A partitioned pressure forming method for a closed airfoil structure

A pressure forming and closed technology, which is applied in household appliances, weight reduction, and other household appliances, etc., can solve the problem of high cost and manufacturing cycle, high cost of single-sided connecting fasteners, and low cross-sectional height of wing structure To achieve the effect of reducing the risk of opening holes, reducing the control problems of hole making precision, and avoiding the risk of collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

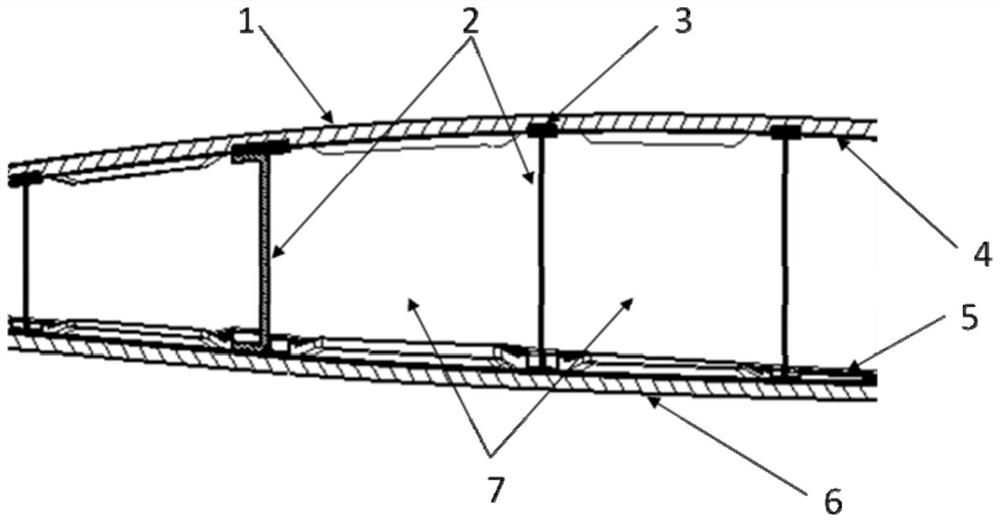

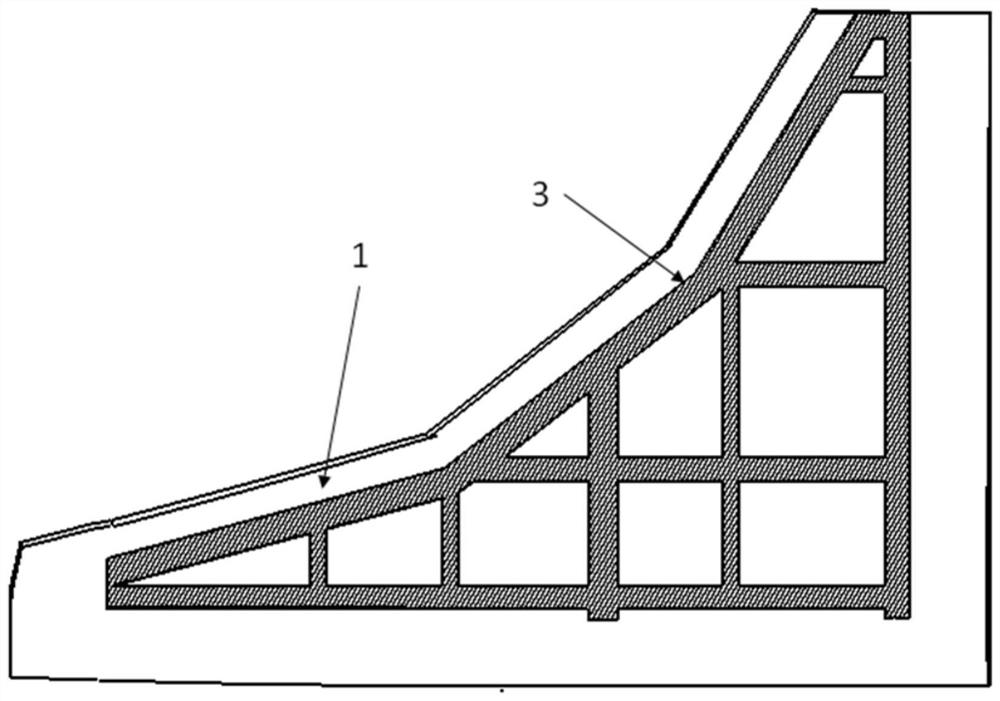

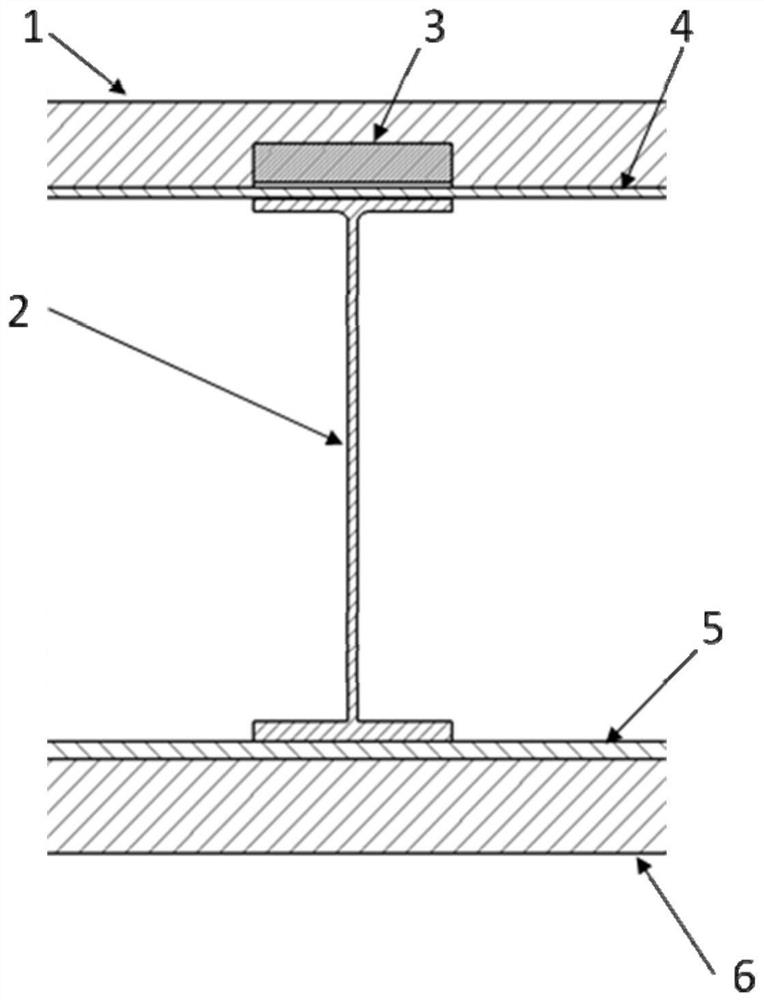

[0021] The present invention is a closed airfoil structure partitioned pressure forming method. The forming structure is as follows: figure 1 As can be seen from the figure, the bonding scheme of the lower skin panel 5 with the skeleton structure and the upper skin panel 4. The airfoil structure includes: an upper skin panel 4 , a lower skin panel 5 , a beam 2 , and a rib 7 . like Figure 4 The shown molding method of the present invention comprises the steps as follows:

[0022] 1) The beam 2 and the rib 7 in the airfoil structure are separately pre-formed: the beam 2 and the rib 7 are set with corresponding female and male molds according to the different cross-sectional shapes, and pre-cured, so that the The hardness state of beam 2 and rib 7 meets the design index;

[0023] 2) Assemble the beam 2 and the rib 7 obtained after the pre-forming treatment in step 1) into a skeleton structure: the beam 2 and the rib 7 are positioned vertically and horizontally into the design...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com