Drive system of mechanical arm

A technology of mechanical arm and driving system, which is applied in the direction of manipulator, program control manipulator, claw arm, etc., which can solve the problems of inconvenient movement, inconvenient use of driving mechanism, and inability to meet different use requirements, so as to achieve convenient installation and disassembly, convenient movement and The effect of height adjustment and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

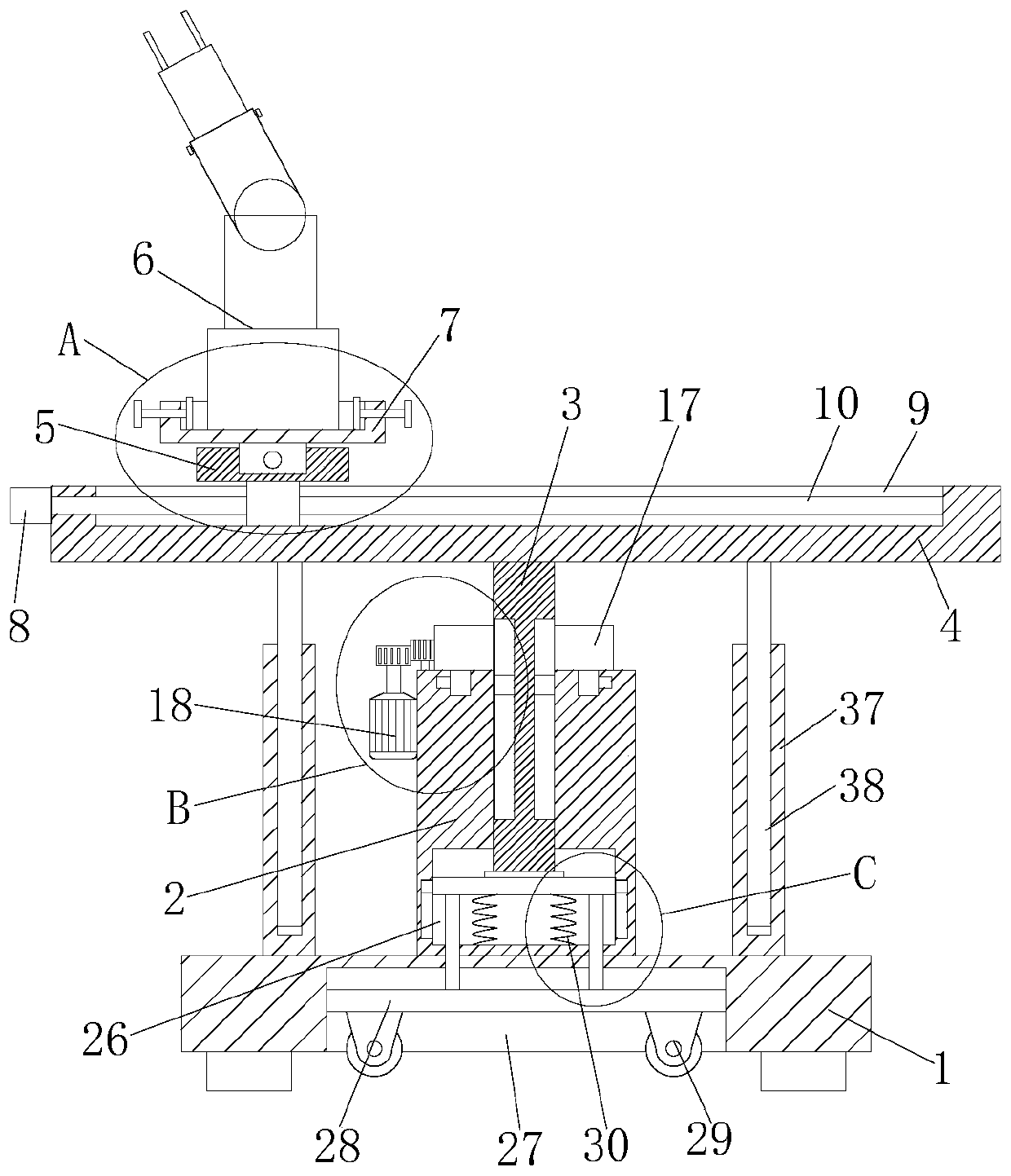

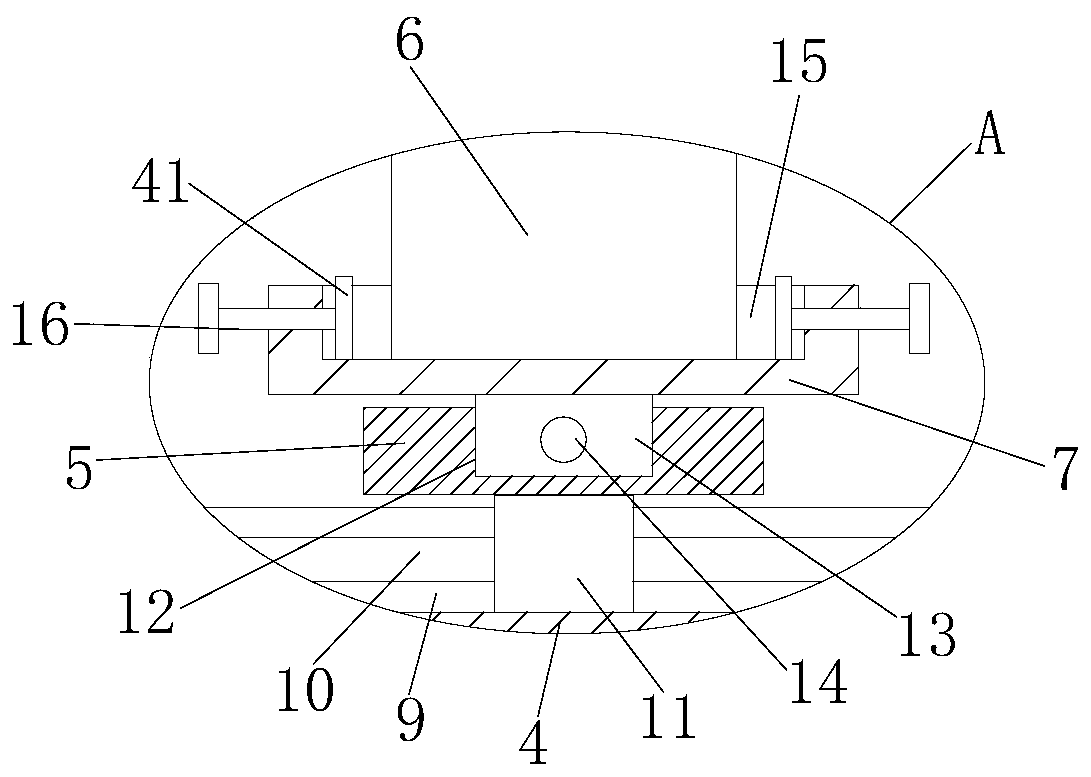

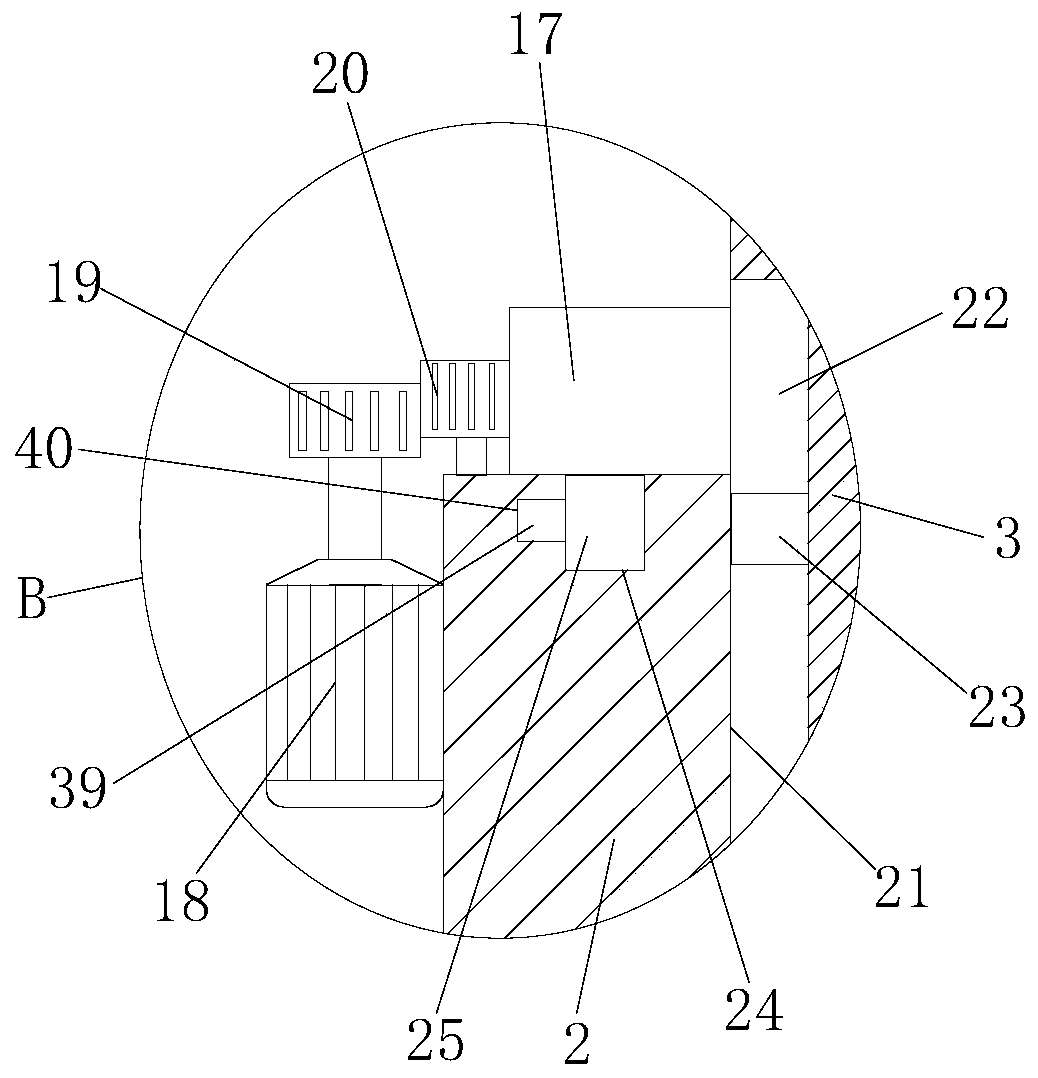

[0031] refer to Figure 1-5 , a driving system of a mechanical arm, comprising a base 1 and a mechanical arm 6, a column 2 is fixedly installed on the top of the base 1, a thrust rod 3 is movably connected to the top of the column 2, and a horizontal adjustment mechanism