Device for detecting horizontal load resistance of guardrail on site and using method thereof

An on-site detection and anti-level technology, applied in the field of measurement, can solve the problems of troublesome measurement, cumbersome operation, low efficiency, etc., and achieve the effect of improving detection accuracy, improving detection efficiency, and good operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

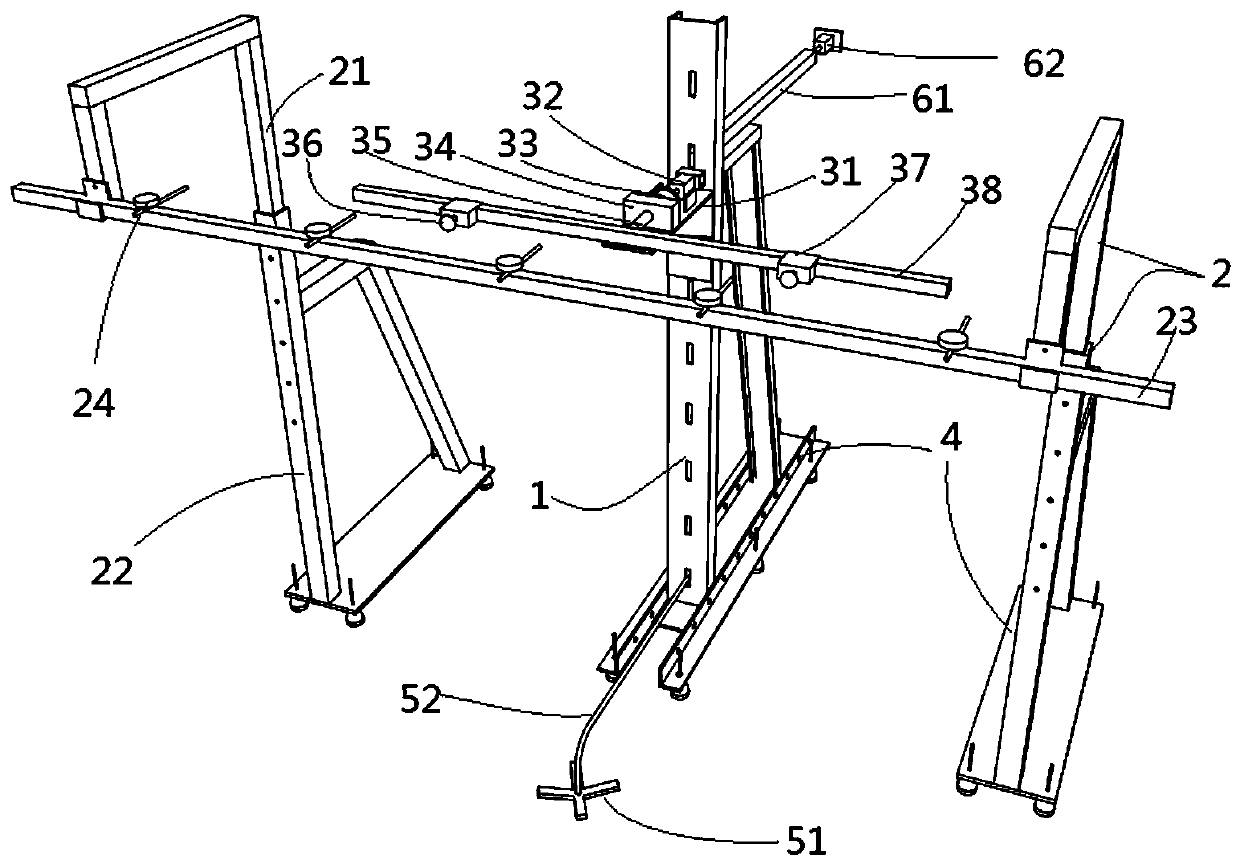

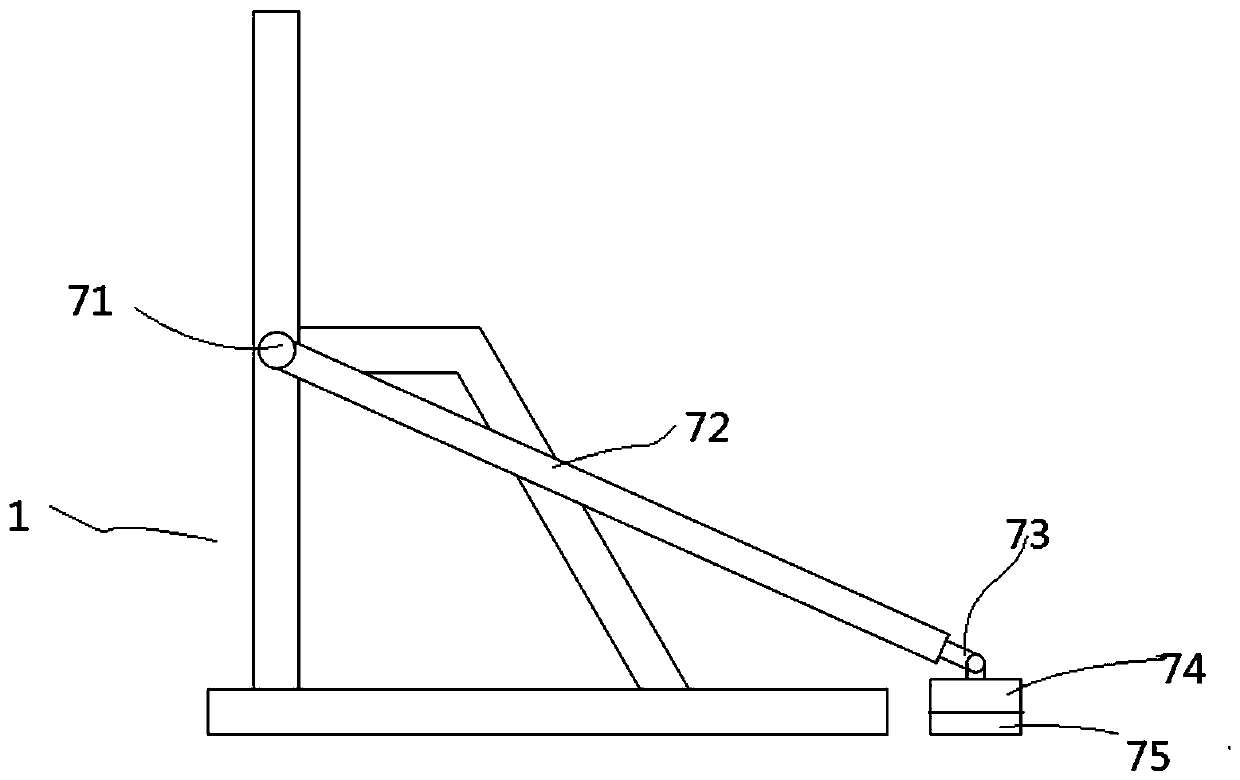

[0053] combine figure 1 This embodiment provides a guardrail anti-horizontal load on-site detection device, including a frame 1, a thrust device, a measuring device, and a reaction device;

