Fiber compressing dipping bath-free dyeing method in super low liquor ratio

A technology of ultra-small liquor ratio and dyeing method, which is applied in the direction of using small liquor ratio liquid textile material treatment, sustainable manufacturing/processing, climate sustainability, etc. Reduction and other problems, to achieve the effect of saving water consumption, reducing sewage discharge, and reducing discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

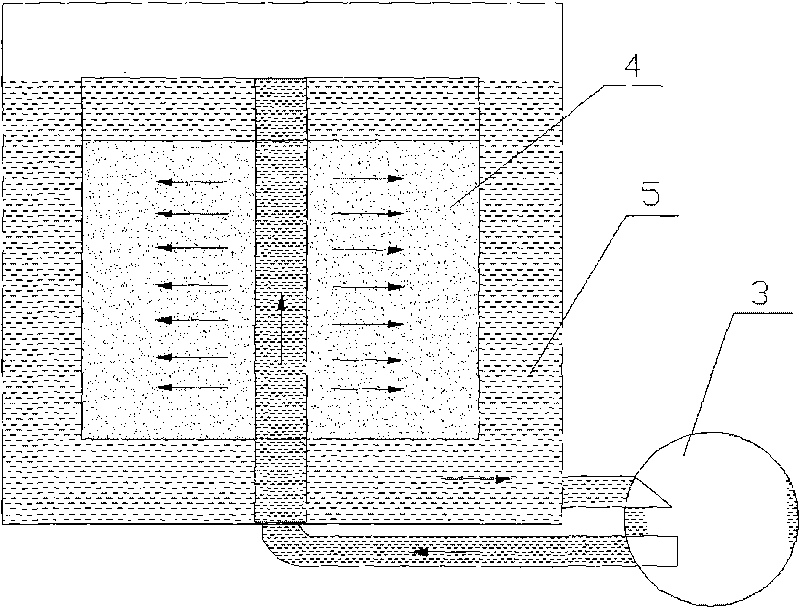

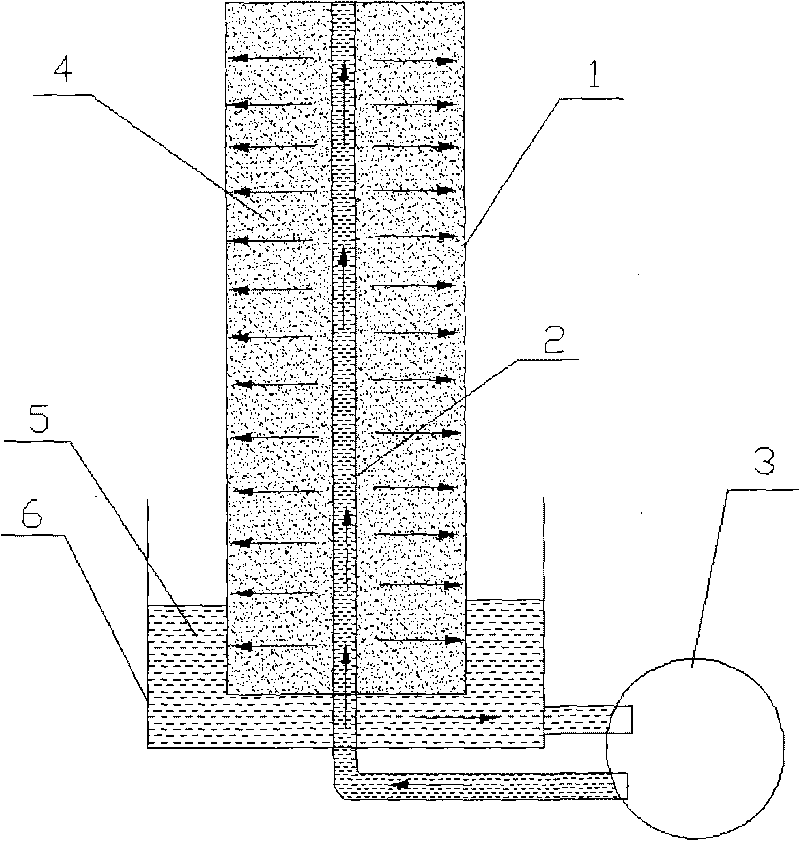

Image

Examples

specific Embodiment

[0027] Adopt dyeing device of the present invention to dye 48-50 S New Zealand washes 180Kg of wool, only 250Kg of water, and the liquor ratio is 1:1.4. The dyeing prescription and dyeing process are as follows:

[0028] Dye Recipe:

[0029] Lanaset Red 2B 0.31%

[0030] Lanaset Yellow 2R 0.58%

[0031] Lanaset Lan 2R 0.068%

[0032] Leveling agent D 0.25%

[0033] Glacial acetic acid 0.8%

[0034] Dyeing process:

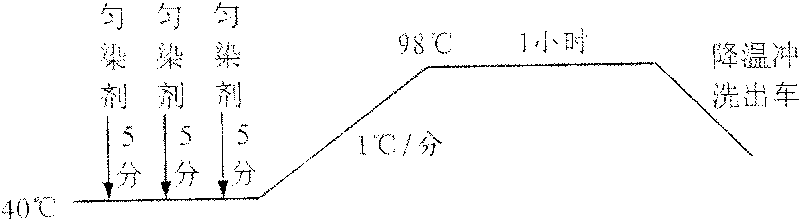

[0035] Circulate the dye solution in the dyeing device through the pump, first raise the temperature to 40°C, add leveling agent, keep it for 5 minutes, then add dye, keep it for 5 minutes, then add glacial acetic acid, keep it for 5 minutes, then, add the dye at 1°C Raise the temperature to 98°C at a heating rate of 1 / min, keep it for 1 hour, then lower the temperature, and rinse the floating color.

[0036] This method can achieve:

[0037]1. Save dyes and auxiliaries: With the decrease of bath ratio, the concentration of dye auxiliary materials in dye l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com