is fixedly installed on the top of the thrust rod 3, A vertical adjustment mechanism is slidingly installed on the horizontal adjustment mechanism, and a placement tray 7 is slidingly installed on the longitudinal adjustment mechanism. Bottom groove 27, base plate 28 is slidably installed in bottom groove 27, and four universal wheels 29 are fixedly installed on the bottom of base plate 28, and the top of column 2 is provided with guide hole 21, and thrust rod 3 is connected with guide hole 21 slidingly, and column 2 The top of the shaft is rotated with an internally threaded gear 17, and the outside of the thrust rod 3 is provided with an external thread, and the external thread is threaded with the inner rin...

Embodiment 2

[0042] refer to Figure 1-5 , a driving system of a mechanical arm, comprising a base 1 and a mechanical arm 6, the top of the base 1 is fixedly installed with a column 2 by welding, the top of the column 2 is movably connected with a thrust rod 3, and the top of the thrust rod 3 is fixedly installed with a Horizontal adjustment mechanism, the vertical adjustment mechanism is slidably installed on the horizontal adjustment mechanism, and the placement plate 7 is slidably installed on the longitudinal adjustment mechanism. There is a bottom groove 27 at the bottom of the bottom groove, and a base plate 28 is slidably installed in the bottom groove 27. Four universal wheels 29 are fixedly installed on the bottom of the base plate 28 by welding. The top of the column 2 is provided with a guide hole 21, and the thrust rod 3 and the guide hole 21 sliding connection, the top of the column 2 is rotated with an internally threaded gear 17, the outer side of the thrust rod 3 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com