Front shock absorption assembly of motorcycle

A front shock absorber, motorcycle technology, applied in bicycle accessories, axle suspension, transportation and packaging, etc., can solve the problems of unreasonable shock absorber mechanism, increased maintenance cost, insufficient shock absorber strength, etc., and achieve easy processing quality, The effect of low maintenance cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

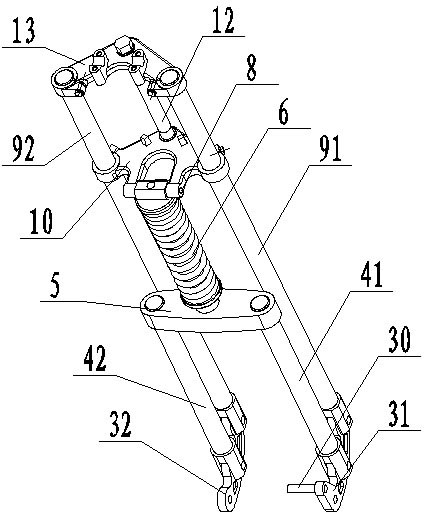

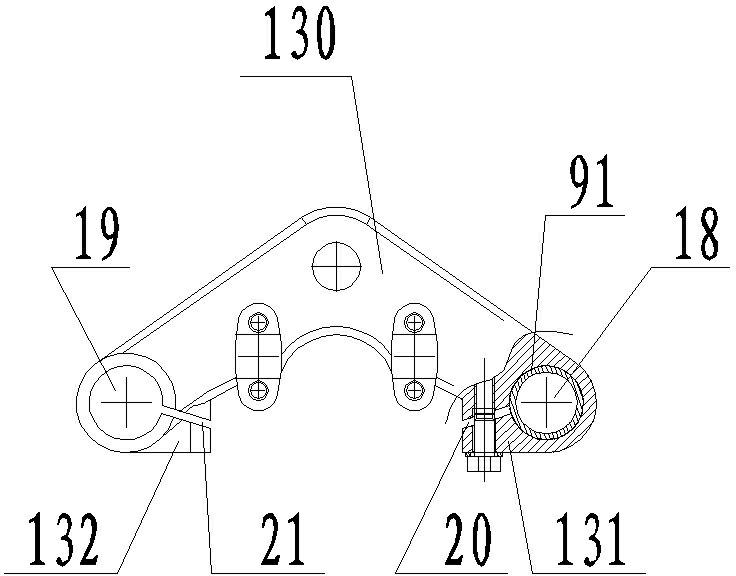

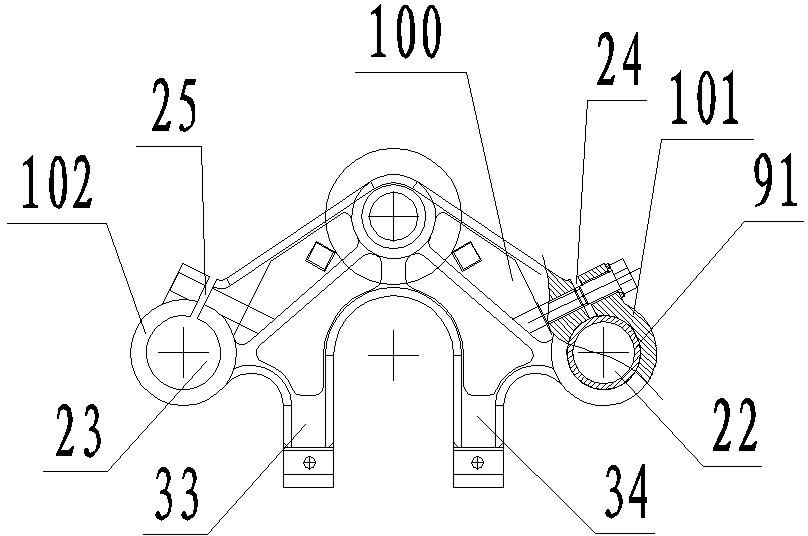

[0027] Embodiment 1: as Figure 1 to Figure 5 As shown, a front shock absorber assembly of a motorcycle includes a damper 7, a shock absorber spring 6, a left support fork tube 91 and a right support fork tube 92.

[0028] An upper spring seat 71 and a lower spring seat 72 are arranged at intervals on the damper 7 , and the damping spring 6 is arranged between the upper spring seat 71 and the lower spring seat 72 .

[0029] The left support fork pipe 91 and the right support fork pipe 92 are fixed in the upper connecting plate 13 and the lower connecting plate 10 arranged at intervals, the lower end of the left supporting fork pipe 91 is fixedly connected with the left turning arm 31, and the lower end of the right supporting fork pipe 92 is connected with the right The rotating arm 32 is fixedly connected. The left pivot arm 31 and the right pivot arm 32 are correspondingly provided with a front wheel left mounting hole 14 and a front wheel right mounting hole 15 for mountin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com