Construction method for large-sized blast furnace foundation

A construction method and basic technology, applied in the direction of infrastructure engineering, construction, etc., can solve the problems of increasing construction difficulty, affecting the normal use of blast furnaces, and affecting the installation of blast furnace bodies, so as to reduce the time required for support installation, avoid mold expansion, and use steel volume saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

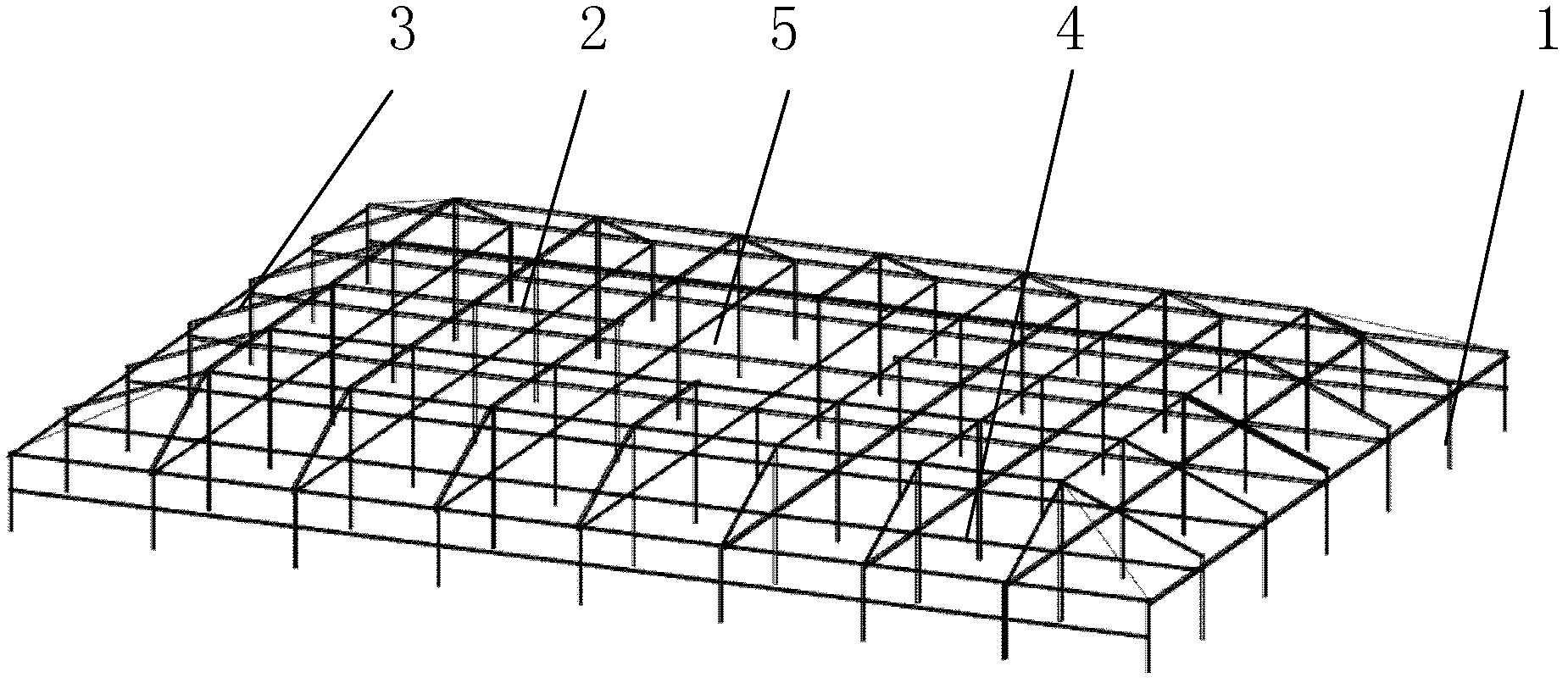

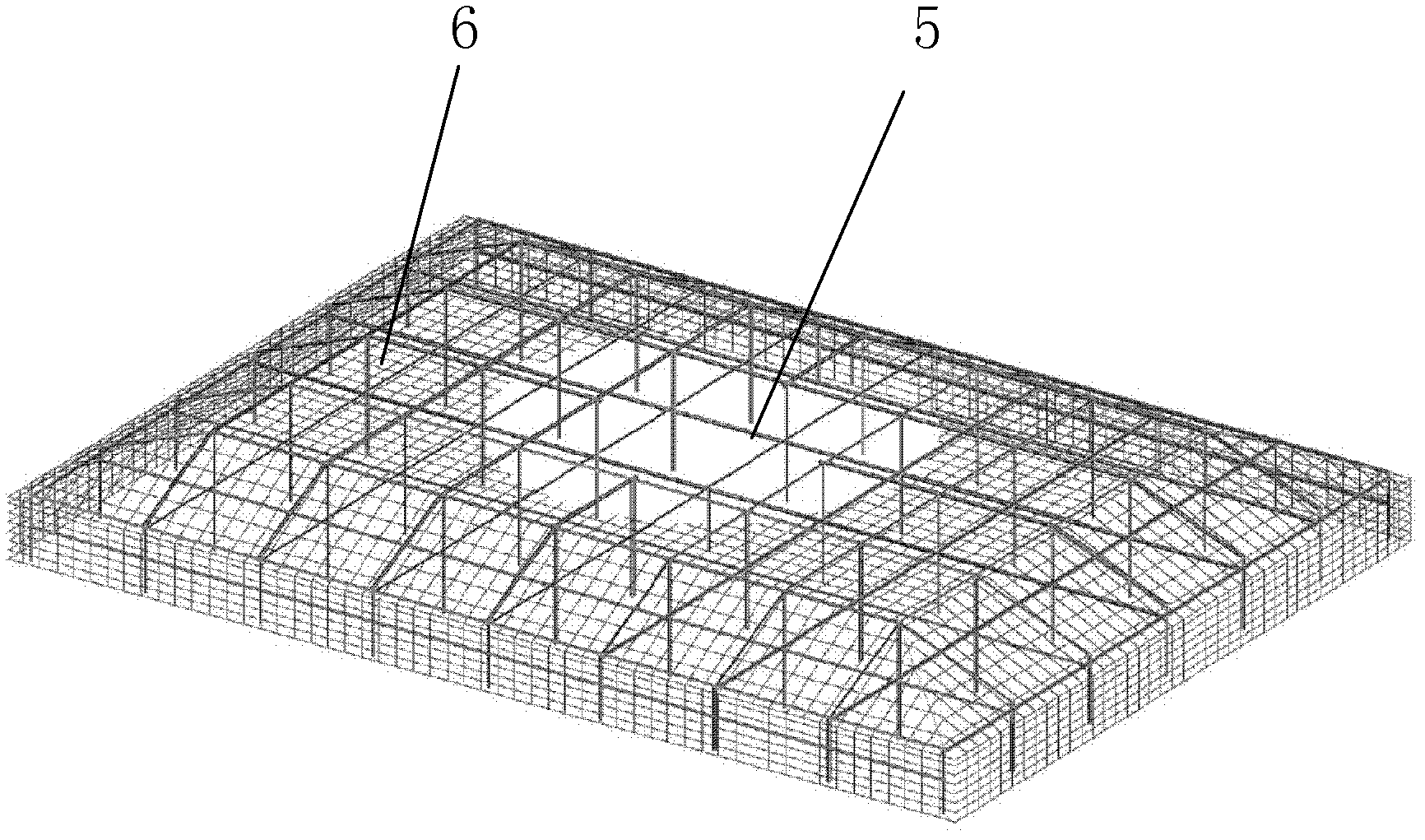

[0042] Take the following large-scale blast furnace foundation as an example, its volume is 2500m 3 , the foundation is 33.5m long, 24m wide, and 3.9m high. It starts from the bottom 2m and retracts toward the middle, forming a prism.

