Hydro-pneumatic suspension system, position detection method thereof and engineering vehicle

A technology of oil-pneumatic suspension and suspension cylinder, which is applied to vehicle components, suspensions, elastic suspensions, etc., can solve the problems of high cost, low maintenance efficiency, and inconvenient maintenance, so as to reduce production cost and maintenance cost, and reduce maintenance difficulty , Improve the effect of maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

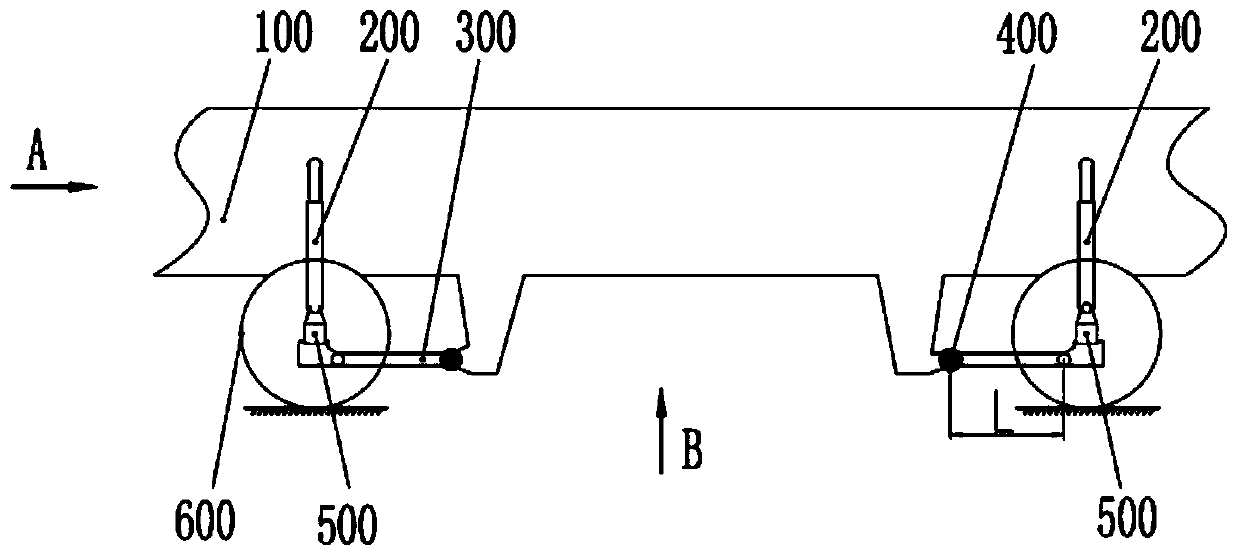

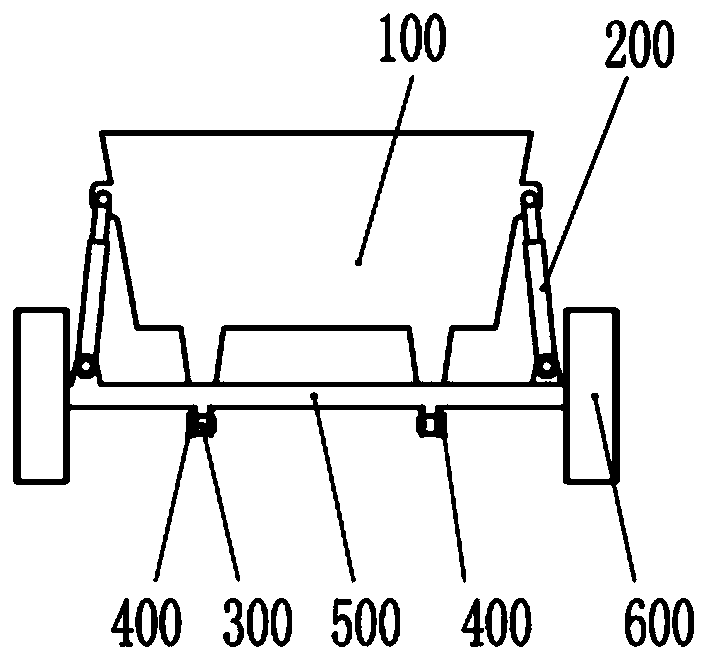

[0040] Such as Figure 1-Figure 4 As shown, the hydropneumatic suspension system provided by the present invention includes a vehicle frame 100 , an axle 500 , a suspension cylinder 200 , a thrust rod 300 and a rotation angle sensor 400 .

[0041] The vehicle frame 100 and the vehicle axle 500 are connected through the suspension cylinder 200, one end of the suspension cylinder 200 is connected to the vehicle frame 100, and the other end is connected to the vehicle axle 500, when the suspension cylinder 200 stretches, it can Realize that the frame 100 moves in the erecting direction relative to the axle 500 .

[0042] One end of the thrust rod 300 is connected to the vehicle frame 100 , and the other end of the thrust rod 300 is connected to the axle 500 .

