Two-way V-shaped thrust lever upper bracket and bracket beam assembly

A technology of thrust rods and frame beams, applied in the field of thrust rod brackets, can solve the problems of increasing the cost of manufacturing, processing and management, and the large number of parts and components, and achieve the effects of strong position accuracy, high assembly efficiency and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

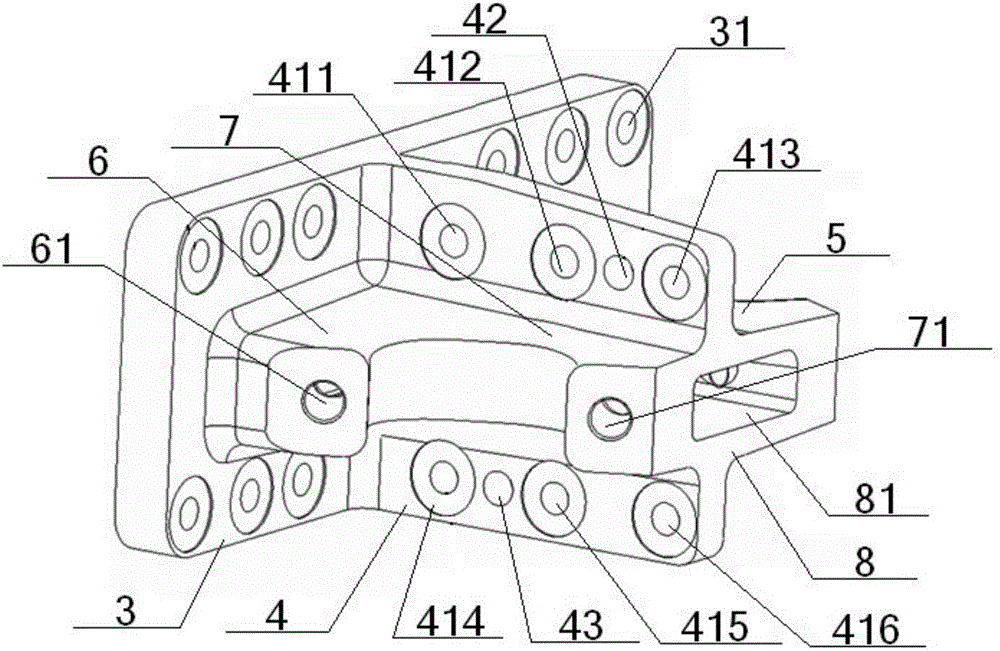

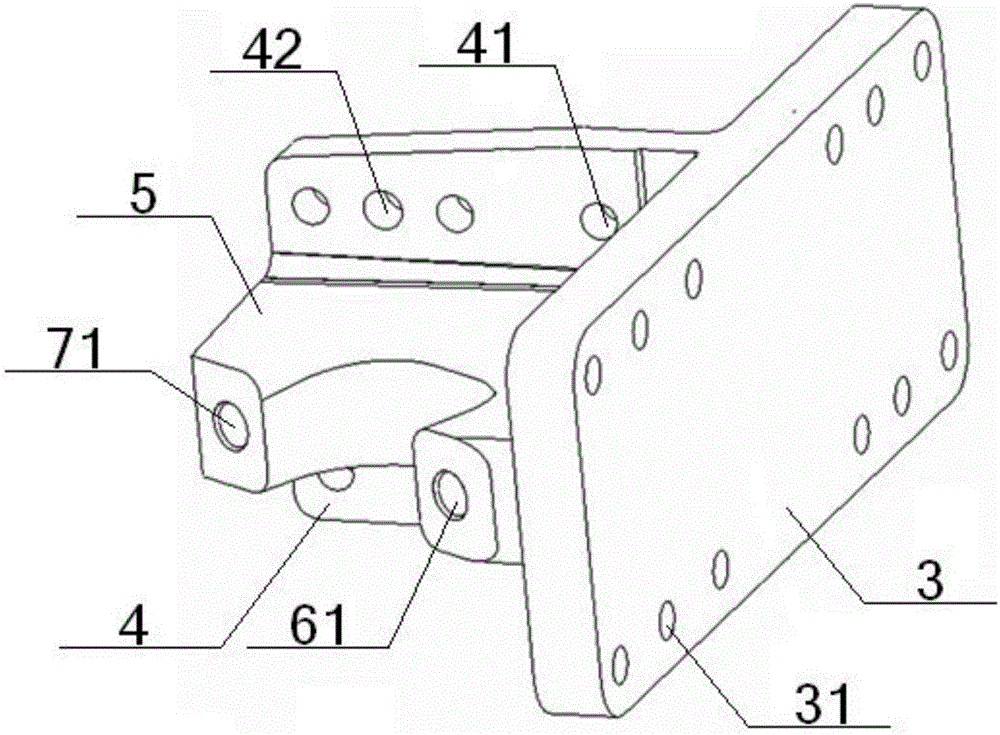

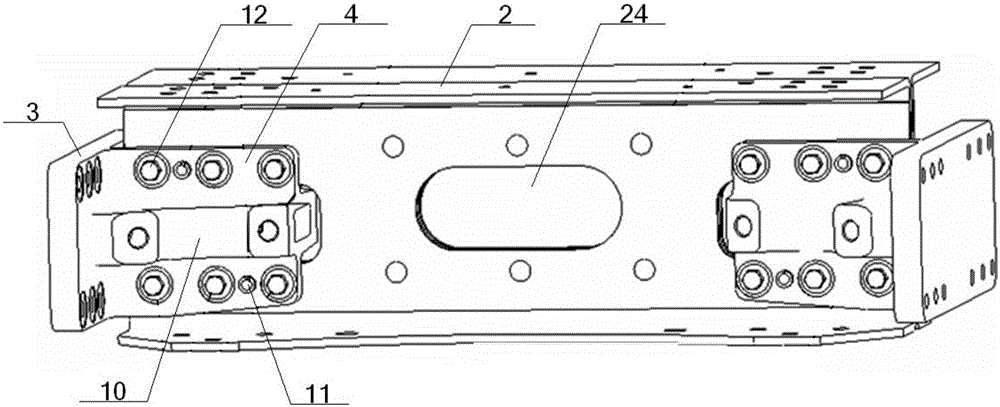

[0054] see Figure 1 to Figure 6 , a two-way V-shaped thrust rod upper bracket, comprising a longitudinal beam connecting plate 3, a cross beam connecting plate 4 and a support seat 5, the longitudinal beam connecting plate 3 is fixedly connected to the vehicle frame longitudinal beam 1, and the cross beam connecting plate 4 is connected to the vehicle The frame crossbeam 2 is fixedly connected, the number of the support base 5 is two, the middle part of the longitudinal beam connecting plate 3 is vertically connected with the bottom of the crossbeam connecting plate 4, and the positive and negative sides of the middle part of the crossbeam connecting plate 4 are connected with the A supporting seat 5 is respectively arranged between the longitudinal beam connecting plates 3, and the two supporting seats 5 are plane-symmetrical with respect to the beam connecting plate 4, and longitudinal beam connecting plates 3 and supporting seats 5 are arranged on both sides of the upper an...

Embodiment 2

[0056] Basic content is the same as embodiment 1, the difference is:

