Shield station-crossing construction method capable of achieving layered backfill in small and narrow vertical shaft

A layered backfill and construction method technology, applied in the direction of filling, earth cube drilling, safety devices, etc., can solve the problems of time-consuming and labor-consuming, ground collapse, shaft flooding, etc., achieve high efficiency, reduce construction, avoid Effects of Structural Damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

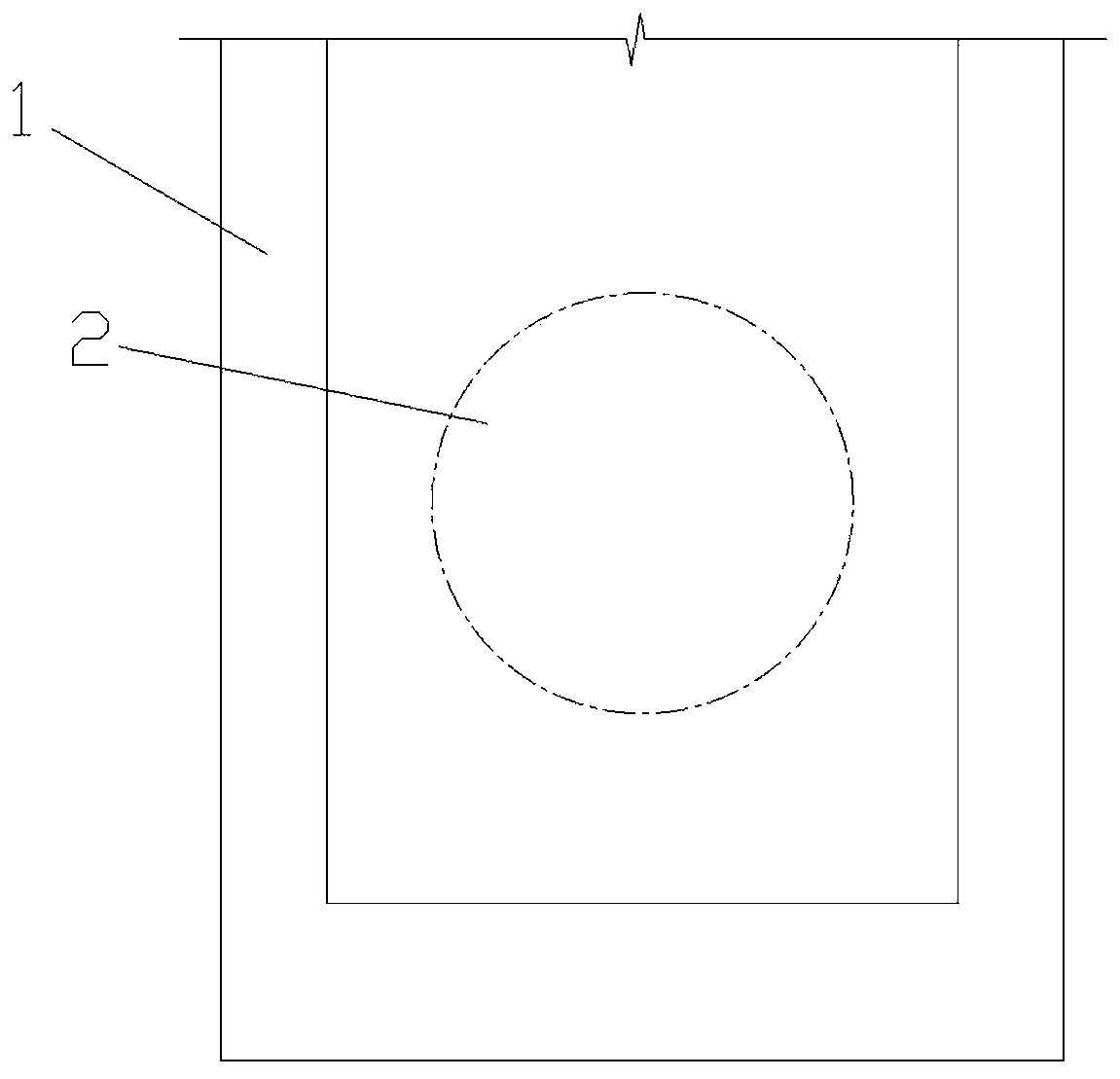

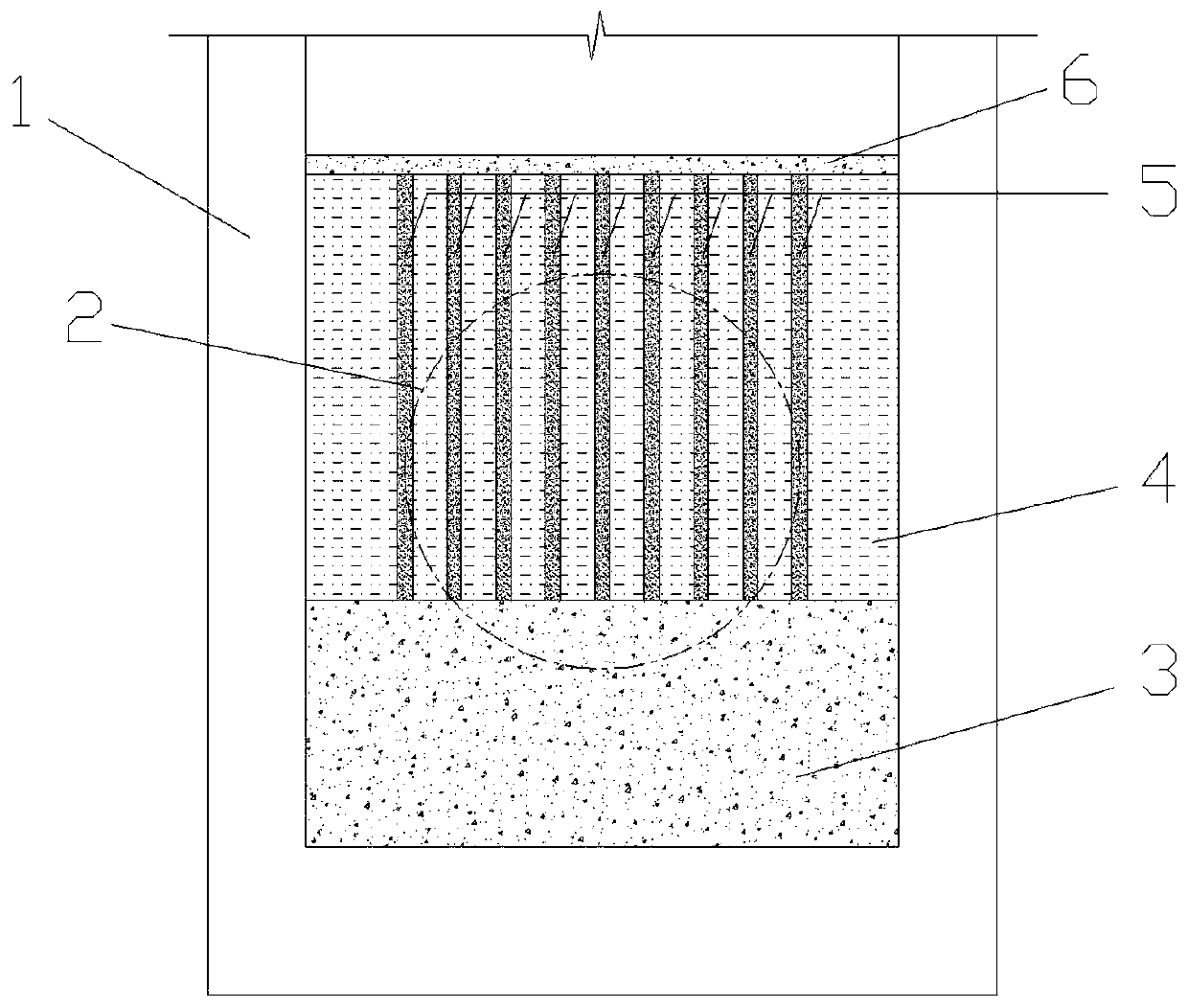

