Unsaturated polyester black backing varnish with high fillibility and preparation method thereof

An unsaturated and filling technology, used in polyester coatings, coatings, etc., can solve the problems of high construction environment requirements, inability to form a film at one time, and increase construction costs, achieving high solid content, easy maintenance, and improved production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

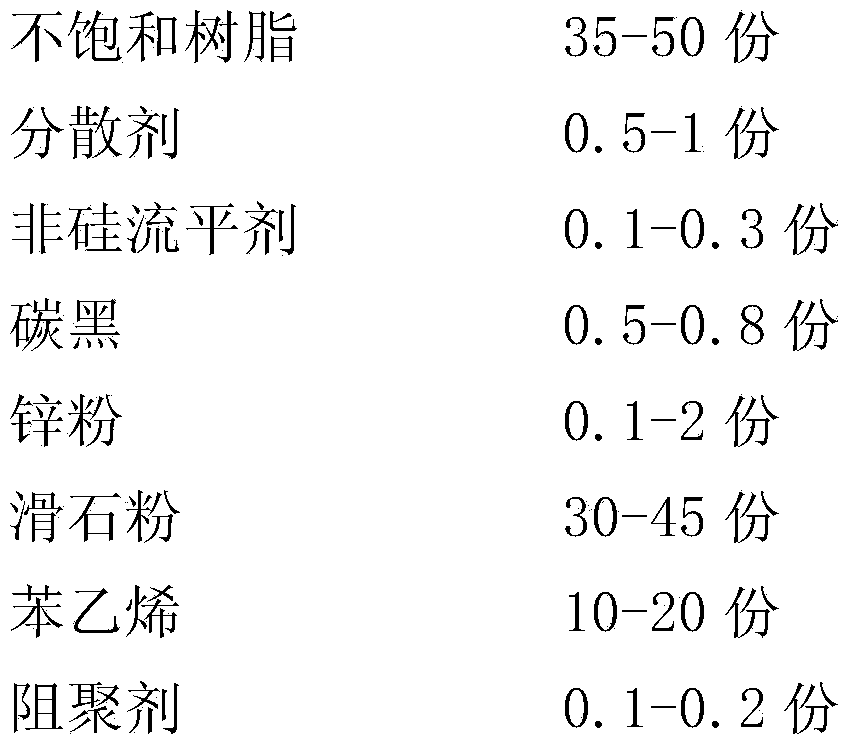

Method used

Image

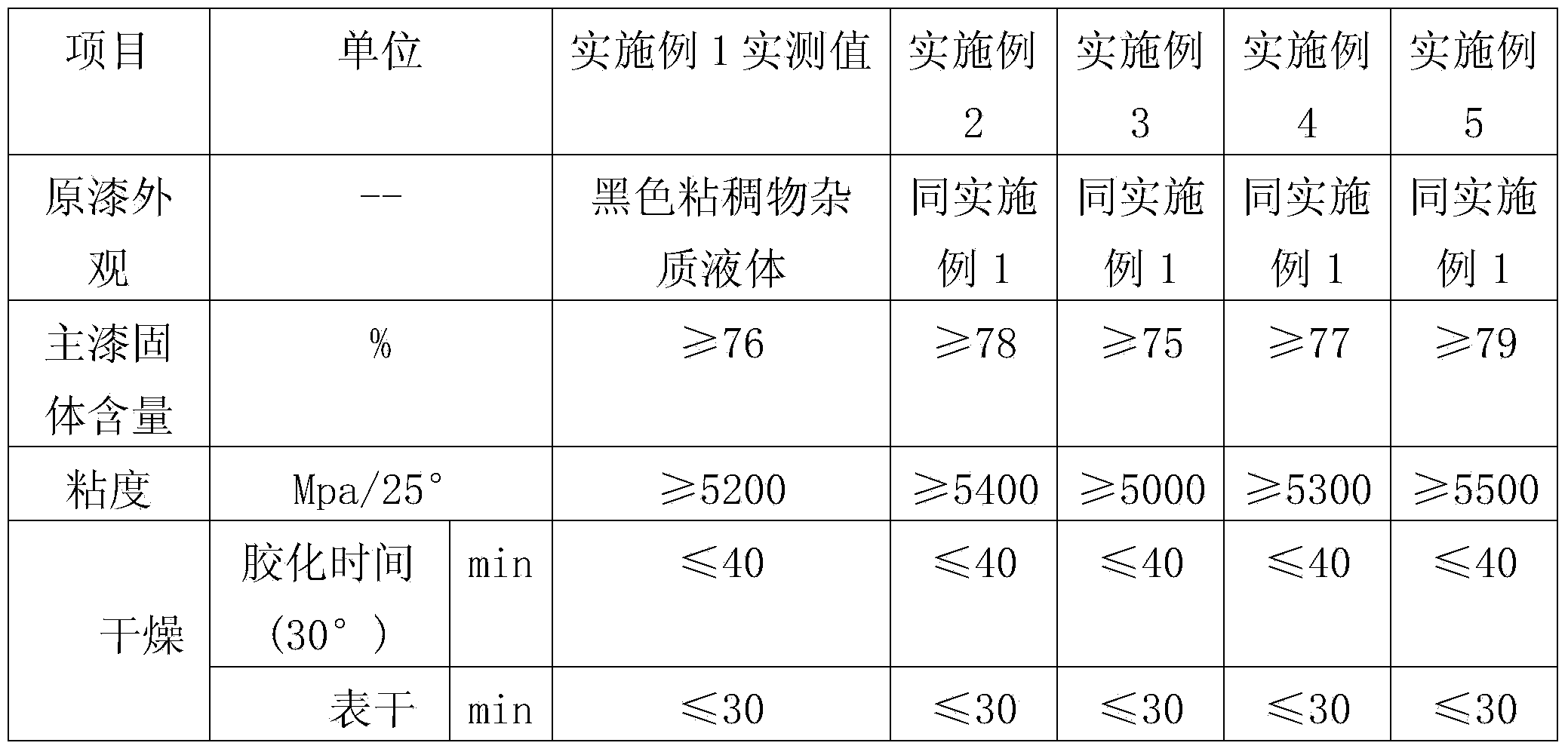

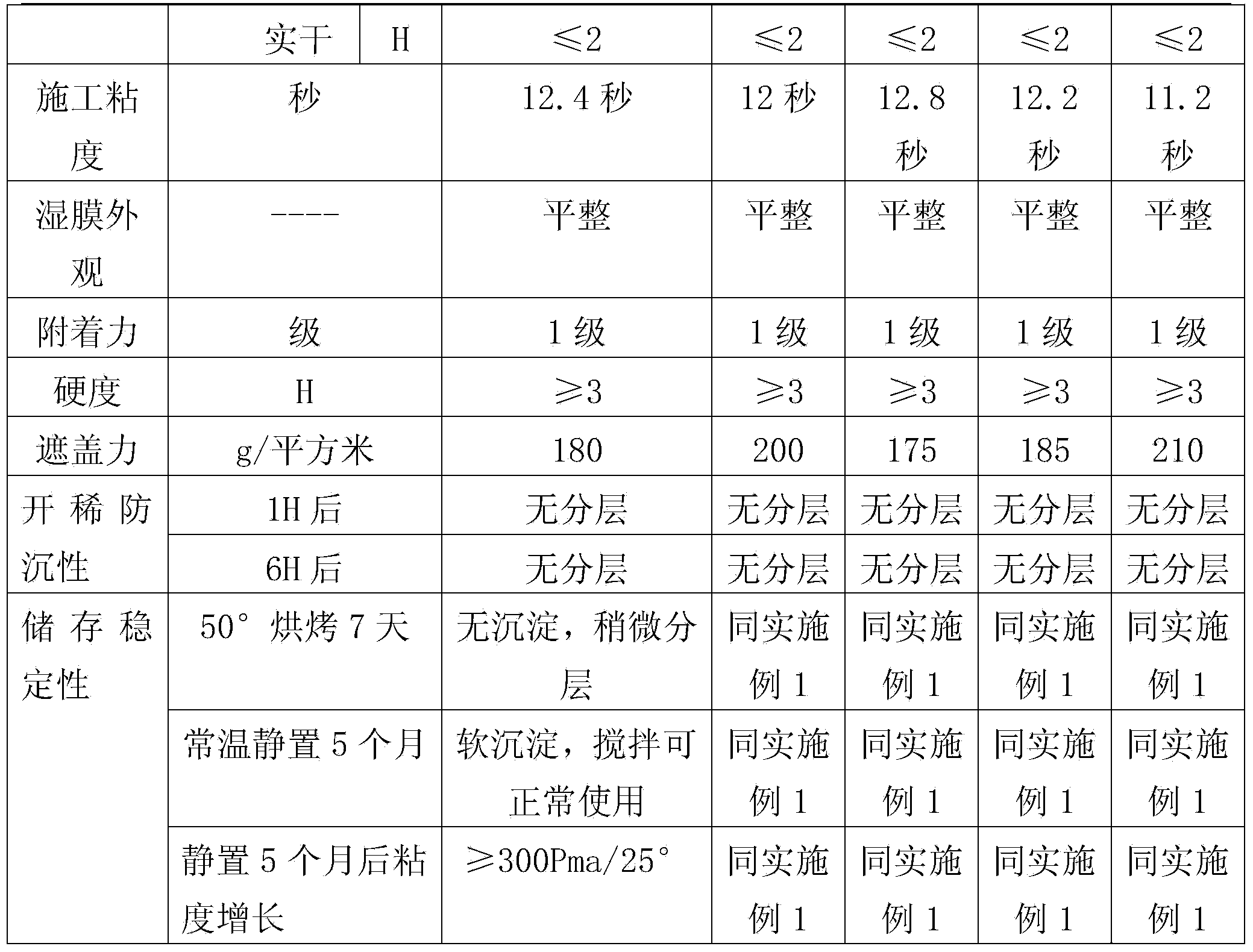

Examples

Embodiment 1

[0031] A kind of highly filling unsaturated polyester black primer, which is prepared by the weight ratio of main agent, accelerator, initiator and diluent in the ratio of 100:1:1.2:28;

[0032] The main ingredient is prepared according to the following steps:

[0033] (1) Mix hydroquinone and butyl ester at a weight ratio of 0.01:0.09 to form a polymerization inhibitor;

[0034] (2) After mixing 38.5 parts of unsaturated resin, 1 part of EFAK4010 and 0.3 parts of EFAK fluorocarbon modified polymer, disperse at 1000 rpm for 5 minutes;

