Purification device of automobile tail gas treatment equipment

A purification device and automobile exhaust technology, which is applied in exhaust treatment, exhaust devices, noise reduction devices, etc., can solve the problems of low utilization rate of activated carbon and incomplete utilization of activated carbon, etc., and achieve easy disassembly and installation, and large adsorption effect , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

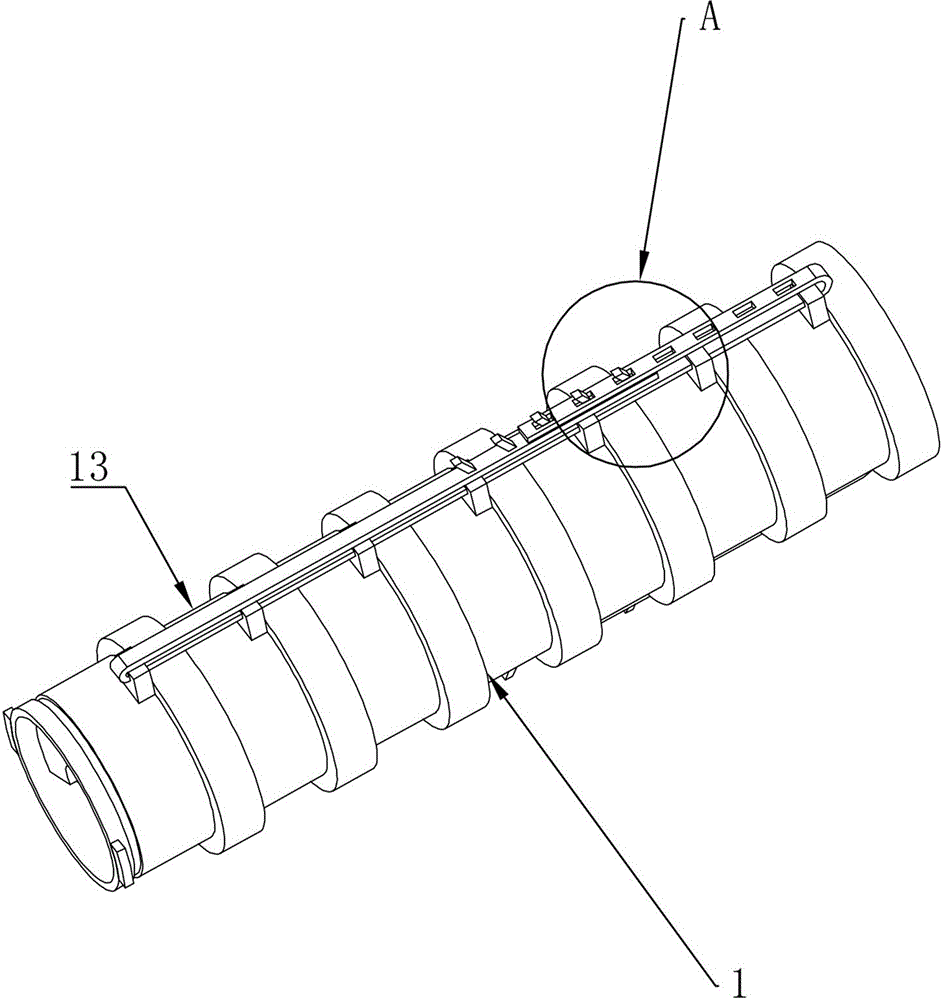

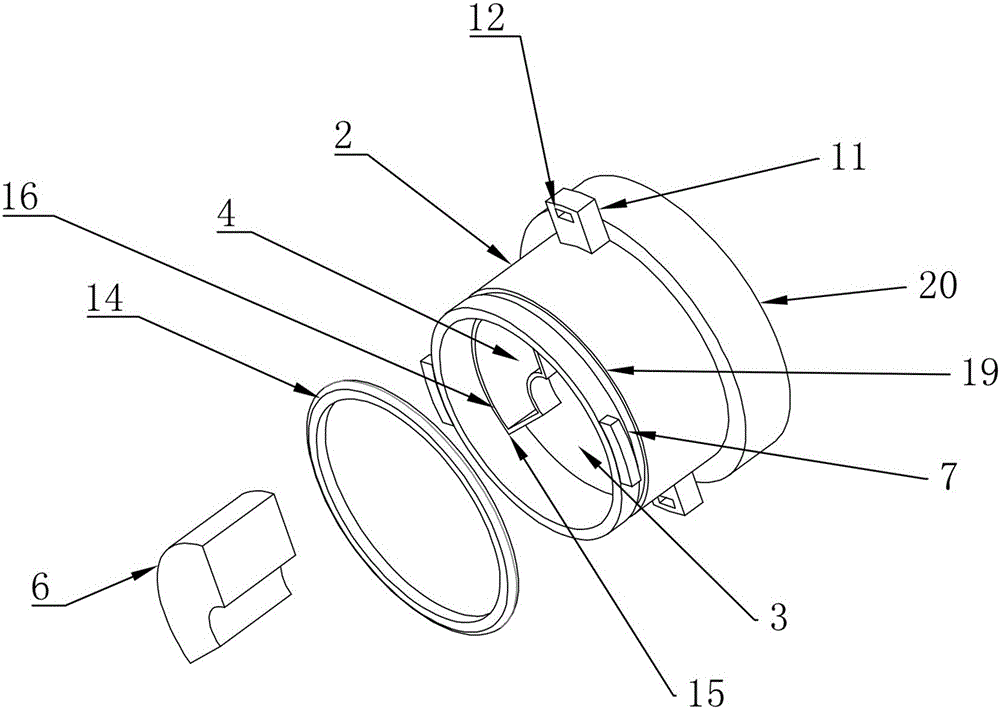

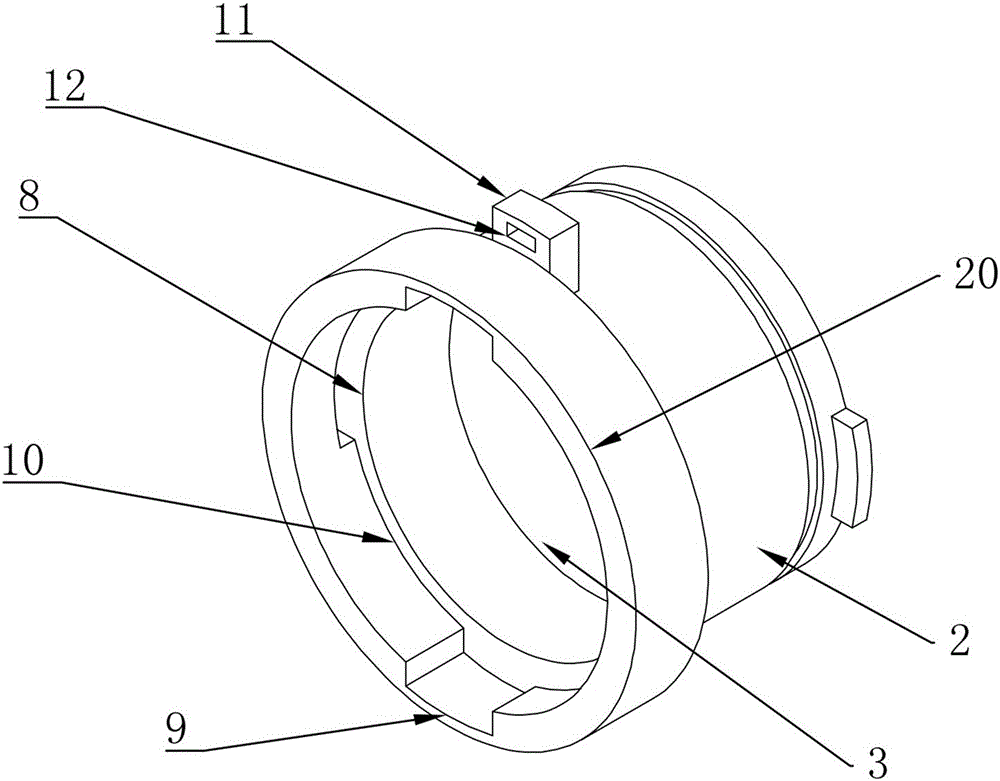

[0033] A purification device for an automobile exhaust processor, comprising a filter cartridge 1, the filter cartridge 1 comprising a plurality of spliced pipes 2 spliced with each other, a plurality of spliced pipes 2 are provided with sealing plates 3, and the sealing plates 3 are provided with There is a through hole 4, and the through hole 4 of the sealing plate 3 on the other splicing pipe 2 is misplaced. The through hole 4 is provided with a filter element, and the filter element is made of coal-based activated carbon, coconut shell activated carbon, modified At least one kind of activated carbon is a filter plate 6 made of raw materials. The tail gas enters from the air inlet and is discharged from the air outlet after passing through the filter plates 6 on several sealing plates 3. One end of the splicing pipe 2 is provided with a plug 7 , the inner wall at the other end is provided with a slide rail 8 for inserting the insert block 7 to rotate, the slide rail 8 ...

Embodiment approach

[0034] As an improved specific embodiment: several baffles 15 are arranged on both sides of the sealing plate 3 relative to the opening direction of the through hole 4, and the baffles 15 on the same side are spliced end-to-end with each other to form a filter plate for fixing 6, the two ends of the filter plate 6 respectively extend out of the insertion groove 16.

[0035] As an improved specific embodiment: the positioning bar 13 passes through all the positioning holes 12 and then bends back toward the filter cartridge 1. After bending, the two ends overlap, one end of which is provided with a number of clamping holes 17, and the other end is provided with There is a clamping piece 18 embedded in the clamping hole 17 .

[0036] As an improved specific embodiment: the splicing pipe 2 is provided with an annular groove 19 , and the sealing ring 14 is embedded in the annular groove 19 . The through-holes 4 are fan-shaped and arranged in the circumferential direction with th...

Embodiment 1

[0051] Embodiment 1, in the selection of filter plate material, coal-based activated carbon is selected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com