Automobile thrust rod

A thrust rod and automobile technology, which is applied to vehicle parts, base materials, cantilevers mounted on pivots, etc., can solve the problems of low assembly precision of hot riveting and pressing, increasing local strength of thrust rods, and inconsistent connection methods. The strength and precision of the connection are high, the structure is simple and reliable, and the fixing effect is firm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

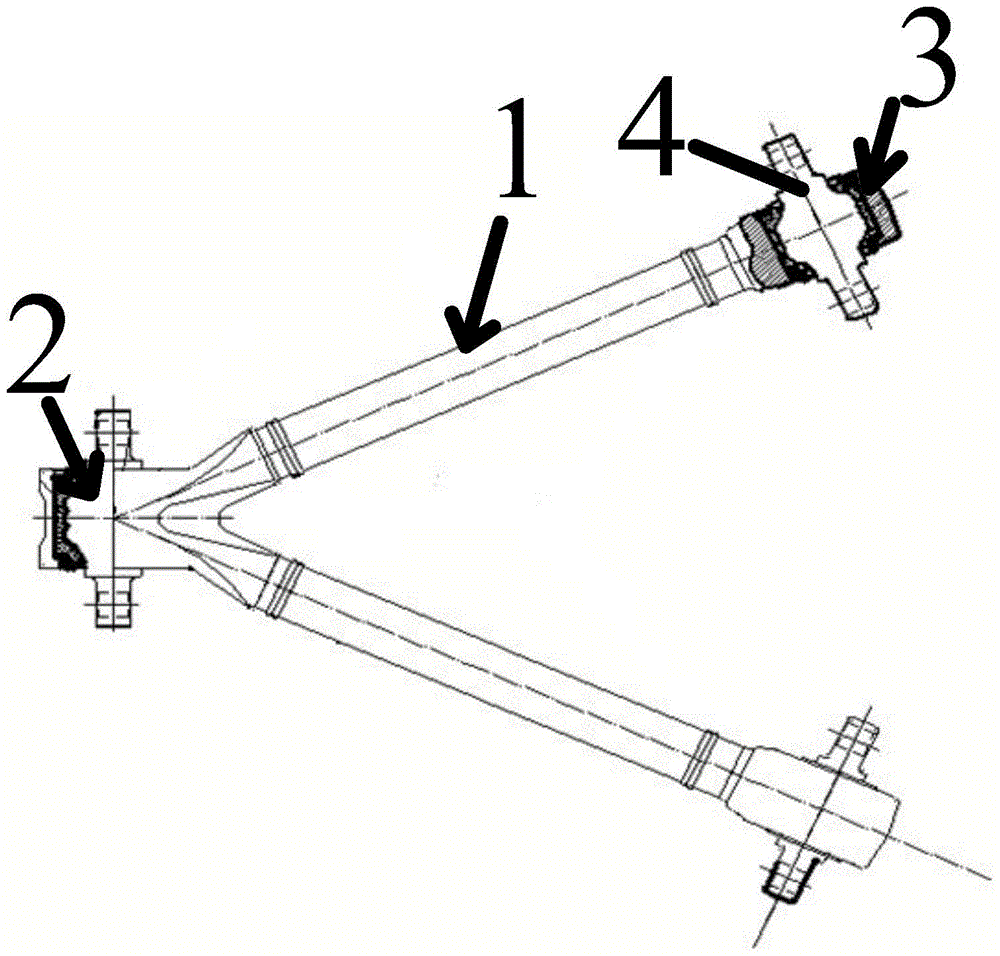

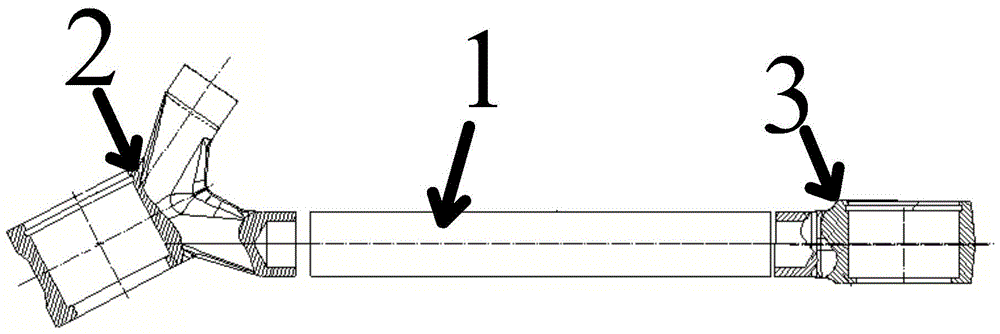

[0040] Such as figure 1 and figure 2 Shown, a kind of automobile thrust rod, it comprises the V-shaped thrust rod that is made of shaft 1,

