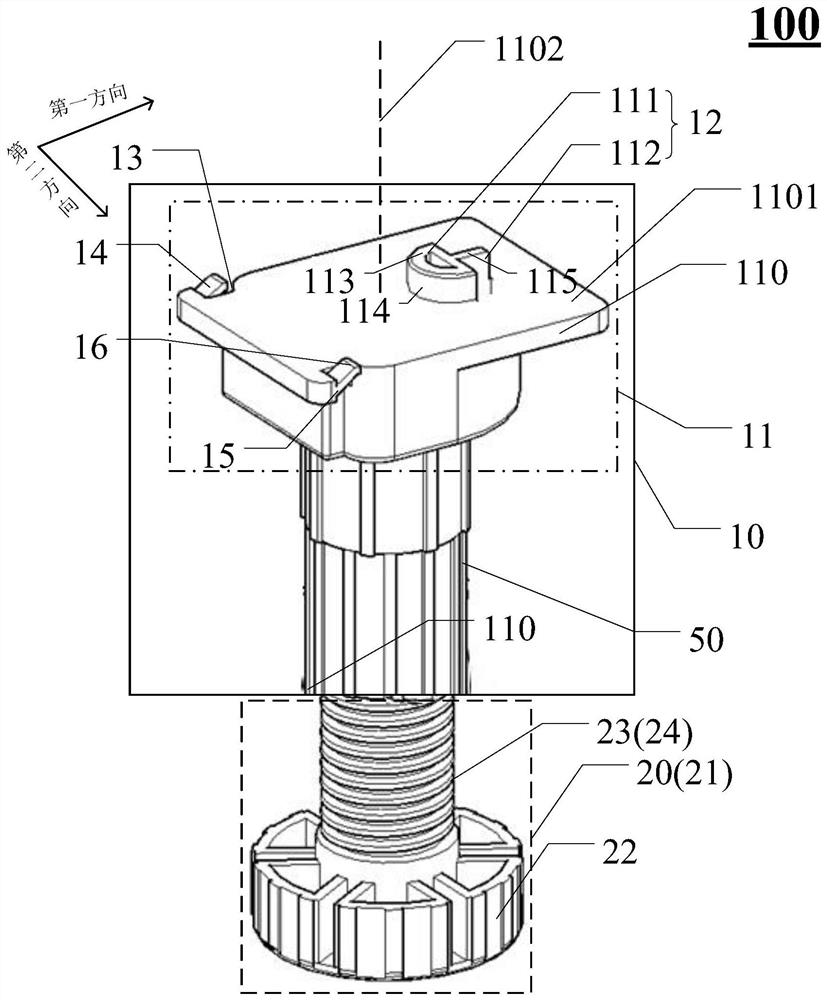

Cabinet adjusting leg

PendingCN113841998AAvoid position deflectionReduce installation difficultyFeetEngineeringStructural engineering

Owner:博洛尼智能科技(青岛)有限公司

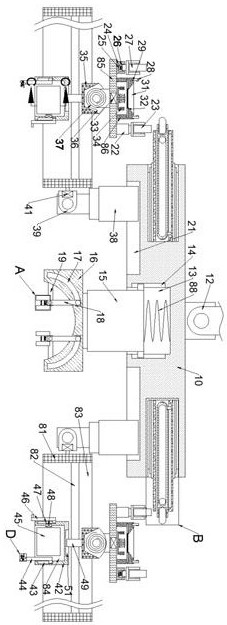

Ancient building roof tile detecting and repairing equipment

InactiveCN112727133AAvoid risk of collapseGuaranteed stabilityBuilding repairsShaping press ramRoof tileArchitectural engineering

The invention discloses ancient building roof tile detection and repair equipment. The ancient building roof tile detection and repair equipment comprises a base and a translation electric sliding rail arranged on the lower surface of the base; a translation hydraulic press is slidably arranged in the translation electric sliding rail; an angle block is rotatably arranged on a hydraulic rod of the translation hydraulic press; a motor is fixedly arranged on the rear side of a rotating shaft of the angle block; and a overturning motor is fixedly arranged on the left side of the angle block. After the ancient building roof tile detection and repair equipment is placed at a designated position, the ancient building roof tile detection and repair equipment can detect damage or breakage of tiles according to the stability of the tiles and gaps between the tiles, then repair or refilling is conducted according to a model of the tiles, and in the process of repairing and detecting, the stability of the equipment can be guaranteed by adjusting the contact angle of wheels and a main ridge, so the collapse risk of an ancient building is avoided and potential safety hazards are reduced.