[0035] (3) While dispersing, add 0.5 part of MA100 carbon black, 0.1 part of coating grade zinc stearate TV-A and 45 parts of 800 mesh chemical grade talc powder, and disperse at a speed of 1400 rpm until the fineness is less than 60 microns;

[0036] (4) Continue to add 14.5 parts of styrene monomer for common coatings and 0.1 part of polymerization inhibitor, and then disperse at 900 rpm for 5 minutes until uniformly mixed.

[0037] Acceler...

Embodiment 2

[0041] A kind of highly filling unsaturated polyester black primer, which is prepared by the weight ratio of main agent, accelerator, initiator and diluent in the ratio of 100:1:1.1:30;

[0042] The main ingredient is prepared according to the following steps:

[0043] (1) Mix hydroquinone and butyl ester at a weight ratio of 0.01:0.09 to form a polymerization inhibitor;

[0044] (2) After mixing 41.2 parts of unsaturated resin, 0.7 parts of EFAK4010 and 0.2 parts of EFAK fluorocarbon modified polymer, disperse at 800 rpm for 5 minutes;

[0045] (3) While dispersing, add 0.6 parts of MA100 carbon black, 2 parts of coating grade zinc stearate TV-A and 42 parts of 800 mesh chemical grade talc powder, and disperse at a speed of 1200 rpm until the fineness is less than 60 microns;

