Swivel joint

A technology of rotary joints and rotary shafts, which is applied in the direction of pipes/pipe joints/fittings, adjustable connections, turntables/moving tables, etc., which can solve problems such as equipment failures, mechanical wear, and reduce the service life of rotary joints. Strong bearing capacity, long service life and flexible rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

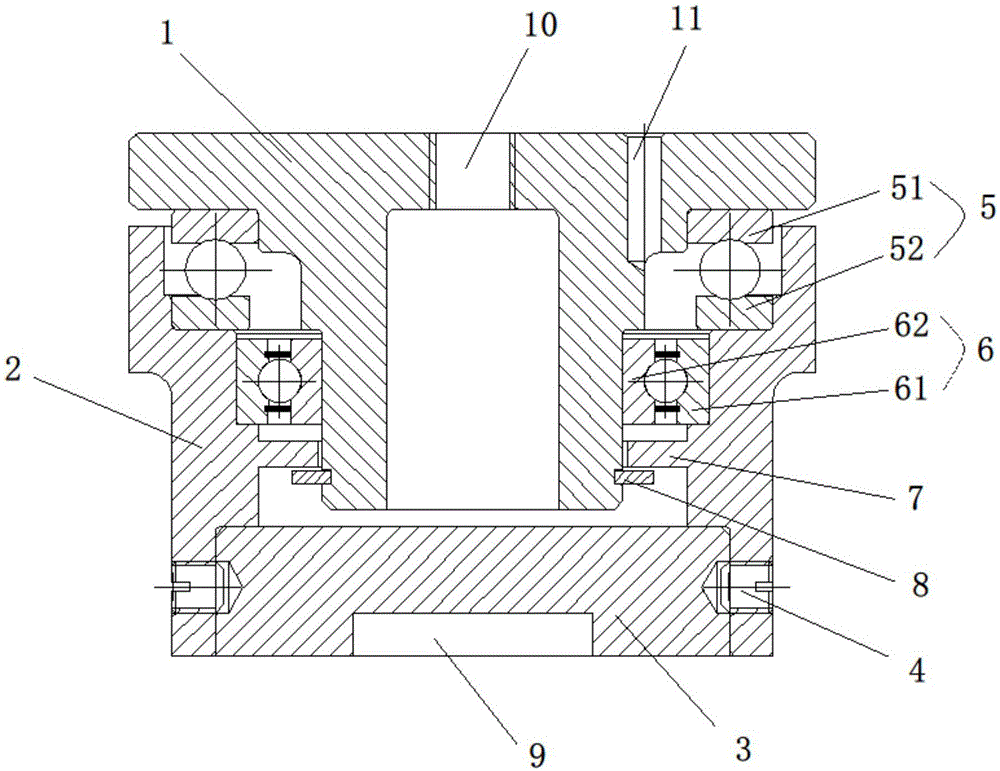

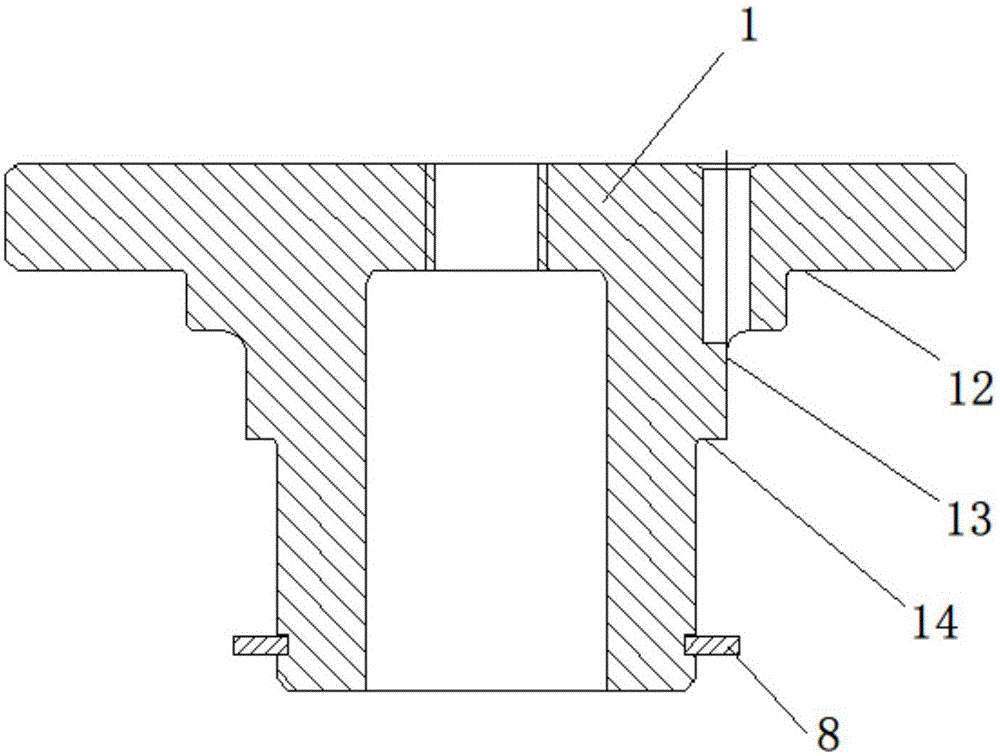

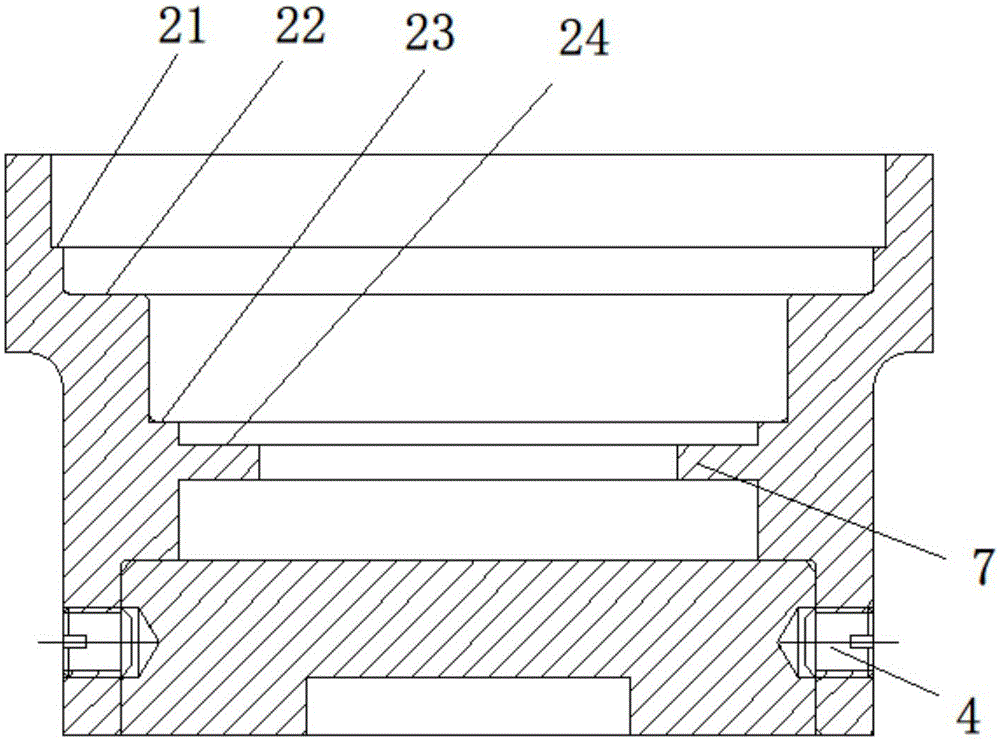

[0042] Such as Figure 1-3 As shown, the present invention provides a rotary joint, including a rotary sleeve 2 and a rotary shaft 1, the lower part of the rotary shaft 1 is sleeved in the rotary sleeve 2, and the lower end of the rotary shaft is rotationally connected with the rotary sleeve 2 A first bearing 5 for providing axial support and a second bearing 6 for providing radial support are arranged between the rotary sleeve 2 and the rotary shaft 1, the raceway 52 of the first bearing is in contact with the The inner hole of the rotary sleeve 2 is matched, the shaft ring 51 of the first bearing is matched with the rotary shaft 1, the outer ring 61 of the second bearing is matched with the inner hole of the rotary sleeve 2, and the The inner ring 62 of the second bearing is sleeved on the rotary shaft 1 . Each component of the rotary joint of the present invention is made of carbon steel or alloy steel, and undergoes quenching and tempering treatment without quenching or n...

Embodiment 2

