Welding equipment of plastic door-window welding machine

A technology of plastic doors and windows and welding devices, which is applied in the field of welding devices, can solve problems such as uncompact structure, low processing efficiency, and poor welding quality of profiles, so as to improve the strength and stability of welding corners, facilitate manufacturing and maintenance, and heat and melt even amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

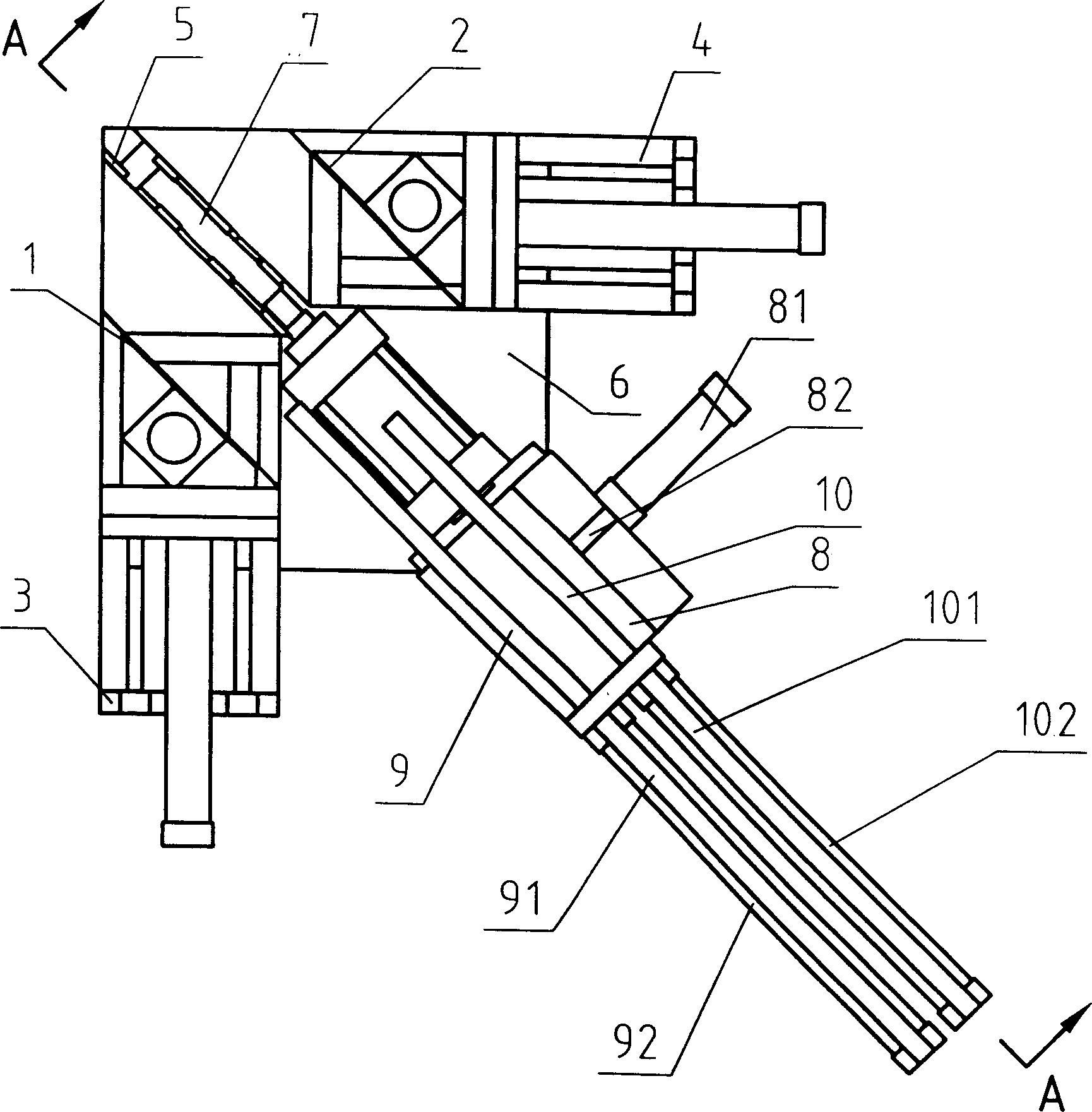

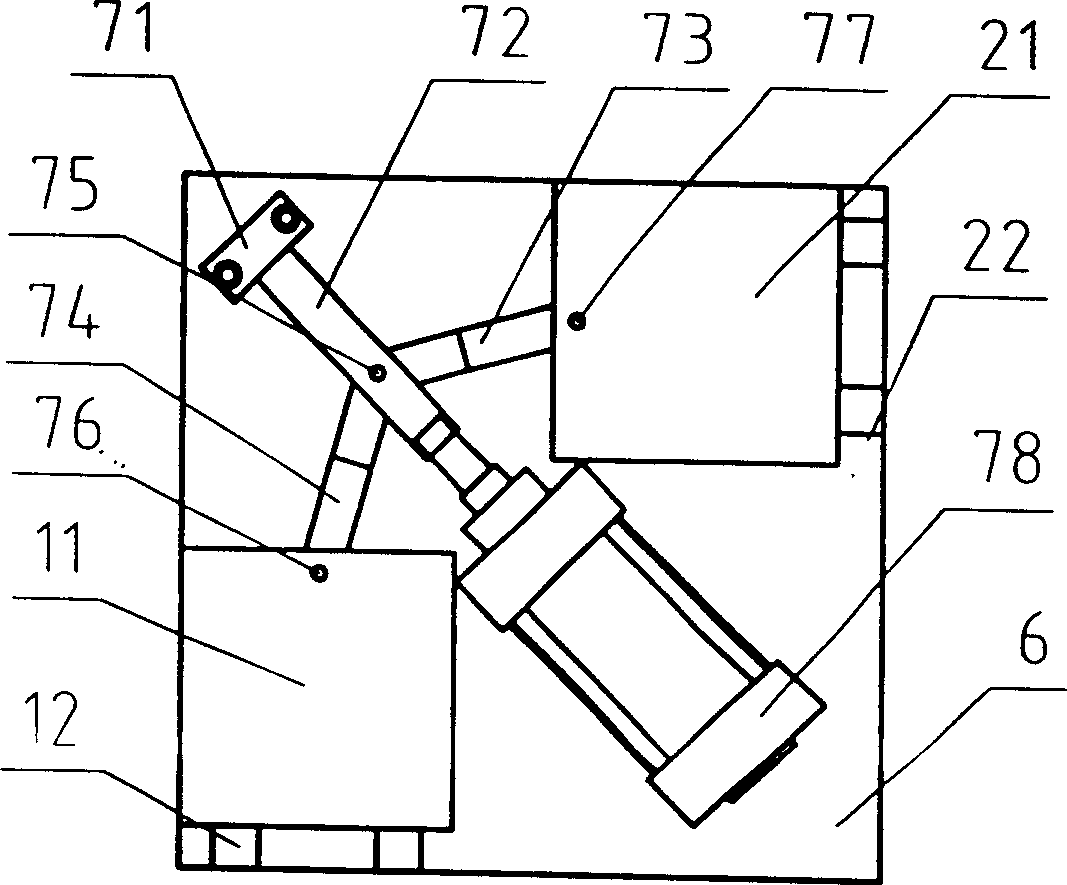