[0057] The support seat 5 is an L-shaped structure, including a short vertical part 6 and a long horizontal part 7 connected to each other, the bottom of the short vertical part 6 is connected to the middle part of the longitudinal beam connecting plate 3, and the bottom of the long horizontal part 7 is connected to the cross beam. The middle part of the connecting plate 4 is bonded and connected, the outer end of the short vertical part 6 is provided with a longitudinal connecting rod hole 61, the inner end of the short vertical part 6 is connected with the inner end of the long horizontal part 7, and the outer end of the long horizontal part 7 is opened There is a transverse link hole 71 , and the projection of the transverse link hole 71 on the longitudinal beam connecting plate 3 is located between the projection of the longitudinal link hole 61 on the longitudinal beam connecting plate 3 and the bottom ...

Embodiment 3

[0059] Basic content is the same as embodiment 1, the difference is:

[0060] An upper pin hole 42 and a lower pin hole 43 are respectively arranged on the upper and lower sides of the cross-beam connection plate 4 and the supporting seat 5, and the center connection between the upper pin hole 42 and the lower pin hole 43 The line is an oblique line; the positional relationship between the upper pin hole 42 and the lower pin hole 43 is: the upper pin hole 42 is set near the top of the beam connecting plate 4, and the lower pin hole 43 is set near the bottom of the beam connecting plate 4, or the upper pin hole 42 are arranged near the bottom of the crossbeam connecting plate 4, and the lower pin holes 43 are arranged near the top of the crossbeam connecting plate 4. The upper pin holes 42 , lower pin holes 43 and their corresponding positioning pins 11 are interference fit, and the longitudinal beam bolt holes 31 , cross beam bolt holes 41 and their corresponding connecting bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com