Resilient printed circuit board pad structure

A technology for printed circuit boards and pads, which is applied in the directions of printed circuit components, electrical connection printed components, etc., can solve the problems of uneven pads, entering them, inconvenient cleaning, etc., and achieves the effect of improving the reliability of electrical connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

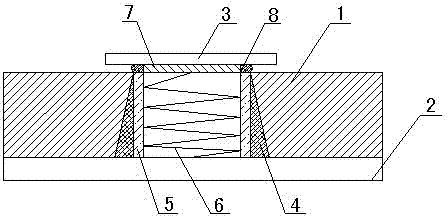

[0014] like figure 1 As shown, the flexible pad structure of the printed circuit board according to the embodiment of the present invention includes an insulating layer 1 and a base 2. The insulating layer 1 is arranged above the base 2, and a pad 3 is arranged on the top at the center of the insulating layer 1, located at A through hole is provided in the insulating layer 1 below the pad 3, and a triangular reinforcing rib 4 is respectively provided on both sides of the through hole, and a conductive layer 5 is provided on the inner side of each triangular reinforcing rib 4;

[0015] The spring assembly 6 is arranged inside the closed chamber surrounded by the conductive layer 5, the upper surface of the spring assembly 6 is connected to the pressure plate 7 and the upper surface of the pressure plate 7 is pressed against the lower bottom surface of the pad 3, and it is located on the outer edge of the pressure plate 7 and in the pad 3 and the conductive layer 5 are additiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com