Owner:单伟阳

A partitioned pressure forming method for a closed airfoil structure

ActiveCN111016224BLightweightAchieve application breakthroughWeight reductionDomestic articlesThreaded pipeEngineering

A closed airfoil structure partition press molding method, suitable for composite material structure molding method and mold with large elongation scale, double curvature shape and upper, lower, left and right closed sections of aircraft airfoil Scheme, the airfoil structure scheme consists of upper and lower skin honeycomb sandwich panel structures and multiple longitudinal beam structures arranged in the middle. The forming method includes the use of upper and lower shape control molds and vacuum bags for the panel in the interlayer area between the internal beams. And the combination of threaded pipe torque adjustable auxiliary struts and baffles is used to realize the pressure control of all surfaces of the composite material. The present invention can realize the integrated high-precision molding of the structure through co-curing by adopting the method of unequal pressurization in different regions under the condition of different curing pressures required for pressing different parts such as honeycomb sandwich and laminated board.

Owner:CHINA ACAD OF LAUNCH VEHICLE TECH

Shield station-crossing construction method capable of achieving layered backfill in small and narrow vertical shaft

ActiveCN110985026AImprove torsion resistanceGuaranteed digging attitudeMaterial fill-upTunnelsArchitectural engineeringStructural engineering

The invention discloses a shield station-crossing construction method capable of achieving layered backfill in a small and narrow vertical shaft. The method of layered backfill is adopted to form soilwith certain strength, a shield tunneling machine can simulate a normal strata for tunneling during station crossing, on the first layer, a hard backfill material is backfilled, it is ensured that the backfill material has the enough bearing force, the too large sinking generated by self weight during station crossing of the shield tunneling machine is prevented, on the second layer, an originalsoil layer is backfilled, the phenomenon that during station-crossing propelling of the shield tunneling machine, too large resistance is generated, and a pipe segment is structurally damaged is avoided, a cement pile in the backfill soil increases the shield body torque resistance during tunneling of the shield tunneling machine, and the tunneling posture of the shield tunneling machine can be ensured. The method greatly reduces receiving and starting risks during shield station crossing, the hole door water burst sand burst ground collapse risk can be avoided, shield concrete guide platformconstruction, hole door water stop device mounting and an end reinforcing grouting material can be reduced, meanwhile, the time for mounting of a guide platform and other station-crossing materials inthe small and narrow vertical shaft can be omitted, and the shield construction proceed can be improved.

Owner:CCFEB CIVIL ENG

Garden slope repairing device and repairing method thereof

InactiveCN114411770AAvoid churnBeautify the ecological environmentSelf-acting watering devicesExcavationsAgricultural engineeringEconomic benefits

The garden side slope repairing device comprises a side slope main body, the upper end of the side slope main body is fixedly connected with a connecting device, the front end of the side slope main body is fixedly connected with a fixing plate, and the upper groove walls and the lower groove walls of two first mounting grooves are fixedly connected with stabilizing devices. A plurality of greening devices are fixedly connected to the front end of the fixing plate, a plurality of first long grooves are formed in the front end of the fixing plate, reinforcing plates are fixedly connected to the inner groove walls of the first long grooves, the reinforcing plates correspond to the lower portions of the greening devices one to one, and a plurality of concrete columns are fixedly connected to the front ends of the reinforcing plates. According to the garden side slope repairing device and the repairing method thereof, water supply to green plants is achieved, the survival rate of the plants is increased, soil is stabilized through root systems of the plants, water and soil loss can be further prevented, the soil structure can be better improved, the side slope repairing cost is reduced, and high economic benefits are achieved.

Owner:深圳市山月园园艺有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com