Rotor sheet of asynchronously-started PMSM (permanent magnet synchronous motor)

A technology of asynchronous starting and permanent magnet synchronization, applied in synchronous machines, electrical components, electromechanical devices, etc., can solve the problems of wasting manpower, material and financial resources, the magnetic steel is easily broken by force, and the mechanical strength is reduced, and achieves punching efficiency and labor saving. Time-saving, economical improvement, and high punching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

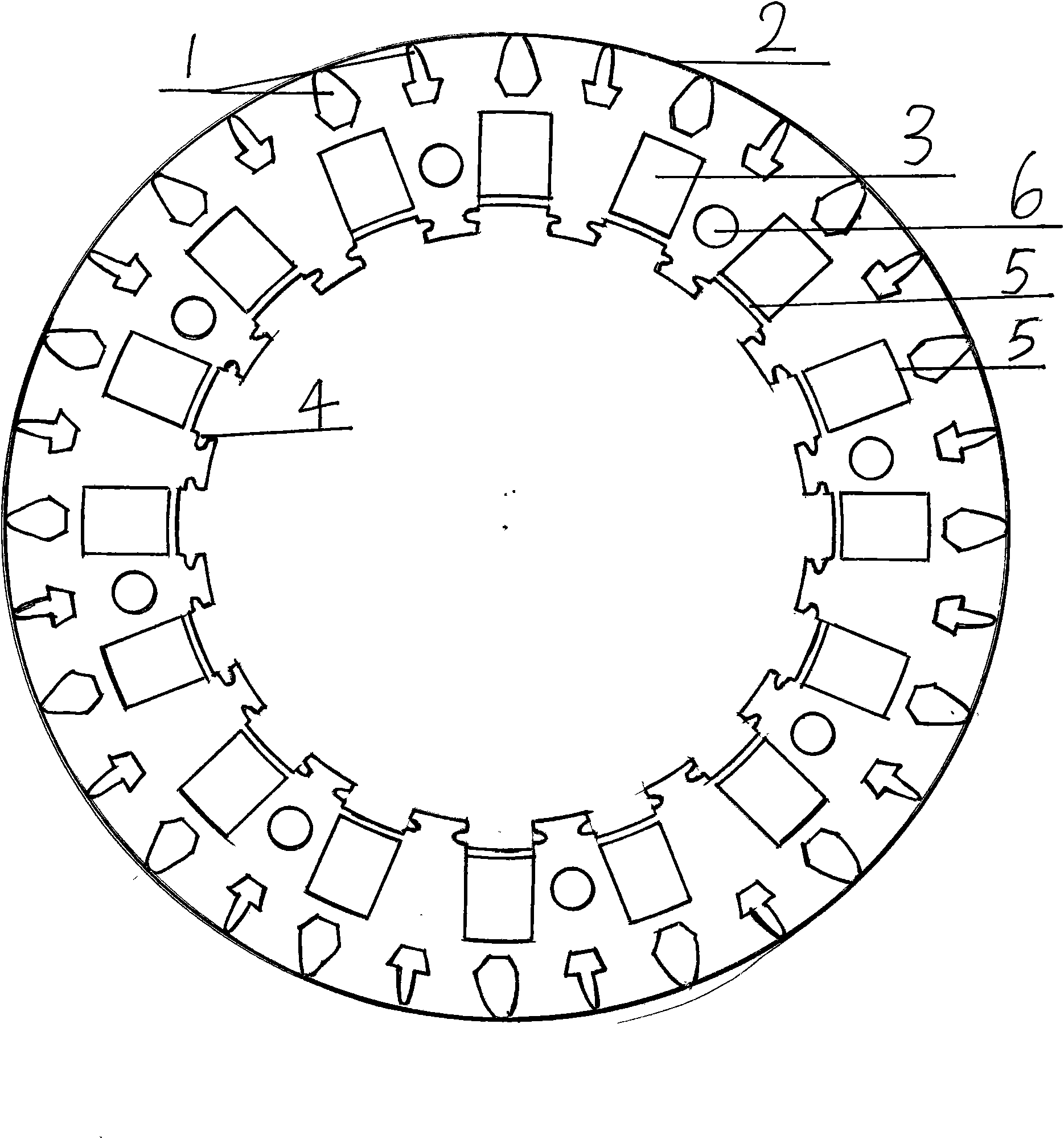

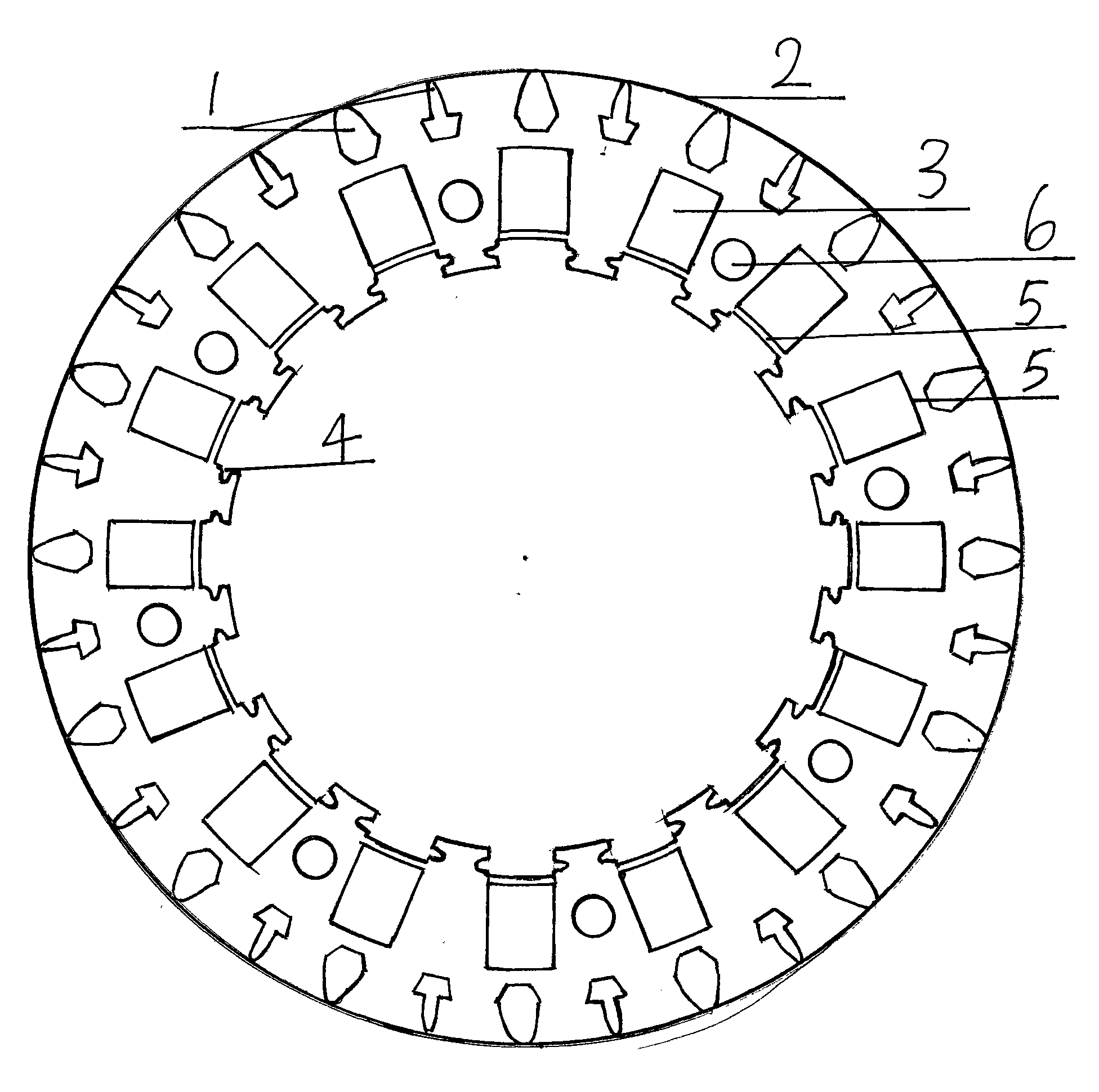

[0009] The present invention will be further explained below with reference to the drawings and examples. figure 1 According to the motor power, frame size, size, groove shape, width, budget, and the process of drawing and mold opening after the design, the present invention is one of the preferred methods for motor punching enterprises. However, if you want to develop the present invention, you must obtain the permission of the designer, and it is impossible to break the scope of the claims of the present invention, and there is no limitation on any implementation mode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com