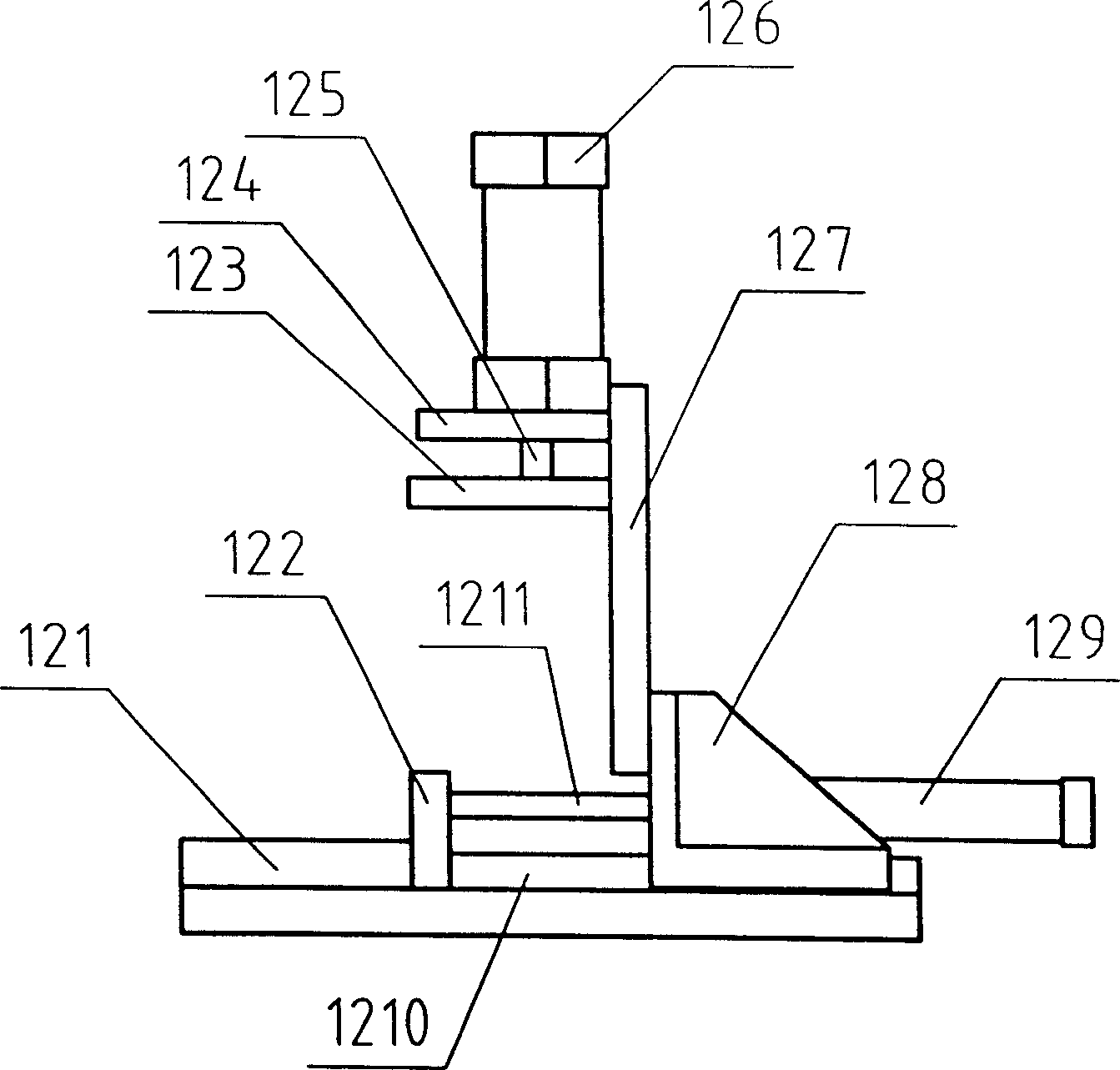

[0015] Such as figure 1 , figure 2 The welding device of the plastic door and window welding machine shown includes two clamp devices (1, 2), a positioning heating device and a welding flux limiting mechanism (5), and the two clamp devices (1, 2) Each is provided with a set of sliding mechanisms that are fixedly connected thereto, and the two sliding mechanisms are connected with a press feed device (7) that can move synchronously. The sliding mechanism of the clamp device (1) is composed of a sliding block (11) and a sliding shaft (12), and the sliding shaft (12) is fixedly connected with the carriage (6). The clamp device (1) is fixedly connected with the slider (11) through the connecting plate (3). The sliding mechanism of the clamp device (2) is composed of a sliding block (21) and a sliding shaft (22), and the sliding shaft (22) is fixedly connected with the carriage (6). The clamp device (2) is fixedly connected with the slider (21) through the connecting plate (4)....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com