Planet carrier for a gearbox

A planetary gear carrier and planetary gear technology, applied in belt/chain/gear, transmission parts, mechanical equipment, etc., can solve problems such as expensive positioning or centering measures, hinder the economical manufacture of planetary gear carriers, etc. The effect of radial positioning and radial positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

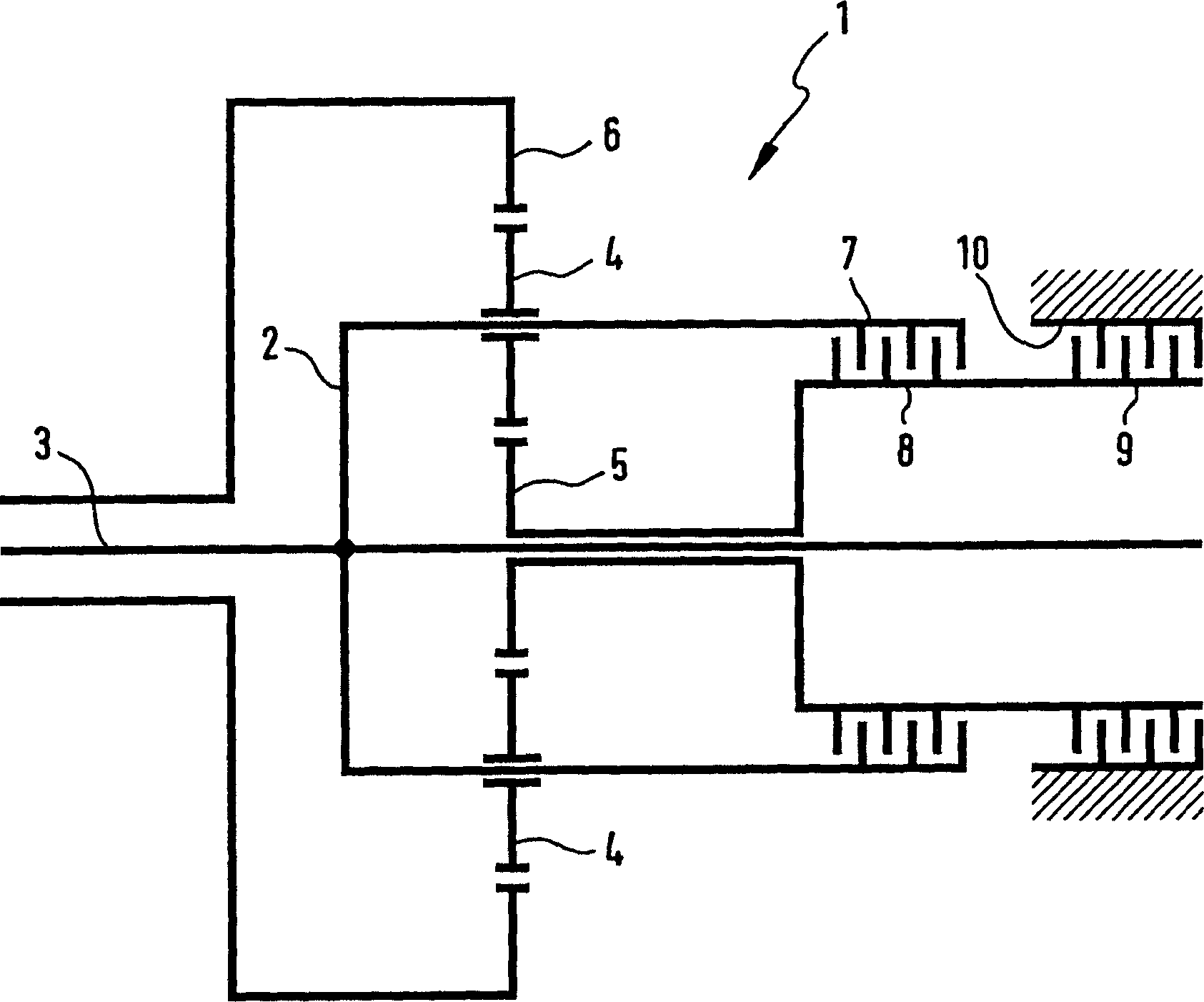

[0023] figure 1 A schematic diagram of a planetary gear train 1 is shown as an example of using the teaching according to the invention, wherein the planetary gear carrier is denoted by 2 . The planet carrier 2 is connected in a rotationally fixed manner to a shaft 3 and is provided with planet gears 4 outside its longitudinal axis. The axes of rotation of the planet gears 4 are parallel to the longitudinal axis of the planet carrier 2 . The sun gear 5 and the ring gear 6 are coaxially and rotatably mounted on the planet gear carrier 2 or the shaft 3 , and the sun gear and the ring gear 6 are continuously meshed with the planet gear 4 . The planetary gear carrier 2 is provided with a first friction plate body 7 . These components can be coupled to one another via the second disk body 8 connected to the sun gear 5 . By means of the third disk body 9 connected to the sun gear 5 , the sun gear can be braked via the fourth disk body 10 fixed to the housing.

[0024] Also in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com