[0046] (4) Continue to add 13.2 parts of styrene monomer for common coatings and 0.1 part of polymerization inhibitor, and then disperse at 1000 rpm for 6 minutes until uniformly mixed.

[0047] Acce...

Embodiment 3

[0051] A kind of highly filling unsaturated polyester black primer, which is prepared by the weight ratio of main agent, accelerator, initiator and diluent in 100:1:1.2:25;

[0052] The main ingredient is prepared according to the following steps:

[0053] (1) Mix hydroquinone and butyl ester at a weight ratio of 0.02:0.18 to form a polymerization inhibitor;

[0054] (2) After mixing 50 parts of unsaturated resin, 0.5 part of EFAK4010 and 0.1 part of EFAK fluorocarbon modified polymer, disperse at 900 rpm for 5 minutes;

[0055] (3) While dispersing, add 0.7 parts of MA100 carbon black, 2 parts of coating grade zinc stearate TV-A and 36 parts of 800 mesh chemical grade talcum powder, and disperse at a speed of 1300 rpm until the fineness is less than 60 microns;

[0056] (4) Continue to add 10.5 parts of styrene monomer for common coatings and 0.2 parts of polymerization inhibitor, and then disperse at 1000 rpm for 5 minutes until uniformly mixed.

[0057] Accelerator is cob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com