[0041] The V-shaped thrust rod is provided with a connection end 2 and a free end 3, and the connection end 2 and the free end 3 of the thrust rod are provided with a frame connection pin 4 perpendicular to the axial direction of the shaft 1 .

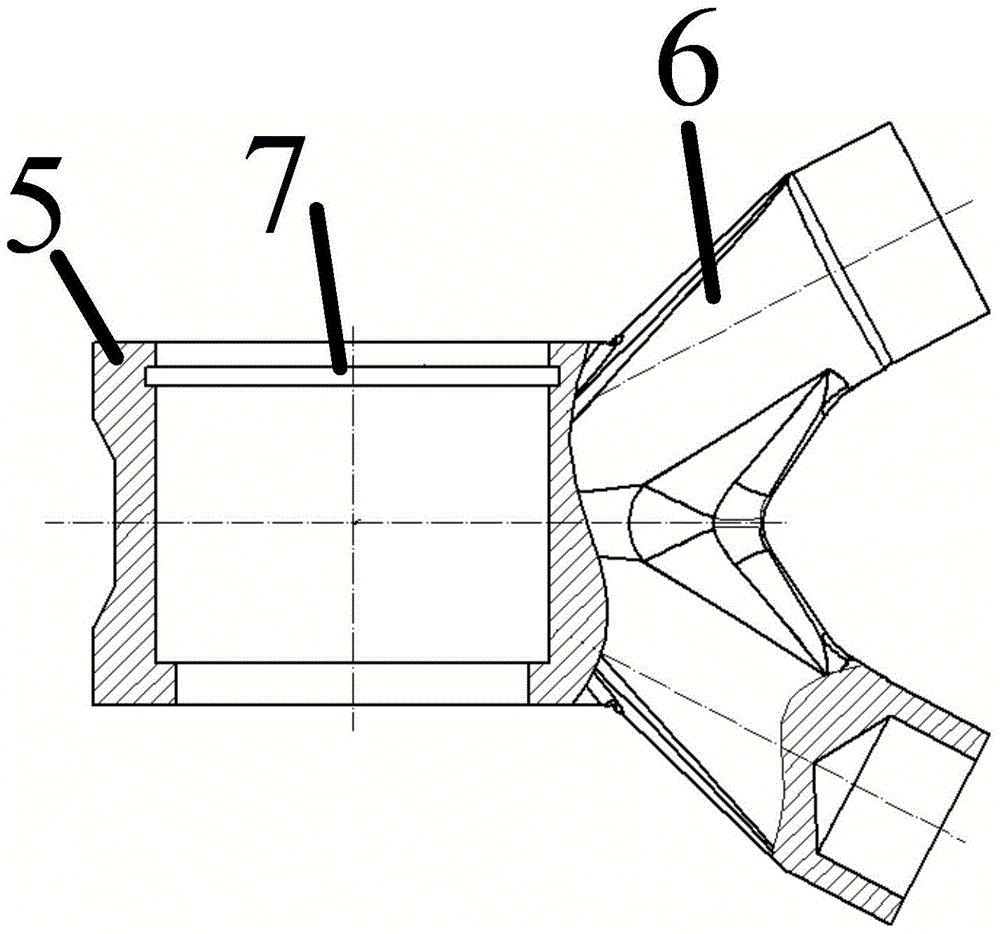

[0042] Such as Figure 4 As shown, the free end 3 includes a fixed cylinder 5 arranged along the vertical direction of the axial direction and a connecting rod 6 arranged outside the fixed cylinder 5 and perpendicular to its axial direction;

[0043] Such as image 3 As shown, the connecting end 2 is a connecting rod with a V-shaped longitudinal section composed of one fixing cylinder 5 and two connecting rods 6 .

[0044] The two ends of the inner cavity of the fixed cylinder 5 are respectively provided with a retaining ring 7 and a boss arranged along its radial direction;

[0045] The con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com