Ultrahigh ultra-large open caisson and construction method

A construction method and caisson technology, applied in caisson, infrastructure engineering, construction and other directions, can solve the problems of foundation pit collapse, high cost, long construction period, etc., to save construction period and construction cost, promote value, avoid foundation The effect of pit collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

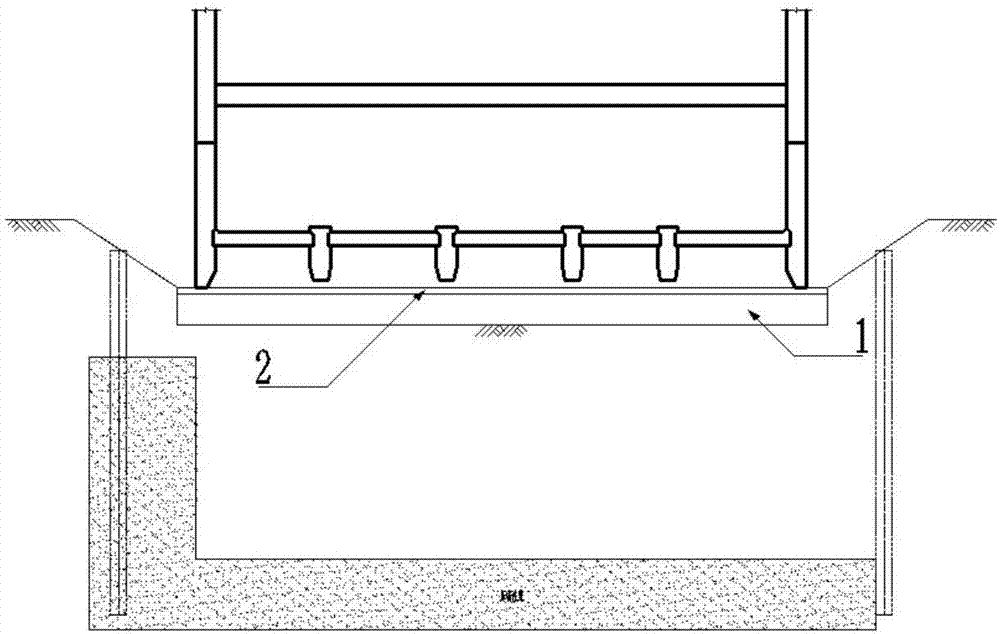

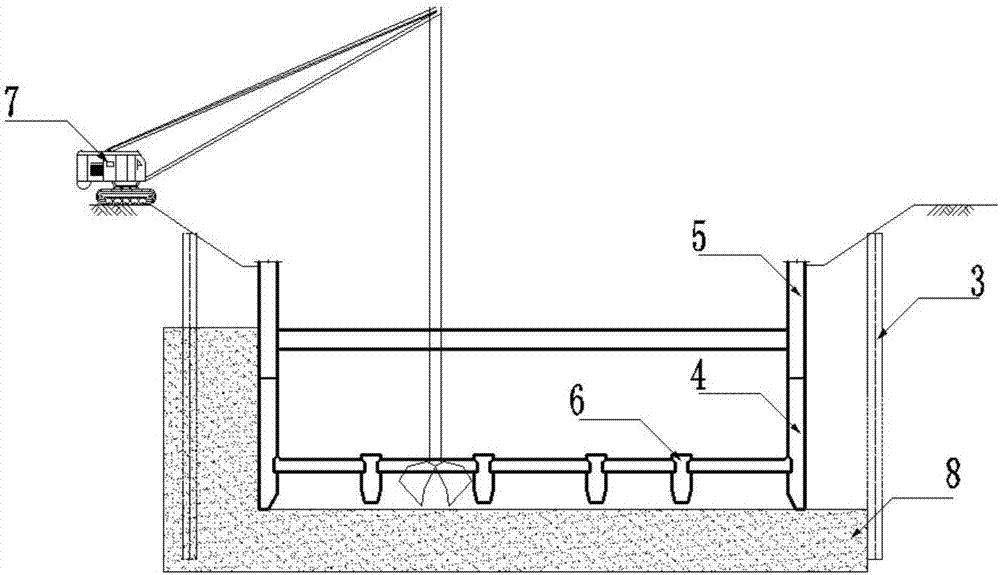

[0029] Combine below figure 1 with figure 2 The construction method of the super high caisson of the present invention will be described in detail.

[0030] The construction method of the super high caisson includes the following steps:

[0031] Step 1. Construction water-stop curtain 3: Double rows of high-pressure jet grouting piles with a diameter of 800mm are used as the water-stop curtain around the caisson, and the lap height is ≥ 250mm, so as to prepare for the caisson construction.

[0032] Step 2: Construct the back cover 8 with compaction grouting. The thickness of the grout is 3m below the concrete bottom plate of the caisson, so as to isolate the sand and water at the bottom of the well, and further prepare for the subsequent cast-in-place caisson.

[0033] Step 3. Since the caisson is fabricated on-site, after the construction of the water-stop curtain 3 and the compacted grouting bottom cover 8 is completed, the foundation is cleaned and leveled, and a cushion...

Embodiment 2

[0050] Please continue to refer figure 1 with figure 2 , this embodiment also provides a super high caisson manufactured by the aforementioned construction method. The super high caisson is cast on site. The super high caisson includes a top cover, caisson structure and bottom cover. The caisson structure includes the first caisson 4 and the second caisson which are poured vertically The caisson 5 is provided with a blade foot 6 at the lower end of the caisson structure, a partition wall is arranged in the shaft of the caisson, and a groove is arranged on the inner side of the well wall above the blade foot 6 .

[0051] To sum up, the super-high caisson and construction method of the present invention saves the horizontal support system and avoids the risk of foundation pit collapse through "making twice, caisson once". It eliminates the risk in the process of making a super-high caisson, saves the construction period and construction cost, and has a good promotion value. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com