Phased-array ultrasonic nondestructive detection fixture of welding rotor

A technology for welding rotors and non-destructive testing, which is applied in the use of sound waves/ultrasonic waves/infrasonic waves for material analysis, measuring devices, instruments, etc., and can solve problems such as visual sensor identification, inability to use welded rotors, and no positioning device design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

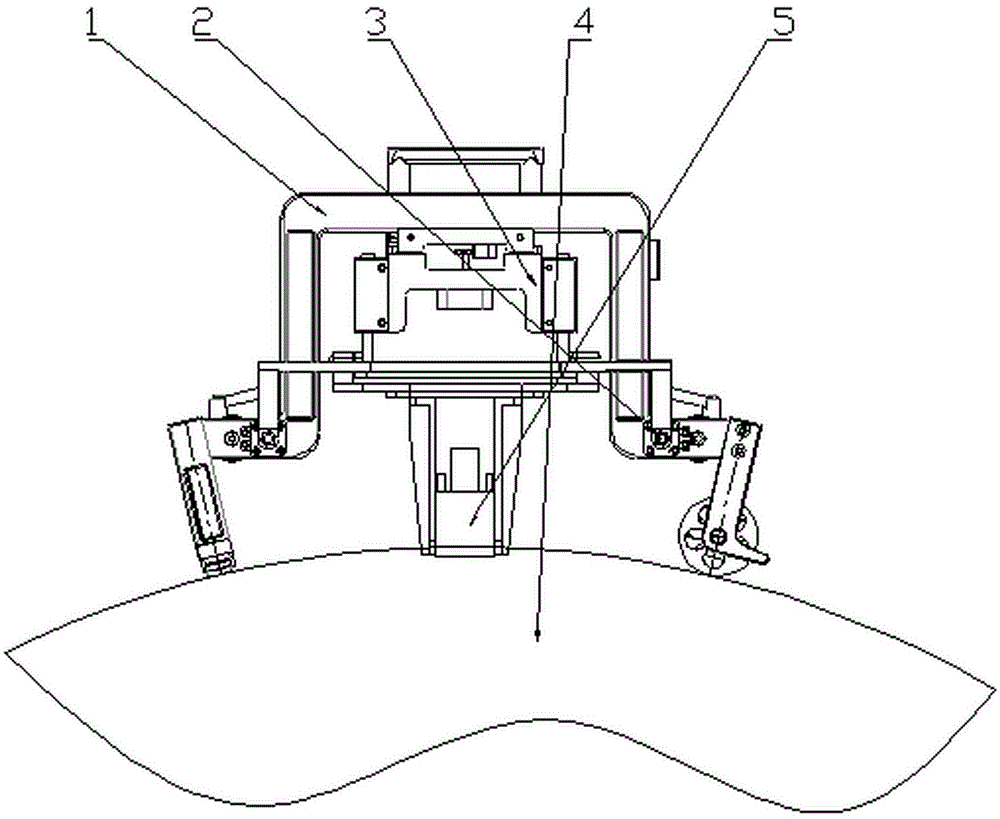

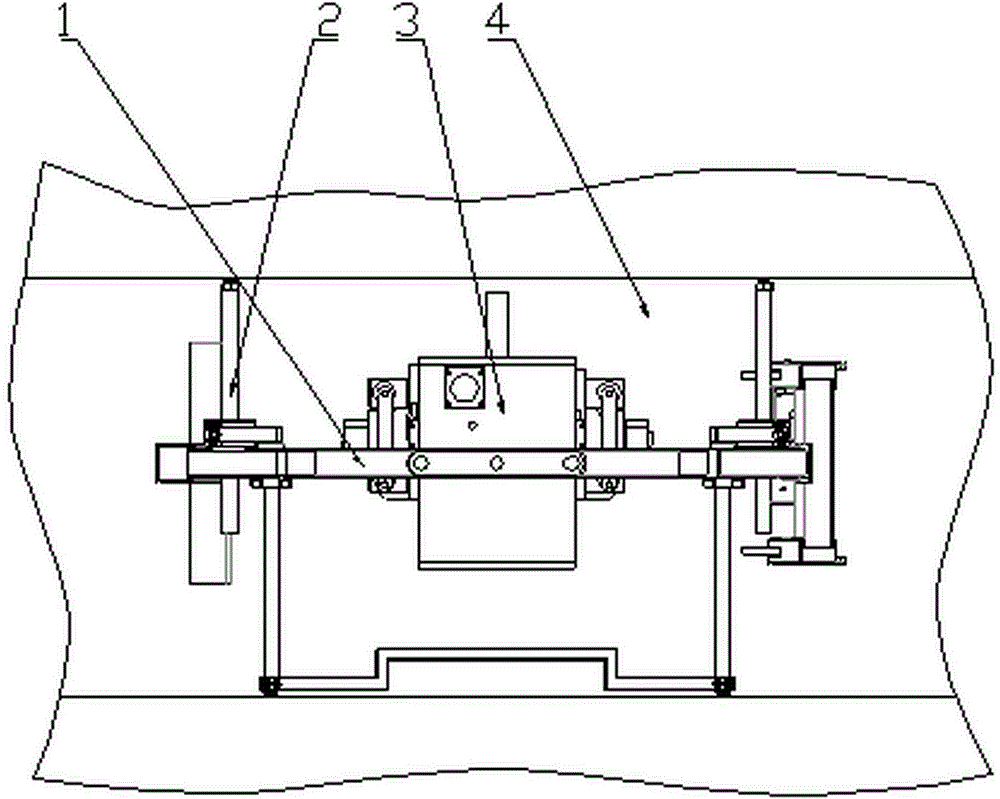

[0030] like figure 1 , figure 2 As shown, the welding rotor phased array ultrasonic nondestructive testing fixture is composed of an adsorption mobile platform 1 , a positioning system 2 and a drivable fixture 3 . The adsorption-type mobile platform 1 is adsorbed on the surface of the welding rotor 4 and can slide freely along the circumferential direction of the welding rotor 4; the positioning system 2 is fixed on the adsorption-type mobile platform 1 and is in contact with the walls on both sides of the welding rotor 4 , to achieve axial positioning; the drivable fixture 3 is fixed on the adsorption-type mobile platform 1, and clamps the phased array detection wedge 5 to make it contact with the surface of the welding rotor 4 for detection.

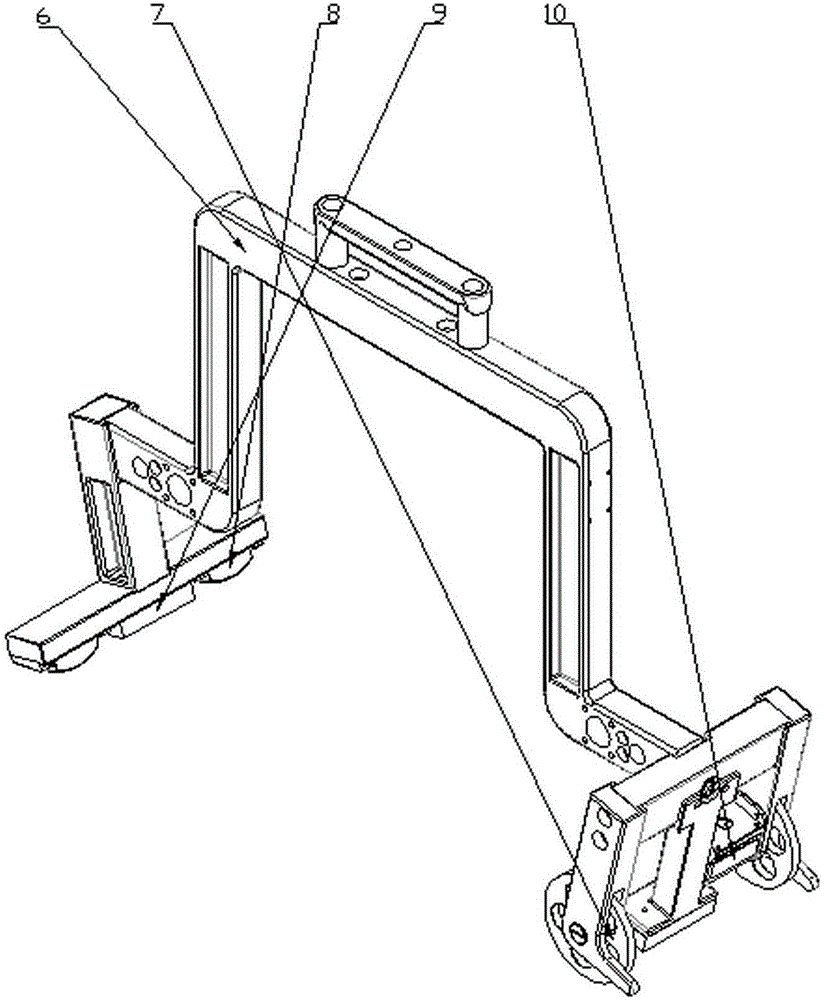

[0031] like image 3 As shown, the adsorption mobile platform 1 is composed of a support frame 6 , a scroll whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com