[0043] The rotation angle sensor 400 is used to detect the rotation angle of the thrust rod 300 relative to the initial position, and according to the rotation angle, the suspension state of the oil-pneumatic suspension s...

Embodiment 2

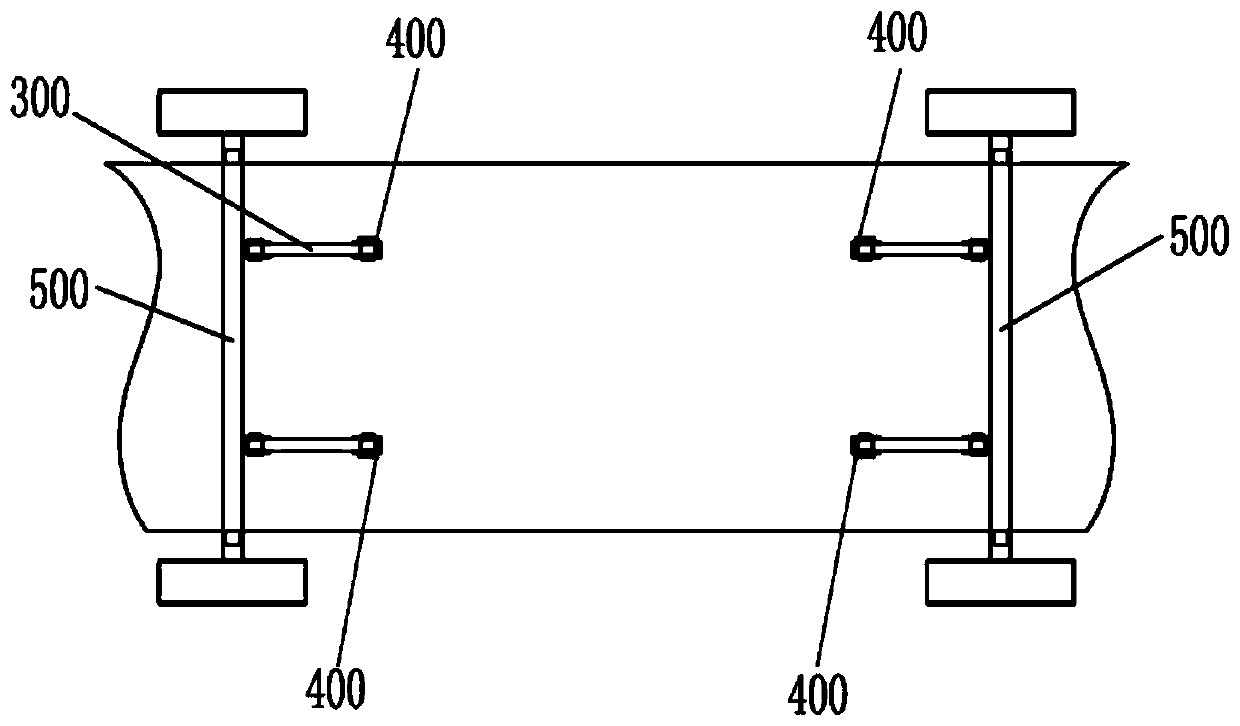

[0055] Such as Figure 5 As shown, the difference from Embodiment 1 is that further, the rotation angle sensor 400 is arranged at the hinge of the thrust rod 300 and the axle 500 .

[0056] Specifically, in the present embodiment, the rotation angle sensor 400 is installed at the joint joint of the axle 500 and the thrust rod 300 . The fixed part of the rotation angle sensor 400 is fixedly connected with the vehicle axle 500 , and the rotating part of the rotation angle sensor 400 is fixedly connected with the thrust rod 300 . When the suspension cylinder 200 expands and contracts, when the vehicle frame 100 moves up and down, it drives one end of the thrust rod 300 connected to the axle 500 to move. 300 will rotate relative to the hinge point of thrust rod 300 and vehicle frame 100, thereby generating angular displacement. At this time, the angular displacement and rotation angle data of the thrust rod 300 can be detected by the rotation angle sensor 400, and the mutual pos...

Embodiment 3

[0058] Such as Figure 6 , Figure 7 As shown, the difference from Embodiment 1 is that, further, the hydropneumatic suspension system includes an auxiliary rod 700; one end of the auxiliary rod 700 is hinged to the axle 500, and the other end is connected to the vehicle frame 100. .

[0059] The rotation angle sensor 400 is arranged on the auxiliary rod 700 for detecting the swing angle of the auxiliary rod 700, and according to the swing angle, obtains the suspension state of the oil-pneumatic suspension system.

[0060] Further, the rotation angle sensor 400 is arranged at the hinge of the auxiliary rod 700 and the vehicle frame 100 .

[0061] Specifically, in this embodiment, an auxiliary rod 700 is arranged between the vehicle frame 100 and the axle 500, the auxiliary rod 700 can be arranged at the middle position of the two wheels, and the rotation angle sensor 400 is arranged between the auxiliary rod 700 and the vehicle axle. The hinge of the frame 100 , that is, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com