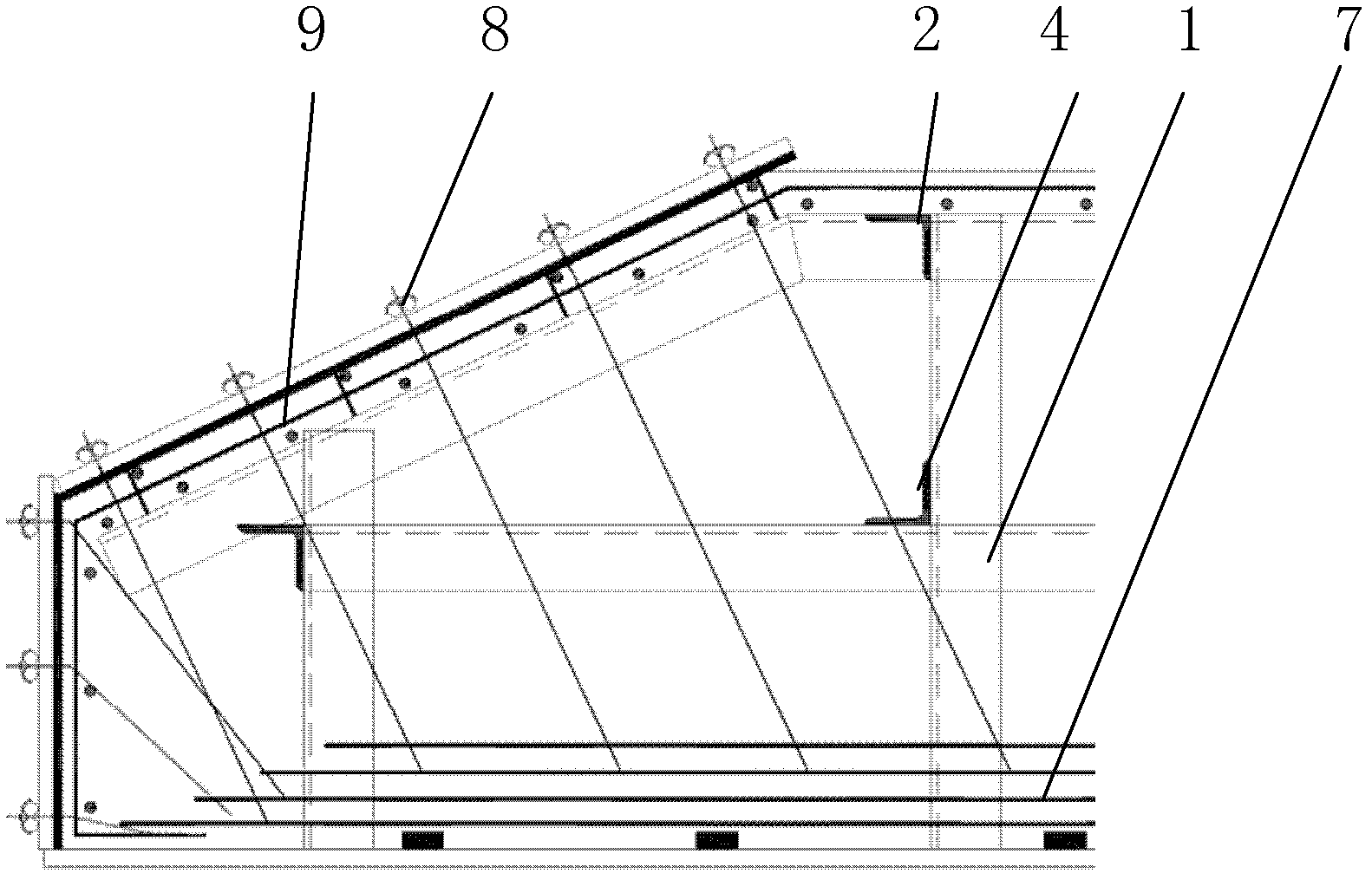

[0043] 1. Binding steel bars 7 for the foundation floor of the blast furnace;

[0044] 2. Start to install the steel support frame 5. The installation sequence is: welded steel column 1 → weld top horizontal bar 2 at the top of column 1 and reinforce horizontal bar 4 in the middle of column 1 → weld inclined surface bar 3 at the inclined surface of the parallel prism → weld oblique support firmly. The column 1 of the section steel supporting frame 5 adopts angle steel ∠75×6, with a distance of about 4m. The root is welded to the steel bar 7 of the bottom plate, and the top is 100mm lower than the surface concrete; There are two vertical and horizontal horizontal bars in total at the top horizontal bar 2; the reinforced horizontal bar 4 adopts...

Embodiment 2

[0050] Taking a certain blast furnace as an example, the comparison of materials used in the method of the present invention and the existing method is shown in the following table:

[0051]

[0052] It can be seen from the above table that the amount of non-reusable steel buried in the concrete by the construction method provided by the present invention is less than that of the existing method, and the total amount of steel is greatly saved, thereby reducing the time for supporting installation and reducing the construction difficulty. Construction frees up time and space.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com