Single-step-type light single-side wall formwork trolley

A formwork trolley, light-weight technology, applied in the direction of shaft equipment, shaft lining, mining equipment, etc., can solve the problems of poor adjustability, small adaptability, inconvenient pouring, etc., to achieve increased contact area, strong operability, avoid The effect of being crushed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

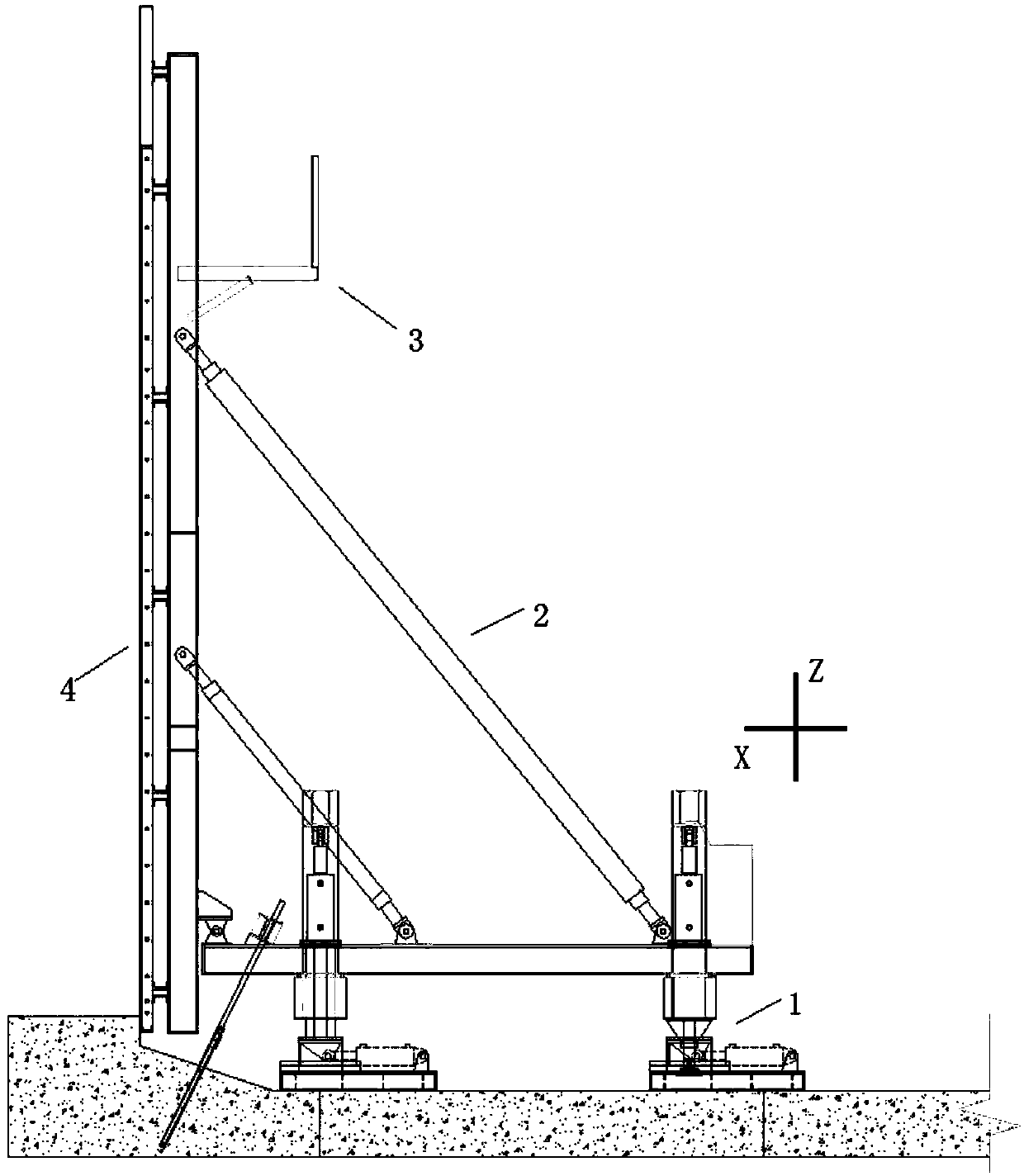

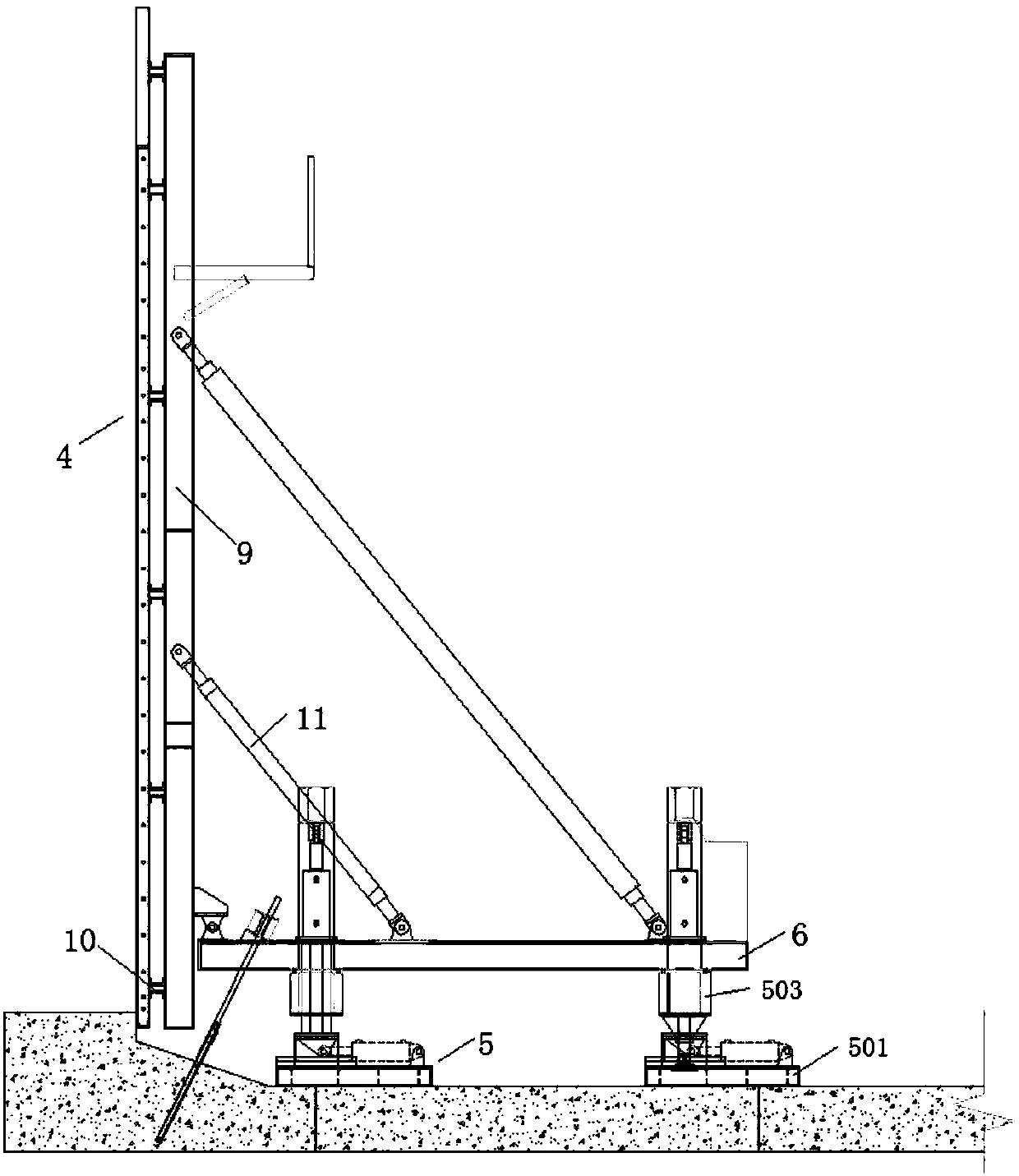

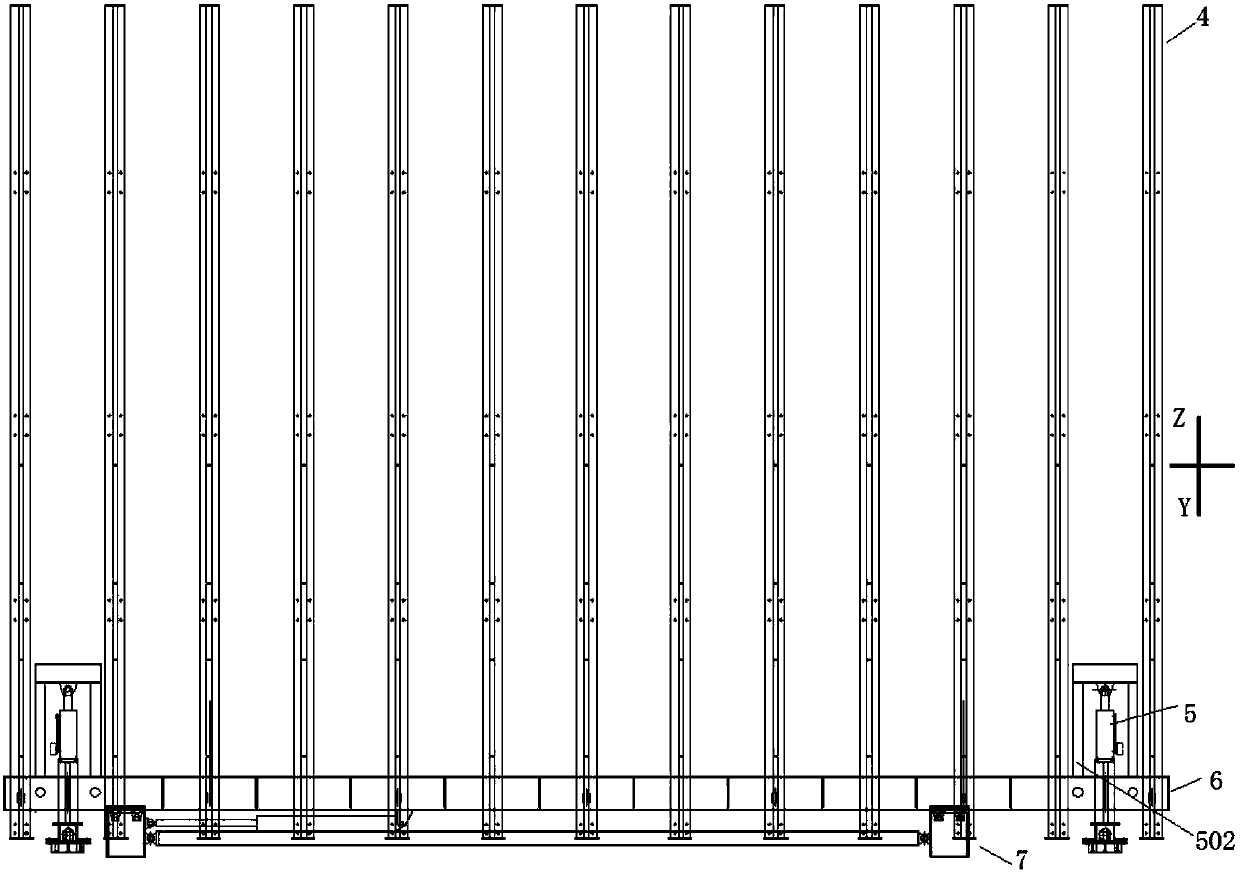

[0065] Such as Figure 1-3 As shown, the silicon-step light-duty single-side wall formwork trolley of the present invention is composed of a walking system 1, a standard tripod 2, an operating platform 3, a steel formwork 4, and a hydraulic system. The walking system 1 is installed on the bottom of the standard tripod 