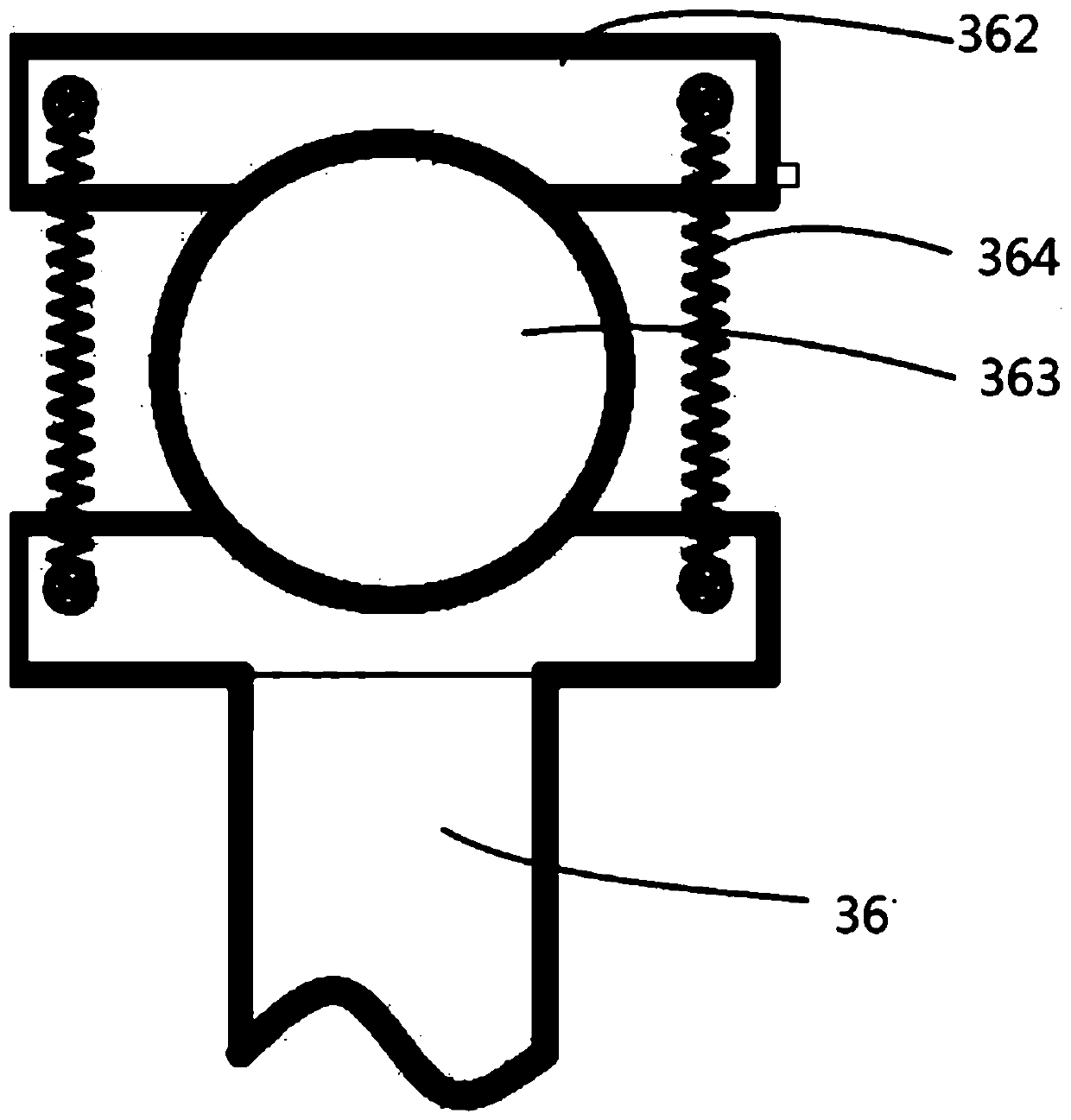

[0054] The thrust device includes an adjustable base 31, a loading device, a horizontal thrust rod 35, and an adjustable support rod 36. The adjustable base 31 is movably connected to the frame 1 in an adjustable manner, and the loading device It is a jack 32; the jack 32 is fixedly connected to the adjustable base 31, and the horizontal thrust rod 35 is slidably connected to the adjustable base 31. In this embodiment, the sliding connection is on the adjustable base 31. The fixed block 34 is fixedly arranged, and the fixed block 34 is provided with a limit hole. The horizontal thrust rod 35 passes through the limit hole and is slidably connected. One end of the horizontal thrust rod 35 is connected with the loading device jack 32, and the other end is connected with the loading device jac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com