Screw-type extrusion system and 3D printer comprising same

A screw type and screw technology, applied in 3D object support structure, coating device, additive manufacturing, etc., can solve the problems that the material cannot be heated to a high temperature, cannot be formed, etc., to achieve optimized temperature distribution and better performance , the effect of flexible heating methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

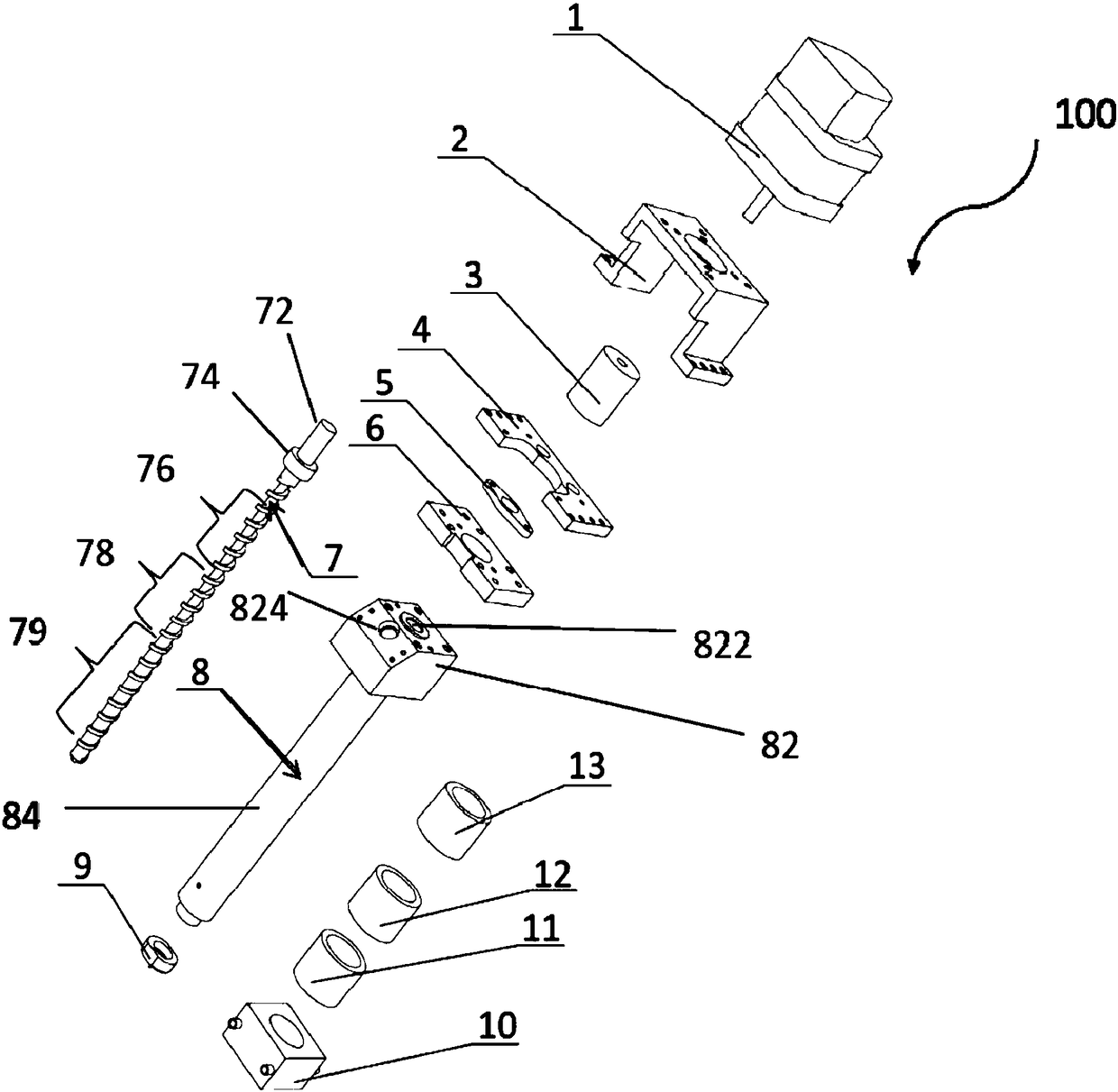

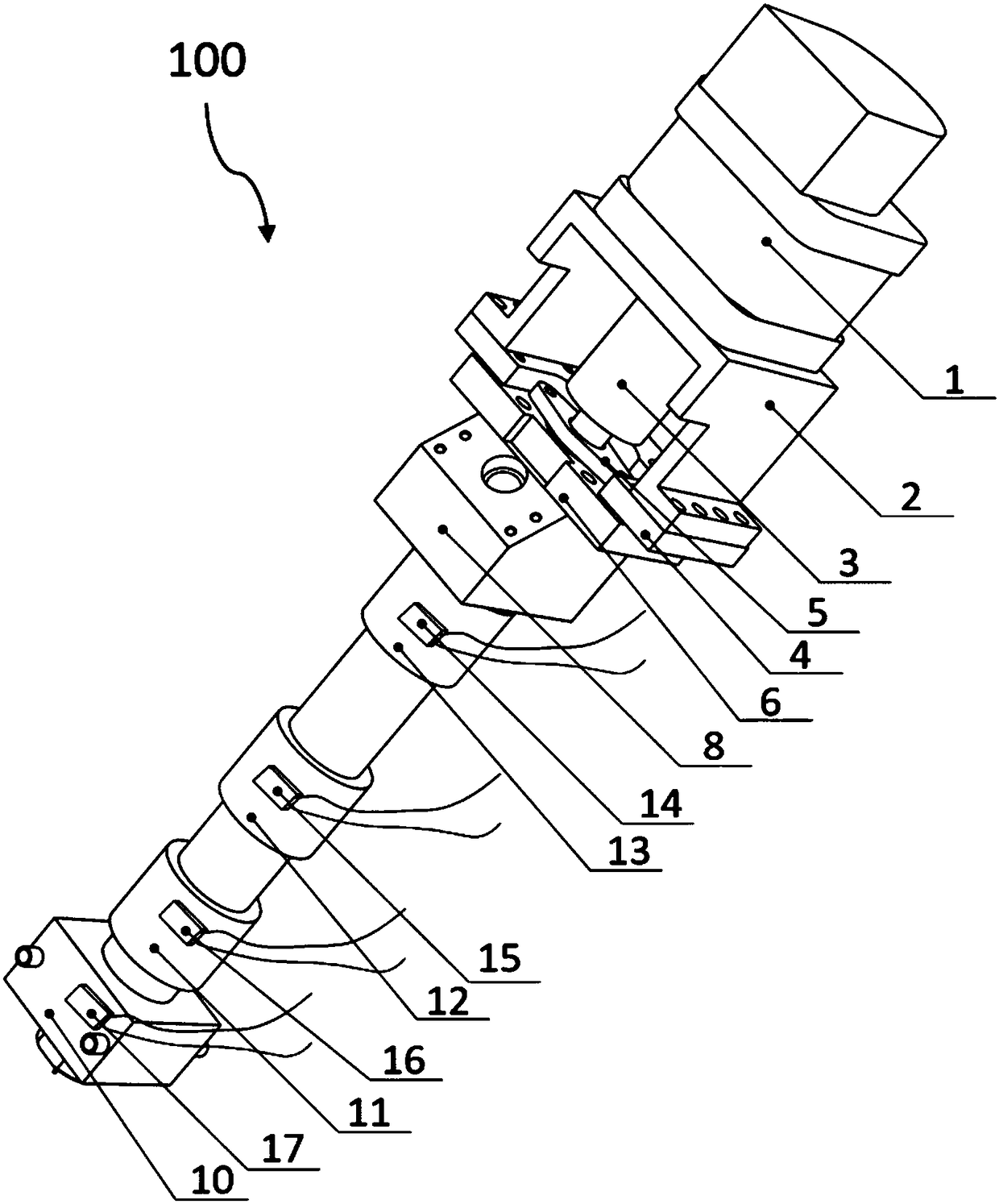

