Device for continuous dyeing through bubble wet steaming

A foam and wet steaming technology, which is applied in solvent dyeing, continuous processing of textile materials, and processing of textile materials, etc., can solve the problems of serious hydrolysis of dyes, achieve the effect of satisfying wearing performance, accelerating heating rate, and simple working process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

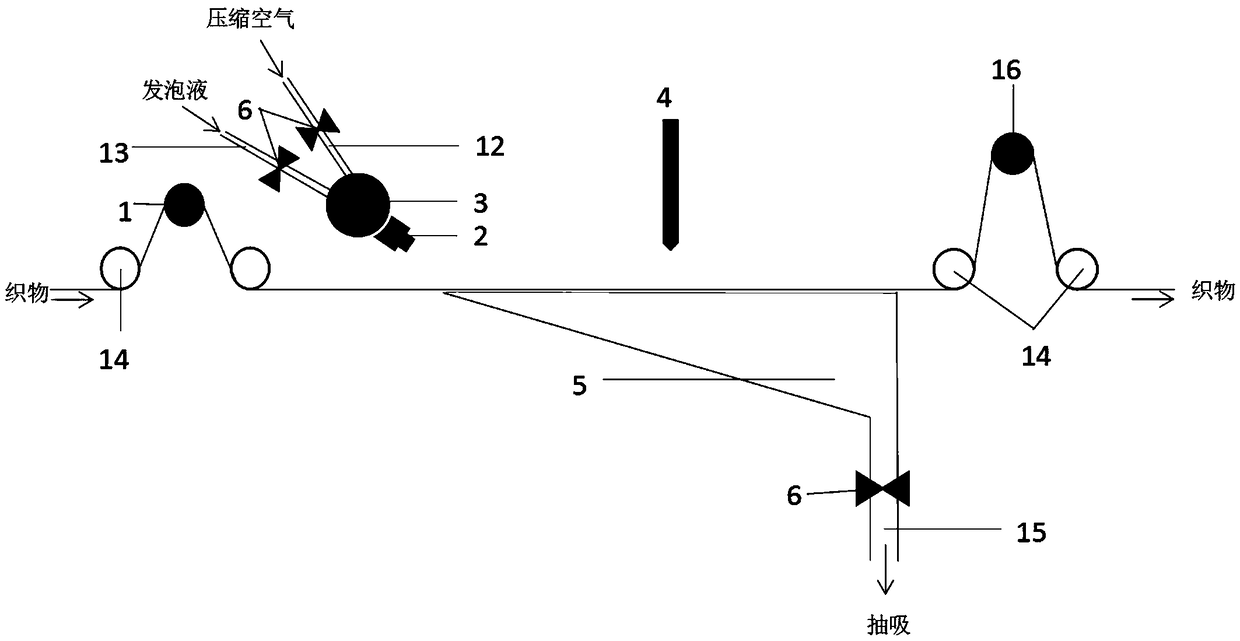

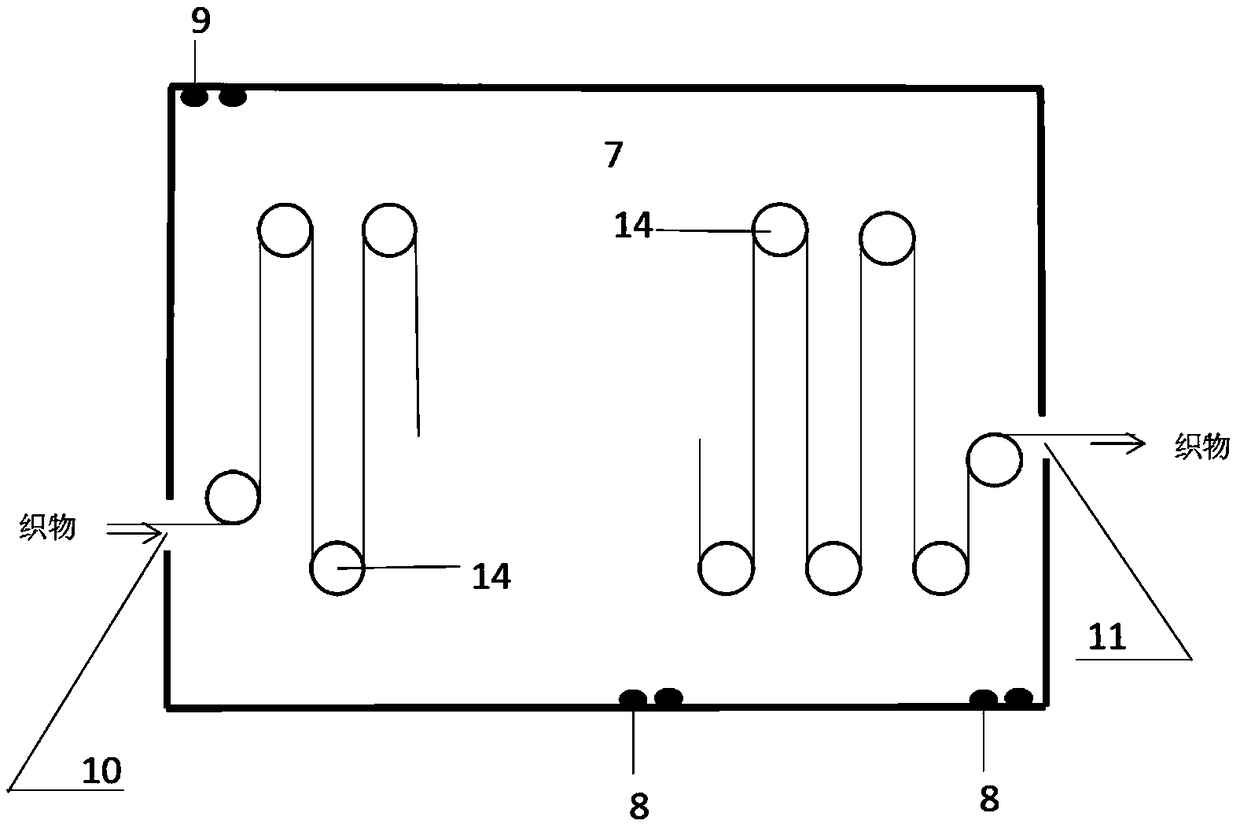

[0027] In this example, see figure 1 and figure 2 , a device for continuous dyeing using foam wet steaming, mainly includes a steam box and a fabric delivery device, the fabric delivery device is mainly composed of a series of rubber rollers, and the steam box mainly includes a box body 7 and several synchronously rotating cloth guide rollers 14. The fabric dyed by the wet method enters the cloth inlet 10 of the steam box, and after steaming and fixing the color in the steam box, it comes out from the cloth outlet 11 of the steam box to complete the dyeing process of the fabric; continuous dyeing by foam wet steaming The device also includes a foam application device and a suction device.

[0028] The foam application device is mainly composed of a height-limiting plate 4 and a series of spray guns 2. The muzzles of a series of spray guns 2 face the surface of the fabric. The muzzle arrangement extension direction of the series of spray guns 2 is kept perpendicular to the f...

Embodiment 2

[0056] This embodiment is basically the same as Embodiment 1, especially in that:

[0057] In this embodiment, by adjusting the amount of foam applied to the spray gun 2, the position of the foam height limiter 4, the strength of the suction wind of the suction device, and the formula of the foaming solution containing the color fixing agent and the dye, one side of the fabric can be made Any one of three different dyeing processes in coloring, front and back yin and yang coloring and front and back same color coloring. Cotton fabrics with different coloring effects can be dyed by using this device for dyeing processing, and at the same time have high soaping fastness and rubbing fastness, which can meet the needs of wearing performance. Dyeing is carried out by using the wet-steaming dyeing device of reactive dyes in this embodiment. The liquid-carrying rate of the fabric before steaming is as low as 15-35%, which is suitable for dyeing cotton fabrics with reactive dyes, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com