2. The steel template 4 is installed on the side of the standard tripod 2, the hydraulic system provides power for the operation of the walking system 1, and the operating platform 3 is installed on the tripod column 9 of the standard tripod 2.

[0066] A further technical solution is that the bottom beam 6 of the walking system 1 of the silicon-step light-duty single-side wall formwork trolley is installed with a ground anchor screw connected with the embedded parts.

[0067] A further technical solution is that an auxiliary support is provided between the beam in the Y-axis direction and the ground.

[0068] The walking system 1 includes an X-axis moving brack...

Embodiment 3 Embodiment 3

[0092] Embodiment 3 Embodiment 3 is the structure of installing and adjusting the tripod on the basis of Embodiment 1

[0093] Such as Figure 23 As shown, the trolley is additionally equipped with an adjustment tripod 8, and the tripod column 9 is equipped with an adjustment tripod 8, and the adjustment tripod 8 is hingedly connected with the bottom beam 6 through an adjustable hinged hydraulic strut 11.

[0094]The adjustment tripod 8 is composed of a transverse channel steel and two diagonal braces, one end of the transverse channel steel is installed on the tripod column 9 through a bolt, and the other end is suspended in the air, one end of the two diagonal braces is installed on the tripod column 9, and the other end is installed on the horizontal column 9. In the suspended part of the channel steel, the side projection of the two diagonal braces connected with the transverse channel steel is two isosceles right triangles, the two diagonal braces are adjustable hinged hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com