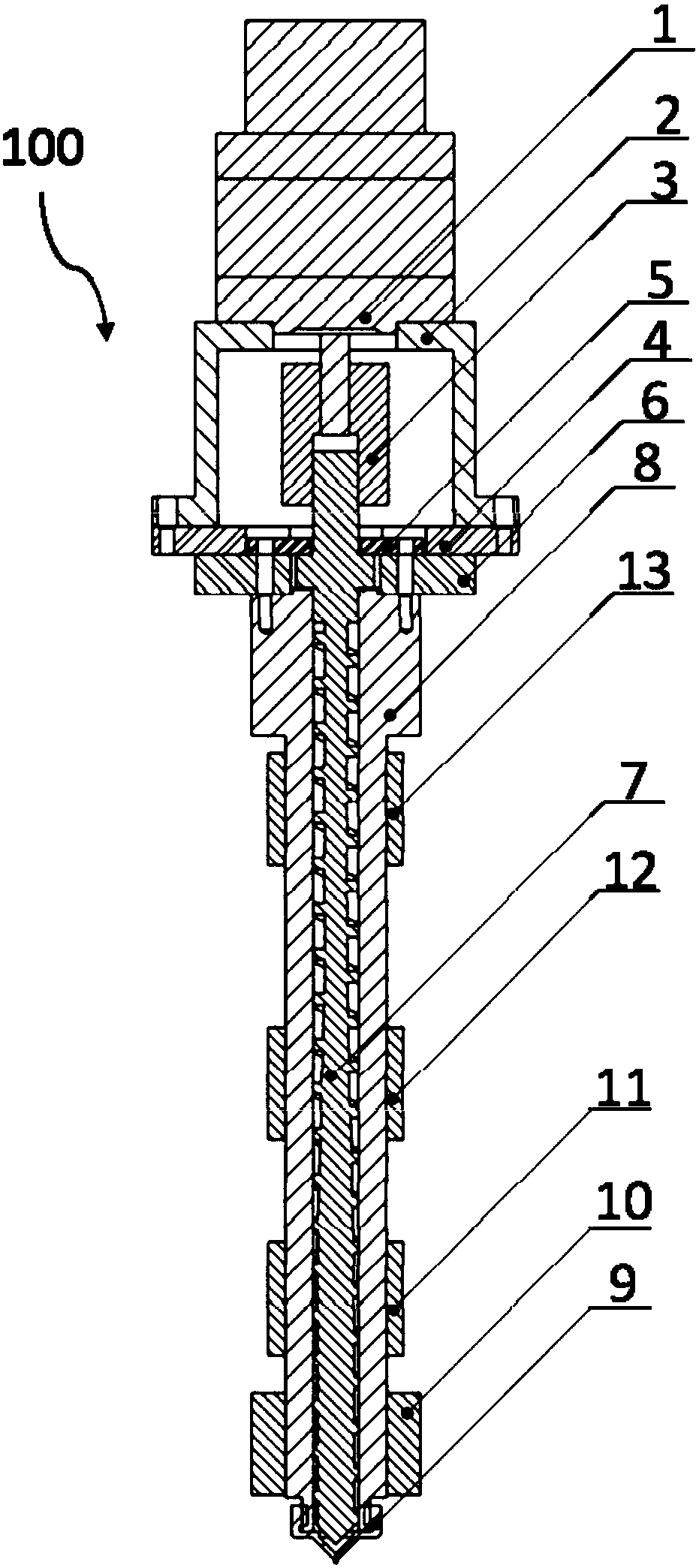

[0026] Figure 1 to Figure 3 A screw extrusion system 100 according to one embodiment of the present application is schematically shown. In this embodiment, the screw extrusion system 100 is used to be installed on a three-dimensional printer using Fused Deposition Modeling (FDM) technology to realize three-dimensional printing of hot-melt materials (especially thermoplastic polymer materials). It should be understood, however, that the extrusion system can also be used on 3D printers using other technologies such as low temperature deposition.

[0027] The extrusion system 100 includes a barrel 8, a nozzle 9 detachably installed at the lower end of the barrel 8, a screw 7 rotatably installed in the barrel 8, and three heating devices 11 arranged around the outer wall of the barrel 8, 12, 13. The extrusion system 100 also includes a cooling device 10 arranged around the outer wall of the barrel 8 and adjacent to the spray head 9 . Due to the existence of the cooling device,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com