Minitype rod traveling wave type ultrasonic motor

An ultrasonic motor, rod-type technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc. problems, to achieve the effect of compact structure, high processing and assembly, easy installation and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

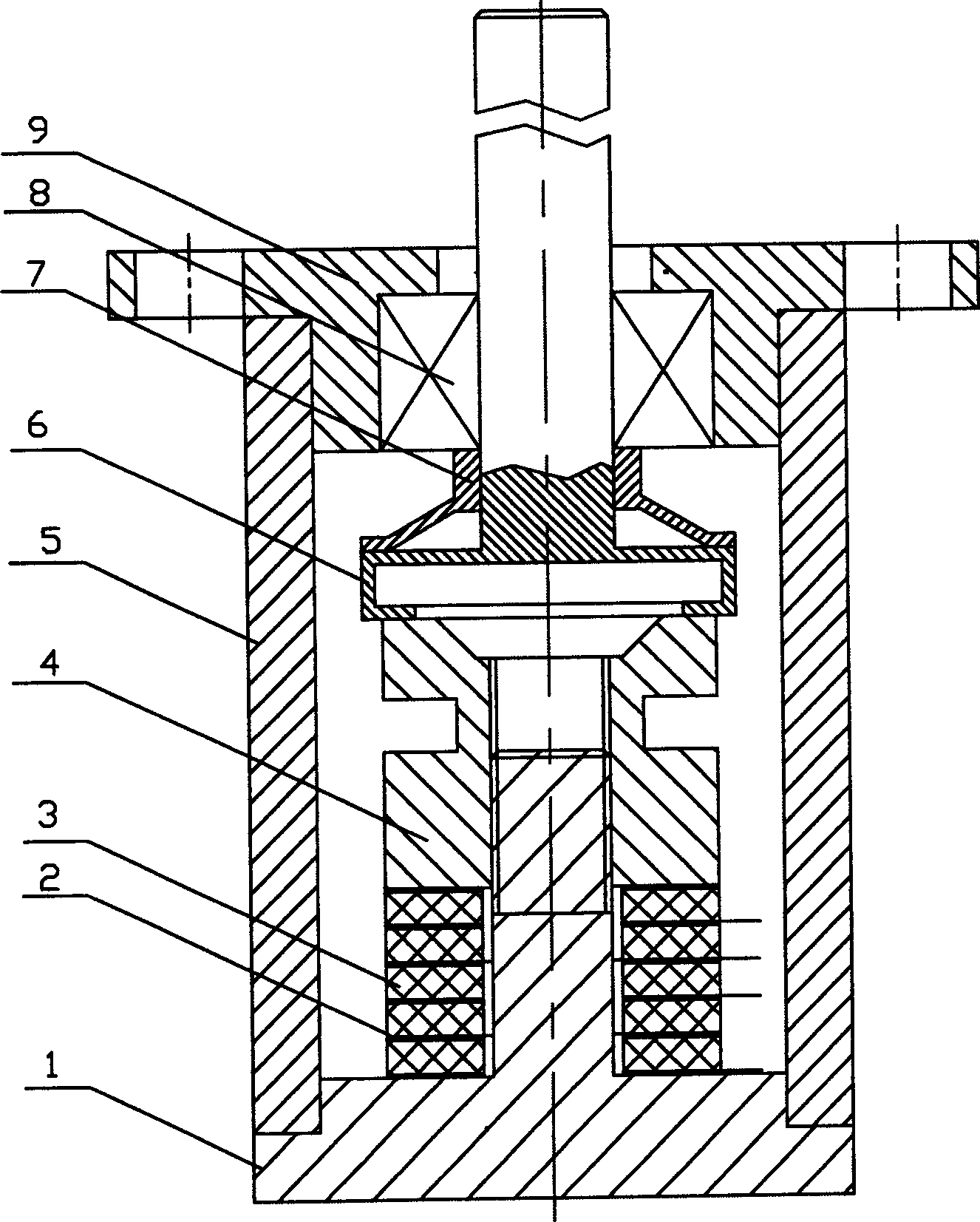

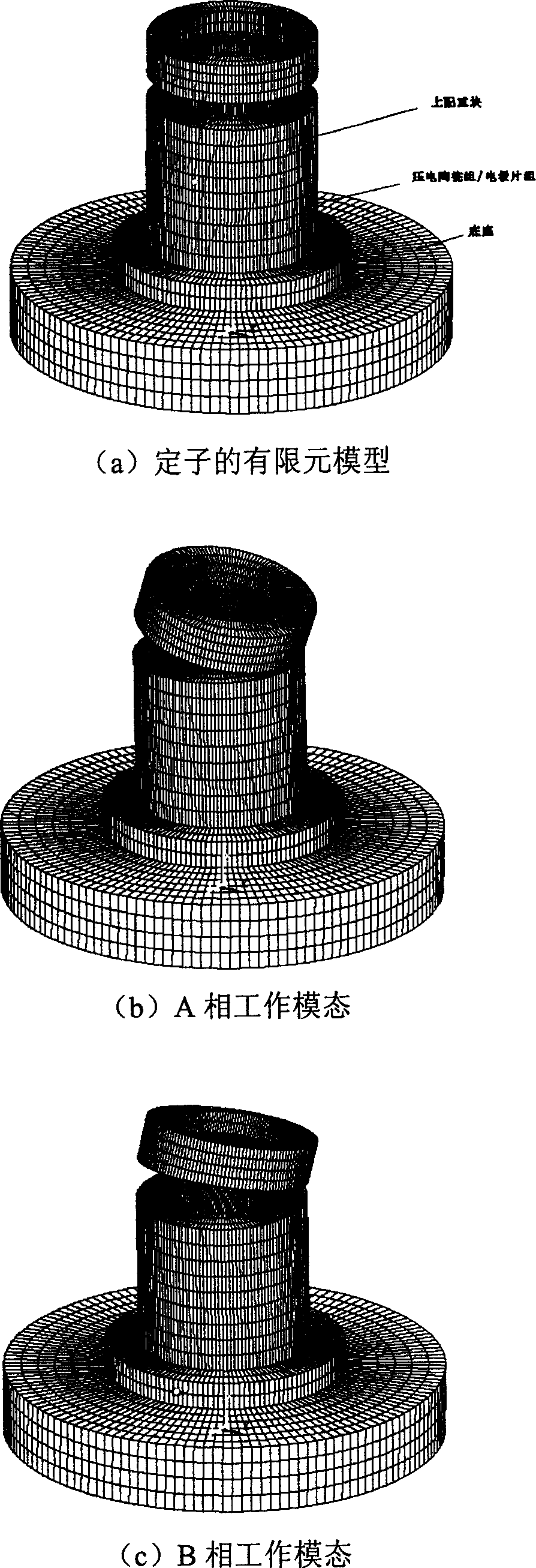

[0009] The invention is a novel ultrasonic motor developed based on the piezoelectric effect of the piezoelectric ceramic sheet to excite the second-order bending vibration mode of an elastic beam with one end fixed and one end free. It is mainly composed of three parts: stator, rotor and shell. Fig. 1 is the concrete structure schematic diagram of the present invention, as can be seen from the figure, the stator of motor is made piezoelectric ceramic group 3 (total 5 pieces) / electrode sheet group 2 (total 6 pieces) by base 1 and upper counterweight 4, through base The screw on the shaft compresses to form an elastic beam. The base is glued to the shell to form a boundary condition where one end of the vibrator is fixed and the other end is free. In this way, the installation of the motor is more convenient and reliable, and the working mode of the motor will not be affected by the installation position. Last counterweight 4 becomes band outer ring groove. The groove size a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com