Tire locking brake for electric power construction transfer vehicle

A technology for electric power construction and transfer vehicles, which is applied to trolleys, motor vehicles, trolley accessories, etc., and can solve problems such as trolleys tilting, tires cannot be locked, and work tools are damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

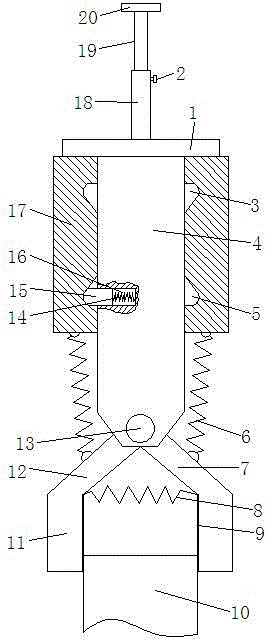

[0015] In order to clearly illustrate the technical characteristics of this solution, the following will describe this solution through specific implementation modes and in conjunction with the accompanying drawings.

[0016] A wheel lock brake for electric construction transfer vehicles, as shown in the figure, it includes a fixed block 17 and a sliding shaft 4, the center of the fixed block 17 is provided with a through hole for the sliding shaft 4 to pass through, and the fixed block 17 The upper end of the sliding shaft 4 is fixedly connected with the driving plate 1, and the lower end is hinged with the clamping brackets 7 used in pairs. Preferably, the driving plate 1 and the sliding shaft 4 are welded and fixed. The upper end surface is fixed with a sleeve 18, the sleeve 18 is provided with a telescopic rod 19 that matches it, and the upper end of the sleeve 18 is provided with a locking knob 2 that cooperates with the telescopic rod 19, and the upper end of the telescop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com