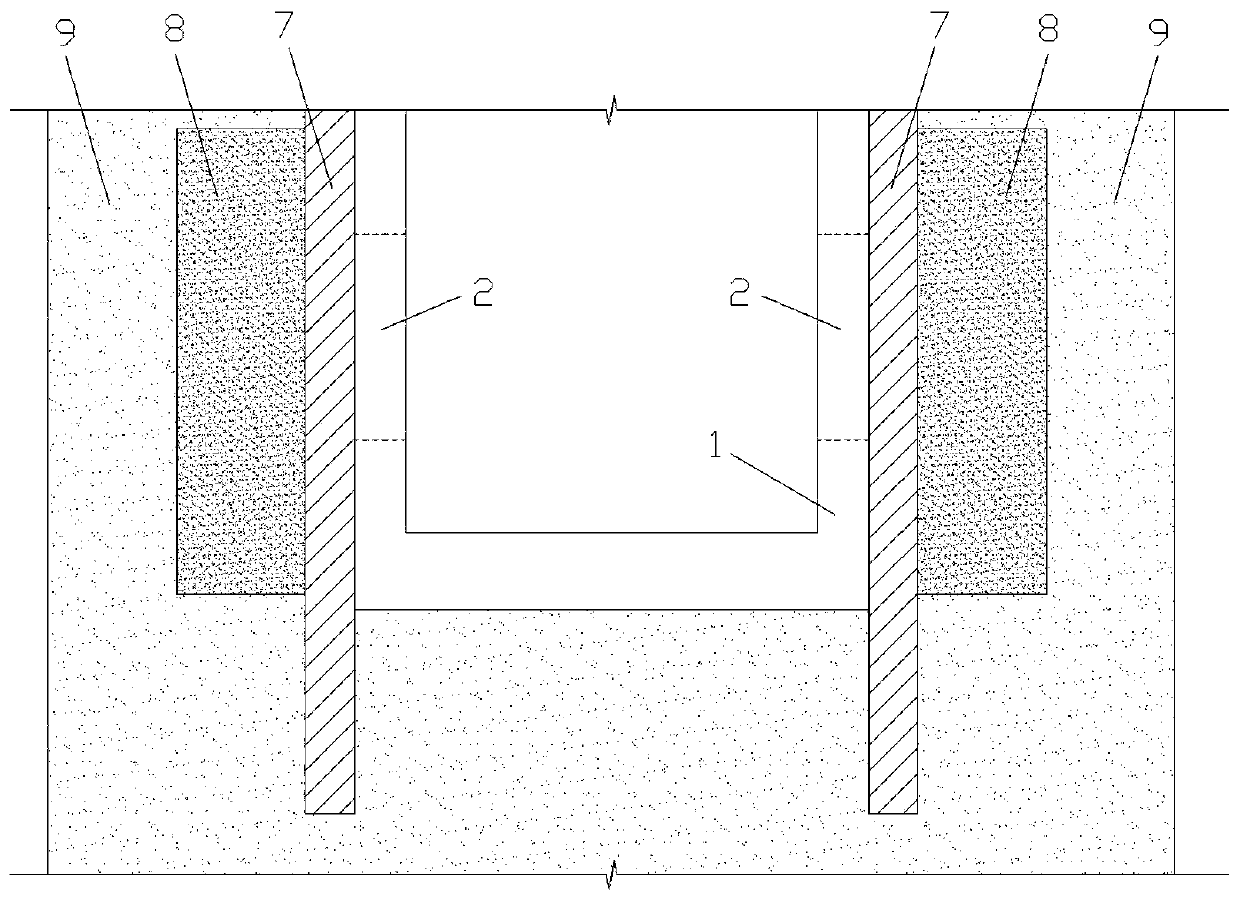

[0030] A shield tunneling construction method for layered backfilling in narrow shafts, please refer to Figure 1 to Figure 5 , which includes the following steps:

[0031] S1. Before the shield machine 10 passes through the station and after the bottom layer of the main structure of the shaft 1 is completed, backfill the hard backfill 3 in the shaft 1 to 0.5m~1.0m above the bottom of the portal 2; Backfill the undisturbed soil 4 after the backfill 3 is completed and reaches a certain strength. The undisturbed soil 4 is backfilled to 0.5m~1.0m above the top of the portal 2. In the process, small machines are used for layered compaction; among them, the hard backfill is made of pea stone, medium-coarse sand and cement in a mass ratio of 7:2:1;

[0032] S2. After the undisturbed soil 4 is backfilled and fully compacted, drill holes in the undisturbed soil 4 and inject ordinary Portland cement with a strength grade of 42.5 to form a cement pile 5. The diameter of the cement pile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com