[0054] Figure 4 It is a schematic structural diagram of the rotary joint of the second embodiment of the present invention, the rotary joint includes a rotary sleeve 2, a rotary shaft 1, a first bearing 5, a second bearing 6 and a top block 3, this embodiment is basically the same as the first embodiment above , the difference is that the thrust ball bearing in Embodiment 1 is replaced by a tapered roller bearing, the seat ring 52 of the thrust ball bearing is replaced by the outer ring 502 of the tapered roller bearing, and the shaft ring 51 of the thrust ball bearing is replaced It is the inner ring 501 of the tapered roller bearing.

[0055] In this embodiment, the tapered roller bearing provides radial support and axial support at the same time, its maximum axial load can reach two tons, and its maximum bending moment can reach 700Nm.

Embodiment 3

[0057] See attached Figure 5-12 , The rotary joint of the present invention is used in a jacking, turning, and turning device, and the jacking, turning, and turning device includes a jacking mechanism and a turning mechanism that cooperate with each other. in:

[0058] The jacking mechanism includes a lower support member 31, a jack 34 and a leg 38. The lower support member 31 is a circular cylinder with at least two pairs of first connecting seats at its lower end, and each pair of first connecting seats is connected to a corresponding leg. 38. Each pair of the first connecting seat includes two first blocking pieces 314 with through holes, and a leg 385 is provided at one end of the leg 38, and a pad 311 for adjusting the height of the leg is arranged on the leg 385, and the leg The other end of 38 has a leg supporting part 381 and a leg connecting part 382 with a through hole; the leg and the first connecting seat are hinged through a first connecting mechanism, and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com