Power-on curing machine for PTC (Positive Temperature Coefficient) heaters

A heater and curing machine technology, which is applied to heating elements, ohmic resistance heating parts, etc., can solve the problems of unsafe operation, inconvenient removal, and poor heat dissipation effect, and achieves safe operation, convenient removal, and good heat dissipation effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

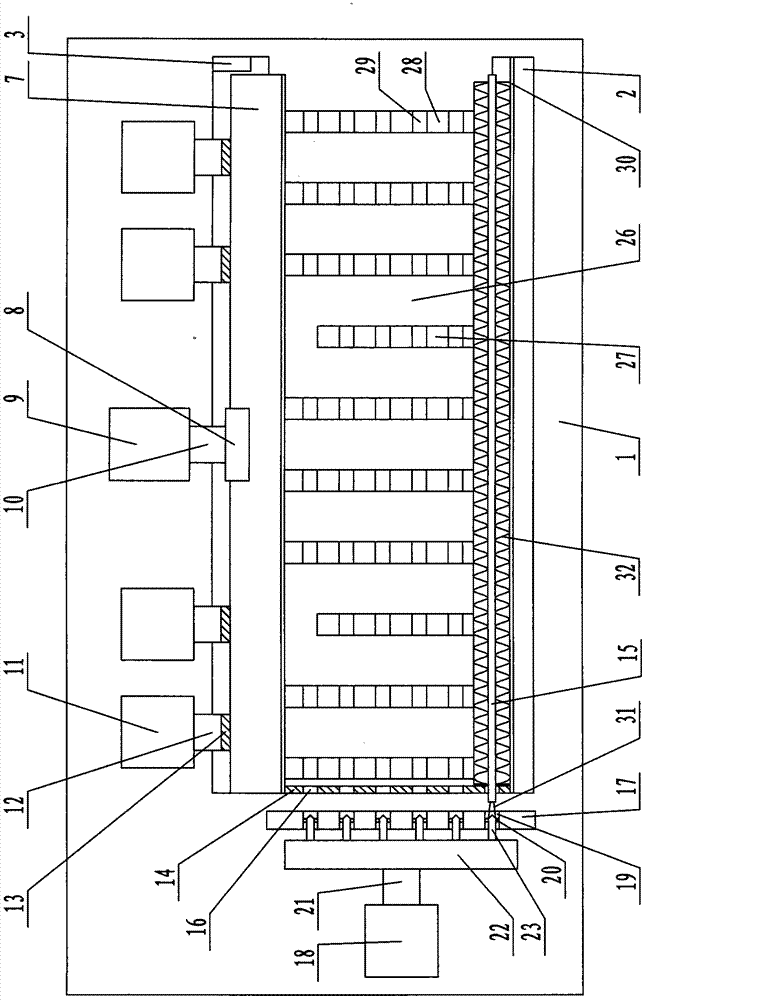

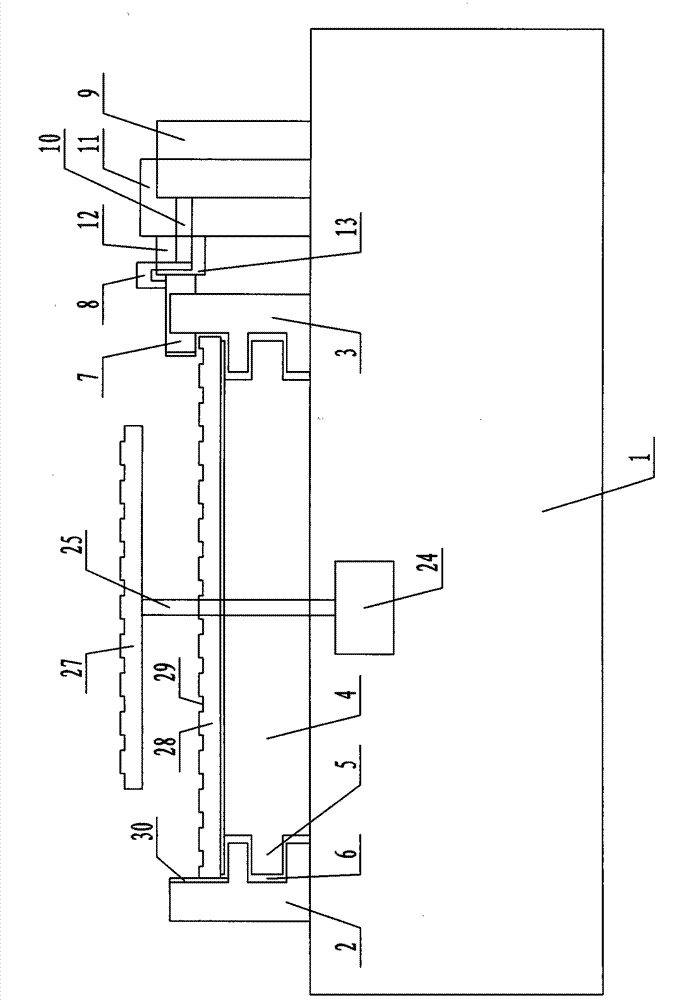

[0012] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0013] Such as figure 1 , figure 2 As shown, the PTC heater power-on curing machine includes: a frame 1, on which a left support block 2 and a right support block 3 are arranged, and between the left support block 2 and the right support block 3 There are several middle support blocks 4, and slide blocks 5 are arranged on both sides of the middle support block 4, and a chute 6 cooperating with the slide block 5 is arranged on the inner side of the lower end of the left support block 2 and the right support block 3 , a sliding platen 7 is arranged on the right supporting block 3, the middle part of the sliding platen 7 is connected with the piston rod 10 of the positioning cylinder 9 through the connecting block 8, and the positioning cylinder 9 is arranged on the frame 1 , the frame 1 on both sides of the positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com