All-weather burning-resistant breather valve device

A breathing valve, all-weather technology, applied in the direction of valve device, safety valve, packaging, etc., can solve the problems of not being able to meet the fire resistance, major safety and hidden dangers of the breathing valve, and achieve the effect of preventing explosion and fire, ensuring safety and reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

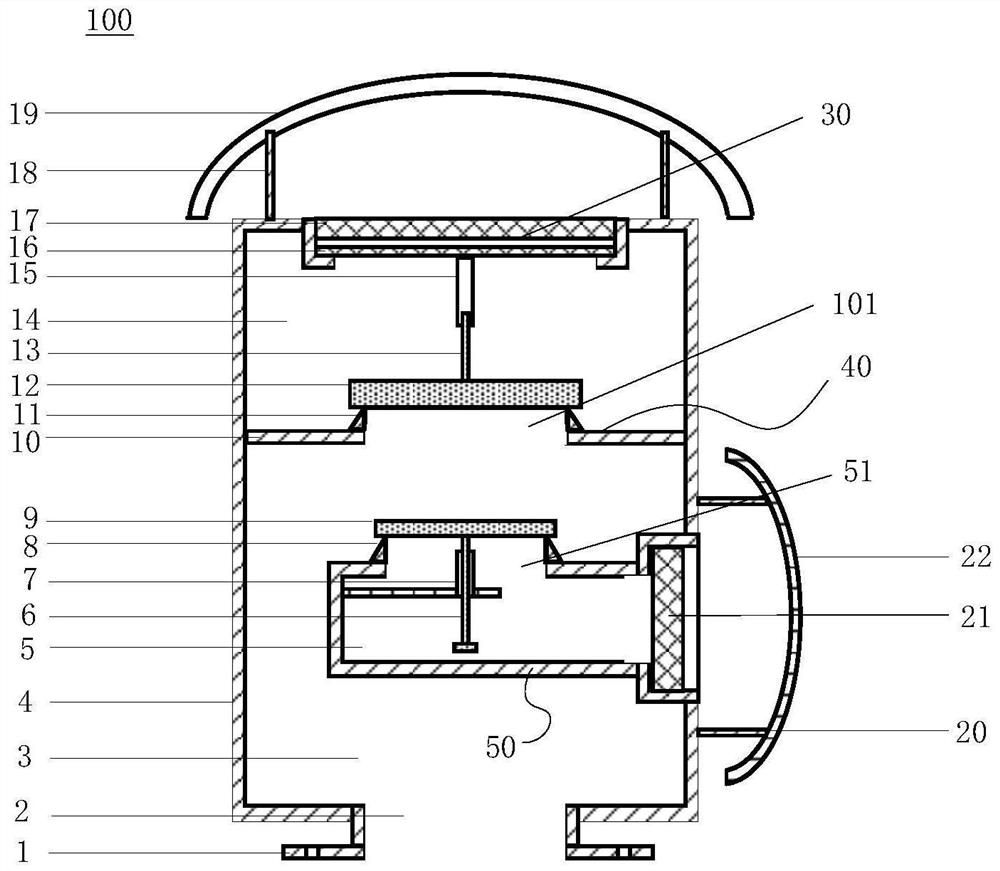

[0024] The present invention is introduced below by accompanying drawing.

[0025] In this application, it should be noted that the directional terms or qualifiers "upper end" and "lower end" used in this application all refer to the attached figure 1 In terms of. They are not intended to define the absolute positions of the parts involved, but may vary on a case-by-case basis.

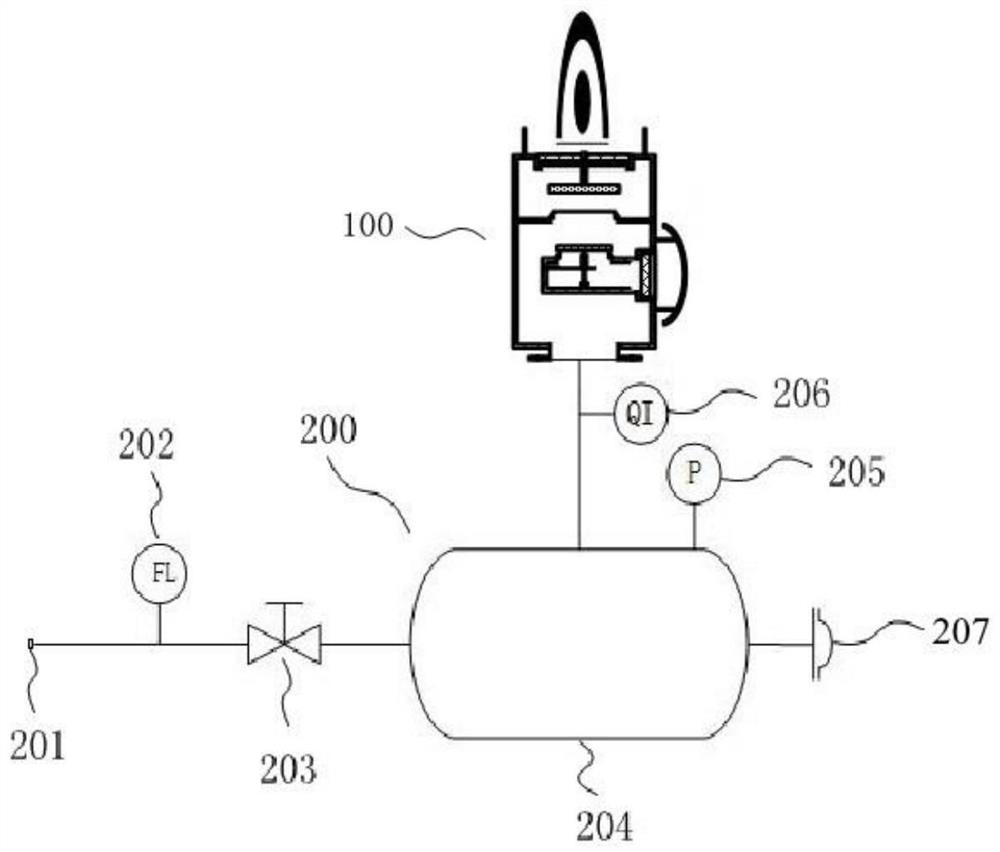

[0026] figure 1 The structure of the all-weather fire-resistant breathing valve device 100 according to the present invention is shown. Such as figure 1 As shown, the all-weather fire-resistant breathing valve device 100 includes a main valve body 4, a fire-resistant and fire-resistant assembly 30, a pressure valve 40 formed inside the main valve body 4, a vacuum valve 50 arranged in the main valve body 4, a detonation valve Fire retardant plate 21. The main valve body 4 is cylindrical in shape, with vertical openings at the upper and lower ends, and lateral openings on the side walls. The bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com